Professional Documents

Culture Documents

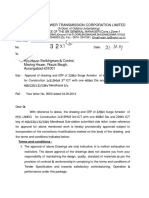

Gas Insulated SwitchGear

Uploaded by

Ankur GoelCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Gas Insulated SwitchGear

Uploaded by

Ankur GoelCopyright:

Available Formats

Gas Insulated SwitchGear

Ashvita Mandal

freundlich.madchen.ashvita@gmail.com

ABSTRACT

The introduction of SF6 gas has

revolutionized not only the

technology of

GIS has its unique problems,

among which is the susceptibility of

the insulation

system under very fast transients

(VFT) caused by disconnector

operation.

circuit breakers but also the layout

of substations.

Gas insulated substations (GIS)

have found an increasingly wide

range of application during the last

three decades because of their

remarkable advantages over their

conventional counterparts. These

advantages include compactness,

freedom from environmental

influences, high

reliability and minimum

maintenance, excellent protection

against atmospheric over voltages

and flexibility in choice of

arrangement and for future

expansion. The development of GIS

technology has made it

competitive and, in many cases,

preferable in techno- economic

comparison with the open-air type

substation. In spite of these merits,

INTRODUCTION

The introduction of SF6 gas has

revolutionized not only the

technology of circuit breakers but

also the layout of substations. The

dielectric strength of SF6 gas at

atmospheric pressure is

approximately three times that of

air. It is incombustible, non toxic,

colorless and chemically inert. It

has arc-quenching properties 3 to 4

times better than air at equal

pressure. Space requirement is

only 10 to 25 percent of what is

required is a conventional

substation.

Why we need GIS?

GIS has small ground space

requirements. Gas insulated

Substations have easy

maintenance( nearly zero

Maintenance Less field erection

time & less erection cost. For

underground powerhouse of Hydro

electric power project where space

constraint is a major issue. For Fast

Growing Major Cities where land

availability is costlier. NonFlammability & Non-Explosive ,Oilfree & Less Pollution.

High-voltage circuit-breakers have

greatly changed since they were

first introduced about 40 years ago,

and several interrupting principles

have been developed that have

contributed successively to a large

reduction of the operating energy.

These breakers are available for

indoor or outdoor applications, the

latter being in the form of breaker

poles housed in ceramic insulators

mounted on a structure.

Current interruption in a highvoltage circuit-breaker is obtained

by separating two contacts in a

medium, such as SF6, having

excellent dielectric and arc

quenching properties. After contact

separation, current is carried

through an arc and is interrupted

when this arc is cooled by a gas

blast of sufficient intensity.

Gas blast applied on the arc must

be able to cool it rapidly so that

gas temperature between the

contacts is reduced from 20,000 K

to less than 2000 K in a few

hundred microseconds, so that it is

able to withstand the transient

recovery voltage that is applied

across the contacts after current

interruption. Sulphur hexafluoride

is generally used in present highvoltage circuit-breakers (of rated

voltage higher than 52 kV).

Into the 1980s, the pressure

necessary to blast the arc was

generated mostly by gas heating

using arc energy. It is now possible

to use low energy spring-loaded

mechanisms to drive high-voltage

circuit-breakers up to 800 kV.

Brief history

The first patents on the use of

SF6 as an interrupting medium

were filed in Germany in 1938 by

Vitaly Grosse (AEG) and

independently later in the USA in

July 1951 by H.J. Lingal, T.E. Browne

and A.P. Storm (Westinghouse). The

first industrial application of SF6 for

current interruption dates back to

1953. High-voltage 15 kV to 161 kV

load switches were developed with

a breaking capacity of 600 A. The

first high-voltage SF6 circuit-breaker

built in 1956 by Westinghouse,

could interrupt 5 kA under 115 kV,

but it had 6 interrupting chambers

in series per pole. In 1957, the

puffer-type technique was

introduced for SF6 circuit breakers

where the relative movement of a

piston and a cylinder linked to the

moving part is used to generate

the pressure rise necessary to blast

the arc via a nozzle made of

insulating material (figure 1). In

this technique, the pressure rise is

obtained mainly by gas

compression. The first high-voltage

SF6 circuit-breaker with a high

short-circuit current capability was

produced by Westinghouse in 1959.

