Professional Documents

Culture Documents

Railroad Wheel Dynamo Meter AAR

Uploaded by

Marcus Oneil0 ratings0% found this document useful (0 votes)

268 views8 pagesRailroad Wheel Dynamo Meter AAR

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentRailroad Wheel Dynamo Meter AAR

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

268 views8 pagesRailroad Wheel Dynamo Meter AAR

Uploaded by

Marcus OneilRailroad Wheel Dynamo Meter AAR

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 8

ASSOCIATION OF

AMERICAN RAILROADS

CHICAGO TECHNICAL CENTER

R AILROAD W

HEEL

DYNAMOMETER

T HE A MERICAN S OCIETY of M ECHANICAL E NGINEERS

91 st NATIONAL HISTORIC MECHANICAL

ENGINEERING LANDMARK

Nov. 29, 1988

AMERICAN SOCIETY OF MECHANICAL ENGINEERS

RAIL TRANSPORTATION DIVISION

CHICAGO SECTION, REGION VI

NATIONAL HISTORIC MECHANICAL ENGINEERING LANDMARK

RAILROAD WHEEL DYNAMOMETER

ASSOCIATION OF AMERICAN RAILROADS

1955

THIS INERTIA DYNAMOMETER TESTS RAILROAD

WHEELS UNDER CONTROLLED CONDITIONS

EXCEEDING NORMAL SERVICE: (A) MAXIMUM BRAKE

SHOE FORCE OF 40,000 POUNDS; (B) SPEEDS UP TO

178 MPH; (C) THE LARGEST EQUIVALENT INERTIA

WHEEL LOAD IN RAILROAD PRACTICE OF 127,000

POUNDS; (D) SIMULTANEOUSLY APPLYING LATERAL

AND VERTICAL LOADS OF 15,000 POUNDS AND 60,000

POUNDS, RESPECTIVELY (A UNIQUE CAPABILITY).

SPECIFICATION: JOSEPH M. WANDRISCO (US STEEL);

DESIGN AND CONSTRUCTION SUPERVISION: REX C.

SEANOR (ADAMSON UNITED). IN 1983 IT WAS MOVED

FROM US STEEL TO THE AAR. COMPUTER CONTROL

ADDED IN 1987.

INTRODUCTION

EARLIEST WHEEL AND SHOE DYNAMOMETERS

The railroad wheel supports the car or locomotive

as it rolls on its tread along the rail and guides the

vehicle through curves and switches with its flange

which projects outward from the tread. The cast or

wrought steel wheel also acts as a brake drum. When

brakes are applied, the brake shoes press against the

wheel tread, and through their rubbing friction slow

down, stop, or control train speed. As running speeds

and weights on wheels doubled and redoubled in the

later part of the 19th century, the combination of

mechanical and thermal stresses often caused cracks to

develop in the cast iron wheels. Some of the cracks

led to loss of large chunks of wheel material and

disastrous wheel failures (train wrecks).

On the Southern Pacific Railroad, every route into

California involves continuous heavy grade-braking for

20 to as long as 85 miles, as from the Sierra summit

at Norden down to Roseville. To identify and cull out

inadequate wheel designs and manufacture, Southern

Pacific designed and built the first known full-scale

wheel and braking dynamometer in 1891. A description

of this machine and many test results appeared in the

1892 Master Car Builders Association (MCB)

Proceedings (Ref. 1).

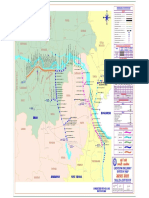

Figure 1 shows a full wheel set, two wheels

mounted on an axle, resting on track or drive wheels

powered by a Corliss steam engine. An adjustable

spring force beam loaded each journal, a brake beam

with cast or wrought iron brake shoes applied braking

forces to both test wheels, a scale beam measured

retarding forces, and a brake cylinder and lever gave

typical braking ratios and forces on freight and

passenger car wheels of the day. Starting with 10

psi, brake cylinder pressure was increased 5 psi each

five minutes through 50 or more psi. At 30 mph, up to

100 braking hp per wheel was generated which cracked

any but the best chilled iron wheels. Continued

difficulties in the next decade or so led Southern

Pacific to start using all-steel wheels (wrought steel

at the time).

About 100 years ago, railway mechanical engineers

and metallurgists began formal investigation of cast

iron wheel failures, and of wheel and brake shoe

design, materials and manufacture. This resulted in

development of dynamometers so full-sized wheels and

brake shoes could be tested under controlled

conditions to improve service performance and enhance

railroad safety.

Prior to the use of dynamometers, only a drop test

was used to determine the resistance to fracture of

cast iron wheels. However, the drop test did not

adequately predict performance in grade braking (Ref.

1).

2

THE STEEL REVOLUTION: LONGER HEAVIER CARS & TRAINS.

