Professional Documents

Culture Documents

IE tools, roles and productivity

Uploaded by

Nageswara Rao ThotaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

IE tools, roles and productivity

Uploaded by

Nageswara Rao ThotaCopyright:

Available Formats

Unit 1

INDUSTRIAL ENGINEERING & MANAGEMENT1

Unit 1: INTRODUCTION: Definition of Industrial Engineering (IE) - Development, Applications, Role of an

industrial engineer, Differences between production management and industrial engineering, Quantitative tools of IE

and productivity measurement. Concepts of management, importance, functions of management. Scientific

Management Taylors principles. Theory X and Theory Y. Fayols principles of management.

Definition:

Industrial Engineering is defined as: The special field of engineering concerned with the design,

improvement and installation of integrated systems of people, materials, equipment and energy.It

draws upon specialized knowledge and skill in the mathematical, physical and social sciences

together with the principles and methods of engineering analysis and design to specify, predict

and evaluate the results to be obtained from such systems.

Thus, industrial engineering is an engineering approach to the detailed analysis of the use

and cost of the resources of an organization. The main resources are men, money,

materials, equipment and machinery. The industrial Engineer carries out such analysis in

order to achieve the objectives (to increase productivity, profits etc) and follow the

policies of the organization.

Essentially, the industrial engineer is engaged in the design of a system and his function

is primarily that of management.

If an industrial engineer had to focus on only one concept to describe his field of interest

and objective, it would have to be productivity improvement.

Productivity improvement implies:

(i) a more efficient use of resources;

(ii) less waste per unit of input supplied;

(iii) higher levels of output for fixed level of input supplied etc.

The inputs may be:

(i)

Human efforts;

(ii)

Energy in any of its numerous forms;

(iii)

Materials;

(iv)

Invested capital etc.

1 Prepared by Prof. T.S.Nageswara Rao, Department of Management Studies, DVR &

Dr. HS MIC College of Technology, Kanchikacherla as a class notes. Adapted from

various sources.

1

Unit 1

HISTORY & DEVELOPMENT OF INDUSTRIAL ENGINEERING

Industrial engineering had its roots in Industrial Revolution (around 1750). It was

nourished by individuals who sought to advance organization and management principles

at an early date. It emerged as a separate discipline and was formalized in the late 19 th

and early 20 th centuries. It achieved maturity after World War II.

The Industrial Revolution resulted from the advent of new inventions, especially in the

textile industry, then steam engine, advances in metal cutting and the production of

machine tools. These led to factories with large number of workers. With the growth in

the size of industries, came the beginning of management and management thinking.

The important steps and mile stones in the development of Industrial Engineering are :

(a) Division of Labour (Adam Smith)

(b) Scientific Management (Frederick Taylor)

(c) Analytical Calculating Machine (Charles Babbage)

(d) Method Study (Frank and Lillian Gilbreth)

(e) Operations Research

(f) Value Engineering & Systems Analysis

(g) Human Engineering (or) Ergonomics.

Before 1940, industrial engineering was applied mainly to manufacturing industries for

improving methods of production, to develop work standards or to formulate production

control and wage policies. Later on, the use of industrial engineering spread to nonmanufacturing activities such as construction, transportation, air-line operations and

maintenance, public utilities, government and military operations.

Even today, industrial engineering finds major applications in manufacturing plants and

industries. In an industry, besides production, the departments utilizing industrial

engineering concept are marketing, finance, purchasing, industrial relations etc.

ROLES OF AN INDUSTRIAL ENGINEER

The following are the different types of roles and functions an industrial engineer may need to

take on.

(1) Advisor/Consultant

The Industrial Engineer is available to others for interpretation of data, and to review it.

(2) Advocate/Activist

The Industrial Engineer promotes a process or approach actively..

(3) Analyst

The Industrial Engineer separates a whole into parts and examines them to explore for

insights and characteristics.

(4) Boundary Spanner

2

Unit 1

The Industrial Engineer bridges the information gap between industrial engineering and

user.

(5) Motivator

The Industrial Engineer provides stimulus and skill availability to a group or an

individual.

(6) Decision-maker

The Industrial Engineer selects a preference from among many alternatives for the topic

of concern.

(7) Designer/Planner

The Industrial Engineer produces the solution specifications.

(8) Expert

The Industrial Engineer provides a high level of knowledge, skill and experience on a

specific topic.

(9) Coordinator and Integrator

The Industrial Engineer coordinates the activities of various personnel.

(10) Innovator/Inventor

The Industrial Engineer seeks to produce a creative or advanced technology solution.

(11) Measurer

The Industrial Engineer obtains data and facts about the existing conditions.

(12) Project Manager

The Industrial Engineer operates, supervises and evaluates projects.

(13) Trainer/Educator

The Industrial Engineer trains employees with the skills and knowledge of industrial

engineering.

