Professional Documents

Culture Documents

Intercalation of Organic Ammonium Ions Into Graphite Oxide

Uploaded by

sashankchappidigmailCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Intercalation of Organic Ammonium Ions Into Graphite Oxide

Uploaded by

sashankchappidigmailCopyright:

Available Formats

4926

Langmuir 2002, 18, 4926-4932

Intercalation of Organic Ammonium Ions into Layered

Graphite Oxide

Zong-huai Liu, Zheng-Ming Wang, Xiaojing Yang, and Kenta Ooi*

Marine Resources and Environment Research Institute, National Institute of Advanced

Industrial Science and Technology, 2217-14 Hayashi, Takamatsu, 761-0395 Japan

Received November 15, 2001. In Final Form: March 18, 2002

The intercalation of large organic ammonium ions (tetramethylammonium ions (TMA+), tetraethylammonium ions (TEA+), tetrapropylammonium ions (TPA+), and tetrabutylammonium ions (TBA+)) into

layered graphite oxide (GO) was systematically investigated. The intercalation reactions were completed

at 25 C after 3 days, and stable colloidal suspensions were obtained at TAAl/Hs ) 5 (molar ratio of

tetraalkylammonium ions (TAA+) over exchangeable protons in GO). The sediments after centrifuging the

colloidal suspensions showed amorphous phase X-ray diffraction patterns, indicating that exfoliation of

the layered structure into nanosheets took place in the suspension. When the sediments were dried at 70

C for 3 days, layered structures of TAA+-intercalated GO materials with basal spacings of 1.56, 1.67, 1.84,

and 2.37 nm, respectively, appeared. The basal spacing of the layered compounds decreased with a decrease

of relative humidity during drying. When the dried TAA+-intercalated GO compounds were exposed to a

humid saturated atmosphere, the basal spacing increased gradually, finally becoming an amorphous

structure. The maximum saturation of intercalated TAA+ ions into GO decreased with the increase in alkyl

chain length. When the TAA+-intercalated materials were washed with distilled water and acid-treated,

a process of deintercalation of TAA+ ions from the interlayer occurred. A schematic model for the

deintercalation-intercalation involving a exfoliation process is proposed. The layered structure of TAA+intercalated GO materials is discussed in terms of the dimension of the GO layer and the sizes of H2O

molecules and TAA+ ions.

Introduction

Intercalation into layered compounds has drawn much

attention from both the fundamental and practical

viewpoints.1-4 Graphite oxide (GO) is a typical twodimensional solid in bulk form, with strong covalent

bonding within the layers. Weaker interlayer contact is

made by hydrogen bonds between intercalated water

molecules.5-7 Some functional groups, such as hydroxyl,

carbonyl, and other groups, embedded in carbon sheets in

GO lamellae make graphite oxide hydrophilic and exhibit

a rich intercalation chemistry. So far, many intercalated

GO materials have been synthesized and their physicochemical properties investigated.8-17 To control the space

occurring between intercalated surfactant ions, Matsuo

et al. have used various kinds of surfactants with different

* Address correspondence to this author. Telephone: +81-87869-3511. Fax: +81-87-869-3551. E-mail: k-ooi@aist.go.jp.

E-mail: zonghuai-liu@aist.go.jp.

(1) Barrer, R. M. Zeolites and Clay Minerals as Sorbents and

Molecular Sieves; Academic Press: London, 1978; p 407.

(2) Clearfield, A., Ed. Inorganic Ion Exchange Materials; CRC Press:

Boca Raton, FL, 1982.

(3) Ogawa, M.; Kuroda, K. Bull. Chem. Soc. Jpn. 1997, 70, 2593.

(4) Schollhorn, R. Chem. Mater. 1996, 8, 1747.

(5) Nakajima, T.; Mabuchi, A.; Hagiwara, R. Carbon 1988, 26, 357.

(6) Lerf, A.; He, H.; Forster, M.; Klinowski, J. J. Phys. Chem. B 1998,

102, 4477.

(7) Mermoux, M.; Chabre, Y.; Rousseau, A. Carbon 1991, 29, 469.

(8) Matsuo, Y.; Niwa, T.; Sugie, Y. Carbon 1999, 37, 897.

(9) Liu, P.; Gong, K. Carbon 1999, 37, 701.

(10) Inagaki, M.; Suwa, T. Carbon 2001, 39, 915.

(11) Cassagneau, T.; Fendler, J. H. J. Phys. Chem. B 1999, 103, 1789.

(12) Matsuo, Y.; Tahara, K.; Sugie, Y. Carbon 1997, 35, 113.

(13) Cassagneau, T.; Cuerin, F.; Fendler, J. H. Langmuir 2000, 16,

7318.

(14) Matsuo, Y.; Tahara, K.; Sugie, Y. Carbon 1996, 34, 672.

