Professional Documents

Culture Documents

ChE410 PFRHGFHGF

Uploaded by

Annerlynn SolanoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ChE410 PFRHGFHGF

Uploaded by

Annerlynn SolanoCopyright:

Available Formats

METU Chem. Eng. Dept.

Ch.E. 410 Chem. Eng. Lab II

EXPERIMENT 3.2.

TUBULAR FLOW REACTOR

OBJECTIVES

1. To determine the rate law using tubular flow reactor data.

2. To demonstrate the temperature dependence of the reaction and the rate constant.

3. To understand tubular flow reactor performance.

BACKGROUND INFORMATION

In the majority of industrial chemical processes, the reactor is the key item of equipment

in so far that the required chemical change of raw materials to form desired products

occur at this point in the whole process. The design and operation of chemical reactors are

thus crucial to the whole success of the industrial operations.

Tubular flow reactors are commonly used in the industry. If the flow field in a tubular

reactor is highly turbulent plug flow assumption is generally made in the design of such

reactors (Fogler, 1992; Smith, 1981; Levenspiel, 1972). Due to mixing in the longitudinal

direction and incomplete mixing in the radial direction, deviations from ideal tubular flow

(plug flow) behaviour are possible. The reaction chosen in this experiment is the

saponification of ethyl acetate (EtOAc) with dilute sodium hydroxide (NaOH):

NaOH + EtOAc NaOAc + EtOH

EXPERIMENTAL

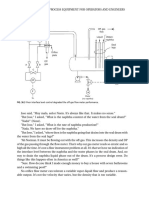

Equipment: The equipment that will be used in the experiments is an Armfield CETTubular Flow Reactor. Description of the equipment and details of the operating

instructions are available in the Instruction Manual. A tubular reactor of length 22 m and

volume 0.4 lt is placed in a constant temperature water bath. Temperature of the reactor

was adjusted to the desired value by controlling the water bath temperature which is

heated by heating elements. Two feed tanks contain the reactants which are pumped by

the two positive displacement type pumps through the flowmeters into the inlet feed

pipes. From here they enter the reactor coil. The mean residence time in the coil is a

function of the flowrate, set by the flowmeters. Control of the equipment which is situated

on the front panel, is governed by a mains on/off switch, pump switches, a temperature

scale and stirrer motor switch. (See the manual)

Supply: The chemicals needed in the experiments are 0.1 M NaOH, 0.1 M HCl, 0.1 M

EtOAc and phenolphthalein indicator. Additional equipment needed in the analysis of the

reactants and products are: flasks, pipette, burette, graduate cylinder.

1/2

METU Chem. Eng. Dept.

Ch.E. 410 Chem. Eng. Lab II

Experim ent 3.2.

Tubular Flow Reactor

Procedure:

1. Carry out reaction experiments in the tubular reactor using equal molar flowrates of

the reactants. Repeat these experiments at 4 different space times. Analyze inlet and

outlet concentrations of NaOH. In each run obtain data at different times until steady

state is reached.

2. Repeat tubular flow experiments at 4 different temperatures.

TAKE HOME

1. You are expected to determine the fractional conversion values in each experiment.

2. You should determine the reaction order and rate constants.

3. You should determine the activation energy and an expression for the temperature

dependence of the rate constant.

4. You should calculate the Reynolds and Peclet numbers in your reactor. Comment

and discuss whether deviations from ideal plug flow behaviour are significant or not.

Compare the ideal plug flow reactor volume with the real one. (Ref.3).

NOTE: Bring a graph paper to the experiment.

PRELIMINARY WORK (to be prepared on the notebook)

1. How can you analyze reactants and products of a saponification reaction by titration?

2. Derive the design equation of a plug flow reactor.

3. Read the instruction manual.

4. Make an experimental plan before performing the experiment. Discuss the type of

experiment you would carry out to find the rate law (rate constant and rate order in

PFR).

5. How can you find the activation energy of this reaction?

6. Read Chapter 13 (p. 293-296, 309-317) in Levenspiel related to axial dispersion.

REFERENCES

1. Smith, J.M., Chemical Engineering Kinetics, McGraw Hill Int., 1981.

2. Fogler, H.S., Elements of Chemical Reaction Engineering, Prentice-Hall Inc., USA,

2nd Ed, 1992.