(14) Negotiator

The Industrial Engineer helps the management in the negotiations with workers.

Unit 1

QUANTITATIVE TOOLS USED IN INDUSTRIAL ENGINEERING

(1) Decision Matrices

Allocation and investment problems involving a relatively small number of possible

solutions

(2) Decision Trees

Allocation and investment problems involving several decision periods

(3) Mathematical Programming

Attempts to maximize the attainment level of one goal subject to a set of requirements

and limitations.

Linear Programming, Transportation Problem, Assignment model, and Integer

Programming are examples.

(4) Network Models

Family of tools designed for the purpose of planning and controlling complex projects.

The best known models are PERT and CPM.

(5) Dynamic Programming

An approach to decisions that are sequential in nature or can be reformulated so as to be

considered sequential.

(6) Markov Chains

Used for predicting the outcome of processes where systems or units change their

condition over time (e.g., consumers change their preference for certain brands of

products).

(7) Game Theory

Provides a systematic approach to decision-making in competitive environments and a

frame work for the study of conflict.

(8) Inventory Models

Used for inventory control problems to decide the optimal order quantity that will

minimize the annual inventory cost.

(9) Queuing Models

Used to predict the performance of service systems involving queues.

Unit 1

(10) Simulation Models

Used for the analysis of complex systems when all other models fail.

PRODUCTIVITY

Productivity is defined as the ratio between output and input.

Output means the amount produced or the number of items produced.

Inputs are the various resources employed, e.g., land and building, equipment and

machinery, materials, labour etc.

Every organization (whether manufacturing or service) is interested in determining and

increasing its labour productivity and productivity of machinery.

If by using 200 workers, the company is able to produce goods worth Rs 20 lakhs daily,

the daily labour productivity is Rs 10,000.

Similarly, in APSRTC, if there are 10,000 buses and the daily revenue is Rs 2 crores, the

daily productivity of a bus is Rs 2,000.

The Motivation to Increase Productivity

(A) For Management

(i) To earn good profits

(ii) To repay the debts acquired from different sources

(iii)

To sell more and

(iv)To stand better in the market.

(B) For Workers

(i) Higher wages

(ii) Better working conditions

(iii)

Higher standard of living and

(iv)Job security and satisfaction

(C) For Customers

Reduced prices of articles.

Productivity Measures

(a) Labour Productivity

The inputs are aggregated in terms of labour hours.

(b) Direct Labour Cost Productivity

The inputs are aggregated in terms of direct labour costs.

(c) Capital Productivity

5

Unit 1

The inputs may be the charges during the period to depreciation or the book value of

capital investment.

(d) Direct Cost Productivity

The inputs are all items of direct cost associated with resources aggregated on a monetary

value basis.

(e) Energy Productivity

The input is the amount of energy consumed.

(f) Raw Material Productivity

In this formulation, the numerators are usually weights of product; the denominator is the

weight of raw material consumed.

Increasing Productivity of Resources

Increasing productivity implies getting more output from the same amount of input.

(1) Material

Industries in which the cost of raw material is a big percentage of the cost of finished

goods, higher productivity can be achieved through proper use of materials i.e., by

reducing scrap.

Sometimes, a little change in the design of the component or component layout may save

a lot of material.

Productivity of materials can also be increased by using correct process, properly trained

workers, suitable material handling and storage facilities and proper packaging.

(2) Labour

A little change in the design of component parts so as to facilitate final assembly can

increase the number of products assembled per day with the same amount of labour.

(3) Plant, Equipment and Machinery

Productivity can be increased through the use of improved tools, simple attachments and

other devices, and by proper maintenance of the machinery.

Total production times can be reduced considerably by improving machine setting up

methods.

Unit 1

(4) Land and Buildings

A suitable plant layout can accommodate more machinery in the same space and thus

raise productivity.

Proper orientation, construction and inside conditions of a building definitely increase

productivity.

PRODUCTION MANAGEMENT

Production management centers on two major areas:

(1) Design of the production system (which includes product, process, plant, equipment etc.,)

and

(2) Development of the control systems to manage inventories, product quality, production

schedules and productivity.

The functions of production management also include consideration of control system such

as:

(1)

(2)

(3)

(4)

(5)

(6)

(7)

Inventory control policies

Quality control policies

Production-schedule control policies

Productivity and cost control policies

Constructing control systems

Implementing and operating control systems

Modifying policies and designs.

Differences between Production Management and Industrial Engineering

Production Management

Industrial Engineering

Production management attempts to familiarize

a person with concepts and techniques specific

to the analysis and management of a

production activity.

Industrial engineering deals with the analysis,

design and control of productive systems. (A

productive system is any system that produces

either a good or service).

It tells how to manage, i.e., how to direct It does not focus on how to manage but

human efforts in a production environment focuses only on designing the system.

with less attention paid to the analysis and

design of productive systems.