The years from 1895-1905 saw steel rapidly take

over in freight car construction and 40- and 50-ton

capacity freight cars became common as all wood cars

quickly disappeared. In passenger service, the move

to stronger and safer all-steel cars became a reality

before 1910. Two results of the MCB 50-car train air

brake tests of 1886-7 were the conversion to the

quick-action automatic air-brake starting in 1889 and

the invention of the energy-absorbing friction draft

gear. These three developments permitted longer and

heavier freight trains to boost railroad capacity

during the 1905 - 1925 era.

As car weights increased, heat input to the wheel

treads increased. Higher operating speeds with more

powerful locomotives increased the braking heat during

stopping by the square of the speeds. These factors

placed even further demands on the integrity of the

wheels.

Figure 1.

Several other dynamometers were built to

investigate braking and its effect on shoes and

wheels. American Brake Shoe and Foundry Co. designed

and started operating the first of several

dynamometers at their Mahwah, NJ, works in 1908 to

study the effects of increased braking loads. The

Mahwah dynamometer was used for detailed analyses of

the several types of shoes used in the

Pennsylvania-Westinghouse steel passenger-train tests

of 1913 (Ref. 6). These tests brought together an

improved Universal Control Valve with an

electro-pneumatic option, and clasp-brake rigging (two

shoes/wheel) with 150 percent braking ratio at 100

psi (1.5 x car weight). This system enabled a 1200-ft

emergency stop from 60 mph with twelve 6l-ton steel

cars and a 200-ton 4-6-2 K2s steam locomotive and

tender. Around 1910, the University of Illinois

constructed a braking dynamometer. As nearly as can

be determined, the Pennsylvania RR designed and built

a brake-shoe and wheel testing machine about the time

of WWI.

Southern Pacific RR 1891 Full Wheel Set

Dynamometer.

In 1893, the MCB Association, forerunner of the

Mechanical Division of the Association of American

Railroads (AAR), determined that a full-scale brake

shoe testing machine was essential to establish an

industry-wide standard for friction and wear of the

many makes of brake shoes in use (Ref. 2-4). With

assistance from the Pennsylvania Railroad (PRR),

George Westinghouse (later ASME President) and William

A. Sellers Co., the brake shoe testing machine in

Figure 2 was manufactured in the PRR shops and

assembled in Westinghouse Air Brakes plant in

Wilmerding, PA. Here the new machine and its

dynamometer were put through exhaustive initial and

operating tests. At the time, "dynamometer" referred

only to the mechanical force measuring apparatus,

which along with speed, time and distance we now

include in the term "instrumentation". In 1900, the

MCB testing machine was transferred to Purdue

University in West Lafayette, IN (Ref. 5) where the

official MCB tests were continued until the machine

was scrapped in 1942.

Figure 2.

Although the quality of chilled cast iron wheels

improved through the research of the Association of

Chilled Car Wheel Manufacturers, steel steadily took

over for passenger and locomotive wheels. Passenger

car weights steadily increased to the 90-ton range

through the 1920s and into the 1930s when mechanical

air conditioning was added. Locomotive tenders

similarly began their growth to truly mammoth size

which required wrought steel wheels.

Master Car Builders (MCB) Brake Shoe

Testing Machine Designed 1893.

Section Showing Jaw-type Clutch.

Elevation.

3

THE DAWN OF A NEW AGE: DIESEL-ELECTRIC STREAMLINERS

1933 and 1934 saw the light-weight diesel-electric

streamliners burst upon the scene with Union Pacifics

aluminum "City of Salina" and the Chicago, Burlington

and Quincys stainless steel "Pioneer Zephyr". Light

weight, high speeds, air-conditioned comfort and

modern design were the watchwords in helping railroads

regain many passengers lost to the automobile in the

late 20s and early 30s. After covering the 1070 odd

miles from Denver to Chicago at over 77 mph average,

and running long distances at 90 and 100+ mph, the

"Pioneer Zephyr" was proudly displayed at the Chicago

Worlds Fair. This first Zephyr and its 600-hp

General Motors 201-A two-cycle diesel engine was

ASMEs 54th National Landmark in 1980 and is on

display at Chicagos Museum of Science and Industry,

some five miles south of the Illinois Institute of

Technology and the AAR Technical Center.

Many railroaders felt the PRR/WABCO 1913 emergency

train stop of 1200 ft from 60 mph had become a

benchmark. By ratioing the squares of the initial

speeds and adding about 8 percent, the 100 mph

streamliner should stop in about 3600 ft in emergency

on level track. At higher speeds and total shoe

forces, cast iron shoe friction decreases. Therefore,

speed sensitive brake equipment was developed which

used much higher shoe forces than the then standard

150 percent braking ratio. Speed governor control

provided 250 percent braking ratio from 100+ down to

60 mph, 200 percent to 40 mph, 150 percent to 20 mph,

then stepping down to 100 percent. This enabled the

90-100 mph streamliner with HSC (High Speed Control)

to make emergency and full-service stops in a mile or

less. However, the instantaneous braking hp per wheel

in high speed zones went up into the 500 to 1000 hp

range!

Figure 3.

PRR Dynamometer at AAR Chicago 1955 - 1976.

