Professional Documents

Culture Documents

Preparation of Interconnected Highly Porous Polymeric Structures by A Replication and Freeze-Drying Process

Uploaded by

Matei Marius AlexandruOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Preparation of Interconnected Highly Porous Polymeric Structures by A Replication and Freeze-Drying Process

Uploaded by

Matei Marius AlexandruCopyright:

Available Formats

Preparation of Interconnected Highly Porous Polymeric

Structures by a Replication and Freeze-Drying Process

Qingpu Hou, Dirk W. Grijpma, Jan Feijen

Institute for Biomedical Technology (BMTI) and Department of Polymer Chemistry and Biomaterials, Faculty of Science and

Technology, University of Twente, P.O. Box 217, 7500 AE, Enschede, The Netherlands

Received 3 September 2002; revised 14 March 2003; accepted 23 April 2003

Abstract: Three-dimensional degradable porous polymeric structures with high porosities

(9398%) and well-interconnected pore networks have been prepared by freeze-drying polymer solutions in the presence of a leachable template followed by leaching of the template.

Templates of the pore network were prepared by fusing sugar or salt particles to form a

well-connected structure. The interstices of the template were then lled with a polymer

solution (515% w/v) in 1,4-dioxane, followed by freeze-drying of the solvent. Subsequent

leaching of the sugar template ensures the connectivity of the pore network. The scaffold

architecture consists of relatively large interconnected pores modeled after the template and

smaller pores resulting from the freeze-drying process. The total porosity of the resultant

porous structures is determined by the interstitial space of the leachable template and by the

polymer concentration in the freeze-drying solution. The freezing temperature also has an

effect on the nal morphology of the porous structures. Compared with freeze-drying and

combination of freeze-drying /particulate leaching techniques, this method facilitates higher

interconnectivity of the scaffolds. Porous structures have been prepared from several relevant

polymers in the biomedical and tissue-engineering eld: poly(D,L-lactide) (PDLLA),

1000PEOT70PBT30, a segmented poly(ether ester) based on polyethylene oxide and polybutylene terephthalate, and poly(-caprolactone) (PCL). The mechanical properties of the

porous structures prepared by this technique depend on the nature of the polymer, porosity,

and the freezing temperature. With porosities in the range of 9597%, the compression moduli

of scaffolds prepared from the different polymers could be varied between 13.0 and 301.5 kPa.

2003 Wiley Periodicals, Inc. J Biomed Mater Res Part B: Appl Biomater 67B: 732740, 2003

Keywords: biodegradable polymers; leachable template; freeze-drying; porous structures;

tissue engineering

INTRODUCTION

Tissue engineering, which aims at developing functional substitutes for damaged or diseased tissues, has attracted much

attention during the last decade.13 In tissue engineering,

three-dimensional biodegradable polymeric scaffolds play an

important role as biologically active, temporary supports for

the transplantation of specic cells and tissues. Besides biocompatibility, biodegradability, processability, sterilizability,

and mechanical strength of the scaffolding material, careful

design of the microstructure and morphology of the porous

structures is of critical importance for their success. In gen-

Correspondence to: Jan Feijen, Institute for Biomedical Technology (BMTI) and

Department of Polymer Chemistry and Biomaterials, Faculty of Science and Technology, University of Twente, P.O. Box 217, 7500 AE, Enschede, The Netherlands (e-mail:

j.feijen@utwente.nl)

Contract grant sponsor: European Community, Brite-Euram; contract grant number:

BE 97-4612

2003 Wiley Periodicals, Inc.

732

eral, a high porosity and a high interconnectivity of the

scaffold is desired to minimize the amount of implanted

polymer and to increase the specic surface area for cell

attachment and tissue ingrowth. Furthermore, the pore morphology can affect the growth of cells and even alter cell

function.4 Interconnected pores larger than the dimensions of

the cells are essential for allowing inltration of the cells into

the scaffold, whereas smaller pores may positively inuence

the exchange of nutrients and cellular waste products.5 Therefore, an appropriate pore size range and distribution of pore

sizes is benecial to the viability and function of the cells

within the tissue-engineering scaffolds.

Various methods have been used for the preparation of

porous polymeric structures for biomedical applications and

tissue engineering. Techniques involving phase inversion

processes6 such as liquidliquid phase separation and liquid

solid phase separation have been explored. Freeze-drying has

also been used frequently in the preparation of porous polymeric structures.7 The morphologies and properties of the

resultant scaffolds largely depend on the phase separation

733

PREPARATION OF POLYMERIC STRUCTURES

Scheme 1. Preparation of porous polymeric structures by a replication and freeze-drying process.

different polymeric materials, such as high melting polymers.

Thermal processing, which often leads to decreased molecular weights, is not required during the procedure. This versatility provides for the optimization of scaffolds used in the

biomedical eld, especially in applications involving the ingrowth of cells and tissues, such as in tissue engineering.

EXPERIMENT

mechanism.8 In methods based on the leaching of soluble

particulates,9,10 the porosity can be effectively controlled by

variation of the amount of leachable particles, and the pore

size of the porous structure can be adjusted independently of

the porosity by using particles of different sizes. To improve

the pore interconnectivity of the scaffold, particulate leaching

has been used in combination with gas foaming,11 solvent

casting,12,13 freeze-drying,14,15 immersion precipitation,16,17

coprecipitation,18 and compression molding.10

More recently, rapid prototyping techniques involving the

processing of polymer melts and powders, such as precise

extrusion,19 three-dimensional printing,20 and fused deposition modelling,21 have received considerable interest. Complex free-form parts can be readily produced from computeraided design (CAD) models. However, these techniques are

time-consuming and require sophisticated equipment. The

maximum porosities obtained are limited to approximately

80%. A more versatile method is the thermal processing of

polymer composites with leachable particles by extrusion and

compression moulding.10,22 These methods yield porous

structures with reproducible morphologies and maximum porosities of 90%.