Example: Training of a pilot

Example: Designing an aircraft

Unit 1

CONCEPT OF MANAGEMENT

Management may be labelled as the art of getting work done through people, with

satisfaction for employer, employees and the public.

For getting the work done (of an enterprise) through efforts of other people, it is

necessary to guide, direct, coordinate and control human efforts towards fulfillment of the

goals of the enterprise.

The goals of the enterprise are fulfilled through the use of resources like men, money,

materials and machinery.

Importance of Management

(1) No enterprise can survive without management, even if it possesses large amount of

money, excellent machinery and expert man-power, because without management, it will

be all confusion and nobody will know what to do and when to do it.

(2) Management creates a vital, dynamic and life-giving force to the enterprise.

(3) Management coordinates activities of different departments in an enterprise and

establishes team spirit among the employees.

(4) Management provides new ideas and vision to the organisation to do better.

(5) Management tackles business problems and provides a tool for the best way of doing

things.

(6) Only management can meet the challenge of change.

(7) Management provides stability to the enterprise by changing and modifying the resources

in accordance with the changing environment of the society.

(8) Management helps in personality development thereby raising efficiency and

productivity.

Characteristics of Management

(1) Management is goal-oriented.

(2) Management works as a catalyst to produce goods using labour, materials and capital.

(3) Management is a process comprising of functions such as planning, organising, staffing,

directing and controlling.

(4) Management represents a system of authority a hierarchy of command and control.

Managers at various levels possess varying degrees of authority.

(5) Management is a unifying force. It integrates human and other resources to achieve the

desired objectives.

(6) Management harmonises the individuals goals with the organizational goals to minimize

the conflicts in the organization.

FUNCTIONS OF MANAGEMENT

8

Unit 1

(1)

(2)

(3)

(4)

(5)

One way to look at the process of management is to identify the basic functions which

make up the process.

Some functions are basic to managerial activities and are applicable to all business

enterprises.

The functions used to describe the process of management are: (i) Forecasting; (ii)

Planning; (iii) Organising: (iv) Staffing; (v) Directing; (vi) Coordinating; (vii)

Controlling and (viii) Decision-making.

Forecasting

Forecasting estimates the future work or what should be done in future.

Forecasting is a necessary preliminary to planning.

Forecasting begins with the sales forecast and is followed by production forecast and

forecasts for costs, finance, purchase, profit etc.

Planning

Planning is a rational, economic and systematic way of making decisions today which

will affect the future e.g., what is to be done in the future, who will do it, and where it

will be done.

Without planning, the activities of an organisation will lead to confusion.

Prior planning is very essential for utilizing the available facilities (men, materials,

machines etc.) to the best advantage.

Organizing

Organizing is the process by which the structure and allocation of jobs is determined.

Organizing involves determining activities required to achieve the companys activities,

grouping these activities in a logical basis and finally assigning persons to the job

designed.

Organizing means organizing people, materials, jobs, time etc and establishing a

framework in which responsibilities are defined and authorities are laid down.

Staffing

Staffing is the process by which staff are selected, trained, promoted and compensated.

Staffing involves the developing and placing of qualified people in various jobs in the

organization.

Staffing is a continuous process. The aim is to have appropriate persons to move in to

vacated positions or newly created positions in the organization.

Directing

Directing is the process by which performance of subordinates is guided towards the

common goals of the organization.

Directing involves motivating, guiding and supervising subordinates toward company

objectives. Directing thus involves: (a) Giving instructions to the subordinates; (b)

Guiding the subordinates to do their work; and (c) Supervising the subordinates to make

certain that the work done by them is as per the plan established.

Directing involves: (i) Leadership; (ii) Communication; (iii) Motivation and (iv)

Supervision.

(i)

Leadership

Unit 1

Leadership is the quality of the behaviour of the managers whereby they inspire

confidence and trust in their subordinates, get maximum cooperation from them and

guide their activities in an organized effort.

Leadership is more than personal ability and skill.

(ii)

Communication

Communication is the process by which ideas are transmitted, received and understood

by others for the purpose of carrying out desired results.

Communication may include verbal or written orders, reports, instructions etc.

An ineffective communication leads to confusion, misunderstanding, dissatisfaction and

sometimes even strikes.

(iii)

Motivation

Motivation means inspiring the subordinates to do a work or to achieve company

objectives effectively and efficiently.

Motivation could be classified as:

(a) Financial motivation such as salary, bonus, extra increments, cash awards

etc., and

(b) Non-financial motivation such as promotion, recognition, praise etc.

(iv)

Supervision

Supervision is necessary in order to ensure:

(a)

that the work is going on as per the plan established;

(b)

that the workers are doing as they were directed to do.

(6) Coordinating

Coordinating means achieving harmony of individual effort towards the accomplishment

of companys objectives.

Ineffective coordination between different functions of a business enterprise such as

production, sales, administration can ruin the enterprise.