33,000-lb wheel loads. As a consequence, modern 4000+

hp diesel reduces units have dynamic/blended braking

which reduces the heat input to the locomotive

wheels. The AAR dynamometer was scrapped in 1976

because of old age.

COMPOSITION BRAKE SHOES

In the 1960s, the high friction composition brake

shoe, consisting of composite friction material bonded

to a steel backing plate, became widely accepted.

Composition shoes had as their chief advantage two to

three times the kinetic friction on a steel wheel as

that of cast iron brake shoes at medium to high

speeds. Therefore, because much lower shoe forces

could be used to obtain the same stopping ability,

brake systems were redesigned and simplified. The

clasp brake rigging with two shoes per wheel, needed

with cast iron shoes, was in most cases replaced with

a single composition brake shoe per wheel. Smaller

brake cylinders and associated rigging parts led to

lower brake system cost.

By 1947, high speed streamliner service covered

most of the country. As streamliner service grew, the

diesel-electric locomotive expanded into the 2000-2250

hp range. Electric multiple-unit control enabled

three or four to be operated from one control station

to provide the 6000 to 8000 tractive hp required for

quite long trains of 15-18 streamlined cars.

In the late 1940s, the 6000-7000 hp four-unit

diesel-electric freight locomotives had amply

demonstrated their worth and the full North American

motive power revolution was off and running. Within

15 years, virtually every railroad in North America

had changed from steam to diesel-electric. The last

remaining unit of the original 4-unit 5400 hp General

Motors "FT" demonstrator with the 567 diesel engine is

preserved at the National Museum of Transport in St.

Louis and was ASMEs 77th National Landmark.

THE LANDMARK DYNAMOMETER

U. S. Steel Corp., a major manufacturer of wrought

steel wheels and axles, created preliminary design

specifications for a railroad wheel and axle

dynamometer in the early 1950s. USS wanted

capabilities that went beyond those of braking

dynamometers, such as those owned by American Brake

Shoe and Foundry Co., American Steel Foundries, ARMCO

Steel, The Budd Co., and Westinghouse Air Brake.

WHEEL PROBLEMS FROM HIGH ENERGY TREAD BRAKING

During the late 40s and early 50s, increasing

numbers of diesel-electric locomotive wheel failures

were occurring. It became apparent that these wheels

were being thermally overloaded. Wheel manufacturers

began research to develop new designs and heat

treatments. The University of Illinois dynamometer

was used to conduct wheel industry research on thermal

cracking and explosive failures. The AAR Chicago

Technical Center acquired the Pennsylvania RRs brake

shoe and wheel dynamometer (Ref. 7) in 1955 to examine

thermal braking loads with cast iron shoes, Figure 3.

These studies led to a more cautious approach to

braking 36-40 in. diameter wheels with 27,000 to

The Adamson United Company of Akron, Ohio (now a

part of Wean Industries) was contracted by USS in 1954

to build the dynamometer for the Applied Research

Laboratory in Monroeville, PA. Adamson United had

extensive experience in building dynamometers for the

automotive and aircraft tire industries. This machine

was used at USS for nearly three decades to evaluate

the performance of railroad wheels, axles, and brake

shoes (Ref. 8).

In the early 1980s, The Association of American

Railroads wanted to acquire a dynamometer to evaluate

4

the effects of grade or drag braking parameters and

rolling loads on residual stress alterations in

various freight-car wheel designs. AAR also needed a

dynamometer to test composition and metal brake shoes

for certification and quality control purposes.

Therefore, AAR purchased the AU/USS dynamometer in

1983. The cover and Figure 4 show the machine at the

AAR Chicago Technical Center.

TABLE I.

Wheel

Dia.,

Inches

Dynamometer

Equivalent

Wheel Load,

Pounds

Min

Max

28

6,400 127,000

45-Ton-Capacity

Auto Rack Car

24,375

This dynamometer has the capacity to test wheels

under a variety of braking and rolling-contact loading

conditions. Grade, stop, and static braking tests can

be conducted with a high degree of precision. In

addition, axles can be tested as rotating cantilever

beams (Ref.9).

33

4,600 92,000

70-Ton-Capacity

Hopper Car

27,500

36

3,900 77,000

100-Ton-Capacity

Tank or Gondola Car

32,875

38

3,500 69,000

125-Ton-Capacity

Covered Hopper Car

39,375

A modern control and data acquisition system was

installed in 1987 to provide automatic test sequence

control, automatic speed control, closed-loop servo

control of brake application, digital display of test

inputs and test results, and digital data gathering.

40

3,200 62,000

4-axle 3800 hp

35,000

The machine is powered by a 200-hp DC mill motor

to speeds ranging from 0 to 1500 rpm (0 to 178 mph for

a 40-in. wheel). For reference, maximum domestic

freight and passenger train speeds are 80 and 120 mph,

respectively. Up to 450 hp is available during

acceleration or deceleration. The power supply for

the motor is a 250 kW generator with an adjustable

voltage regulator with current limit. The generator

is driven by a 400-hp synchronous motor.