A replication technique has also been used to prepare

highly porous materials with controllable pore sizes from

inorganic materials,23,24 and polymer materials.2527 This

technique is a multistep procedure, in which rst a replica of

the porous structure is made from wax or another material

that can easily be removed by melting or dissolution. This

replica is then used as a negative casting mold; the interstices

are lled with the desired polymer in the liquid phase. After

hardening of the liquid polymer by curing, cooling, or precipitation, the mold forming the pore network is removed.

Very recently fused sugar or salt particles5,28,29 were used to

improve the pore interconnectivity of polymer scaffolds.

These porous scaffolds were fabricated either by a solventcasting/ template or by a gas-foaming/ template process.

This article describes a simple and effective method for

the preparation of highly porous polymeric structures that

combines a replication technique and a freeze-drying process.

The predesigned template models the pore network and ensures interconnectivity, while freeze-drying allows a very

high porosity scaffold to be obtained. First, results with

poly(D,L-lactide) have recently been presented.30 In this way

porous structures have been prepared from poly(D,L-lactide)

(PDLLA), a 1000PEOT70PBT30 poly(ether ester) block copolymer31 and poly(-caprolactone) (PCL), which are all

widely used in the biomedical eld. This technique also

allows for the preparation of porous structures from many

Materials

Poly(D,L-lactide) (PDLLA) (L- to D-lactide ratio 50/50,

Mn 116,000) was prepared by ring-opening polymerization

in the melt at 140 150 C with Sn(Oct)2 as a catalyst.32 The

obtained polymer is amorphous, with a glass transition temperature (Tg) of 52 C. The residual lactide monomer content

was 1.9%. 1000PEOT70PBT30, a poly (ether ester)

multiblock copolymer based on polyethylene oxide and polybutylene terephthalate, was prepared by a two-step polycondensation reaction of polyethylene glycol (PEG with molecular weight 1000), 1,4-butanediol, and dimethyl terephthalate.33 The ratio of soft to hard segments is 70/30. The

resulting polymer has a Tg of 50 C, and Tm of 148 C.

Commercial-grade poly(-caprolactone) (PCL, CAPA 680

with Mn 76.7 103 and Mw 120.0 103) was obtained

from Solvay-Interox (UK). It is a semicrystalline polymer

with a glass transition temperature of 62 C and a melting

temperature of 57 C. 1,4-dioxane was purchased from Merck

(Germany). Ethanol and chloroform were purchased from

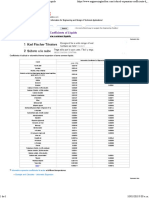

TABLE I. Porosities of Porous Polymer Scaffolds Prepared by

Freeze-Drying

Polymer

Concentration

(w/v %)

Freezing

Temperature

(C)

Porosity

(%)

PDLLA

3

3

5

5

10

10

15

15

6

25

6

25

6

25

6

25

95.7

95.4

92.7

92.7

88.6

87.6

83.9

81.9

1000PEOT70PBT30

10

10

15

15

6

25

6

25

88.3

88.1

84.8

85.9

PCL

3

3

5

5

10

10

15

15

6

25

6

25

6

25

6

25

96.6

96.4

93.6

93.6

89.2

89.2

85.1

84.8

Polymer

734

HOU, GRIJPMA, AND FEIJEN

Figure 1. SEM micrographs of PDLLA, 1000PEOT70PBT30, and PCL scaffolds prepared from 10%

(w/v) solutions in 1,4-dioxane by freeze-drying. (a) PDLLA, freezing temperature: 6 C, porosity:

88.6%; (b) PDLLA, freezing temperature: 25 C, porosity: 87.6%; (c) 1000 PEOT70PBT30, freezing

temperature: 6 C, porosity 88.3%; (d) 1000 PEOT70PBT30, freezing temperature: 25 C, porosity:

88.1%; (e) PCL, freezing temperature: 6 C, porosity 89.2%; (f) PCL, freezing temperature: 25 C,

porosity 89.2%.

Assink and Biosolve (The Netherlands), respectively. All

chemicals were of analytical grade. The sucrose templates

(27.5 18 12 mm in size, bulk density: 1.007 g/cm3,

porosity: 36.5%) were commercial food-quality sugar cubes

from Van Gilse, the Netherlands. Alternatively, sugar or

sodium chloride templates were prepared by fusing the sugar

or salt particles (see below). These particles were sieved with

standard testing sieves (ASTM11 specications, Fisher Scientic BV, the Netherlands) with mesh sizes of 106, 250,

425, 500, and 710 m placed on a sieve shaker (Retsch,

Germany).

Preparation of Porous Polymer Structures

by Freeze-Drying

PDLLA, 1000 PEOT70PBT30, and PCL polymers were dissolved in 1,4-dioxane to make 515% (w/v) solutions. The

polymer solutions were poured into cylindrical polypropylene

containers (height: 70 mm, inner diameter: 10 mm, wall

thickness: 1 mm) and subsequently frozen at 6 or 25 C for

20 h. After phase separation, the solvent crystals were removed by freeze-drying for a period of 23 days in vacuum.

The highly porous cylinders could easily be removed from

the polypropylene containers.