This dead tank circuit-breaker could

interrupt 41.8 kA under 138 kV

(10,000 MVA) and 37.6 kA under

230 kV (15,000 MVA). This

performance was already

significant, but the three chambers

per pole and the high pressure

source needed for the blast

(1.35 MPa) was a constraint that

had to be avoided in subsequent

developments. The excellent

properties of SF6 lead to the fast

extension of this technique in the

1970s and to its use for the

development of circuit breakers

with high interrupting capability, up

to 800 kV.

and 800 kV, with respectively 2, 3,

and 4 chambers per pole, lead to

the dominance of SF6 circuit

breakers in the complete range of

high voltages. Several

characteristics of SF6 circuit

breakers can explain their success:

The achievement around 1983 of

the first single-break 245 kV and

the corresponding 420kV to 550 kV

Simplicity of the interrupting

chamber which does not

need an auxiliary breaking

chamber;

Autonomy provided by the

puffer technique;

The possibility to obtain the

highest performance, up to

63 kA, with a reduced

number of interrupting

chambers;

Short break time of 2 to 2.5

cycles;

High electrical endurance,

allowing at least 25 years of

operation without

reconditioning;

Possible compact solutions

when used for "gas insulated

switchgear" (GIS) or hybrid

switchgear;

Integrated closing resistors or

synchronized operations to

reduce switching overvoltages;

Reliability and availability;

Low noise levels.

The reduction in the number of

interrupting chambers per pole has

led to a considerable simplification

of circuit breakers as well as the

number of parts and seals required.

As a direct consequence, the

reliability of circuit breakers

improved, as verified later on by

CIGRE surveys.

Gas Insulated Switchgear

Substation

Gas Insulated Substations (GIS)

is a compact, multicomponent

assembly enclosed in a ground

metallic housing in which the

primary insulating medium is

compressed Sulphur

hexafluoride (SF6) gas.

SF6 acts as an insulation

between live parts & the earthed

metal closure.

CIRCUIT BREAKER

A circuit breaker is an

automatically-operated electrical

switch designed to protect an

electrical from damage caused by

overload or short circuit. Its

basic function is to detect a fault

condition and, by interrupting

continuity, to immediately

discontinue electrical flow.

Unlike a fuse, which operates

once and then has to be replaced,

a circuit breaker can be reset

(either manually or automatically)

to resume normal operation

Current interruption in a highvoltage circuit-breaker is obtained

by separating two contacts in a

medium, such as SF6, having

excellent dielectric and arc

quenching properties.

After contact separation, current is

carried through an arc and the arc

is interrupted & cooled by a gas

blast of sufficient intensity.

Design of a Circuit Breaker

Each CB comprises three single-phase

metal enclosed breaker poles.Each

Pole consists of operating mechanism,

the interrupter column with 2

interrupting chambers in series & the

enclosure with the basic support

structure. To guarantee simultaneous

interruption, the chambers are

mechanically connected in series.

One grading capacitor

guarantees an equalized voltage

distribution.

Recent Breakthrough in GIS

Thermal blast chambers

New types of SF6 breaking

chambers, which implement

innovative interrupting principles,

have been developed over the past

30 years, with the objective of

reducing the operating energy of

the circuit-breaker. One aim of this

evolution was to further increase

the reliability by reducing the

dynamic forces in the pole.

Developments since 1980 have

seen the use of the self-blast

technique of interruption for

SF6 interrupting chambers.

These developments have been

facilitated by the progress made in

digital simulations that were widely

used to optimize the geometry of

the interrupting chamber and the

linkage between the poles and the

mechanism.

This technique has proved to be

very efficient and has been widely

applied for high voltage circuit

breakers up to 550 kV. It has

allowed the development of new

ranges of circuit breakers operated

by low energy spring-operated

mechanisms.

The reduction of operating energy

was mainly achieved by the

lowering energy used for gas

compression and by making

increased use of arc energy to

produce the pressure necessary to

quench the arc and obtain current

interruption. Low current

interruption, up to about 30% of

rated short-circuit current, is

obtained by a puffer blast.

Self-blast chambers

Further development in the thermal

blast technique was made by the

introduction of a valve between the

expansion and compression

volumes. When interrupting low

currents the valve opens under the

effect of the overpressure

generated in the compression

volume. The blow-out of the arc is

made as in a puffer circuit breaker

thanks to the compression of the

gas obtained by the piston action.

