Professional Documents

Culture Documents

Horizontal Separator Working Principle

Uploaded by

muki10Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Horizontal Separator Working Principle

Uploaded by

muki10Copyright:

Available Formats

Horizontal Separator Working Principle

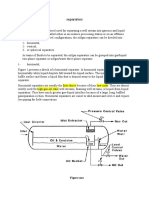

There are three common type of

process separator: horizontal

separator, vertical separator, or

spherical separator. The figure

above

is

an

example

of horizontal

two

phase

separator basic diagram.

The first step separation occurs

at the inlet diverter, on the inlet

diverter liquid and vapor will be

separated as the fluid enter

vessel and hits the inlet diverter that will create sudden change in momentum. The liquid droplet

will fall out from the gas stream into the bottom section. Since it will take times to collect the

amount of liquid, this section will provide the retention time.

Retention time is needed to vapor the entrained gas in the liquid. If there are slugs in the liquid,

this retention time provides a surge volume to handle the slugs. The extracted liquid then flows

through an outlet valve which regulated by a level controller.

The gas part will flow over the inlet diverter into the gravity settling section which located above

the liquid. The gas may entrain some liquid; this liquid will be separated out by gravity in

thisgravity settling section and it will fall down to the gas liquid interface.

Before the gas leaves the vessel, it will pass through a coalescing section. The smaller drop

which cant be separated in the gravity settling section will be trapped in the mist extractor. The

mist extractor or coalescing section consists of vane element to remove the small droplet.

The pressure inside the vessel is controlled by a pressure controller. If the pressure too high,

pressure controller will give a signal to open the pressure control valve so the gas can leave

from the vapor space. To maximize the gas liquid interface area, horizontal separator normally

operated at half full.

References:

1. Surface Production Operations, Ken Arnold and Maurice Stewart

CFD Simulation of Three-Phase

Separator: Effects of Size

Distribution

N. Kharoua, L. Khezzar and H. Saadawi

ASME Proceedings | 13th International Symposium on Gas-Liquid Two-Phase Flows

abstract

The gas/oil/water separation in a three-phase horizontal separator, employed by the ADCO

company in Abu Dhabi, was studied previously using the Eulerian-Eulerian with the k-

model assuming mono-dispersed secondary phases (oil and water). The separator was

equipped with new internals due to the increasing amounts of water and Gas-to-Oil Ratio

GOR from the field. The approach allowed the description of several features of the internal

flow but the prediction of the overall efficiency was largely overestimated compared to the

measured value from the field. The source of the discrepancy could be traced back to the

assumption of mono-dispersed secondary phases and possibly to the unknown structure of

the size distribution at the inlet of the separator preventing thus a correct modeling of drag

between the phases and, hence, influencing momentum and secondary phases (oil and

water) dispersion. Investigations, using the Population Balance Model, for size distribution,

were conducted. Normal and Skewed distributions were employed to represent, only, the

secondary water phase due to the limitation of the population model used to only one

secondary phase. The paper presents, in addition to the separation efficiency, the internal

multiphase flow behavior in terms of overall and local phase distributions. The simulations

with PBM model showed a clear improvement of the results in terms of separation efficiency

compared with field tests although no experimental data related to the size distribution were

available.

Copyright 2013 by ASME

You might also like

- Separador BifásicoDocument42 pagesSeparador BifásicoAldoDeLaCerda100% (1)

- Two Phase SeparatorDocument67 pagesTwo Phase SeparatorRaden MasNo ratings yet

- Oil and Gas SeparatorsDocument8 pagesOil and Gas SeparatorsMaryJane Ayisha Sado-ObahNo ratings yet

- Chapter 4 (A) General Theory & Two Phase SeparatorsDocument139 pagesChapter 4 (A) General Theory & Two Phase Separatorsdinesh_hsenid100% (2)

- Chapter 4 SeparatorsDocument109 pagesChapter 4 Separatorsdinesh_hsenid100% (1)