3. Levenspiel, O., Chemical Reaction Engineering, Third ed.,John Wiley and Sons, New

York, 1999.

4. Armfield CET-Tubular Flow Reactor, Instruction Manual, 1993.

2/2

You might also like

- Anschp 22Document16 pagesAnschp 22pashelo001No ratings yet

- 10 5923 J Ajee 20140406 04 PDFDocument7 pages10 5923 J Ajee 20140406 04 PDFAnnerlynn SolanoNo ratings yet

- Chapter 6Document44 pagesChapter 6Annerlynn SolanoNo ratings yet

- Acid/Base Problem Set KeyDocument21 pagesAcid/Base Problem Set KeySwisskelly1No ratings yet

- Chapter 6 - in Review (3 Out of 6)Document2 pagesChapter 6 - in Review (3 Out of 6)Ruel CedeñoNo ratings yet

- ORGANOLEPTIC TASTE PROFILES OF FOOD ACIDSDocument21 pagesORGANOLEPTIC TASTE PROFILES OF FOOD ACIDSAnnerlynn SolanoNo ratings yet

- 2006 Flow Measurement and Instrumentation Velocity Profile Effects ReviewDocument16 pages2006 Flow Measurement and Instrumentation Velocity Profile Effects ReviewAnnerlynn SolanoNo ratings yet

- 10 5923 J Ajee 20140406 04 PDFDocument7 pages10 5923 J Ajee 20140406 04 PDFAnnerlynn SolanoNo ratings yet

- AB Appl KeyDocument14 pagesAB Appl KeySevgi Has DavudNo ratings yet

- Alkalinity Data Sheet f04Document4 pagesAlkalinity Data Sheet f04Annerlynn SolanoNo ratings yet

- Chapter 6 - in Review (3 Out of 6)Document2 pagesChapter 6 - in Review (3 Out of 6)Ruel CedeñoNo ratings yet

- Stoichiometric Calculations for Combustion AnalysisDocument47 pagesStoichiometric Calculations for Combustion AnalysisHandayani KesumadewiNo ratings yet

- Angle Measure PDFDocument10 pagesAngle Measure PDFAnnerlynn SolanoNo ratings yet

- Algebra 4Document65 pagesAlgebra 4Michael Damian100% (1)

- Adsorption Equil Principles - 483Document28 pagesAdsorption Equil Principles - 483MarwahNo ratings yet

- Work by Integration ProblemsDocument6 pagesWork by Integration ProblemsNicholson ZapantaNo ratings yet

- Thermal Energy Transfer & States of MatterDocument4 pagesThermal Energy Transfer & States of MatterAnnerlynn SolanoNo ratings yet

- Theo Nez EngDocument7 pagesTheo Nez EngAnnerlynn SolanoNo ratings yet

- 1 - 6 Function - Operations - and - Composition - of - FunctionsDocument29 pages1 - 6 Function - Operations - and - Composition - of - FunctionsAnnerlynn Solano0% (1)

- 7 Youths Heaven EnglDocument13 pages7 Youths Heaven EnglAnnerlynn SolanoNo ratings yet

- Work by Integration ProblemsDocument6 pagesWork by Integration ProblemsNicholson ZapantaNo ratings yet

- Basics of Lab SolutionsDocument9 pagesBasics of Lab SolutionsKaushik DekaNo ratings yet

- Upload Approved Docs for AccessDocument1 pageUpload Approved Docs for AccessAnnerlynn SolanoNo ratings yet

- Get Unlimited Downloads With A MembershipDocument1 pageGet Unlimited Downloads With A MembershipAugusto AntonioNo ratings yet

- 56027960Document41 pages56027960Annerlynn SolanoNo ratings yet

- Jamie GoodeDocument1 pageJamie GoodeAnnerlynn SolanoNo ratings yet

- Srubber CycloneDocument1 pageSrubber CycloneAnnerlynn SolanoNo ratings yet

- and Print This Document: Read and Print Without Ads Download To Keep Your Version Edit, Email or Read oDocument1 pageand Print This Document: Read and Print Without Ads Download To Keep Your Version Edit, Email or Read oAnnerlynn SolanoNo ratings yet

- LaboraDocument6 pagesLaboraAnnerlynn SolanoNo ratings yet

- TitleDocument2 pagesTitleAnnerlynn SolanoNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5782)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- MAR COR - Manual, 23g Series Ro System-3024270Document144 pagesMAR COR - Manual, 23g Series Ro System-3024270Juan GarciaNo ratings yet