In the case of high currents

interruption, the arc energy

produces a high overpressure in

the expansion volume, which leads

to the closure of the valve and thus

isolating the expansion volume

from the compression volume. The

overpressure necessary for

breaking is obtained by the optimal

use of the thermal effect and of the

nozzle clogging effect produced

whenever the cross-section of the

arc significantly reduces the

exhaust of gas in the nozzle. In

order to avoid excessive energy

consumption by gas compression, a

valve is fitted on the piston in order

to limit the overpressure in the

compression to a value necessary

for the interruption of low short

circuit currents.

Self-blast circuit breaker chamber

(1) closed, (2) interrupting low

current, (3) interrupting high

current, and (4) open.

This technique, known as selfblast has now been used

extensively since 1980 for the

development of many types of

interrupting chambers. The

increased understanding of arc

interruption obtained by digital

simulations and validation through

breaking tests, contribute to a

higher reliability of these self-blast

circuit breakers. In addition the

reduction in operating energy,

allowed by the self blast technique,

leads to longer service life.

Hybrid GIS

Issues related to

SF6 Switchgear

The following issues are associated

with SF6 switchgear:

Greenhouse gas

Sulphur

hexafluoride#Greenhouse_gas

SF6 is the most potent greenhouse

gas that the Intergovernmental

Panel on Climate Change has

evaluated. It has a global warming

potential that is 23,900 times

worse than CO2.[3] SF6 has been

classified as a restricted gas under

the Kyoto Protocol.[4]

Toxic lower order gases

When an arc is formed in SF6 gas

small quantities of lower order

gases are formed. Some of these

byproducts are toxic and can cause

irritation to eyes and respiratory

system.

Oxygen displacement

SF6 is heavier than air so care must

be taken when entering low

confined spaces due to the risk of

oxygen displacement.

Alternatives to SF6 Circuit

Breakers

Circuit Breakers are usually classed

on their insulating medium. The

follow types of circuit breakers may

be an alternative to SF6 types.

Air blast

Oil

Vacuum

References

Conclusion

[1] C.Y. lui and J. Hiley,

Computational study of very fast

transients in GIS with special

reference to effects of trapped

charge and rise time on

overvoltage amplitude, IEE Proc.Genre. Transom. Distrib., vol. 141,

no. 5, pp. 485-490, September

1994.

[2] IEEE TF on Very Fast Transients

(D. Povh, Chairman), "Modeling and

analysis guidelines for very fast

transients," IEEE Trans. on Power

Delivery, vol. 11, no. 4, pp. 20282035, October 1996.

[3] Hirohiko Yatsuzuka, Manabu

Takamoto, Masaharu Matsuyama,

New 550-kV Gas-insulated

Switchgear, Hitachi Review vol.

48, no. 5, pp. 285- 289,1999.

[4] ABB-Insulation Co-ordination

Maharani bag, New Delhi, 2007.

[6] Z. Haznadar, S. Cariimamovid,

R.Mahmutdehajid, More accurate

modeling of gas insulated

substation components in digital

simulations of Very fast transients,

Transactions on Power Delivery,

vol. 7 no. 1, pp. 434- 441, January

1992.

[7] M. Mohan Rao, M. Joy Thomas,

and B. P. Singh, Frequency

characteristics of very fast

transient currents in a 245 KV GIS,

IEEE Transaction on Power delivery,

vol. 20, no. 4, pp. 2450-2457,

October 2005.

You might also like

- The Joy of Numbers-Shakuntala DeviDocument157 pagesThe Joy of Numbers-Shakuntala DeviAnkur GoelNo ratings yet

- 21 Business Strategy Frameworks That Every Business Leader Should Know - IdeaGeniusDocument29 pages21 Business Strategy Frameworks That Every Business Leader Should Know - IdeaGeniusAnkur GoelNo ratings yet

- Upgrading The ProtectionDocument4 pagesUpgrading The ProtectionMukesh KumarNo ratings yet

- MSS SP-93-2020 Liquid Penetrant Examination MethodDocument10 pagesMSS SP-93-2020 Liquid Penetrant Examination MethodKenyi Omar Holguino Sulla0% (1)