- Principles of Separation: Incoming Stream Spin Around Reaction Force From The Separator WallDocument10 pagesPrinciples of Separation: Incoming Stream Spin Around Reaction Force From The Separator Wallmohamad alamehNo ratings yet

- Three Phase SeparatorDocument80 pagesThree Phase SeparatorRaden Mas100% (2)

- Chap3 Seperators and Seperation TechniquesDocument37 pagesChap3 Seperators and Seperation TechniquestahaNo ratings yet

- Chap3 - Seperators and Seperation TechniquesDocument37 pagesChap3 - Seperators and Seperation Techniquesghgh140No ratings yet

- 2 3 Phase Separation SystemDocument14 pages2 3 Phase Separation SystemDodiya Nikunj100% (1)

- Separator Fundamentals - Process DesignDocument30 pagesSeparator Fundamentals - Process Designlaleye_olumide100% (3)

- ВведениеDocument47 pagesВведениеЕлнур ИкимбаевNo ratings yet

- Gas Liquid Separators Bothamley JM CampbellDocument9 pagesGas Liquid Separators Bothamley JM CampbellLTORRESMNo ratings yet

- There Phase Oil Water Gas SeparatorsDocument6 pagesThere Phase Oil Water Gas SeparatorsHAMZA GUERFI100% (1)

- Paper EIC 2016 SipDocument4 pagesPaper EIC 2016 SipRizqi AzaidanNo ratings yet

- Gas TechnologyDocument28 pagesGas Technologyفاضل يحيى العصمNo ratings yet

- Oil& Gas SeparationDocument9 pagesOil& Gas SeparationHomam MohammadNo ratings yet

- Quantifying Oil - Water Separation Performance in Three-Phase Separators-Part 1.PDF - ImportantDocument12 pagesQuantifying Oil - Water Separation Performance in Three-Phase Separators-Part 1.PDF - ImportantmofiyinfoluNo ratings yet

- Inlet Nozzles MomentumDocument9 pagesInlet Nozzles Momentum404FileNotFoundNo ratings yet

- Separatori I GazitDocument7 pagesSeparatori I GazitelisbetaNo ratings yet

- Quantifying Oil - Water Separation Performance in Three-Phase Separators-Part 1 PDFDocument12 pagesQuantifying Oil - Water Separation Performance in Three-Phase Separators-Part 1 PDFRaghulal SethumadhavanNo ratings yet

- Separators: Figure OneDocument8 pagesSeparators: Figure OneMohamed Moder100% (1)

- Design Two Phase SeperatorsDocument8 pagesDesign Two Phase SeperatorsabhmarsNo ratings yet

- Three-Phase OilWaterGas SeparatorsDocument6 pagesThree-Phase OilWaterGas SeparatorsSandy MsdNo ratings yet

- Oil and Gas SeparatorsDocument23 pagesOil and Gas SeparatorsSofea Hanom NordinNo ratings yet

- Gas Liquid Separators Quantifying Separation Performance Part 1 PDFDocument11 pagesGas Liquid Separators Quantifying Separation Performance Part 1 PDFEduardo BenalcazarNo ratings yet

- Gas Liquid Separators Sizing Parameter MM083015Document42 pagesGas Liquid Separators Sizing Parameter MM083015Mubarik AliNo ratings yet

- Unit 6 SeparatorsDocument20 pagesUnit 6 SeparatorsAnuranjan100% (1)

- Separator Design GuideDocument3 pagesSeparator Design Guidelaleye_olumideNo ratings yet

- Mud Gas Separator Sizing and EvaluationDocument3 pagesMud Gas Separator Sizing and EvaluationIvan Cerda0% (1)

- Gas - Liquids Separators-Quantifying Separation Performance-Part 2Document14 pagesGas - Liquids Separators-Quantifying Separation Performance-Part 2Mubarik AliNo ratings yet

- Introduction To Production SeparatorsDocument37 pagesIntroduction To Production Separatorsjps21No ratings yet

- Chapter 1&2&3&4&5Document51 pagesChapter 1&2&3&4&5esraaoraby24No ratings yet

- Oil and Gas Separation System and Process: Unit-4Document18 pagesOil and Gas Separation System and Process: Unit-4Rinkesh GuptaNo ratings yet