Preparation of Porous Polymeric Structures by a

Combination of Freeze-Drying and Particulate Leaching

For comparison purposes, porous polymeric scaffolds were

rst prepared by a combination of freeze-drying and particulate leaching. PDLLA or PCL was dissolved in 1,4-dioxane

at room temperature to make a 10 w/v% solution. The polymer solution was poured into cylindrical polypropylene containers (height: 70 mm, inner diameter: 10 mm, wall thickness: 1 mm), and 92 w/w% of sugar or salt particles were

added to the polymer solution. Subsequently the polymer

solution and sugar/salt particles were frozen at 6 or 25 C

for 20 h. After phase separation, the solvent crystals were

Figure 2. SEM micrographs of porous structures prepared by freeze-drying and particulate leaching.

(a) PDLLA, salt size: 500 710 m, overall porosity: 95.8%; (b) PCL, salt size: 500 710 m, overall

porosity: 96.6%.

PREPARATION OF POLYMERIC STRUCTURES

TABLE II. Sugar/ Salt Templates Prepared by Fusing Sugar or

Salt Particles.

(a)

Relative

humidity (%) Time (day) Porosity (%)

Stability*

Sugar

Sugar

Sugar

Sugar

Sugar

Sugar

Sugar

75

81

81

97

97

97

97

2

2

4

1

2

4

10

n.d.

n.d.

n.d.

37.0

36.2

35.2

26.5

Partially dissolved

Salt

Salt

Salt

Salt

Salt

Salt

Salt

Salt

75

81

81

81

81

97

97

97

2

1

2

4

10

1

2

4

n.d.

n.d.

43.1

42.0

40.0

44.7

42.3

41.8

735

1. Sugar/salt particles with desired size range were put into a

plastic container and placed in desiccators with relative humidity of 75%, 81%, and 97% for 2 days. The atmosphere

with 75%, 81%, and 97% relative humidity was created by

using an excess of sodium chloride, ammonium sulfate, and

potassium sulfate in contact with their saturated solution in an

enclosed space at 25 C, respectively.34 Then the template

composed of fused sugar or salt powder was dried and

removed from the container.

2. Sugar or salt particles with certain size ranges were rst

soaked in a mixture of acetone and water (7.5/2.5 to 9/1

v/v), then gently packed into a plastic container with

desired shape and size. After drying, the sugar or salt

template could be removed from the container.

The porosity of the sugar or salt templates was calculated

in the same way as the porous polymeric structures. The

densities of the crystal sugar and salt are 1.587 and 2.165

g/cm3, respectively.

(b)

Sugar

Sugar

Salt

Acetone/water (v/v)

Porosity (%)

9/1

7.5/2.5

9/1

36.3

36.4

44.2

Stability*

*: minimally stable; : stable; : very stable; n.d., not determined.

removed by freeze-drying for a period of 23 days in vacuum. The porous cylinders could easily be removed from the

polypropylene containers after leaching out the sugar or salt

particles.

Preparation of Sugar or Salt Templates for Replication

To obtain scaffolds of various shapes and sizes and with

controllable interconnected pore size ranges, sugar or salt

templates were predesigned and prepared by either of the

following methods.

Preparation of Porous Polymeric Structures by a

Replication and Freeze-Drying Process

The procedure for the preparation of porous scaffolds by a

replication and freeze-drying process is shown in Scheme 1.

Commercially available sugar cubes or fused sugar/salt templates were used as the leachable templates. Briey, the

polymer of choice was rst dissolved in 1,4-dioxane (at room

temperature for PDLLA and PCL, 80 C in the case of

1000PEOT70PBT30 copolymer) to make 315% solutions

(w/v). The sugar templates were then immersed into the

polymer solutions and the interstices of the templates were

lled with the polymer solution by repeated application of a

low vacuum (30 mbar). The sugar templates do not dissolve

in 1,4-dioxane.

The sugar templates lled with the polymer solutions were

immediately frozen at temperatures of 6 or 25 C for 20 h.

The solvent was then removed by freeze-drying at 0.04 mbar

for 23 days. Subsequently, the structures were placed in

gently stirred demineralized water for a period of 4 5 days to

Figure 3. SEM micrographs of the fracture surface of sugar templates. (a) Commercially available

sugar cube (particle size range: 100 600 m, porosity: 36.5%); (b) sugar template prepared by fusing

sugar particles (particle size range: 425500 m; relative humidity: 97%; time: 2 days; porosity:

38.0%).

736

HOU, GRIJPMA, AND FEIJEN

Figure 4. SEM micrographs of PDLLA scaffolds prepared from freeze-drying polymer solutions of

1,4-dioxane in the presence of a sugar template. The larger pores (approximately 100 600 m) result

from leaching of the sugar template; the smaller pores (smaller than approximately 100 m) result from

the freeze-drying. (a) Polymer concentration: 10%, freezing temperature: 6 C, porosity: 97.2%; (b)

polymer concentration: 10%, freezing temperature: 25 C, porosity: 97.7%; (c) polymer concentration: 5%, freezing temperature: 6 C, porosity: 98.5%; (d) polymer concentration: 5%, freezing

temperature: 25 C, porosity: 98.5%.

leach out the sugar template. The resulting polymer scaffolds

were vacuum dried.

Characterization of Scaffolds

Determination of porosities of the scaffolds. The density

and the porosity of the scaffolds were determined in triplicate

by measuring the dimensions and the mass of the scaffold.

The density (d) of the scaffolds was calculated as follows:

m

V

(1)

where m is the mass and V is the volume. The porosity po was

calculated as

po 1

d

dp

(2)

where dp is the density of the nonporous compression moulded polymer also determined from the specimen mass and

volume (dp 1.246 0.009, 1.188 0.008, 1.103 0.007

g/cm3 for PDLLA, 1000PEOT70PBT30, and PCL, respectively).35 The relative error in the porosity determinations

was less than 2%.