Coordination involves making plans that coordinate the activities of subordinates,

regulate their activities on the job, and regulate their communications.

(7) Controlling

Controlling is the process that measures current performance and guides it towards some

pre-determined goal.

Controlling involves: (i) the monitoring of programme activities to make sure that end

objectives are being met and (ii) the initiation of corrective action as required to

overcome problems, if any, hindering the accomplishment of objectives.

Controlling is necessary to ensure that orders are not misunderstood, rules are not

violated and objectives have not been unknowingly shifted.

Controlling is a continuous process which measures the progress of operations, verifies

their conformity with the predetermined plan and takes corrective action, if required.

10

Unit 1

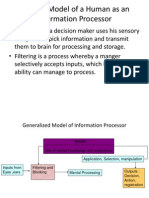

(8) Decision-making

Decision making is the process by which a course of action is consciously chosen from

available alternatives for the purpose of achieving desired results.

An outstanding quality of a successful manager is his ability to make sound and logical

decisions.

THEORY OF SCIENTIFIC MANAGEMENT (Frederic Taylor)

Frederick W Taylor proposed the concept of scientific management, in 1910.

The basic assumption here is that MAN IS ECONOMIC IN NATURE

Scientific Management is the result of applying scientific knowledge and the scientific

methods to the various aspects of management.

The primary emphasis of scientific management was on planning, standardizing and

improving human effort at the operative level in order to maximizing output with

minimum input.

Basic Approach of Scientific Management

(i)

Analyse work scientifically. Investigate all aspects of work on a scientific basis rather

than using rules of thumb.

Provide specific guidelines for worker performance.

Develop one best way of doing a job (using time and motion studies).

Select workers best suited to perform the specific tasks.

Train and develop each workman in the most efficient method for doing the job.

Divide the work so that workmen and management share almost equally in the daily

performance of each task; workers do their jobs as per the standards laid down and

management does planning.

Achieve support and cooperation from workmen by arranging better working conditions,

service conditions and guidance and by giving them greater economic rewards which in

turn are obtained through increased efficiency and productivity.

(ii)

(iii)

(iv)

(v)

(vi)

(vii)

Scientific Management removed the workers judgment in planning, organizing and controlling

his own task performance. Rather, it required that management should plan, organize and control

the workers performance.

Opposition to Scientific Management

Primary resistance to scientific management came from the managements, who were not

prepared to discard the old style of working in favour of scientific approach.

11

Unit 1

Another cause for opposition was that the scientific management treated workers like

cogs in a well-oiled machine and that the system destroyed humanistic practices in

industry.

THEORY X and THEORY Y (Douglas McGregor)

Management researcher Douglas McGregors research suggested that managers

assumptions about worker motivation tended to fall into one of two categories.

McGregor felt that such assumptions exert a heavy influence on how managers operate:

The two theories are: (1) Theory X (Traditional Theory) and (2) Theory Y (Modern Theory).

THEORY X

The assumptions of Theory X are:

(i)

Employees inherently (= naturally) dislike work and always try to avoid it.

(ii)

Most employees are less ambitious, they do not want to take any responsibility and do

not want to improve the wok through interest but wait for formal

directions/instructions.

(iii)

Most people need to be coerced (compelled), controlled and threatened with

punishment to get them to work and achieve goals.

(iv)

Motivation occurs only at the physiological and safety levels.

(v)

Most people have little capacity for creativity, problem solving, and decision making.

(vi)

Workers feel that they are of less importance in an organization. They think that they

are considered as cogs in the wheel.

Based on the above assumptions, Theory X suggests that workers are to be directed,

controlled and punished to achieve the desired results.

THEORY Y

The assumptions of Theory Y are:

(i)

Work is as natural as play or leisure, if the conditions are favourable.

(ii)

The workers are committed to the objectives of the organization. They are self-controlled

and no coercion (= force) is required.

(iii)

The workers feel responsible for the work for which they are appointed.

(iv)

The workers are active, creative and have the capability of decision-making. They also

actively participate in decision-making.

12

Unit 1

(v)

Motivation occurs through self-actualization and satisfaction.

(vi)

The intellectual potentials of most individuals are only partially utilized in most

organizations.

(vii)

When conditions are favourable, the average person not only accepts responsibility but

also seeks it.

Thus, Theory Y suggests that people are self-driven, self-controlled and are participative in

nature. So, the management must create an environment suitable for the employees to excel.

THEORY X (or) THEORY Y?

McGregor felt that in some situations Theory X assumptions may be more appropriate

than those of Theory Y.

For example, when people are being asked to perform tasks they would strongly prefer

not to perform, Theory X is more appropriate. Here, the work is not as natural as play.

From McGregors point of view, an effective leader should apply the appropriate theory

depending upon the context.

PRINCIPLES OF MANAGEMENT (Henri Fayol)

Henri Fayol, a French industrialist is known as the father of modern management

theory. He joined a coal-and-iron company as an apprentice mining engineer and

reached the top position of Managing Director.