Ten thick and four thin 64-inch-diameter steel

flywheel disks can be bolted to the flanged rotor

shaft to produce the inertia effect of dynamic wheel

loads. Thus, 54 increments of 95 slug-ft each

provide inertias ranging from 270 to 5405 slug-ft.

This inertia capability is more versatile and larger

than that of any other railroad dynamometer. The

equivalent wheel load capability, which is dependent

on wheel diameter, is shown in Table I for several

wheel sizes.

Figure 4.

Type

Gross

Wheel

Load,

Pounds

Locomotive

The flanged stub axle, Figure 5, is instrumented

with strain gages to measure torque during braking.

This method of measuring retarding force and hp

replaced the original method of measuring the

differential output of load cells supporting the brake

cylinder torque beam in 1968. Wiring for the torque

cell and other strain or temperature sensors is routed

through the hollow axle to a slip ring mounted on the

outboard bearing.

The test wheel (28 to 46-in diameter) is mounted

on the stub axle. The flange is bolted to a flexible

coupling which is in turn bolted to the inertia

shaft. The other end of the stub axle fits in the

outboard bearing. When the rail wheel is used for

tests, the outboard bearing is allowed to float to

permit vertical loads of up to 60,000 lb to be applied

to the wheel tread with the motor/screw and spring

load frame.

AAR Dynamometer (former US Steel) from

Motor End.

5

Typical Vehicle

brake shoe tests. The other system has a capacity of

13,000 lb and is used for locomotive and passenger-car

wheel and brake shoe tests. The servo system permits

constant torque and constant force tests to be

conducted and also allows the torque and force build

up rates to be controlled. The original clasp-type

brake arrangement, suitable for testing locomotive

cast-iron brake shoes at brake forces of up to 40,000

lb per shoe, is also available.

As shown in Figure 6, the replaceable

friction-driven rail is a continuous ring of

heat-treated rail steel and is bolted to a fabricated

wheel. The rail wheel can be loaded laterally (up to

15,000 lb) with a hydraulic cylinder and can be

oscillated laterally at 0.2 to Hz to simulate curving

and lateral instability.

Two grinders are used to maintain proper profiles

of the wheel and rail. An armor steel guard protects

personnel should a test wheel fracture and also

assists in the collection of dust for hydrostatic

cleaning. Cooling for wheel and brake shoe tests is

provided by suction from the air cleaning unit, an

8650 cfm fan, or water spray, if desired.

Figure 5.

Wheel and Strain Gaged Axle with Brake

Shoes, Load Cells, and Brake Cylinders.

Briefly, the landmark dynamometer is capable of

subjecting full-size railroad wheels to controlled

brake-shoe forces of up to 13,000 lb with composition

shoes and 40,000 lb with cast iron shoes at speeds up

to 178 mph with equivalent inertia wheel loads up to

127,000 lb. In addition lateral and vertical contact

loads up to 15,000 and 60,000 lb, respectively, can be

applied during braking. These capabilities are in

excess of those required to duplicate service

conditions on North American railways.

Braking is provided by two single-shoe systems.

One system, consisting of brake cylinder, load cell,

brake head, and brake shoe, has a shoe-force capacity

of 6,500 lb and is used for freight-car wheel, and

Figure 6.

Elevation Drawing Showing Rail Wheel in Pit

Beneath Machine.

6

SUMMARY

BIOGRAPHICAL SKETCHES

During the past century, the use of dynamometers

by AAR has been intermittent as various wheel and

brake shoe problems arose and were solved. This

progression started in 1894 with the MCB machine at

WABCO and then Purdue until the WWII years, resumed

with the PRR machine in Chicago during the 1955-1975

period, and continues with the present AU/USS machine

in Chicago beginning in 1983. The ability to apply

lateral and vertical rolling contact loads and thermal

braking loads to the wheel tread with modern control

and instrumentation makes this machine unique in the

railroad dynamometer field.

Joseph M. Wandrisco, Mem. ASME, was born and raised in

the Pittsburgh, PA, area. He was graduated from Grove

City College in 1939 with a degree in Chemical

Engineering and also attended Carnegie Institute of

Technology. His career with US Steel started in 1940

at the Homestead, PA, works and he joined the Research

Department in 1950. He rose to become Chief Research

Engineer, Railroad Products, at the Monroeville, PA,

Applied Research Laboratory of US Steel, retiring in

1979. Mr. Wandrisco was responsible for the

functional design specifications and successful

operation of the Landmark dynamometer. He is known as

the co-inventor of the highly successful USS

CURVEMASTER Rail.

REFERENCES

3. Master Car Builders Association Proceedings 1895,

Pages 131-161 (Tests at WABCO on various types of

shoes and wheels).

Rex C. Seanor, Mem. ASME, was Chief Engineer at

Adamson United Co. when the Landmark dynamometer was

designed and constructed. After obtaining his B.S. in

Mechanical Engineering at Carnegie Institute of

Technology in 1931, he began his career at General

Electric Co. in Lynn, MA. In 1935 he joined E. W.