Scanning electron microscopy (SEM). A Hitachi S800

scanning electron microscope was used to examine the morphology of the porous scaffolds. The specimens were cut with

a razor blade after being frozen in liquid nitrogen for about 5

min. Cross-sections of the scaffolds were coated with gold with

the use of a sputter-coater (Turbo Sputter Coater E6700, UK).

Mechanical testing in compression. The compression

modulus Ec of the porous polymeric structures in the dry state

at room temperature was determined in triplicate with the use

of a Zwick tensile tester equipped with a 500-N load cell at a

crosshead speed of 2 mm/min. The load was applied until

approximately 25% of the original thickness of the specimen

remained. The initial compressive moduli were determined

from the slope of the linear part of the stressstrain curves at

a compressive strain of approximately 5%.35 The relative

error in the measurements was less than 10%.

RESULTS AND DISCUSSION

Preparation of Porous Structures by Methods Based on

Freeze-Drying Process

Porous polymeric structures of very high porosity can be

obtained by freeze-drying. By varying the concentration of

PREPARATION OF POLYMERIC STRUCTURES

737

Figure 5. SEM micrographs of 1000PEOT70PBT30 scaffolds prepared from freeze-drying polymer

solutions of 1,4-dioxane in the presence of a sugar template. The larger pores (approximately

100 600 m) result from leaching of the sugar template; the smaller pores (smaller than approximately 100 m) result from the freeze-drying. (a) Polymer concentration: 15%, freezing temperature:

6 C, porosity: 94.0%; (b) polymer concentration: 15%, freezing temperature: 25 C, porosity:

93.1%; (c) polymer concentration: 10%, freezing temperature: 6 C, porosity: 96.3%; (d) polymer

concentration: 10%, freezing temperature: 25 C, porosity: 95.0%.

the polymer solutions in 1,4-dioxane, the porosity of the

porous PDLLA, 1000PEOT70PBT30 and PCL scaffolds

could be well controlled, as shown in Table I. Figure 1 shows

SEM micrographs of PDLLA, 1000PEOT70PBT30 and PCL

scaffolds prepared from 10% (w/v) solutions in 1,4-dioxane

by freeze-drying. The pore sizes are relatively small, with a

maximum pore size of approximately 150 m. All scaffolds

prepared by freeze-drying show an irregular porous structure

with poor pore interconnectivity. Furthermore, the pore sizes

and shapes vary considerably throughout the scaffold, and

large voids or defects are often observed within the structure.

No cells can enter the closed pores of the scaffolds, which

render them unsuitable for tissue engineering. Improved scaffolds can be obtained by combining the freeze-drying process

with particulate leaching.14,15 This method is suitable when

large fractions of leachable particles and high concentrations

of polymers of high molecular weight in 1,4-dioxane are

used. However, the nal pore architecture is still not highly

interconnected. Figure 2 shows SEM micrographs of PDLLA

and PCL scaffolds prepared in this manner. After leaching

out the sugar/salt particles, a dense polymer layer remained in

between the resulting pores. The addition of leachable particles to the polymer solution before freeze-drying does not

ensure complete interconnectivity of the porous structures.

Preparation of Leachable Templates

Leachable templates with various shapes and sizes can be

prepared by fusing the sieved sugar or salt particles of determined size range in an (enclosed) atmosphere with a relative

humidity (RH) of 97% for about 2 days, followed by drying

in ambient air. Salt cubes can be prepared in an atmosphere

of RH of 75 81%, but the preparation of sugar cubes requires

a relative humidity as high as 97% to obtain very stable

templates. The porosity of the templates slightly decreases as

the fusing time increases. The results are shown in Table

II(a). Alternatively, the templates can be fabricated by compacting the soaked sugar or salt particles of certain size range

in an acetone/ water mixture, as sugar cubes were reported to

be prepared by compressing moist sugar particles.36 When

the acetone/water ratio is in the range of 7.5/2.5 to 9/1 (v/v),

all prepared templates are stable. The porosities of the resultant templates are close to those prepared by the rst method,

as shown in Table II(b). Figure 3(a) shows an SEM micrograph of the fracture surface of the commercially available

sugar cubes. Figure 3(b) shows the micrograph of templates

prepared by fusing sugar particles of 425500 m. It can be

seen that both consist of a fused structure in which the sugar

particles are well connected. As the sugar template will be

leached out with water after the freeze-drying step, this

738

HOU, GRIJPMA, AND FEIJEN

Figure 6. SEM micrographs of PCL scaffolds prepared from freeze-drying polymer solutions of

1,4-dioxane in the presence of a sugar template. The larger pores (approximately 100 600 m) result

from leaching of the sugar template; the smaller pores (smaller than approximately 100 m) result from

the freeze-drying. (a) Polymer concentration: 10%, freezing temperature: 6 C, porosity: 96.5%; (b)

polymer concentration: 10%, freezing temperature: 25 C, porosity: 96.8%; (c) polymer concentration: 5%, freezing temperature: 6 C, porosity: 97.8%; (d) polymer concentration: 5%, freezing

temperature: 25 C, porosity: 97.5%.

structure will reect the connected pore network of the polymer scaffold.

Preparation of Porous Polymer Structures by

Replication and Freeze-Drying Process

Typical SEM micrographs of PDLLA, 1000PEOT70PBT30,

and PCL scaffolds prepared by freeze-drying a 515% (w/v)

polymer solution in 1,4-dioxane in the presence of commercially available sugar cubes are shown in Figures 4 6.