- Porters Five Forces - What It Means For Your BusinessDocument4 pagesPorters Five Forces - What It Means For Your Businessanil_baddi100% (10)

- Auxiliary Relays RXMB 1 RXMB 2 and RXMC 1Document12 pagesAuxiliary Relays RXMB 1 RXMB 2 and RXMC 1jenskg100% (1)

- IEEE STD C57.19.00-2004 (CN - EN)Document18 pagesIEEE STD C57.19.00-2004 (CN - EN)pdrich8No ratings yet

- IEC VS ANSI CT Burden Comparision PDFDocument3 pagesIEC VS ANSI CT Burden Comparision PDFflyzalNo ratings yet

- Marking Scheme For Computer Networks ExamDocument18 pagesMarking Scheme For Computer Networks Examtuyambaze jean claudeNo ratings yet

- Reeving Information Grove CranesDocument19 pagesReeving Information Grove CranesLouisAucamp100% (2)

- Power Systems Relays Relion 670Document43 pagesPower Systems Relays Relion 670kass_ecsNo ratings yet

- IsolatorsDocument12 pagesIsolatorsmichol2014No ratings yet

- Calculate Symmetrical Fault CurrentsDocument27 pagesCalculate Symmetrical Fault CurrentsBoy TulaNo ratings yet

- Accelerate Secure and Lntegrate With IBM WebSphere DataPower SOA Appliances - Vol 1Document406 pagesAccelerate Secure and Lntegrate With IBM WebSphere DataPower SOA Appliances - Vol 1Falsedad Mas FalsoNo ratings yet

- Outdoor Type Three-Phase Transformers Up To and Distribution Including 100 kVA 11 Kv-SpecificationDocument7 pagesOutdoor Type Three-Phase Transformers Up To and Distribution Including 100 kVA 11 Kv-SpecificationGaurav AgarwalNo ratings yet

- Failure Analysis of A Power Transformer Using Dissolved Gas Analysis - A Case StudyDocument4 pagesFailure Analysis of A Power Transformer Using Dissolved Gas Analysis - A Case StudyInternational Journal of Research in Engineering and Technology100% (1)

- Cigre Paper On CT FailureDocument6 pagesCigre Paper On CT Failureahmadshoeb19No ratings yet

- Change Management Tip SheetDocument2 pagesChange Management Tip SheetMario WallaceNo ratings yet

- Transformer BhelDocument17 pagesTransformer BhelAayushiNo ratings yet

- Gas Insulated SubstationDocument8 pagesGas Insulated SubstationNayanNo ratings yet

- BESS Feeder - EFDocument1 pageBESS Feeder - EFTosikur RahmanNo ratings yet

- 110V Battery Sizing - Ni-Cad-Dhunge Shangu SS - Rev-02Document21 pages110V Battery Sizing - Ni-Cad-Dhunge Shangu SS - Rev-02Janmejey BarikNo ratings yet

- Busbar Basic (Refresher) +relays SelectionDocument20 pagesBusbar Basic (Refresher) +relays SelectionJawi KuswantoNo ratings yet

- List of Is Standards For Substation EquipmentsDocument9 pagesList of Is Standards For Substation EquipmentsRajj Pruthivi100% (1)

- COM600Document51 pagesCOM600castrojpNo ratings yet

- PVsyst Training Part IDocument96 pagesPVsyst Training Part IBarun BiswasNo ratings yet

- 420KV SF6 Circuit Breaker Operation and TestingDocument18 pages420KV SF6 Circuit Breaker Operation and TestingArlone ManaladNo ratings yet

- Approved - 216 KV LA - GTP & DrgsDocument22 pagesApproved - 216 KV LA - GTP & DrgsGuru MishraNo ratings yet

- Rseries O&mDocument107 pagesRseries O&mKamran IbadovNo ratings yet

- KVMRT MMJV SBK SS05 Sysw Rep PDS 000089Document349 pagesKVMRT MMJV SBK SS05 Sysw Rep PDS 000089syafiqishamuddinNo ratings yet

- BS 5628 Part 3 MasonryDocument132 pagesBS 5628 Part 3 MasonryMohamed Habola79% (19)