Bliss Co. in Salem, OH, and designed rolling mills.

He joined Adamson United Co. in 1946, was responsible

for the design of large dynamometers for the aircraft

industry and machinery for the rubber and plastics

industries, and retired in 1973. He is a former

chairman of the Akron Section of ASME and is a member

of Tau Beta Pi and Pi Tau Sigma.

4. Master Car Builders Association Proceedings 1901,

Pages 99-141 (Tests at Purdue University starting

in 1900), Pages 466 and 489 (Brake Shoe Friction

Limits and Adoption as Standard).

ACKNOWLEDGMENTS

1. Master Car Builders Association Proceedings 1892,

Pages 115-131 (Southern Pacific Wheel Dynamometer

Tests).

2. Master Car Builders Association Proceedings 1894,

Pages 149-161 (Description of MCB Brake Shoe Test

Machine).

The Chicago Section and the Rail Transportation

Division of ASME and Region VI gratefully acknowledge

the efforts of all who have contributed and cooperated

in the designation of the Association of American

Railroads (AAR) Railroad Wheel Dynamometer as a

National Historic Mechanical Engineering Landmark. In

particular, we thank the AAR for their aid and

assistance in preparing the dynamometer and allowing

us to propose it for landmark status. Thanks also are

extended to the Illinois Institute of Technology on

whose campus the AAR Chicago Technical Center is

located.

5. Young, G. A., M.E., Head, School of Mechanical

Engineering, Purdue University Purdue University

and the American Railways, 1928, Purdue Library

No.: Goss 625.0 Ro, 85p.

6. Pennsylvania-Westinghouse Brake Tests at Absecon,

N.J. 1913, copyright 1913 Pennsylvania Railroad,

Printed by Westinghouse Air Brake Co.

7. Research Center Annual Reports of 1956, 1957 and

1960, Association of American Railroads, Technology

Center, Chicago, 16, IL. (Brake shoe and wheel

tests with former Pennsylvania R. R. Dynamometer).

This brochure was written by D. G. Blaine and G. F.

Carpenter. Photographs were by John F. Valente,

typing by Rita A. Potts, and printing by Ethel M. and

Rosetta Frazier. Thomas E. Johnson is presently

responsible for operation and maintenance of the

dynamometer.

8. Wandrisco, J. M., and Dewez, F. J., Jr., Study of

Defects that Originate in the Treads of Railroad

Wheels During Service, ASME Paper 60-RR-1,

ASME-AIEE Joint Spring Railroad Conference,

Pittsburgh, PA., 1960. (Wheel tests at U. S.

Steel).

9. Carpenter, G. F., and Johnson, T. E., AAR

Dynamometer, Proceedings of the 1988 Joint

ASME-IEEE Railroad Conference, Pittsburgh, PA,

April 13-14, 1988, pages 103-109.

THE HISTORY AND HERITAGE PROGRAM OF ASME

THE ASME NATIONAL HISTORY & HERITAGE COMMITTEE

The ASME History and Heritage Program began in

September 1971. To implement and achieve its goals,

ASME formed a History and Heritage Committee, composed

of mechanical engineers, historians of technology, and

the Curator of Mechanical and Civil Engineering at the

Smithsonian Institution. The Committee provides a

public service by examining, noting, recording, and

acknowledging mechanical engineering achievements of

particular significance.

Euan F. C. Somerscales, Chairman

The AAR Dynamometer is the 91st National Historic

Mechanical Engineering Landmark to be designated.

Since the ASME History and Heritage program began, 128

Historic Mechanical Engineering Landmarks, five

Mechanical Engineering Heritage Sites, and one

Mechanical Engineering Heritage Collection have been

recognized. Each reflects its influence on society,

either in its immediate locale, nationwide, or

throughout the world. A landmark represents a

progressive step in the evolution of mechanical

engineering. Site designations note an event or

development of clear historical importance to

mechanical engineers. Collections mark the

contributions of a number of objects with special

significance to the historical development of

mechanical engineering.

J. L. Lee, P.E.

Robert M. Vogel, Secretary

Robert M. Gaither

J. Paul Hartman, P.E.

Richard S. Hartenberg, P.E.

Joseph P. Van Overveen, P.E.

Carron Garvin-Donahue

Staff Liaison

THE ASME CHICAGO SECTION

Thomas B. Newcomb, Chairman

David W. Mattoon, Secretary

Kevin Meade, Treasurer

Grant H. Arrasmith, History & Heritage

The ASME History and Heritage program illuminates

our technological heritage and serves to encourage the

preservation of the physical remains of historically

important works. It provides an annotated roster for

engineers, students, educators, historians, and

travelers, and helps establish persistent reminders of

divergent paths of discovery. For further

information, please contact the Public Information

Department, The American Society of Mechanical

Engineers, 345 East 47th Street, New York, NY 10017,

212-705-7740.