Highly porous structures, with porosities over 97%, have

been prepared. Figures 4 6 show that highly interconnected

porous structures are obtained with large pore sizes of 100

600 m. This is because the relatively large sugar particles of

the template are well bound; therefore, the pores obtained

after leaching of the template are open and well interconnected. At the same time much smaller pores (less than 150

m) are obtained by the freeze-drying process. It can be seen

that these pores are not well interconnected. The nal pore

structure of the scaffolds is determined by the size and

content of the sugar particles of the template as well as by the

solvent-crystal morphology after freezing of the 1,4-dioxane

solution. The average size of pores obtained from the leaching of the sugar template can be controlled by varying the

characteristics of the sugar particles used. The average size of

the pores from freeze-drying can be adjusted to be in the

range of several microns to 150 microns by changing the

freezing temperature.35

The overall porosities are mainly dependent on the interstitial space of the sugar templates, showing a lesser dependence on the concentration of the polymer solution in the

range of 315% (w/v) and freezing temperature, as shown in

Table III. The calculated porosity of the scaffold can be

obtained by the following equation:

p c 100% 36.5%

100

36.5% ,

100 c/d p

(3)

where pc is the calculated porosity, c is the concentration of

the polymer solution (g/100 ml), dp is the density of the

polymer, and 36.5% is the porosity of the sugar template.

It can be seen that the porosity of the resultant scaffolds

are close to the calculated values. However, volume shrinkage of the scaffolds occurred during drying after leaching

when the concentration of the polymer solution was less than

5% (w/v); thus the resulting pores were partially deformed.

On the other hand, when the concentration of the polymer

solution was over 15%, it became difcult to ll the voids of

the templates due to the high viscosity of the polymer solu-

739

PREPARATION OF POLYMERIC STRUCTURES

tion. Hence, the concentration of the polymer solution should

be preferably at the range of 515% (w/v) for PDLLA and

PCL, and 10 15% for 1000PEOT70PBT30. Under these

conditions, all porous structures prepared were physically

stable. The height, breadth and width of the employed sugar

templates and the resulting porous structures were measured,

and found to differ by less than 3%.

Table IV shows the compression moduli of the polymer

scaffolds prepared by the replication and freeze-drying process. It can be seen that the scaffolds prepared by freezing at

relatively high temperature possess higher compression moduli. Scaffolds prepared from freezing at a higher temperature

have larger pores after removal of the solvent crystals.35 It

has previously been observed37 that an increase in pore size

causes a rise of the modulus of both exible and rigid foams.

Furthermore, these pore sizes are closer to the average size of

the pores obtained from leaching of the sugar particles. As a

result, the overall pore size distribution is narrower than those

obtained from freezing at a lower temperature. The homogeneity of the pore structure enhances the mechanical properties

of the polymeric scaffolds.28,38

CONCLUSIONS

Large porous polymer structures that have very high porosities up to 98% and an interconnected pore network were

prepared by a technique that combines template leaching with

freeze drying. The process includes three main steps: lling

the interstices of a leachable template with a polymer solu-

TABLE III. Porosities of Porous Polymeric Scaffolds Prepared

by a Replication and Freeze-Drying Process.

Polymer

PDLLA

Polymer

Freezing Overall Calculated

Concentration Temperature Porosity Porosity

(w/v %)

(C)

(%)

(%)

3

3

5

5

10

10

15

15

6

25

6

25

6

25

6

25

98.6

98.7

98.5

98.5

97.2

97.7

94.0

96.2

99.1

99.1

98.6

98.6

97.3

97.3

96.1

96.1

1000PEOT70PBT30

10

10

15

15

6

25

6

25

96.3

95.0

94.0

93.1

97.2

97.2

95.9

95.9

PCL

3

3

5

5

10

10

15

15

6

25

6

25

6

25

6

25

97.5

97.5

97.8

97.5

96.5

96.8

95.1

95.5

99.0

99.0

98.4

98.4

97.0

97.0

95.6

95.6

TABLE IV. Compression Moduli of Polymer Scaffolds Prepared

by a Replication and Freeze-Drying Process.

Polymer

Polymer

Freezing Overall

concentration Temperature porosity

(w/v %)

(C)

(%) Ec (kPa)

PDLLA

10

6

25

97.2

97.7

301.5

227.4

1000PEOT70PBT30

10

6

25

96.3

95.0

21.4

13.0

PCL

10

6

25

96.5

96.8

69.3

44.6

PCL

15

6

25

95.1

95.5

90.9

54.5

tion; freeze-drying of the lled template; and leaching the

template out in water. The scaffold architecture is determined

by the properties of the leachable template, involving the size

of the particles employed in the preparation of the templates,

the initial concentration of the polymer solution employed in

freeze-drying, and the freezing temperature. The porosities of

the resulting porous structures are determined by the interstitial space in the leachable templates and by the initial concentration of the polymer solution used in freeze-drying.

The ability to obtain a very high porosity with an interconnected pore network and tailored pore size distribution,

the applicability to a wide variety of polymers, and ease of

preparation of porous polymer structures with different

shapes and sizes, are major advantages of this pore-forming

technique. The method for the preparation of highly porous

polymer structures presented here can be utilized in the

biomedical eld as well as in many other elds. The particle

size range and distribution of which the templates are prepared can readily be optimized for a specic application.

M. B. Claase is acknowledged for his kind help.

REFERENCES

1. Freed LE, Vunjak-Novakovic G, Biron RJ, Eagles DB, Lesnoy

DC, Barlow SK, Langer R. Biodegradable polymer scaffolds for

tissue engineering. Biotechnology 1994;12:689 693.

2. Langer R, Vacanti JP. Tissue engineering. Science 1993;260:

920 926.