(15) Matsuo, Y.; Hatase, K.; Sugie, Y. Chem. Mater. 1998, 10, 2266.

(16) Kotov, N. V.; Dekany, I.; Fendler, J. H. Adv. Mater. 1996, 8, 637.

(17) Kyotani, T.; Moriyama, H.; Tomita, A. Carbon 1997, 35, 1185.

chain lengths to synthesize surfactant-intercalated GO

materials. These materials can be used as hosts for

molecular recognition.8 The exfoliation of GO particles

occurs easily in dilute (alkaline) aqueous solution; polyaniline-intercalated GO material and nanometer compounds with particle properties have been synthesized by

an exfoliation/adsorption process.9-11 Using the hydrophilicity of GO, some polar organic molecules and polymers, such as alcohol,12 poly(ethylene oxide) (PEO),13,14

poly(vinyl alcohol) (PVA),15 poly(diallyldimethylammonium chloride) (PDDA),16 poly(furfuryl alcohol) (PFA),17

and even others,18 can be easily inserted into its lamellae

to form intercalated GO nanocomposites by different

methods with different c-axis repeat distances. The

existence of these polymers enables the physicochemical

properties of GO to be greatly changed. Liu et al.19 have

synthesized a poly(vinyl acetate) intercalated GO nanocomposite using poly(vinyl acetate) (PVAc), with an oilsoluble polymer as guest molecules. The compound has a

high stability against extraction by organic solvent due

to a strong interaction between the GO layers and PVAc

chains.

In the present work, systematic studies on the

intercalation reaction of large organic ions into layered GO were conducted using tetraalkylammonium ions

with different methylene chain lengths. The TAA+intercalated GO materials were obtained by an exfoliation/

reassembling process, and a structural model for the

exfoliation/reassembling process involving the intercalation reaction is proposed.

(18) Kovtyukhova, N. I.; Ollivier, P. J.; Martin, B. R.; Mallouk, T. E.;

Chizhik, S. A.; Buzaneva, E. V.; Gorchinskiy, A. D. Chem. Mater. 1999,

11, 771.

(19) Liu, P.; Gong, K.; Xiao, P.; Xiao, M. J. Mater. Chem. 2000, 10,

933.

10.1021/la011677i CCC: $22.00 2002 American Chemical Society

Published on Web 05/15/2002

Intercalation of Organic Ammonium Ions into GO

Langmuir, Vol. 18, No. 12, 2002 4927

Experimental Section

Materials. The starting material, GO, was synthesized from

natural graphite by the Staudenmaier method.20 The pH titration

toward Na+ ions was obtained in (0.1 M NaCl + NaOH) solutions

with different NaOH concentrations at 25 C. The ion-exchange

capacity was evaluated from the titration curve.

Tetraalkylammonium hydroxides were purchased from Wako

Pure Chemical Co. They included tetramethylammonium hydroxide (15 wt % solution), tetraethylammonium hydroxide (10

wt %), tetrapropylammonium hydroxide (10 wt %), and tetrabutylammonium hydroxide (10 wt %).

Intercalation Reaction. Intercalation reactions of tetramethylammonium ions (TMA+) were studied batchwise. Weighed

samples (0.1 g) of GO were soaked in TMA+ hydroxide solutions

(20 cm3) with different concentrations at 25 C for 3 days. The

amount of tetramethylammonium hydroxide added ranged from

1 to 25-fold that of the exchangeable capacity of GO (1 e TMAl/

Hs e 25). After soaking, the solutions were separated by

centrifugation, and the resultant colloids were subjected to X-ray

diffraction (XRD) analyses in their wet state, followed by airdrying at a relative humidity of 40% at 25 C or heating at 70

C for 3 days. The influence of relative humidity on the basal

spacing was studied by equilibrating the sample with an

atmosphere at a different humidity. The hydroxide ion concentrations in the supernatant solutions were determined by acid

titration.

Intercalation reactions of TEA+, TPA+, and TBA+ ions were

carried out at TAAl/Hs ) 5, and the colloids obtained were treated

by the same procedure as that for TMA+-intercalated colloids.

The colloids in the wet state were washed with 30 cm3 of water

three times, and the gels obtained were air-dried at a relative

humidity of 40% at 25 C for 2 days.

Deintercalation of TAA+ ions from the interlayer of GO was

carried out by mixing the TAA+-intercalated GO materials with

0.1 M HCl solution at 25 C for 2 days. The extractability of

TAA+ ions was calculated from the difference between TN

concentrations in the samples before and after the acid treatment.

Chemical Analyses. The TN (total nitrogen) and TC (total

carbon) contents of the TAA+-intercalated GO compounds, the

acid-treated compounds, and the water-washed compounds were

determined by a Sumigraph type NCH-21 NCH analyzer.