On the basis of his experience as a top-level manager, Fayol realized that it is possible to

develop theories about management that could be taught to individuals with

administrative responsibilities.

Fayol outlined a number of principles that he found useful in running his large

organization.

The fourteen principles are: (1) Division of work; (2) Authority & responsibility; (3)

Discipline; (4) Unity of command; (5) Unity of direction; (6) Subordination of individual

interest to general interest; (7) Remuneration; (8) Centralization; (9) Scalar chain; (10)

Order; (11) Equity; (12) stability of personnel tenure; (13) Initiative and (14) Espirit de

Corps.

He added that these principles apply not only to business but also to political, religious,

charitable, military and other organizations.

(1) DIVISION OF WORK

Division of work or work specialization results in efficient use of resources and increases

productivity. This is applicable to both managerial and technical functions.

13

Unit 1

(2) AUTHORITY & RESPONSIBILITY

Authority means the right to give orders or command. Responsibility is the obligation to

achieve objectives. Authority and responsibility should be commensurate with each other.

If there is too much authority, it is likely to be misused. If there is too much

responsibility, it may result in frustration.

(3) DISCIPLINE

Discipline means following of rules, regulations, policies and procedures by all

employees of the organizations. Discipline is absolutely necessary for running of an

organization. There must be a clear and fair agreement for observing the rules and

regulations.

(4) UNITY OF COMMAND

An employee should receive orders from one supervisor only to avoid possible confusion

and conflict. (= A worker should not be under the control of more than one supervisor).

(5) UNITY OF DIRECTION

The activities of an organization should be organized such that there is one plan and one

person in charge.

(6) SUBORDINATION OF INDIVIDUAL INTEREST TO GENERAL INTEREST

The interests of one employee or group of employees should not be given importance

over the interests of the organization.

(7) REMUNERATION

Compensation and methods of compensation should be fair to both the employee and the

employer.

(8) CENTRALIZATION

If all the powers are vested in the top management, it is called centralization of authority.

If all the powers are vested in the lower management, it is called decentralization. A

balance between centralization and decentralization must be achieved. The objective here

is the optimum utilization of the capabilities of the personnel.

14

Unit 1

(9) SCALAR CHAIN

A scalar chain of authority extends from the highest to the lowest rank of an organization

and defines the communication path. However, horizontal communication may also be

encouraged as long as managers are kept informed.

(10)

ORDER

Order is the principle of arrangement of things and people.

Everything should be in its place and there must be a place for everything.

Order leads to the creation of sound organization with efficient management.

(11)

EQUITY

Organizations run best when managers are fair with their employees.

(12)

STABILITY OF TENURE OF EMPLOYEES

Stability of tenure increases the efficiency of the employees and is a symbol of sound

management. Because time is required to understand the jobs at hand and become

effective in new jobs, high turnover of employees should be prevented.

(13)

INITIATIVE

Managers should encourage and develop the subordinates to take initiative.

Initiative is the result of creative thinking and imagination and helps in formulating,

planning and in execution.

(14)

ESPIRIT DE CORPS

Espirit de corps means team spirit.

Union is strength. Harmony and teamwork, the prerequisites for better performance and

effective organization, are essential in every organization.

-----------xxxxxxxxxxx-------------

15

You might also like

- Wisdom of SolomonDocument48 pagesWisdom of SolomonTeodorescu Virgiliu100% (1)

- Job CostingDocument17 pagesJob CostingNageswara Rao ThotaNo ratings yet

- WC GlossaryDocument8 pagesWC GlossaryKarna Palanivelu100% (2)

- Unit II - Turning MachinesDocument137 pagesUnit II - Turning MachinesKanda SamyNo ratings yet

- Future Workplace PDFDocument36 pagesFuture Workplace PDFLyndi CandariNo ratings yet

- Hire To Retire Process - OverviewDocument3 pagesHire To Retire Process - Overviewankit saxena100% (3)

- CNRMC m4700.1 Sbs RBDG 22 Feb 13Document226 pagesCNRMC m4700.1 Sbs RBDG 22 Feb 13Balasubramanian RasuNo ratings yet

- Start Ups and Legal Compliance in IndiaDocument43 pagesStart Ups and Legal Compliance in Indianishetha HemaNo ratings yet

- Philippine labor dispute appeal memorandumDocument16 pagesPhilippine labor dispute appeal memorandumGil Angelo De Leon100% (1)

- Organizational-Behavior (1) by EasepdfDocument50 pagesOrganizational-Behavior (1) by EasepdfSharonNo ratings yet

- OB Key Concepts and Models in 40 CharactersDocument52 pagesOB Key Concepts and Models in 40 CharactersDarshanNo ratings yet

- OB theories and modelsDocument7 pagesOB theories and modelsojhu91 ojhu91No ratings yet