3. Cima LG, Vacanti JP, Vacanti C, Ingber D, Mooney D, Langer

R. Tissue engineering by cell transplantation using degradable

polymer substrates. J Biomech Eng Trans ASME 1991;113:

143151.

4. Schugens C, Maquet V, Grandls C, Jerome R, Teyssie P.

Biodegradable and macroporous polylactide implants for cell

transplantation.1. Preparation of macroporous polylactide supports by solidliquid phase separation. Polymer 1996;37:1027

1038.

5. Zhang RY, Ma PX. Synthetic nano-brillar extracellular matrices with predesigned macroporous architectures. J Biomed Mater Res 2000;52:430 438.

6. Hinrichs WLJ, Lommen E, Wildevuur CRH, Feijen J. Fabrication and characterization of an asymmetric polyurethane mem-

740

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

HOU, GRIJPMA, AND FEIJEN

brane for use as a wound dressing. J Appl Biomater 1992;3:

287303.

Aubert JH, Sylwester AP. Morphological characterization of

microcellular carbon foams. J Mater Sci 1991;26:57415752.

Schugens C, Maquet V, Grandls C, Jerome R, Teyssie P.

Polylactide macroporous biodegradable implants for cell transplantation. 2. Preparation of polylactide foams by liquidliquid

phase separation. J Biomed Mater Res 1996;30:449 461.

Gogolewski S, Pennings AJ. Resorbable materials of poly(Llactide). III. Porous materials for medical application. Colloid

Polymer Sci 1983;261:477 484.

Thomson RC, Yaszemski MJ, Powers JM, Mikos AG. Fabrication of biodegradable polymer scaffolds to engineer trabecular

bone. J Biomater Sci Polym Ed 1995;7:2338.

Nam YS, Yoon JJ, Park TG. A novel fabrication method of

macroporous biodegradable polymer scaffolds using gas foaming salt as a porogen additive. J. Biomed Mater Res 2000;53:

17.

Lam KH, Nieuwenhuis P, Molenaar I, Esselbrugge H, Feijen J,

Dijkstra PJ, Schakenraad JM. Biodegradation of porous versus

nonporous poly(L-lactic acid) lms. J Mater Sci Mater Med

1994;5:181189.

Mikos AG, Sarakinos G, Leite SM, Vacanti JP, Langer R.

Laminated 3-dimensional biodegradable foams for use in tissue

engineering. Biomaterials 1993;14:323330.

de Groot JH, Nijenhuis AJ, Bruin P, Pennings AJ, Veth RPH,

Klompmaker J, Jansen HWB. Use of porous biodegradable

polymer implants in meniscus reconstruction .1. Preparation of

porous biodegradable polyurethanes for the reconstruction of

meniscus lesions. Colloid Polym Sci 1990;268:10731081.

Spaans CJ, de Groot JH, Belgraver VW, Pennings AJ. A new

biomedical polyurethane with a high modulus based on 1,4butanediisocyanate and epsilon-caprolactone. J Mater Sci Mat

Med 1998;9:675 678.

Pego AP, Poot AA, Grijpma DW, Feijen J. Copolymers of

trimethylene carbonate and epsilon-caprolactone for porous

nerve guides: Synthesis and properties. J Biomater Sci Polym

Ed 2001;12:3553.

Holy CE, Shoichet MS, Davies JE. Biodegradable polymer

scaffold. 1999, PCT WO 99/25391.

Hou QP, Grijpma DW, Feijen J. Preparation of porous poly(caprolactone) structures. Macromol Rapid Commun 2002;23:

247252.

Xiong Z, Yan YN, Zhang RJ, Sun L. Fabrication of porous

poly(L-lactic acid) scaffolds for bone tissue engineering via

precise extrusion. Scripta Mater 2001;45:773779.

Giordano RA, Wu BM, Borland SW, Cima LG, Sachs EM,

Cima MJ. Mechanical properties of dense polylactic acid structures fabricated by three dimensional printing. J Biomater Sci

Polym Ed 1996;8:6375.

Hutmacher DW, Schantz T, Zein I, Ng KW, Teoh SH, Tan KC.

Mechanical properties and cell cultural response of polycaprolactone scaffolds designed and fabricated via fused deposition

modeling. J Biomed Mater Res 2001;55:203216.

22. Widmer MS, Gupta PK, Lu LC, Meszlenyi RK, Evans GRD,

Brandt K, Savel T, Gurlek A, Patrick CW, Mikos AG. Manufacture of porous biodegradable polymer conduits by an extrusion process for guided tissue regeneration. Biomaterials 1998;

19:19451955.

23. Weber JM, White EW, Lebiedzik J. New porous biomaterials

by replication of echinoderm skeletal microstructures. Nature

1971;233:337339.

24. Weber JM, White EW. Replamineform: A new process for

preparing porous ceramics, metal, and polymer prosthetic materials. Science 1972;176:922924.

25. White RA, Hirose FM, Sproat RW, Lawrence RS, Nelson

RJ. Histopathologic observations after short-term implantation

of two porous elastomers in dogs. Biomaterials 1981;2:171

176.

26. Imhof A, Pine DJ. Ordered macroporous materials by emulsion

templating. Nature 1997;389:948 951.

27. Shastri VP, Martin I, Langer R. Macroporous polymer foams by

hydrocarbon templating. Proceedings of the National Academy

of Sciences of the United States of America 2000;97:1970

1975.

28. Ma PX, Choi JW. Biodegradable polymer scaffolds with welldened interconnected spherical pore network. Tissue Eng

2001;7:2333.