THE ASME RAIL TRANSPORTATION DIVISION

V. Terrey Hawthorne, P.E., Chairman

Ormond Pendy, Vice Chairman

Thomas Schofield, Secy.-Treasurer

Geoffrey E. Cobden, P.E., History & Heritage

THE ASSOCIATION OF AMERICAN RAILROADS

George H. Way, Vice President

Research & Test

THE AMERICAN SOCIETY OF MECHANICAL ENGINEERS

Ernest L. Daman, President

Keith L. Hawthorne, P.E., Asst. V. P.

Chicago Technical Center

Vjecoslav Pavlic, Vice President

Region VI

George F. Carpenter, P.E., Manager,

Metallurgy Labs.

C. Dan Mote, Vice President

Environment & Transportation Group

David G. Blaine, P.E., CEng., Consultant

David L. Belden, Executive Director

Arthur W. Ebeling, Director

Midwest Regional Office

H136

You might also like

- Pwi Journal 1017 Vol135 Pt4 - Rail Thermal Force Calculations For Jointed Track - Article 3Document7 pagesPwi Journal 1017 Vol135 Pt4 - Rail Thermal Force Calculations For Jointed Track - Article 3gururaja nNo ratings yet

- Points and Crossings Are Provided To Help Transfer Railway Vehicles From One Track To AnotherDocument17 pagesPoints and Crossings Are Provided To Help Transfer Railway Vehicles From One Track To AnotherMuhammad ÍmranNo ratings yet

- GCRT5019 Iss 2 Track StandardsDocument40 pagesGCRT5019 Iss 2 Track StandardsSofia D'AlessandroNo ratings yet

- A7 B7 Locomotive Brake Equipment TestDocument14 pagesA7 B7 Locomotive Brake Equipment TestFrancesca Parrino100% (1)

- Rolling Stock Technology Lecture1Document33 pagesRolling Stock Technology Lecture1RyanKelinNo ratings yet

- Remove and Reset Continuous Welded RailDocument6 pagesRemove and Reset Continuous Welded Raileltiosoyyo295No ratings yet

- Standard Turnouts PDFDocument8 pagesStandard Turnouts PDFfbturaNo ratings yet

- Wa0014Document334 pagesWa0014Paramvir chahliaNo ratings yet

- Railroad Track Mechanics and Technology: Proceedings of a Symposium Held at Princeton University, April 21 - 23, 1975From EverandRailroad Track Mechanics and Technology: Proceedings of a Symposium Held at Princeton University, April 21 - 23, 1975Arnold D. KerrRating: 5 out of 5 stars5/5 (1)

- Transportation Engineering: Types of Rails Spacing and Stifness of RailsDocument30 pagesTransportation Engineering: Types of Rails Spacing and Stifness of Railsyousaf khanNo ratings yet

- New Advances in Design of Railway Track System (PDFDrive)Document29 pagesNew Advances in Design of Railway Track System (PDFDrive)dmehary100% (1)

- The Story of Railroading’s Most Remarkable Brothers: W. Graham Claytor, Jr. and Robert B. ClaytorFrom EverandThe Story of Railroading’s Most Remarkable Brothers: W. Graham Claytor, Jr. and Robert B. ClaytorNo ratings yet

- Railway Braking PDFDocument6 pagesRailway Braking PDFTANYA AGARWALNo ratings yet

- Handbook of Railroad Construction; For the use of American engineersFrom EverandHandbook of Railroad Construction; For the use of American engineersNo ratings yet

- Gradeability For Automobiles: Akilesh YamsaniDocument7 pagesGradeability For Automobiles: Akilesh YamsaninrjmanitNo ratings yet

- GCRT5021 Iss 5-Track System RequirementsDocument49 pagesGCRT5021 Iss 5-Track System RequirementsGeorge Alexiadis0% (1)

- US Army Railroad Course - Loading, Blocking, and Bracing On Rail Cars TR0690Document94 pagesUS Army Railroad Course - Loading, Blocking, and Bracing On Rail Cars TR0690Dexster SmithNo ratings yet

- AAR Report On US Railroads and Ecnomic Recovery 2010Document26 pagesAAR Report On US Railroads and Ecnomic Recovery 2010Bimal BhattacharyaNo ratings yet

- Track/Train Dynamics and Design: Advanced TechniquesFrom EverandTrack/Train Dynamics and Design: Advanced TechniquesGerald J. MoyarNo ratings yet

- 1967-13 A Strip Theory For Rolling With Slip and SpinDocument21 pages1967-13 A Strip Theory For Rolling With Slip and SpinStefan TudoracheNo ratings yet

- Part 5, Rail Transit CapacityDocument134 pagesPart 5, Rail Transit CapacityJonor AtaatNo ratings yet

- Train Resistance CalculationsDocument6 pagesTrain Resistance Calculationssalkan_rahmanovic810No ratings yet

- Ballastless Track - Superstructure TrackopediaDocument9 pagesBallastless Track - Superstructure TrackopediaSahan100% (1)

- Heavy Construction MachinesDocument32 pagesHeavy Construction MachinesSufian AhmadNo ratings yet

- CWR TurnoutsDocument8 pagesCWR Turnoutsveer narayan100% (1)