Physical Properties. The sediment from each different

humidity state was subjected to XRD analysis using a Rigaku

type RINT 1200 X-ray diffractometer with a graphite monochromator at 25 C. TG-DTA curves were obtained on a MAC

Science thermal analyzer (System 001, TG-DTA 2000) at a

heating rate of 10 C/min. SEM observation was carried out with

a Hitachi S-246N scanning electron microscope.

Results and Discussion

Characterization of GO. An SEM image of synthesized GO is given in Figure 1. The sample shows platelike

forms without any amorphous or other kinds of crystallized

phase particles. XRD analysis shows diffraction patterns

corresponding to a layered structure with a basal spacing

of 0.88 nm.

The pH titration curve of GO toward Na+ ions is given

in Figure 2. The total exchange capacity of GO is evaluated

as 4.4 mmol/g from the ion-exchange reaction in a 0.1 M

NaOH solution. The titration curve shows a multi-base

acid character, suggesting that the synthesized GO

contains more than one kind of exchangeable protons.

The dispersibility of GO in solution depends on the degree

of neutralization (R). Colloidal suspensions were not

observed, and the supernatant solutions were transparent

at R < 0.4. The peptization of GO takes place at R > 0.4,

and completely dispersed colloidal suspensions are obtained at R > 0.9. This shows that the neutralization of

most of the acid sites is necessary in order to have a

(20) Standenmaier, L. Ber. Dtsch. Chem. Ges. 1989, 31, 1481.

Figure 1. SEM image of starting GO.

Figure 2. The pH titration curve of GO toward Na+.

sufficient electrostatic repulsion between each sheet to

form stable colloidal suspensions.

Exfoliation by the Intercalation of TAA+ Ions. All

of the intercalation reactions were carried out at 25 C for

3 days to make sure the intercalation was complete. Stable

colloidal suspensions were obtained by treating GO with

TAA hydroxide solutions at TAAl/Hs ) 5. The suspensions

were centrifuged, and the colloidal sediments were

subjected to XRD measurement in the wet state. The water

contents, roughly evaluated from the weight loss by

maintaining at 150 C, were around 80% for all the TAA+intercalated GO samples. The XRD patterns of all sediments obtained are shown in Figure 3. The patterns gave

no clear peaks but only a broad diffraction halo in a 2

range of 20-40, in striking contrast to that of starting

GO (Figure 3a). The broad halo is most likely related to

scattering from dispersed single sheets of GO and water

as a solvent, similar to the case of layered titanic acid.21,22

This indicates that the stacked sheets of GO are exfoliated

when GO is soaked in TAA hydroxide solution. Because

GO contains acidic groups, negatively charged sites are

(21) Sasaki, T.; Watanabe, M.; Hashizume, H.; Yamada, H.; Nakazawa, H. J. Am. Chem. Soc. 1996, 118, 8329.

(22) Sasaki, T.; Watanabe, M. J. Am. Chem. Soc. 1998, 120, 4682.

4928

Langmuir, Vol. 18, No. 12, 2002

Liu et al.

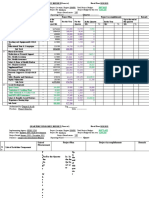

Table 2. Structural Models of Samples of

Ammonium-Intercalated GOa Dried at 70 C for 3 days

cation

cation size,b

nm

TMA

0.50-0.60

TEA

0.65-0.75

TPA

0.80-0.90

TBA

0.95-1.05

model of sample

one layer of TMA

one layer of water

one layer of TEA

one layer of water

one layer of TPA

one layer of water

one layer of TBA

two layers of water

observed interlayer

spacing of sample,

nm

1.56

1.67

1.84

2.37

a Based on GO slab thickness of 0.60 nm and a van der Waals

radius of water of 0.28 nm. b Szostak, R. Molecular Sieves: Principal

of Synthesis and Identification; Van Nostrand Reinhold: New York,

1989; p 95.

Figure 3. Wet-state XRD patterns of GO treated with TAAOH

solutions at TAAl/Hs ) 5. (a) Starting GO; (b) GO treated with

TMAOH; (c) GO treated with TEAOH; (d) GO treated with

TPAOH; (e) GO treated with TBAOH.