- SER SER SER SER Service Manual Vice Manual Vice Manual Vice Manual Vice ManualDocument166 pagesSER SER SER SER Service Manual Vice Manual Vice Manual Vice Manual Vice Manualrenzo andrade100% (1)

- BETA Primer Vibration Control StrategiesDocument35 pagesBETA Primer Vibration Control Strategiesdikim100% (1)

- 02.understanding Process Equipment For Operators & Engineers-53Document5 pages02.understanding Process Equipment For Operators & Engineers-53Aatish ChandrawarNo ratings yet

- KRIBHCO Urea Plant OverviewDocument25 pagesKRIBHCO Urea Plant OverviewHarsh DholakiyaNo ratings yet

- Lecture 1-General Introduction To MechatronicsDocument108 pagesLecture 1-General Introduction To MechatronicsMASOUDNo ratings yet

- An in Depth Comparison of Four Gas Measurement Technologies Orifice Turbine Ultrasonic and Coriolisl PDFDocument37 pagesAn in Depth Comparison of Four Gas Measurement Technologies Orifice Turbine Ultrasonic and Coriolisl PDFKazuto KawakitaNo ratings yet

- Accurate water metering with the Woltmann H4000Document4 pagesAccurate water metering with the Woltmann H4000AnthonyNo ratings yet

- Volume Flow Rate Sensors AnexoDocument12 pagesVolume Flow Rate Sensors AnexoMaguengueNo ratings yet

- ScenchDocument4 pagesScenchKoteswara RaoNo ratings yet

- Air Cooler Design With Aspen EDR PDFDocument26 pagesAir Cooler Design With Aspen EDR PDFNicandroGonzales0% (1)

- Cooling Tower Performance EvaluationDocument3 pagesCooling Tower Performance EvaluationFouzan AbdullahNo ratings yet

- Archives of Civil and Mechanical EngineeringDocument53 pagesArchives of Civil and Mechanical EngineeringFiebigNo ratings yet

- ES-20.14 Waste Heat PTT Public Co., LTD Recovery Units Engineering Standard REV: 02Document10 pagesES-20.14 Waste Heat PTT Public Co., LTD Recovery Units Engineering Standard REV: 02Nikki RobertsNo ratings yet

- Wolfgang Von Meyerinck - CavotecDocument14 pagesWolfgang Von Meyerinck - CavotecRully MediantoNo ratings yet

- 105 0020 4100B - Nov2018Document4 pages105 0020 4100B - Nov2018devendra bansalNo ratings yet

- Flow MeasurementDocument45 pagesFlow MeasurementSomnath SwamyNo ratings yet

- LC PD Meters Brochure Products v18.2 OptimizedDocument8 pagesLC PD Meters Brochure Products v18.2 OptimizedMakarthy gpNo ratings yet

- Unit-2 Tutorial SheetDocument11 pagesUnit-2 Tutorial SheetAbhinav Sahu100% (1)

- Series 47K Gas Detector: Operation ManualDocument32 pagesSeries 47K Gas Detector: Operation ManualGunawan MSNo ratings yet

- Air Cooled Heat Exchnger FormatedDocument43 pagesAir Cooled Heat Exchnger FormatedMustafa Anwar50% (2)

- E 594 - 96 R01 - Rtu5na - PDFDocument7 pagesE 594 - 96 R01 - Rtu5na - PDFpechugonisNo ratings yet

- Analisador de O2Document35 pagesAnalisador de O2Evando PereiraNo ratings yet

- Double Regulating ValveDocument24 pagesDouble Regulating ValveMohamed Rady33% (3)

- Cavitation CFD in A Centrifugal PumpDocument7 pagesCavitation CFD in A Centrifugal Pumpazispn99100% (1)

- Pipesim Project2Document151 pagesPipesim Project2sugiantoNo ratings yet

- IHS PetroChem Collection Listing Aug13Document48 pagesIHS PetroChem Collection Listing Aug13OumorsyNo ratings yet

- Early Flood Detection and Warning System Using IOTDocument6 pagesEarly Flood Detection and Warning System Using IOTharryNo ratings yet

- CHAP03 MunsonDocument94 pagesCHAP03 MunsonYoshua GaloenkNo ratings yet