- Railway Engineering - Points and CrossingDocument21 pagesRailway Engineering - Points and CrossingISHAN TRIVEDINo ratings yet

- Air Brake System of LocomotiveDocument18 pagesAir Brake System of LocomotiveArashdeep Singh100% (2)

- GO Transit Track Standards June 2016 FINALDocument390 pagesGO Transit Track Standards June 2016 FINALFumanchute100% (1)

- Wheel Load Contact AreaDocument13 pagesWheel Load Contact AreaGnabBang100% (1)

- Trasfor: Rolling StockDocument8 pagesTrasfor: Rolling Stockyunus emre Kılınç100% (1)

- 1085.15railway MatlDocument29 pages1085.15railway Matlriko rinaldoNo ratings yet

- L1-CHE-STD-030 Track Drainage StandardDocument28 pagesL1-CHE-STD-030 Track Drainage StandardCK TangNo ratings yet

- Track Maintenance and Eng Instr 2-12-09Document182 pagesTrack Maintenance and Eng Instr 2-12-09Francisco Abraham BaezaNo ratings yet

- Product Catalog: Electric Propulsion Systems and AccessoriesDocument40 pagesProduct Catalog: Electric Propulsion Systems and AccessoriesMarc MPNo ratings yet

- TrackworkDocument28 pagesTrackworkEmanuel MurilloNo ratings yet

- Amtrak Derailment Review - Sound TransitDocument58 pagesAmtrak Derailment Review - Sound TransitMyNorthwestNo ratings yet

- Track Design Handbook TCRP - RPT - 155 2nd Ed. (2012) - Part7Document6 pagesTrack Design Handbook TCRP - RPT - 155 2nd Ed. (2012) - Part7linghuchongNo ratings yet

- L1-NAM-SPE-003 - Track Geometry Maintenance Standards Ver 1Document18 pagesL1-NAM-SPE-003 - Track Geometry Maintenance Standards Ver 14493464No ratings yet

- GE 44-Ton LocomotiveDocument59 pagesGE 44-Ton LocomotiveRhonor Rae ArasulaNo ratings yet

- Rail-Weld Failures Prevention, Monitoring & DetectionDocument8 pagesRail-Weld Failures Prevention, Monitoring & DetectionShipra MishraNo ratings yet

- Lec#8, Points and CrossingsDocument46 pagesLec#8, Points and CrossingsNawaz AliNo ratings yet

- General and Subsidary Rules South Central RailwayDocument501 pagesGeneral and Subsidary Rules South Central Railwayhodibaaba1No ratings yet

- Dynamic Analysis of Steering BogiesDocument57 pagesDynamic Analysis of Steering BogiesAlfath RizkiNo ratings yet

- Track Design Handbook TCRP - RPT - 155 2nd Ed. (2012) - Part2Document6 pagesTrack Design Handbook TCRP - RPT - 155 2nd Ed. (2012) - Part2linghuchongNo ratings yet

- Finally Revised Paper On 'Modern Turnout For High Speed' For IPWE SeminarDocument12 pagesFinally Revised Paper On 'Modern Turnout For High Speed' For IPWE SeminarShipra MishraNo ratings yet

- Metro Rail Design Criteria Section 01 011910Document10 pagesMetro Rail Design Criteria Section 01 011910Monish MNo ratings yet

- Train ResistancesDocument24 pagesTrain ResistancesMahesh RamtekeNo ratings yet

- Preface 1. The Long Rail Laying, Installation / Maintenance Criteria (Proposal)Document23 pagesPreface 1. The Long Rail Laying, Installation / Maintenance Criteria (Proposal)lowryNo ratings yet

- Modelling of Railway Vehicle-Trackunderground Dynamic Interaction Induced by High-Speed TrainsDocument21 pagesModelling of Railway Vehicle-Trackunderground Dynamic Interaction Induced by High-Speed TrainsemiraksopNo ratings yet

- 02 Oliver NenadovicDocument39 pages02 Oliver NenadovicRinu RavikumarNo ratings yet

- Adhesion in The Wheel-Rail ContactDocument44 pagesAdhesion in The Wheel-Rail ContactJoshua Bailey100% (1)

- Rail Adjustment - Engineering ManualDocument65 pagesRail Adjustment - Engineering ManualMuhammad Fahim NaseemNo ratings yet

- Railway Track SleepersDocument31 pagesRailway Track Sleepersqaiserkhan001No ratings yet

- Rail Unlocked PDFDocument115 pagesRail Unlocked PDFsh tanimNo ratings yet

- A-IV C-1 Track Structure For MetroDocument11 pagesA-IV C-1 Track Structure For MetroBhuvan EswarNo ratings yet

- CRN-EPR-EnG-066 ED 0006 Design StandardsDocument4 pagesCRN-EPR-EnG-066 ED 0006 Design StandardsMarcus Oneil100% (1)

- Fatigue ManagementDocument38 pagesFatigue ManagementMarcus OneilNo ratings yet

- Kereta Cepat Bandung Jakarta (Japan) PDFDocument20 pagesKereta Cepat Bandung Jakarta (Japan) PDFMarcus Oneil100% (1)