- Engineering Applications: A Project Resource BookFrom EverandEngineering Applications: A Project Resource BookRating: 2.5 out of 5 stars2.5/5 (1)

- Mendoza v. Officers of MWEUDocument4 pagesMendoza v. Officers of MWEUEva TrinidadNo ratings yet

- Production Mamgnt Ch1Document88 pagesProduction Mamgnt Ch1sjaisonsamNo ratings yet

- Business Ethics SLM 2 Ma. Theresa S. Ebol 1Document27 pagesBusiness Ethics SLM 2 Ma. Theresa S. Ebol 1lovelymehakNo ratings yet

- Introduction To Industrial EngineeringDocument1 pageIntroduction To Industrial EngineeringAl EnggNo ratings yet

- Production and Operations Management: MENG 7037Document80 pagesProduction and Operations Management: MENG 7037NEGESA BEKUMANo ratings yet

- Industrial Management: B.E. Eighth Semester (Mechanical Engineering / Power Engineering) (C.B.S.)Document2 pagesIndustrial Management: B.E. Eighth Semester (Mechanical Engineering / Power Engineering) (C.B.S.)SylvesterNo ratings yet

- Industrial ManagementDocument10 pagesIndustrial ManagementHimanshu GautamNo ratings yet

- Organizational BehaviorDocument17 pagesOrganizational BehaviorAnonymous olkUZ9No ratings yet

- Work Measurement - Time StudyDocument74 pagesWork Measurement - Time StudySrujank100% (1)

- V.K Jain-Advanced Machining Processes-Allied Publications PDFDocument370 pagesV.K Jain-Advanced Machining Processes-Allied Publications PDFMayank Vyas100% (1)

- Industrial EngineeringDocument191 pagesIndustrial EngineeringNikhil WaghalkarNo ratings yet

- IEM Notes Unit 2Document19 pagesIEM Notes Unit 2Nageswara Rao Thota100% (1)

- IEM-UNIT-III NotesDocument26 pagesIEM-UNIT-III NotesVinay KumarNo ratings yet

- Ucmp NotesDocument46 pagesUcmp NotesAnonymous fowICTKNo ratings yet

- Ppce Unit-1Document118 pagesPpce Unit-1Jackson ..No ratings yet

- Ultrasonic Machining of Brittle MaterialsDocument73 pagesUltrasonic Machining of Brittle MaterialsraghurockramNo ratings yet

- A Rajesh Kannan: (With Previous Year DOTE One Mark Quest. &answers)Document23 pagesA Rajesh Kannan: (With Previous Year DOTE One Mark Quest. &answers)Lovely Shalih0% (1)

- Ultrasonic Machinig: Click To Edit Master Title StyleDocument16 pagesUltrasonic Machinig: Click To Edit Master Title Stylebunty231No ratings yet

- Electro Chemical MachiningDocument3 pagesElectro Chemical MachiningRishi RajNo ratings yet

- ME8073 MCQs on unconventional machining processesDocument30 pagesME8073 MCQs on unconventional machining processesBollu SatyanarayanaNo ratings yet

- IQAC GuidelinesDocument30 pagesIQAC GuidelinesTirumalarao Pechetty100% (1)

- ECG Electrochemical Grinding Process ExplainedDocument15 pagesECG Electrochemical Grinding Process Explainedsreejith2786No ratings yet

- UCMP Unit 1Document16 pagesUCMP Unit 1Sreedhar ReddyNo ratings yet

- LENDI PROCESS MANUAL FOR OUTCOME BASED EDUCATIONDocument43 pagesLENDI PROCESS MANUAL FOR OUTCOME BASED EDUCATIONTejaswini PydiNo ratings yet

- Plasma Arc Machining (PAM)Document27 pagesPlasma Arc Machining (PAM)nikunjlimbachiyaNo ratings yet

- 20 7 2012Document64 pages20 7 2012tristanlandonNo ratings yet

- Design and ManufacturingDocument49 pagesDesign and ManufacturingThulasi Doss100% (2)

- Modelling Environmental Management ProcessesDocument11 pagesModelling Environmental Management ProcessesKomalNo ratings yet

- Principles of ManagementDocument16 pagesPrinciples of ManagementSumit ChakrabortyNo ratings yet

- Operations Management: Aggregate PlanningDocument16 pagesOperations Management: Aggregate PlanningArun MishraNo ratings yet

- Unit - 6Document22 pagesUnit - 6N Dhanunjaya Rao BorraNo ratings yet

- Master of Labour WelfareDocument14 pagesMaster of Labour WelfareumangcmodiNo ratings yet

- UNIT II Turret LatheDocument29 pagesUNIT II Turret LathePalak NaikNo ratings yet

- Ece Sar Final 03.09.2019 PDFDocument419 pagesEce Sar Final 03.09.2019 PDFRavi50% (2)