- Production Engineering IDocument7 pagesProduction Engineering IHomam MohammadNo ratings yet

- Separator & Production FacilitiesDocument11 pagesSeparator & Production FacilitiestumiNo ratings yet

- Modeling 3 Phase SeparatorDocument4 pagesModeling 3 Phase Separatorrieza_fNo ratings yet

- Separator SizingDocument3 pagesSeparator SizingMaryJane Ayisha Sado-ObahNo ratings yet

- Separation Lecture 2Document21 pagesSeparation Lecture 2Mohamed S Helmy100% (1)

- Oil and Water SeparationDocument25 pagesOil and Water SeparationMuhammad NaeemNo ratings yet

- 10 Separation Systems 2007 Petroleum Production EngineeringDocument16 pages10 Separation Systems 2007 Petroleum Production EngineeringHaziq YussofNo ratings yet

- Three Phase SeparatorsDocument6 pagesThree Phase SeparatorsJatin RamboNo ratings yet

- What Are Oil and Gas SeparatorsDocument15 pagesWhat Are Oil and Gas SeparatorsFriday IjokgwungNo ratings yet

- Principles of Separation: Production and Test SeparatorsDocument28 pagesPrinciples of Separation: Production and Test SeparatorsهانيزايدNo ratings yet

- Three-Phase Separator .: University of KerbalaDocument11 pagesThree-Phase Separator .: University of Kerbalamuhiemin MazinNo ratings yet

- 10 5923 J Ajfd 20130304 03Document19 pages10 5923 J Ajfd 20130304 03Wil Vasquez CNo ratings yet

- Separators: Advantages DisadvantagesDocument46 pagesSeparators: Advantages DisadvantagesMahmoud Ahmed Ali Abdelrazik100% (1)

- 3 Phase Separators ( Separators') - Ascom SeparationDocument5 pages3 Phase Separators ( Separators') - Ascom Separationnaveenbaskaran1989No ratings yet

- Mud Gas Separator SizingDocument10 pagesMud Gas Separator Sizingermaniez100% (2)

- Oil and Gas SeparationDocument70 pagesOil and Gas SeparationKyle S Jones100% (5)

- Oil and Gas Artificial Fluid Lifting TechniquesFrom EverandOil and Gas Artificial Fluid Lifting TechniquesRating: 5 out of 5 stars5/5 (1)

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingFrom EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingRating: 5 out of 5 stars5/5 (3)

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- Hydraulic Tables; The Elements Of Gagings And The Friction Of Water Flowing In Pipes, Aqueducts, Sewers, Etc., As Determined By The Hazen And Williams Formula And The Flow Of Water Over The Sharp-Edged And Irregular Weirs, And The Quantity DischargedFrom EverandHydraulic Tables; The Elements Of Gagings And The Friction Of Water Flowing In Pipes, Aqueducts, Sewers, Etc., As Determined By The Hazen And Williams Formula And The Flow Of Water Over The Sharp-Edged And Irregular Weirs, And The Quantity DischargedNo ratings yet

- Hydraulic Fracturing in Unconventional Reservoirs: Theories, Operations, and Economic AnalysisFrom EverandHydraulic Fracturing in Unconventional Reservoirs: Theories, Operations, and Economic AnalysisNo ratings yet

- Pneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshFrom EverandPneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshNo ratings yet

- Wear Mechanism of Exhaust ValveDocument8 pagesWear Mechanism of Exhaust Valvemuki10No ratings yet

- Understanding Valve Design and AlloysDocument6 pagesUnderstanding Valve Design and Alloysmuki10No ratings yet

- Yogesh Aghav 2Document7 pagesYogesh Aghav 2pranjalbaruah8No ratings yet

- Thermal Shock Corrosion of Valve SteelsDocument13 pagesThermal Shock Corrosion of Valve Steelsmuki10No ratings yet