Table 1. Amounts of TAA+ Intercalated at Different

Molar Ratios of TAAOH in Solution over Exchangeable

Protons in GO

intercalated

TAA+

TMA+

TEA+

TPA+

TBA+

TAA+/H+

OH- consumed

(mmol/g)

degree of

neutralization (R)

1

5

10

25

5

5

5

3.12

4.11

4.35

4.12

2.72

2.24

0.71

0.94

0.99

0.94

0.62

0.51

formed in every GO layer when GO is neutralized by dilute

TAA hydroxide solution. The electrostatic repulsive force

operating between negatively charged sites between GO

layers causes the formation of exfoliated GO.12 The hump

of the broad diffraction halo differs in shape depending

on the size of TAA+ ions; it decreases with an increase in

the length of the methylene chain. From detailed analysis

of the diffraction envelope, Sasaki et al. have concluded

that their exfoliated nanosheets of titanic acid were

arranged in a nearly amorphous manner except for a

nearest-neighbor correlation.22 In the TPA-GO and TBAGO systems, which have smaller humps in their diffraction

halos, the nearest-neighbor correlation of the exfoliated

GO nanosheet may be smaller and the nanosheets may

behave more freely in the aggregates.

The OH- concentrations of the supernatant solutions

were determined by acid titration and the amounts of

OH- consumed, and the R values were evaluated from the

decrease of OH- concentrations relative to the initial

solutions. The R values evaluated are 0.94, 0.94, 0.62, and

0.51 for GO-TMA, GO-TEA, GO-TPA, and GO-TBA

systems, respectively (Table 1). The latter two systems

show very low R values although the supernatant solution

contains an excess of OH- ions. The TPA+ and TBA+ ions

may be too large to neutralize all the acidic sites in GO

sheets freely without any steric influence. Since exfoliation

takes place in all the systems, the volume fraction of guest

ions in the interlayer may play an important role for

exfoliation, in addition to that of the surface charge density,

similar to the case of layered manganese oxide.23

The surface density of the exchange site can be

calculated from the total ion exchange capacity (4.4 mmol/

g) by assuming that the density of the carbon skeleton of

GO is equal to that (2.3 g/cm3) of graphite and the thickness

of GO is 0.6 nm. The specific surface area of nanosheets

can be evaluated as 103 m2/g from these values. The

number of exchange sites per unit area can be derived as

2.6/nm2, which corresponds to an area per exchange site

of 0.38 nm2. The area per TAA+ ion can be calculated as

0.15, 0.33, 0.57, and 0.92 nm2 for TMA+, TEA+, TPA+, and

TBA+ ions, respectively, assuming spherical ions. The

TMA+ and TEA+ ions are small enough to exchange fully

with the protons of the exchange sites, while the TPA+

and TBA+ ions are too large to exchange freely without

steric influence. The maximum exchange capacities are

calculated as 3 and 1.8 mmol/g for TPA-GO and TBAGO systems, respectively, which agreed comparatively

well with the experimentally determined exchange capacities (Table 1). These calculations suggest that the

exchange sites are distributed homogeneously throughout

the surface of GO layers.

Reassembling by Drying. When the colloidal sediments were dried at 70 C for 3 days, the layered structure

with different basal spacings reappeared as shown in

Figure 4. The XRD patterns of TMA+-intercalated GO

material showed peaks at 1.56, 0.79, and 0.52 nm

corresponding to the (001), (002), and (003) reflections,

respectively. Since the d-values of the (001) crystal spacing

reflections correspond to the interlayer distances, the

interlayer distance is 1.56 nm for the TMA+-intercalated

GO material. The XRD pattern analyses for the other

TEA+-, TPA+-, and TBA+-intercalated GO materials show

interlayer distances of 1.67, 1.84, and 2.37 nm, respectively. Sharp diffraction lines up to the fourth order for

these samples indicate a highly ordered hydrate structure,

similar to the cases of TBA+-intercalated protonic titanate

and TMA+-intercalated birnessite.22,23 The individual

sheets of exfoliated GO are reassembled together by drying

at 70 C; the interlayer distance depends on the size of the

intercalated TAA+ ions.

The rate of intercalation reaction was studied by

changing the soaking time for the TMA-GO system at

TMAl/Hs ) 5. The colloidal suspension could be obtained

after only 2 h of soaking. The sediment obtained by

centrifugation had an interlayer distance similar to that

of the TMA+- intercalated GO materials obtained by drying

(23) Liu, Z.-h.; Ooi, K.; Kanoh, H.; Tang, W.; Tomida, T. Langmiur

2000, 16, 4154.

Intercalation of Organic Ammonium Ions into GO

Figure 4. Changes of XRD patterns of TAA+-intercalated

samples at TAAl /Hs ) 5 after drying at 70 C for 3 days. (a)

TMA+-intercalated GO; (b) TEA+-intercalated GO; (c) TPA+intercalated GO; (d) TBA+-intercalated GO.

at 70 C. The intensity of the XRD peaks was hardly

changed by soaking for 1 day. This indicates that the

intercalation reaction of TAA+ into GO is fast. GO may

be easily dispersed in TAA hydroxide solutions, and is

subject to rapid exfoliation.