- HRM courses legal frameworksDocument4 pagesHRM courses legal frameworksSahil SethiNo ratings yet

- Designing Efficient Man-Machine SystemsDocument33 pagesDesigning Efficient Man-Machine SystemsRaghav Rao100% (1)

- Magnetic Abrasive FinishingDocument9 pagesMagnetic Abrasive FinishingMohamed OmarNo ratings yet

- Sample Copy of JEE (Main) Rank BoosterDocument17 pagesSample Copy of JEE (Main) Rank BoosterResonance Dlpd67% (3)

- Notes in Method StudyDocument3 pagesNotes in Method StudyKathrine Kate CadiangNo ratings yet

- RK College Industrial Engineering Course HandoutDocument7 pagesRK College Industrial Engineering Course HandoutvamsibuNo ratings yet

- Handouts by Total Quality ManagementDocument18 pagesHandouts by Total Quality ManagementRheymar PaguioNo ratings yet

- CH 01 Basic Management Concepts and Industrial OrganizationDocument29 pagesCH 01 Basic Management Concepts and Industrial OrganizationgedamNo ratings yet

- Tips For CSIR NET For Physical SciencesDocument24 pagesTips For CSIR NET For Physical SciencesboltuNo ratings yet

- Sar Nba Etc PartIIDocument225 pagesSar Nba Etc PartIISaurabh BhiseNo ratings yet

- Chemical MachiningDocument23 pagesChemical MachiningAbhishek Chadaga100% (6)

- Evalution of Management ThoughtDocument16 pagesEvalution of Management ThoughtShweta SharmaNo ratings yet

- Linear Programming Formulation and Graphical SolutionDocument54 pagesLinear Programming Formulation and Graphical SolutionSiraj MohammedNo ratings yet

- Chapter One: Introduction To Materials ManagementDocument10 pagesChapter One: Introduction To Materials Managementayal gezeNo ratings yet

- Bus 206 Sample Questions Chapters 1-4Document40 pagesBus 206 Sample Questions Chapters 1-4tableroof100% (1)

- General Model of A Human As An Information ProcessorDocument34 pagesGeneral Model of A Human As An Information ProcessorRahul KachhavaNo ratings yet

- Advanced IC EngineDocument6 pagesAdvanced IC EngineThulasi RamNo ratings yet

- Abrasive Flow MachiningDocument21 pagesAbrasive Flow MachiningnidhidarklordNo ratings yet

- DR Rajesh MongiaDocument54 pagesDR Rajesh MongiaAnonymous 8umLvvHuNo ratings yet

- Mpmec12 Industral Engineering and ManagementDocument38 pagesMpmec12 Industral Engineering and ManagementNITIN NAUTIYALNo ratings yet

- Industrial Engineering Lecture 02Document21 pagesIndustrial Engineering Lecture 02jatinNo ratings yet

- Introduction To Industrial Engineering PJJ-Taufik - D2496Document29 pagesIntroduction To Industrial Engineering PJJ-Taufik - D2496Ganggang PutraNo ratings yet

- IE Sanjib Jaypuria SME,KIIT UniversityDocument26 pagesIE Sanjib Jaypuria SME,KIIT Universitykunal kumar100% (1)

- MEFA Unit 3 of MEFA Offered in 2-2 (CIVIL) of JNTUKDocument23 pagesMEFA Unit 3 of MEFA Offered in 2-2 (CIVIL) of JNTUKNageswara Rao ThotaNo ratings yet

- MEFA Unit 2 (CIVIL) 2-2Document18 pagesMEFA Unit 2 (CIVIL) 2-2Nageswara Rao ThotaNo ratings yet

- MEFA Unit 2 (CIVIL) 2-2Document18 pagesMEFA Unit 2 (CIVIL) 2-2Nageswara Rao ThotaNo ratings yet

- Unit 1 Material of LogisticsDocument6 pagesUnit 1 Material of LogisticsNageswara Rao ThotaNo ratings yet

- Industrial EngineeringDocument19 pagesIndustrial EngineeringNageswara Rao Thota100% (2)

- RM Unit 1Document65 pagesRM Unit 1Nageswara Rao ThotaNo ratings yet

- MEFA Unit 1 of 2-2 (CIVIL)Document31 pagesMEFA Unit 1 of 2-2 (CIVIL)Nageswara Rao ThotaNo ratings yet

- JNTUK MCA II Semester Organizational Structure and HRMDocument14 pagesJNTUK MCA II Semester Organizational Structure and HRMNageswara Rao Thota100% (2)

- Trademarks and Trade NamesDocument35 pagesTrademarks and Trade NamesbharatNo ratings yet

- JNTUK MCA II Semester Organizational Structure and HRMDocument14 pagesJNTUK MCA II Semester Organizational Structure and HRMNageswara Rao Thota100% (2)