- The Technology of Instrument Transformers: Current and Voltage Measurement and Insulation SystemsFrom EverandThe Technology of Instrument Transformers: Current and Voltage Measurement and Insulation SystemsNo ratings yet

- Royal Mail International Claims FormDocument2 pagesRoyal Mail International Claims FormLeslie PerkinsNo ratings yet

- Stories From Panchatantra - Sanskrit EnglishDocument105 pagesStories From Panchatantra - Sanskrit Englishmmsingi100% (9)

- 400kv DBR Assembly & Maintenance Instructions-R6 PDFDocument52 pages400kv DBR Assembly & Maintenance Instructions-R6 PDFiprao100% (1)

- Cap 04Document16 pagesCap 04YolandaNo ratings yet

- Earthing Practices for GIS and Transmission LinesDocument13 pagesEarthing Practices for GIS and Transmission LinesShiva Naga KumarNo ratings yet

- Building Construction ReportDocument15 pagesBuilding Construction ReportDevendra SharmaNo ratings yet

- R5888C Quadramho A4RBDocument336 pagesR5888C Quadramho A4RBdbeard811100% (1)

- Padmount PufferPak Switch GuideDocument22 pagesPadmount PufferPak Switch Guidealfonso.parkerNo ratings yet

- Approved - 400kV LADocument22 pagesApproved - 400kV LAGuru MishraNo ratings yet

- 22kV GIS Cable Terminal - Installation ManualDocument11 pages22kV GIS Cable Terminal - Installation ManualNorma RetamozoNo ratings yet

- Notice For 2nd PSCT TrainingDocument5 pagesNotice For 2nd PSCT Trainings_banerjeeNo ratings yet

- EDOC-Surge Arrester Sizing For SubDocument14 pagesEDOC-Surge Arrester Sizing For SubEl Comedor BenedictNo ratings yet

- Gas Insulated Substation: An Overview of Components and AdvantagesDocument40 pagesGas Insulated Substation: An Overview of Components and AdvantagesÑàmàñ JàiñNo ratings yet

- 6 +acsr+zebra+conductorDocument17 pages6 +acsr+zebra+conductorBagusIrawanSaputraNo ratings yet

- Solar Water PumpDocument10 pagesSolar Water PumpSOLARC GREEN ENERGY SOLUTIONSNo ratings yet

- VSC Course Lecture2Document27 pagesVSC Course Lecture2eng7senNo ratings yet

- Generator Data Sheet of BHELDocument21 pagesGenerator Data Sheet of BHELbramhanand vermaNo ratings yet

- Calculation of Short-Circuit Current EffectsDocument10 pagesCalculation of Short-Circuit Current EffectsLuizNo ratings yet

- Ehv Circuit BreakersDocument12 pagesEhv Circuit BreakersBoreda RahulNo ratings yet

- Working Clearance For Outdoor Installation Ref IEC 61936 Fig 3 Safety Clearance Sectional Clearance Safety ClearanceDocument1 pageWorking Clearance For Outdoor Installation Ref IEC 61936 Fig 3 Safety Clearance Sectional Clearance Safety ClearanceMeghavahinaNo ratings yet

- KSH International Enamelled Copper Conductors/Strips BrochureDocument2 pagesKSH International Enamelled Copper Conductors/Strips Brochurekshintl100% (1)

- Acsr Panther Conductor 10 PDFDocument14 pagesAcsr Panther Conductor 10 PDFSenthil ThanappanNo ratings yet

- Design Calculation For Earthing A.Nomenclature of ParametersDocument31 pagesDesign Calculation For Earthing A.Nomenclature of Parametersaloo leoNo ratings yet

- IRI PRO V3 CatalogueDocument14 pagesIRI PRO V3 CatalogueThomas Joseph100% (2)

- 2018 CIGRE SESSION Technical - Programme June15thDocument34 pages2018 CIGRE SESSION Technical - Programme June15thVenkatasubramanian IyerNo ratings yet

- BBB M, M, KLKLKL JJKDocument16 pagesBBB M, M, KLKLKL JJKEngr Irfan AkhtarNo ratings yet

- Stp030000 Og en 20221130 Synchroteq Plus Operation GuideDocument149 pagesStp030000 Og en 20221130 Synchroteq Plus Operation GuideJeyporess 2021No ratings yet