Effects of TMA+ Concentration and Drying Conditions. The influence of TMA+ concentration on the

intercalation reaction was investigated by changing TMAl/

Hs to 1, 5, 10, and 25. Seventy percent of the acidic sites

were occupied by TMA+ ions at TMAl/Hs ) 1. The XRD

analysis of the sediment in wet state shows a new layered

structure with a basal spacing of 0.98 nm (Figure 5a).

This shows that short-range swelling takes place to form

stable layers having a basal spacing a little larger than

starting GO. At TMAl/Hs g 5, the R values are above 0.9

and the XRD patterns show only amorphous halos in wet

state, corresponding to an exfoliated state.

The sediments at different TMA+ concentrations were

dried at 70 C for 3 days and subjected to XRD analysis

(Figure 5b-e). The layered structure with a basal spacing

of 0.98 nm was retained for the sample at TMAl/Hs ) 1.

The other dried samples show a layered structure with

basal spacing of 1.56 nm, independent of the TMA+

concentration. The exfoliation by TMA+ intercalation and

the reassembling of GO sheets by drying take place

independent of TMA+ concentration in the region TMAl/

Hs g 5.

The TMA+-intercalated GO material obtained at TMAl/

Hs ) 5 was dried under different conditions. The XRD

patterns of the dried samples show that the layered

structure is retained after drying, but the basal spacing

decreases slightly with a decrease of the relative humidity

of the atmosphere (Figure 6). The basal spacing around

1.54 nm hardly changes even after vacuum-drying at 70

C for 1 day. This indicates that the free water molecules

existing in the interlayer of GO dehydrate easily, but there

are some hydrated water molecules that are strongly

attached between TMA+ ions and GO layers. The drying

behavior is different from that in TMA+-intercalated

layered manganese oxide, in which most of the water

molecules are easily dissipated from the interlayer by

vacuum-drying for 1 day.23

Langmuir, Vol. 18, No. 12, 2002 4929

Figure 5. Changes of XRD patterns of TMA+-intercalated

samples at different concentrations dried at 70 C for 3 days.

(a) TMAl/Hs ) 1 in wet state; (b) TMAl/Hs ) 1; (c) TMAl/Hs )

5; (d) TMAl/Hs ) 10; (e) TMAl/Hs ) 25.

Figure 6. XRD patterns of TMA+-intercalated samples under

different drying conditions. (a) TMA+-intercalated sample at

TMAl/Hs ) 5 in wet state; (b) sample a dried at 25 C for 1 day;

(c) sample b dried on silica gel for 1 day; (d) sample c dried at

70 C for 1 day; (e) sample d vacuum-dried at 70 C for 1 day;

(f) sample e exposed to saturated humidity at 25 C for 1 day;

(g) sample e exposed to saturated humidity at 25 C for 5 days.

When the vacuum-dried sample was exposed to an

atmosphere with saturated humidity, the basal spacing

of the layered compound increased again from 1.54 to 1.82

nm after 1 day of exposure (Figure 6f), and finally returned

to an amorphous phase after 5 days (Figure 6g). This

indicates that the dehydration-rehydration of TMA+intercalated GO material involving an exfoliation process

4930

Langmuir, Vol. 18, No. 12, 2002

Liu et al.

Figure 7. Changes of XRD patterns of TAA+-intercalated

samples at TAAl/Hs ) 5 by washing and after drying at 25 C

for 1 day. (a) TMA+-intercalated GO; (b) TEA+-intercalated

GO; (c) TPA+-intercalated GO; (d) TBA+-intercalated GO; (e)

TMA+-intercalated GO acid-treated for 2 days.

is a reversible reaction. This is similar to those of clay

minerals such as montmorillonite and smectite which

swell and exfoliate in wet state by some soft-chemical

procedures, returning to a layered structure in a dried

state.24,25

Effect of Water Washing and Acid Treatment. The

colloidal suspension prepared at TAAl/Hs ) 5 was centrifuged and then washed 3 times with 30 mL of distilled

water, and the sediments were dried at 25 C for 2 days.

The XRD patterns of the dried samples show that the

basal spacings of all compounds decrease to around 1 nm

by water washing, due to the partial deintercalation of

the TAA+ ions from the interlayers. The basal spacing of

the TMA+-intercalated layer is equal to that obtained

directly from the solution with TMAl/Hs ) 1. The total

nitrogen analysis showed that 1.2 mmol/g TMA+ ions

remained in the compound, which means that 70% of

TMA+ ions were deintercalated by water washing.

SEM images of water-washed samples are shown in

Figure 8. The particle morphology of the GO nanocomposite is dependent on preparation procedure. The

air-dried sample has a distinct lamellar morphology with

thin ribbons of about 2 m in width lined up in a regular

parallel arrangement (Figure 8a). On the other hand, the

freeze-dried sample has a thin flaky appearance with

thickness less than 0.5 m (Figure 8b). These results

indicate that the significant reassembling of GO nanosheets progresses during air-drying with each nanosheet

stacked regularly to maintain minimum energy conditions.