- Individual Ethical Decision Making: (From The Book, NO EXIT - by Jean Paul Sartre)Document11 pagesIndividual Ethical Decision Making: (From The Book, NO EXIT - by Jean Paul Sartre)Nageswara Rao ThotaNo ratings yet

- Genetic - Programming PPT 18-08-2011Document30 pagesGenetic - Programming PPT 18-08-2011Nageswara Rao ThotaNo ratings yet

- Six Sigma DMAIC Process for Operational ExcellenceDocument35 pagesSix Sigma DMAIC Process for Operational ExcellencePratibha SainiNo ratings yet

- Pom 6Document11 pagesPom 6Nageswara Rao ThotaNo ratings yet

- Important Questions: Unit 1Document4 pagesImportant Questions: Unit 1Nageswara Rao ThotaNo ratings yet

- Aggregate PlanningDocument23 pagesAggregate PlanningNageswara Rao ThotaNo ratings yet

- Units 1 To 4Document76 pagesUnits 1 To 4Nageswara Rao ThotaNo ratings yet

- Automobile PollutionDocument1 pageAutomobile PollutionNageswara Rao ThotaNo ratings yet

- Effects of Ingroups and Outgroups on Intercultural Technical CommunicationDocument12 pagesEffects of Ingroups and Outgroups on Intercultural Technical CommunicationSuraj Kumar100% (1)

- Chapter 3 Handout - Ethics and Social ResponsibilityDocument9 pagesChapter 3 Handout - Ethics and Social ResponsibilityJayaAntolinAyusteNo ratings yet

- Putting The Balanced Scorecard To Work: Swati Goyal 10FN-113Document17 pagesPutting The Balanced Scorecard To Work: Swati Goyal 10FN-113Swati GoyalNo ratings yet

- Analysis of Financial Statements PDFDocument14 pagesAnalysis of Financial Statements PDFMuhammad Akmal HossainNo ratings yet

- Constitutional Basis: Labor Law 2 Integration Notes Basic PropositionsDocument7 pagesConstitutional Basis: Labor Law 2 Integration Notes Basic Propositionscmv mendozaNo ratings yet

- Assessing TESDA Scholarship ProgramsDocument38 pagesAssessing TESDA Scholarship ProgramsFatima Jose TaarNo ratings yet

- Mergers and Acquisitions of The Financial Institutions - Factors Affecting The Employee Turnover IntentionDocument21 pagesMergers and Acquisitions of The Financial Institutions - Factors Affecting The Employee Turnover Intentionarthasiri.udaNo ratings yet

- Human Resource AssignmentDocument10 pagesHuman Resource AssignmentSentral DsaraNo ratings yet

- UTech Jamaica Business Law SyllabusDocument6 pagesUTech Jamaica Business Law SyllabusGordonNo ratings yet

- C R O L: Hapter - Ii Eview F IteratureDocument32 pagesC R O L: Hapter - Ii Eview F IteratureselbalNo ratings yet

- Trends and Opportunities of Artificial Intelligence in Human Resource Management Aspirations For Public Sector in BahrainDocument5 pagesTrends and Opportunities of Artificial Intelligence in Human Resource Management Aspirations For Public Sector in Bahrainneha rahmanNo ratings yet

- SHRM Assignment 3Document4 pagesSHRM Assignment 3Kingston Nkansah Kwadwo EmmanuelNo ratings yet

- Internship Report On An Analysis of Human Resource Management Practices of Agrani Bank LimitedDocument51 pagesInternship Report On An Analysis of Human Resource Management Practices of Agrani Bank LimitedShuvodebNo ratings yet

- Sample NGO Project Report of Previous Batch Candidate - SGBS TRUST - UNNATIDocument17 pagesSample NGO Project Report of Previous Batch Candidate - SGBS TRUST - UNNATINilay MandalNo ratings yet

- Betterteam Recruitment Plan Template 20201201Document2 pagesBetterteam Recruitment Plan Template 20201201Joyce SuaNo ratings yet

- Open source iHRIS software manages health workforce dataDocument18 pagesOpen source iHRIS software manages health workforce dataAmay SinghNo ratings yet

- (Australia Govt-00) PML99 Laboratory OperationsDocument583 pages(Australia Govt-00) PML99 Laboratory OperationsfaridsidikNo ratings yet

- Application Letter and Cover Letter Are Sometimes Interchangeably UsedDocument20 pagesApplication Letter and Cover Letter Are Sometimes Interchangeably UsedashleyNo ratings yet

- GDP Per CapitaDocument481 pagesGDP Per CapitaShree KhandelwalNo ratings yet

- Bus 5910 Written Assignment Unit 7Document6 pagesBus 5910 Written Assignment Unit 7Sheu BasharuNo ratings yet

- Enterprise Financial Crisis Assessment Survey Questionnaire ManualDocument6 pagesEnterprise Financial Crisis Assessment Survey Questionnaire ManualG35Eliza MittalNo ratings yet