- Transient Thermal Analysis of Engine Exhaust ValveDocument20 pagesTransient Thermal Analysis of Engine Exhaust Valvemuki10No ratings yet

- Valve Face BurningDocument2 pagesValve Face BurningMomina AliNo ratings yet

- Technical Data Sheet: Persang Alloy Industries Pvt. LTDDocument2 pagesTechnical Data Sheet: Persang Alloy Industries Pvt. LTDmuki10No ratings yet

- SAC305 Lead Free Electrolytic Wave Solder Product Bulletin: Metallic Resources, IncDocument2 pagesSAC305 Lead Free Electrolytic Wave Solder Product Bulletin: Metallic Resources, Incmuki10No ratings yet

- Engine Valve Recession, Case StudyDocument4 pagesEngine Valve Recession, Case Studymuki10100% (1)

- 7-Failure Analysis of InternalDocument9 pages7-Failure Analysis of Internalrajeshsrajan1974No ratings yet

- Wear Behaviour of Engine ValveDocument5 pagesWear Behaviour of Engine Valvemuki10No ratings yet

- Wear and Wear Mechanism Simulation of Heavy-Duty Engine Intake Valve and Seat InsertsDocument13 pagesWear and Wear Mechanism Simulation of Heavy-Duty Engine Intake Valve and Seat Insertsmuki10No ratings yet

- Effects of High Temperature On The Microstructure of Engine ValvesDocument5 pagesEffects of High Temperature On The Microstructure of Engine ValvesMomina AliNo ratings yet

- Engine Combustion Deposit PDFDocument16 pagesEngine Combustion Deposit PDFMomina AliNo ratings yet

- SAC ALLOY 305 MaterialDocument2 pagesSAC ALLOY 305 Materialmuki10No ratings yet

- SAC ALLOY 305 MaterialDocument2 pagesSAC ALLOY 305 Materialmuki10No ratings yet

- Gas Lift Paper ResearchDocument15 pagesGas Lift Paper Researchmuki10No ratings yet

- Lead-Free Comparison of AlloysDocument11 pagesLead-Free Comparison of Alloysmuki10No ratings yet

- Nodal Analysis - Based Design For Improving Gas Lift Wells ProductionDocument10 pagesNodal Analysis - Based Design For Improving Gas Lift Wells ProductionSeth CheathamNo ratings yet

- Add To Study GuideDocument16 pagesAdd To Study Guidemuki10No ratings yet

- Technical Data Sheet: Persang Alloy Industries Pvt. LTDDocument2 pagesTechnical Data Sheet: Persang Alloy Industries Pvt. LTDmuki10No ratings yet

- SAC 305 Bar Solder Data SheetDocument2 pagesSAC 305 Bar Solder Data Sheetmuki10No ratings yet

- Ultrapure K100LD Bar SolderDocument2 pagesUltrapure K100LD Bar Soldermuki10No ratings yet

- Wellbore Cleanout ReportDocument2 pagesWellbore Cleanout Reportmuki10No ratings yet

- Metal Foam Heat ExchangerDocument16 pagesMetal Foam Heat Exchangermuki10No ratings yet

- Gas Lift Paper 1Document12 pagesGas Lift Paper 1muki10No ratings yet

- Reference LetterDocument2 pagesReference Lettermuki10No ratings yet

- CNG Cylinder BlastDocument3 pagesCNG Cylinder Blastmuki10No ratings yet

- Demister EfficiencyDocument9 pagesDemister EfficiencyHastelloy Monel100% (1)

- ME4Document12 pagesME4muki10No ratings yet

- Accelerated Aging Versus Realistic Aging in Aerospace Composite Materials. V. The Effects of Hot/Wet Aging in A Structural Epoxy CompositeDocument10 pagesAccelerated Aging Versus Realistic Aging in Aerospace Composite Materials. V. The Effects of Hot/Wet Aging in A Structural Epoxy CompositeOussama El BouadiNo ratings yet

- R&ACDocument2 pagesR&ACsubramanian jNo ratings yet

- Bilal ENVIRONMENTAL Engg.Document29 pagesBilal ENVIRONMENTAL Engg.KhanBangash11No ratings yet