The TMA+-intercalated compound obtained at TMAl/

Hs ) 5 was treated with a 0.1 M HCl solution at 25 C for

2 days to extract TMA+ ions from the interlayer. The XRD

pattern (Figure 7e) shows that the layered structure

(24) Norrish, K. Faraday Discuss. R. Soc. Chem. 1954, 18, 120.

(25) (a) Smalley, M. V. Langmuir 1994, 10, 2884. (b) Smalley, M. V.;

Thomas, R. K.; Braganza, L. F.; Matsuo, T. Clay Clays Miner. 1989, 37,

474.

Figure 8. SEM images of TMA+-intercalated GO nanocomposites: (a) washed with water followed by air-dried; (b)

washed with water followed by freeze-dried.

remains after TMA+ extraction, but the intensity of the

peak becomes weaker and broader. In addition, the basal

spacing decreases to 0.72 nm, which does not coincide

with that of the starting GO. This suggests that some

destruction or rearrangement of layers takes place during

the acid treatment.

DTA-TG Analysis. TG-DTA curves of the starting GO,

TMA+-intercalated GO, TMA+-intercalated GO after

water washing, and TMA+-intercalated GO after acid

treatment are shown in Figure 9. Two exothermic peaks

at 213 and 521 C are observed for the starting GO, similar

to the results by several authors.12,15,19,26 The former is

attributed to the destruction of the carbonyl group, and

the latter to the combustion of the carbon skeleton of GO.19

For TMA+-intercalated GO, small exothermic peaks are

observed at 163 and 313 C below 400 C. The weight loss

between 120 and 400 C is 53%, which is 1.5 times larger

than that (34%) for the starting GO. The large weight loss

may be due to the destruction of TMA+ ions in the

interlayer in addition to the destruction of carbonyl groups

of GO. Water washing causes the deintercalation of 70%

of TMA+ ions, so the weight loss between 120 and 400 C

is due to the decrease of TMA+ content. The acid-treated

sample shows the smallest weight loss in this temperature

range; this suggests that some of the carbonyl groups of

GO are destroyed by the acid treatment.

(26) Dekany, I.; Kruger-Grasser, R.; Weiss, A. Colloid Polym. Sci.

1998, 276, 570.

Intercalation of Organic Ammonium Ions into GO

Figure 9. TG-DTA curves of (a) starting GO, (b) TMA+intercalated GO, (c) TMA+-intercalated GO washed with

distilled water, and (d) TMA+-intercalated GO acid-treated.

Structural Model for the Intercalation-Deintercalation. Schematic representation of structural change

during the intercalation-deintercalation reaction is given

in Figure 10. Pristine GO has a layered structure with a

Langmuir, Vol. 18, No. 12, 2002 4931

basal spacing of 0.88 nm. It is well-known that the basal

spacing of GO varies widely between 1.1 and 0.6 nm

depending on ambient humidity, which has made it

difficult to determine the ideal structure of GO. Two types

of model have been proposed for the structure of GO: one

is the stage-1 type with Ic ) 0.6 nm7 and the other is the

stage-2 type with Ic ) 0.55-0.82 nm.5 The present result

is close to the stage-2 type structural model of well

hydrated GO (basal spacing ) 0.82 nm). Therefore, we

made our structural model based on the stage-2 type. Since

the thickness of GO is known to be 0.61 nm,26 the galley

height can be calculated as 0.27 nm, being close to the van

der Waals diameter (0.28 nm) of water molecules. This

suggests the formation of one molecular layer of water in

the interlayer of GO. The intercalation of TMA+ results

in a short-range swelling in the region 0.3 < R < 0.8; the

basal spacing widens a little to 0.98 nm by the intercalation. The galley height can be calculated as 0.37 nm, which

is close to the ionic size (0.44 nm) of TMA+ ions. Since

there are no water layers between TMA+ ions and GO

sheets, it is stable against drying. The stacked GO layers

are exfoliated into nanosheets in the region R > 0.9. The

layered structure disappears in the XRD patterns, and

only halos are observed.

The swelling and exfoliation behavior of layered materials can be classified into three categories: short-range

swelling, long-range swelling, and exfoliation. The shortrange swelling is characterized by the formation of hydrate

layers in the interlayer. The long-range swelling is

associated with the formation of diffuse double layers and

the consequent change of the electrostatic attractive force

to an osmotic repulsive one. Exfoliation is regarded as the

limiting case of long-range swelling, where the electrostatic

repulsive force between neighboring electrical double

layers occurs even at a very great distance. Long-range

Figure 10. Schematic representation of changes of crystal phase and basal spacing of wet and dried TMA+-intercalated GO

compounds.

4932

Langmuir, Vol. 18, No. 12, 2002

Liu et al.