29. Murphy WL, Dennis RG, Kileny JL, Mooney DJ. Salt fusion:

An approach to improve pore interconnectivity within tissue

engineering scaffolds. Tissue Eng 2002;8:4352.

30. Hou Q, Grijpma DW, Feijen J. Preparation of interconnected

highly porous poly(D,L-lactide) structures by sugar templating

and freeze-drying. J Control Rel 2003;87:304 307.

31. Radder AM, Leenders H, vanBlitterswijk CA. Application of

porous PEO/PBT copolymers for bone replacement. J Biomed

Mater Res 1996;30:341351.

32. Grijpma DW, Altpeter H, Bevis MJ, Feijen J. Improvement of

the mechanical properties of poly(D,L-lactide) by orientation.

Polym Int 2002;51:845 851.

33. Deschamps AA, Grijpma DW, Feijen J. Poly(ethylene oxide)/

poly(butylene terephthalate) segmented block copolymers: The

effect of copolymer composition on physical properties and

degradation behavior. Polymer 2001;42:93359345.

34. Lide DR. CRC Handbook of chemistry and physics (81st ed).

Boca Raton, FL: CRC Press; 2000. p 1525.

35. Hou QP, Grijpma DW, Feijen J. Porous polymeric structures for

tissue engineering prepared by a coagulation, compression

moulding and salt leaching technique. Biomaterials 2003;24:

19371947.

36. Magnusson F, Monteus SH. Manufacturing lump sugar. U.S.

Patent No. 3,122,107, 1964.

37. Shutov FH. Foamed polymers, cellular structure and properties.

Adv Polym Sci 1983;51:155218.

38. Harris LD, Kim BS, Mooney DJ. Open pore biodegradable

matrices formed with gas foaming. J Biomed Mater Res 1998;

42:396 402.

You might also like

- PorouusDocument10 pagesPorouusclifford henryNo ratings yet

- Guan 2005Document11 pagesGuan 2005Ihlasul AmalNo ratings yet

- Porous Polyethylene Membranes by Template-Leaching Technique: Preparation and CharacterizationDocument9 pagesPorous Polyethylene Membranes by Template-Leaching Technique: Preparation and CharacterizationTeresaCastelo-grandeNo ratings yet

- 2012 Bio Matter 0027 RDocument32 pages2012 Bio Matter 0027 Ra_minisoft2005No ratings yet

- The Journal of Supercritical FluidsDocument9 pagesThe Journal of Supercritical FluidsMarco D'AntuonoNo ratings yet

- Biocompatibility and Biodegradation Studies of PCL/ B-TCP Bone Tissue Scaffold Fabricated by Structural Porogen MethodDocument10 pagesBiocompatibility and Biodegradation Studies of PCL/ B-TCP Bone Tissue Scaffold Fabricated by Structural Porogen MethodSreedhar PugalendhiNo ratings yet

- XRD Low AngleDocument12 pagesXRD Low AngleSimona GhimisNo ratings yet

- Tissue Regeneration ScaffoldDocument28 pagesTissue Regeneration ScaffoldShivaniNo ratings yet

- Investigation of Phase Change Material Encapsulation by Complex CoacervationDocument8 pagesInvestigation of Phase Change Material Encapsulation by Complex CoacervationAna Silvia PrataNo ratings yet

- Molecules: A Self-Healing and Shape Memory Polymer That Functions at Body TemperatureDocument12 pagesMolecules: A Self-Healing and Shape Memory Polymer That Functions at Body TemperatureIgnacio Pérez-VictoriaNo ratings yet

- Scaffolds 1Document9 pagesScaffolds 1Dick YoupNo ratings yet

- Porto Carrero Et Al 2019 Journal of Chemical Technology BiotechnologyDocument10 pagesPorto Carrero Et Al 2019 Journal of Chemical Technology BiotechnologynechmadNo ratings yet

- Materials 12 02643Document24 pagesMaterials 12 02643Nicolas JayNo ratings yet

- Polymers 13 01645Document16 pagesPolymers 13 01645PIERO YEFER CONDOR RIVERANo ratings yet

- Porous Membranes of PLLA PCL Blend For Tissue Engineering Applications by M Lebourg 2008Document12 pagesPorous Membranes of PLLA PCL Blend For Tissue Engineering Applications by M Lebourg 2008gurumoorthi ramarNo ratings yet

- Membrane Distillation of Meat Industry Effluent WiDocument19 pagesMembrane Distillation of Meat Industry Effluent WiAlan huINo ratings yet

- Jamie L Ifkovits, Robert F Padera and Jason A Burdick - Biodegradable and Radically Polymerized Elastomers With Enhanced Processing CapabilitiesDocument8 pagesJamie L Ifkovits, Robert F Padera and Jason A Burdick - Biodegradable and Radically Polymerized Elastomers With Enhanced Processing CapabilitiesHutsDMNo ratings yet

- SAF - Mhemdi Et Al 2021 - J - Novel One-Step Process For The Production of Bioplastic From Rapeseed Press CakeDocument14 pagesSAF - Mhemdi Et Al 2021 - J - Novel One-Step Process For The Production of Bioplastic From Rapeseed Press CakeListya Eka AnggrainiNo ratings yet

- 2003.IEEE Sensors Materials - Kastantin.invited BioMEMS - Ieee Sensors Materials 15 (6) 295-311 (2003)Document18 pages2003.IEEE Sensors Materials - Kastantin.invited BioMEMS - Ieee Sensors Materials 15 (6) 295-311 (2003)h_egNo ratings yet