- P438 EN M R-b5-A 311 661 PDFDocument1,192 pagesP438 EN M R-b5-A 311 661 PDFAshutosh KumarNo ratings yet

- Gas Insulated Substation: An OverviewDocument35 pagesGas Insulated Substation: An OverviewSaurabh KumarNo ratings yet

- 0260 573 PVE Y 233 03 Guaranteed Technical Particulars For GISDocument36 pages0260 573 PVE Y 233 03 Guaranteed Technical Particulars For GISBebilson MansinghNo ratings yet

- ! - 1979 - Drouet, M., & Nadeau, F. - Pressure Waves Due To Arcing Faults in A SubstationDocument4 pages! - 1979 - Drouet, M., & Nadeau, F. - Pressure Waves Due To Arcing Faults in A SubstationMikeNo ratings yet

- Info Iec60038 (Ed6.2) en DDocument4 pagesInfo Iec60038 (Ed6.2) en DArief Muhammad LubisNo ratings yet

- High Voltage Busbar ProtectionDocument45 pagesHigh Voltage Busbar ProtectionabhinavksauravNo ratings yet

- Transformers STDMDocument79 pagesTransformers STDMjunfaNo ratings yet

- UniGear ZS3.2 Brochure Rev. B EN PDFDocument8 pagesUniGear ZS3.2 Brochure Rev. B EN PDFbpchimeraNo ratings yet

- 3 66kv630 SQMM 1c Power CableDocument26 pages3 66kv630 SQMM 1c Power CableKeval VelaniNo ratings yet

- DC Cables AnalysisDocument21 pagesDC Cables AnalysisOm SaxenaNo ratings yet

- Deep Bar Vis-À-Vis Double Cage Rotor Design For Large MV MotorsDocument2 pagesDeep Bar Vis-À-Vis Double Cage Rotor Design For Large MV MotorsSUBRATA BISWASNo ratings yet

- Application of Flexible AC Transmission System Devices in Wind Energy Conversion SystemsFrom EverandApplication of Flexible AC Transmission System Devices in Wind Energy Conversion SystemsNo ratings yet

- High-voltage Circuit Breakers: A Brief History and GuideDocument8 pagesHigh-voltage Circuit Breakers: A Brief History and GuideLove Buddha's WordsNo ratings yet

- Market Share-A Key To ProfitabilityDocument20 pagesMarket Share-A Key To ProfitabilityAnkur GoelNo ratings yet

- BCG Report On DiversificationDocument36 pagesBCG Report On DiversificationAnkur GoelNo ratings yet

- World Economic Outlook 2014 PDFDocument236 pagesWorld Economic Outlook 2014 PDFsaul M.cNo ratings yet

- Design of Energy Storage For PVDocument6 pagesDesign of Energy Storage For PVAnkur GoelNo ratings yet

- The Use of Facts Devices in Disturbed Power Systems-Modeling, Interface, and Case StudyDocument5 pagesThe Use of Facts Devices in Disturbed Power Systems-Modeling, Interface, and Case StudyNoppon PatNo ratings yet

- PV BESS Grid IntegrationDocument4 pagesPV BESS Grid IntegrationAnkur GoelNo ratings yet

- Lead Acid BatteryDocument4 pagesLead Acid BatteryAnkur GoelNo ratings yet

- The Curse of Surya - Dev PrasadDocument1,006 pagesThe Curse of Surya - Dev PrasadAnkur Goel50% (2)

- Lectures 2 and 3 - The Solow Growth ModelDocument96 pagesLectures 2 and 3 - The Solow Growth ModelAnonymous VghTxI4HoNo ratings yet

- Master of Science in Quantitative Economics at Indian Statistical InstituteDocument23 pagesMaster of Science in Quantitative Economics at Indian Statistical Institutepatrick_joyNo ratings yet

- Information Sought From All Solar Cell & Module Manufacturers 31012017Document6 pagesInformation Sought From All Solar Cell & Module Manufacturers 31012017Ankur GoelNo ratings yet