- Fatigue ManagementDocument44 pagesFatigue ManagementMarcus OneilNo ratings yet

- Fatigue ManagementDocument44 pagesFatigue ManagementMarcus OneilNo ratings yet

- En 14531-1Document8 pagesEn 14531-1Marcus Oneil0% (2)

- CCB2 Color Air Piping DiagramsDocument12 pagesCCB2 Color Air Piping DiagramsMarcus Oneil100% (1)

- Apta PR PS S 002 98Document49 pagesApta PR PS S 002 98Marcus OneilNo ratings yet

- Si 1999Document589 pagesSi 1999Marcus OneilNo ratings yet

- Railway Level Gate Crossing Controller Using Android & GSMDocument5 pagesRailway Level Gate Crossing Controller Using Android & GSMjoel mshanaNo ratings yet

- 1 Tata Strategic Chemlog PPT 29012016Document18 pages1 Tata Strategic Chemlog PPT 29012016indusexposiumNo ratings yet

- ERTMS Factsheets 1-21s PDFDocument46 pagesERTMS Factsheets 1-21s PDFAnuraj mvNo ratings yet

- Testing Commissioning Process Light Rail ProjectDocument5 pagesTesting Commissioning Process Light Rail Projectsuraiyya begumNo ratings yet

- Hyundai Rotem Rail SystemsDocument8 pagesHyundai Rotem Rail SystemsYoussef ElammariNo ratings yet

- HSR Rolling Stock TechnologyDocument60 pagesHSR Rolling Stock TechnologyVivek RathoreNo ratings yet

- TROM1.3.5-Loco & Crew LinksDocument45 pagesTROM1.3.5-Loco & Crew LinksSandeep Joseph100% (2)

- Technical AcronymsDocument451 pagesTechnical AcronymsSudip SardarNo ratings yet

- 1.3 - Frequency of Inspection With Various Track Recording ModesDocument31 pages1.3 - Frequency of Inspection With Various Track Recording ModesChiranjibNo ratings yet

- Wire Rope Inspection: Onsite - . - InsightDocument4 pagesWire Rope Inspection: Onsite - . - InsightHashem GamNo ratings yet

- Arema Capitulo 4Document2 pagesArema Capitulo 4edisjdav33% (3)

- FRA Track Safety Standards Fact SheetDocument2 pagesFRA Track Safety Standards Fact SheetYacoub CheikhNo ratings yet

- Travel Ticket: Amsterdam & RegionDocument2 pagesTravel Ticket: Amsterdam & RegionCristian IonescuNo ratings yet

- Besing, Jessa Mae - ESSAYDocument5 pagesBesing, Jessa Mae - ESSAYJessa Mae Saguran BesingNo ratings yet

- WGH Fullbooklet 2014Document24 pagesWGH Fullbooklet 2014l1nt4n9luku100% (2)

- Slab Track DesignDocument107 pagesSlab Track DesignSivaneswaran Sabaratnam100% (2)

- Malda Division: Bangladesh BiharDocument1 pageMalda Division: Bangladesh BiharMitesh KumarNo ratings yet

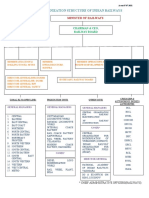

- Organisation Structure of Indian RailwaysDocument1 pageOrganisation Structure of Indian RailwaysSarabjot SinghNo ratings yet

- Logistics Unit 3 PDFDocument24 pagesLogistics Unit 3 PDFsaravanan akashNo ratings yet

- TransportationDocument7 pagesTransportationawasarevinayakNo ratings yet

- BR - Phase I 1.1 Organization of Indian RailwaysDocument60 pagesBR - Phase I 1.1 Organization of Indian RailwaysBhaskar RanjanNo ratings yet

- Signal 1Document107 pagesSignal 1Vikas Srivastav100% (3)

- Permanent Way HandbookDocument99 pagesPermanent Way HandbookPetar SimeonovNo ratings yet

- PDF Download - Flexity 2 - BombardierDocument2 pagesPDF Download - Flexity 2 - BombardierSahil Ullah KhanNo ratings yet

- Making of India's 1 PPP Metro Project: Reliance InfrastructureDocument28 pagesMaking of India's 1 PPP Metro Project: Reliance InfrastructureEticala RohithNo ratings yet

- BVCM (Design-B) Checksheet PDFDocument13 pagesBVCM (Design-B) Checksheet PDFVijay KumarNo ratings yet

- Symonds 2015Document17 pagesSymonds 2015PrasetyaHutamaNo ratings yet

- Carbody TiltingDocument34 pagesCarbody TiltinggundunathNo ratings yet

- Supply Chain Management in Construction Site by Using SPSS SoftwareDocument12 pagesSupply Chain Management in Construction Site by Using SPSS SoftwareInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Rail Wear Modelling: August 2017Document8 pagesRail Wear Modelling: August 2017Masud AlamNo ratings yet