Figure 11. Structural model of TAA+-intercalated GO materials.

swelling was not observed in the present system. The sharp

basal diffraction series with intersheet spacing of above

2 nm was not observed in a low angular range. The

flexibility of the present sheets may leave the long-range

swelling incomplete, resulting in a simultaneous exfoliation with irregularly arranged GO sheets. Similar

results have been observed for TMA+ intercalation into

layered manganese oxide.23 When the exfoliated slurry is

dried at room temperature for 1 day, reassembling takes

place and the layered structure with a basal spacing of

1.64 nm reappears. The basal spacing corresponds to the

distance that two molecular layers of water occupy in the

interlayer. Drying at 70 C results in a slight decrease of

basal spacing to 1.56 nm, which corresponds roughly to

the presence of one molecular layer of water. The

dehydration-rehydration reaction on TMA+-intercalated

GO progresses reversibly depending on the relative

humidity of the atmosphere, accompanied by the exfoliation reaction. These results show that the TMA+intercalated GO exhibits reversibly short-range swelling

and exfoliation, similar to clay minerals.

The water washing caused a deintercalation of TMA+

from the interlayer to give a layered compound with a

basal spacing of 0.97 nm. This phase can be described as

a stable phase since it forms in both the intercalation and

deintercalation reactions. Acid treatment results in the

deintercalation of most of TMA+ ions in the interlayer.

The acid-treated sample retains the layered structure,

but the intensities of the diffraction peaks become weaker

and broader. The resultant basal spacing does not coincide

with that of the starting GO. This suggests that some

destruction or rearrangement of nanosheets takes place

during the acid treatment.

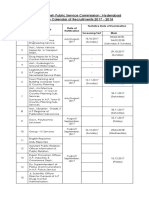

The schematic models of TAA+-intercalated GO compounds are depicted in Figure 11. The intercalation of

TAA+ ions results in the exfoliation of GO nanosheets

independent of the species of TAA+ ions. The drying of the

exfoliated slurry at 70 C results in the reassembling of

nanosheets in stacked layers, with the interlayer distance

depending on the species of TAA+ ions. The structural

model was calculated on the basis of the dimension of the

GO layer, the van der Waals size of water molecules and

the size of the TAA+ ions. The ionic size of TAA+ ions,

evaluated by semiempirical MO calculations with a

MOPAC program, are 0.44, 0.65, 0.85, and 1.08 nm for

TMA+, TEA+, TPA+, and TBA+ ions, respectively. The

galley heights are therefore calculated to be 0.95, 1.06,

1.23, and 1.76 nm for the TMA-GO, TEA-GO, TPAGO, and TBA-GO composites, respectively. The numbers

of molecular layers of water are calculated as one for the

first three composites and two for the last. This indicates

that the basal spacing of the layered compound exhibiting

short-range swelling depends mainly on the ionic size of

the guest ions.

Conclusion

The GO compound shows swelling and exfoliation

behavior during the intercalation of tetraalkylammonium

ions, depending on the neutralization degree of the GO

sheet and the species of the guest ammonium ions. The

exfoliated nanosheets in wet state reassemble into stacked

layers following air-drying with the interlayer distance

depending on the size of guest ions. The exfoliationreassembling process is attractive since it is applicable to

the development of novel nanocomposite materials or

nanoporous materials.

LA011677I

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Select Event Venue and SiteDocument11 pagesSelect Event Venue and SiteLloyd Arnold Catabona100% (1)

- German Specification BGR181 (English Version) - Acceptance Criteria For Floorings R Rating As Per DIN 51130Document26 pagesGerman Specification BGR181 (English Version) - Acceptance Criteria For Floorings R Rating As Per DIN 51130Ankur Singh ANULAB100% (2)

- Basic Operation Electrical - Total - Eng - Prot PDFDocument439 pagesBasic Operation Electrical - Total - Eng - Prot PDFdidik setiawan100% (2)

- Numerical Solution of Elliptic Partial Differential Equations by Haar Wavelet Operational Matrix MethodDocument100 pagesNumerical Solution of Elliptic Partial Differential Equations by Haar Wavelet Operational Matrix Methodsashankchappidigmail100% (1)

- Location Leaks On The GSM Air InterfaceDocument13 pagesLocation Leaks On The GSM Air InterfacessthakurNo ratings yet

- A Computational Model of The Mechanical Behavior Within Reconstructed LixCoO2 Li-Ion Battery Cathode ParticlesDocument11 pagesA Computational Model of The Mechanical Behavior Within Reconstructed LixCoO2 Li-Ion Battery Cathode ParticlessashankchappidigmailNo ratings yet

- Able Target PI at 14 10INDocument1 pageAble Target PI at 14 10INsashankchappidigmailNo ratings yet