- Maxima N MinimaDocument67 pagesMaxima N MinimaAnkur GoelNo ratings yet

- Allied Area ReportDocument13 pagesAllied Area ReportAnkur GoelNo ratings yet

- 12th Five Year PlanDocument146 pages12th Five Year PlanKajal RaiNo ratings yet

- PNC TGDocument12 pagesPNC TGsatyajit03No ratings yet

- UPFC PPTDocument26 pagesUPFC PPTAnkur GoelNo ratings yet

- Results of 7th semester BTech students of Delhi College of EngineeringDocument37 pagesResults of 7th semester BTech students of Delhi College of EngineeringAnkur GoelNo ratings yet

- Contents RevisedDocument92 pagesContents RevisedAnoopKumarMangarajNo ratings yet

- ProbabilityDocument18 pagesProbabilityAnkur Goel0% (1)

- Constitution and Political System of IndiaDocument2 pagesConstitution and Political System of IndiaAnkur GoelNo ratings yet

- Analysis of HVDC On MATLABDocument9 pagesAnalysis of HVDC On MATLABAnkur GoelNo ratings yet

- Financial Markets: A Beginner's ModuleDocument2 pagesFinancial Markets: A Beginner's Moduledavidd121No ratings yet

- Materials ManagementDocument13 pagesMaterials Managementsagar09100% (2)

- PNC TGDocument12 pagesPNC TGsatyajit03No ratings yet

- The Silent War Over Education Reforms - The HinduDocument3 pagesThe Silent War Over Education Reforms - The HinduAnkur GoelNo ratings yet

- 8998 01 Atlas Copco Air MotorsDocument110 pages8998 01 Atlas Copco Air MotorsEduardo EscobedoNo ratings yet

- Introduction To Unix Tutorial: CSIF Computer NetworkDocument11 pagesIntroduction To Unix Tutorial: CSIF Computer NetworkOliviaNo ratings yet

- ARM 54 Look Inside The Book PDFDocument6 pagesARM 54 Look Inside The Book PDFJha NizNo ratings yet

- Informatics Security Handbook 1st Edition PDFDocument410 pagesInformatics Security Handbook 1st Edition PDFMatei StănescuNo ratings yet

- BSNL VENNELA PLUS: Local calls at 60p, 250 free SMSDocument14 pagesBSNL VENNELA PLUS: Local calls at 60p, 250 free SMSVijay KumarNo ratings yet

- ARFCNDocument2 pagesARFCNAnonymous i3gPuCNo ratings yet

- D 869 - 85 R98 - Rdg2oq - PDFDocument2 pagesD 869 - 85 R98 - Rdg2oq - PDFphaindikaNo ratings yet

- Zebra Bi Business Chart WhitepaperDocument18 pagesZebra Bi Business Chart WhitepaperVuong Luu0% (1)

- Courseware SampleDocument8 pagesCourseware SampleScott ConnollyNo ratings yet

- Table of Design Properties For Metric Steel Bolts M5 To M39 - Eurocode 3Document10 pagesTable of Design Properties For Metric Steel Bolts M5 To M39 - Eurocode 3anon_295574042No ratings yet

- BS 5834 Part 1Document40 pagesBS 5834 Part 1Vincent KwekNo ratings yet

- 12 Ka 4Document58 pages12 Ka 4Gunjesh GunjanNo ratings yet

- Fortinet ProductGuide Mar2014 R36 PDFDocument159 pagesFortinet ProductGuide Mar2014 R36 PDFRodrigo PissinNo ratings yet

- Aki̇ş VF 2Document1 pageAki̇ş VF 2SENER AKSOYNo ratings yet

- Easy Smart Switch - UG PDFDocument51 pagesEasy Smart Switch - UG PDFLafaiete Alves F NNo ratings yet

- Abb MNS-MCCDocument4 pagesAbb MNS-MCCMiguel PMNo ratings yet

- Max Heap C ImplementationDocument11 pagesMax Heap C ImplementationKonstantinos KonstantopoulosNo ratings yet

- Photovoltaic Solar Generator Connection FormDocument1 pagePhotovoltaic Solar Generator Connection Formnishutha3340No ratings yet

- National Heavy Vehicle General Dimension RequirementsDocument5 pagesNational Heavy Vehicle General Dimension RequirementsMilan SjausNo ratings yet

- GCR300 DNP3.0 Detail Switch ControlDocument8 pagesGCR300 DNP3.0 Detail Switch ControlJagan VanamaNo ratings yet