- OBM Fluids TechnologyDocument35 pagesOBM Fluids TechnologyYusian Kasiwalli100% (1)

- MSE104 Materials Characterization IntroDocument23 pagesMSE104 Materials Characterization IntroAndrew WangNo ratings yet

- G10 LAP 4.1 Properties of GasesDocument5 pagesG10 LAP 4.1 Properties of GasesAzria SolanaNo ratings yet

- Numerical Study of Second Harmonic GenerDocument473 pagesNumerical Study of Second Harmonic GenerUniversity classesNo ratings yet

- Furnaces and Furnace ReactorsDocument33 pagesFurnaces and Furnace ReactorsSamyak JainNo ratings yet

- Use The Table Below To Answer The Questions That Follow.: A. Multiple-Choice and Bimodal QuestionsDocument13 pagesUse The Table Below To Answer The Questions That Follow.: A. Multiple-Choice and Bimodal QuestionsHUY NGUYỄN PHƯƠNG PHÚCNo ratings yet

- ASTM E70-07 (PH)Document6 pagesASTM E70-07 (PH)MindLiticsNo ratings yet

- Module 5 Chemical Symbols NotesDocument10 pagesModule 5 Chemical Symbols NotesaerinNo ratings yet

- Zeolites As Sensitive Materials For Dielectric Gas SensorsDocument12 pagesZeolites As Sensitive Materials For Dielectric Gas SensorsHenry AlonsoNo ratings yet

- Unit 3 - 1-D Heat Conduction (Part 1) CDocument15 pagesUnit 3 - 1-D Heat Conduction (Part 1) CabhayNo ratings yet

- Sergey Vulfson PHD (Author) - Molecular Magnetochemistry (1998)Document492 pagesSergey Vulfson PHD (Author) - Molecular Magnetochemistry (1998)EUGENNo ratings yet

- TSM Ceramic PDFDocument7 pagesTSM Ceramic PDFMichael MedinaNo ratings yet

- C r407c GuideDocument32 pagesC r407c Guidezam_ramliNo ratings yet

- Basic Concepts of Remote Sensing Earth Observation Data - Dr. Manu MehtaDocument41 pagesBasic Concepts of Remote Sensing Earth Observation Data - Dr. Manu MehtaPro playerNo ratings yet

- SPS 370S - 2024 - Chapter 2Document39 pagesSPS 370S - 2024 - Chapter 2ziziphomkosana2003No ratings yet

- Physical Science Paper 1 November 2010Document23 pagesPhysical Science Paper 1 November 2010BRANDON TINASHENo ratings yet

- 5070 w19 Ms 21Document10 pages5070 w19 Ms 21heerNo ratings yet

- Table For For C-Q C-Q & & C-B C-B Compressors Compressors Series SeriesDocument1 pageTable For For C-Q C-Q & & C-B C-B Compressors Compressors Series SeriesDilmer AgudeloNo ratings yet

- Chapter 10 Phase TransformationDocument26 pagesChapter 10 Phase TransformationEffendy AdipratamaNo ratings yet

- Chapter 4 Ionic EquilibriumDocument61 pagesChapter 4 Ionic EquilibriumSuraj BhattaraiNo ratings yet

- Yang 2013Document4 pagesYang 2013Dwi suparwatiNo ratings yet

- Topic 1 Quantitative Chemistry (New)Document42 pagesTopic 1 Quantitative Chemistry (New)ma hiuming100% (1)

- Tinogard Q TdsDocument4 pagesTinogard Q TdsMarlon2370100% (1)

- STP1239 Eb.1415051 1 PDFDocument283 pagesSTP1239 Eb.1415051 1 PDFpaola100% (1)

- Transport Phenomena: Contents of Heat TransferDocument85 pagesTransport Phenomena: Contents of Heat TransferalbeiroNo ratings yet

- Mockup - Questions - Test - 4 - For API 571Document12 pagesMockup - Questions - Test - 4 - For API 571Metzer LLC100% (1)