- Advtno 2 2014 Srno 4 Sci Officer B OBC CalledDocument1 pageAdvtno 2 2014 Srno 4 Sci Officer B OBC CalledsashankchappidigmailNo ratings yet

- Plotting Functions With MATLAB: F (X) Cos X + eDocument3 pagesPlotting Functions With MATLAB: F (X) Cos X + esashankchappidigmailNo ratings yet

- Jatin 007Document2 pagesJatin 007sashankchappidigmailNo ratings yet

- 1 Leader 2 Dme/Be Design - Mechanical: Function Role Qualification Sr. No. No. of Vacancy'sDocument4 pages1 Leader 2 Dme/Be Design - Mechanical: Function Role Qualification Sr. No. No. of Vacancy'ssashankchappidigmailNo ratings yet

- Test Questions For Oncologic DisordersDocument6 pagesTest Questions For Oncologic Disorderspatzie100% (1)

- 1 BSC Iriigation Engineering 2018 19 Std1Document70 pages1 BSC Iriigation Engineering 2018 19 Std1Kwasi BempongNo ratings yet

- RNP Rnav PDFDocument31 pagesRNP Rnav PDFhb2enbjxNo ratings yet

- Crime Free Lease AddendumDocument1 pageCrime Free Lease AddendumjmtmanagementNo ratings yet

- Kebersihan, Fungsi Sanitasi Dan Drainase - BAHASA INGGRIS - VII - Semester IDocument5 pagesKebersihan, Fungsi Sanitasi Dan Drainase - BAHASA INGGRIS - VII - Semester IRiska AyuNo ratings yet

- Arann Magazine, Issue 1-2-Online VersionDocument36 pagesArann Magazine, Issue 1-2-Online VersionmujismileNo ratings yet

- Toaz - Info Fermentation of Carrot Juice Wheat Flour Gram Flour Etc PRDocument17 pagesToaz - Info Fermentation of Carrot Juice Wheat Flour Gram Flour Etc PRBhumika SahuNo ratings yet

- Traditional vs. Enterprise Risk Management - How Do They DifferDocument4 pagesTraditional vs. Enterprise Risk Management - How Do They DifferJaveed A. KhanNo ratings yet

- Quarterly Progress Report FormatDocument7 pagesQuarterly Progress Report FormatDegnesh AssefaNo ratings yet

- Photoperiodism Powerpoint EduDocument12 pagesPhotoperiodism Powerpoint EduAlabi FauziatBulalaNo ratings yet

- Senographe Crystal: The Choice Is Crystal ClearDocument7 pagesSenographe Crystal: The Choice Is Crystal ClearmuhammadyassirNo ratings yet

- Current and Voltage Controls 3-Phase AC Max. Current Control Type S 178Document3 pagesCurrent and Voltage Controls 3-Phase AC Max. Current Control Type S 178Felipe FarfanNo ratings yet

- Roadmap Video: Answer KeyDocument4 pagesRoadmap Video: Answer KeyMaria JuneNo ratings yet

- Indiana Administrative CodeDocument176 pagesIndiana Administrative CodeMd Mamunur RashidNo ratings yet

- 2 Effective Manufacturing ERP MESDocument17 pages2 Effective Manufacturing ERP MESm_trang2005100% (2)

- Cape 2 Biology - Homeostasis &excretionDocument9 pagesCape 2 Biology - Homeostasis &excretionTamicka BonnickNo ratings yet

- 2022.08.09 Rickenbacker ComprehensiveDocument180 pages2022.08.09 Rickenbacker ComprehensiveTony WintonNo ratings yet

- APPSC Calender Year Final-2017Document3 pagesAPPSC Calender Year Final-2017Krishna MurthyNo ratings yet

- Capstone-ModDocument25 pagesCapstone-ModMohammad Ryyan PumbagulNo ratings yet

- Signage Method of Statement and Risk AssessmentDocument3 pagesSignage Method of Statement and Risk AssessmentNajmal AmanNo ratings yet

- Lead Avr PDFDocument9 pagesLead Avr PDFsiddharthNo ratings yet

- The Power of PositivityDocument5 pagesThe Power of PositivityYorlenis PintoNo ratings yet

- Manual Chiller Parafuso DaikinDocument76 pagesManual Chiller Parafuso Daiking3qwsf100% (1)

- DELIGHT Official e BookDocument418 pagesDELIGHT Official e BookIsis Jade100% (3)

- RB Boiler Product SpecsDocument4 pagesRB Boiler Product Specsachmad_silmiNo ratings yet

- NCP On DiabetesDocument2 pagesNCP On DiabetesShumaila AlviNo ratings yet

- 感應馬達安裝、保養使用說明書31057H402E (英)Document17 pages感應馬達安裝、保養使用說明書31057H402E (英)Rosyad Broe CaporegimeNo ratings yet