- Single-Source Macroporous Hybrid Materials by Melt-Shear Organization of Core-Shell ParticlesDocument14 pagesSingle-Source Macroporous Hybrid Materials by Melt-Shear Organization of Core-Shell ParticlesSantiagoSossaUNo ratings yet

- Materials 15 05903 v2Document21 pagesMaterials 15 05903 v2AiltaoSoaresNo ratings yet

- Ptfe ManufacturingDocument16 pagesPtfe ManufacturingKokki Kumar Dpce100% (1)

- Zhou 2005Document7 pagesZhou 2005sindy mNo ratings yet

- Photosensitive Biodegrable Polymers For Tissue Engineering ApplicationsDocument8 pagesPhotosensitive Biodegrable Polymers For Tissue Engineering ApplicationsPor una Patria NuevaNo ratings yet

- Shear-Induced Advaced Mat InterfacesDocument9 pagesShear-Induced Advaced Mat Interfaceshasib_me_lamarNo ratings yet

- Polymers 2014, 6, 2510-2525 Doi:10.3390/polym6102510Document16 pagesPolymers 2014, 6, 2510-2525 Doi:10.3390/polym6102510Rodrigo JGNo ratings yet

- Consecutive Solvent Evaporation and Co-Rolling Techniques For Polymer Multilayer Hollow Fiber Preform FabricationDocument9 pagesConsecutive Solvent Evaporation and Co-Rolling Techniques For Polymer Multilayer Hollow Fiber Preform FabricationrestuariyusNo ratings yet

- Will - 2013Document9 pagesWill - 2013thuronNo ratings yet

- Food Hydrocolloids: Rocío Pérez-Masiá, Amparo López-Rubio, Jose Maria LagarónDocument10 pagesFood Hydrocolloids: Rocío Pérez-Masiá, Amparo López-Rubio, Jose Maria LagarónBotez MartaNo ratings yet

- 1 s2.0 S2212982024000325 MainDocument12 pages1 s2.0 S2212982024000325 MainmikeairdNo ratings yet

- Thermal Energy Storage Capacity of Composite Solid Desiccant Used in Sun Drying ApplicationsDocument7 pagesThermal Energy Storage Capacity of Composite Solid Desiccant Used in Sun Drying ApplicationsIJRASETPublicationsNo ratings yet

- Paper: Scalable Fabrication of e Cient Organolead Trihalide Perovskite Solar Cells With Doctor-Bladed Active LayersDocument7 pagesPaper: Scalable Fabrication of e Cient Organolead Trihalide Perovskite Solar Cells With Doctor-Bladed Active LayersBhabani Sankar SwainNo ratings yet

- A Preliminary Study On Bladder-Assisted Rotomolding of Thermoplastic Polymer CompositesDocument12 pagesA Preliminary Study On Bladder-Assisted Rotomolding of Thermoplastic Polymer Compositespetrusz1No ratings yet

- Okuyama 2006, Preparation of Functional Nanostructured Particles by Spray DryingDocument25 pagesOkuyama 2006, Preparation of Functional Nanostructured Particles by Spray DryingzakiyyayulandariNo ratings yet

- Polymers: Data-Driven Modelling of Polyethylene Recycling Under High-Temperature ExtrusionDocument23 pagesPolymers: Data-Driven Modelling of Polyethylene Recycling Under High-Temperature ExtrusionAhm SamNo ratings yet

- Materials: Roll-to-Roll Manufacturing of Micropatterned Adhesives by Template CompressionDocument12 pagesMaterials: Roll-to-Roll Manufacturing of Micropatterned Adhesives by Template CompressionLalit HingweNo ratings yet

- 2015 Porous Hydroxyapatite Ceramics Fabricated Via Starch Consolidation TechniqueDocument12 pages2015 Porous Hydroxyapatite Ceramics Fabricated Via Starch Consolidation TechniqueAnton AlgrinovNo ratings yet

- J Memsci 2017 06 075 PDFDocument36 pagesJ Memsci 2017 06 075 PDFAndresa Viana RamosNo ratings yet

- Ceramic Tio - Foams: Characterisation of A Potential ScaffoldDocument8 pagesCeramic Tio - Foams: Characterisation of A Potential ScaffoldEmon BaruaNo ratings yet

- Biopolymers and Renewable Resources: PartlDocument23 pagesBiopolymers and Renewable Resources: PartlFlavia Gerjoi BezerraNo ratings yet

- Organic-Inorganic Composite Pervaporation Membranes Prepared by Self-Assembly of Polyelectrolyte Multilayers On Macroporous Ceramic SupportsDocument2 pagesOrganic-Inorganic Composite Pervaporation Membranes Prepared by Self-Assembly of Polyelectrolyte Multilayers On Macroporous Ceramic SupportsRam VigneshNo ratings yet

- Fabra2016 PDFDocument37 pagesFabra2016 PDFPoema Pevensie BodonkressfieverNo ratings yet

- Fabrication and Optimization of PES PVP Hollow Fiber Membranes Using Box-Behnken Model and CART AlgorithmDocument21 pagesFabrication and Optimization of PES PVP Hollow Fiber Membranes Using Box-Behnken Model and CART Algorithmadil gujriNo ratings yet

- Review Article: Nanomaterial by Sol-Gel Method: Synthesis and ApplicationDocument21 pagesReview Article: Nanomaterial by Sol-Gel Method: Synthesis and ApplicationPam S. PowellNo ratings yet

- Destabilization Mechanism of Polyethylene-Modified Bitumen: A. Pe Rez-Lepe, F. J. Martı Nez-Boza, P. Attane, C. GallegosDocument8 pagesDestabilization Mechanism of Polyethylene-Modified Bitumen: A. Pe Rez-Lepe, F. J. Martı Nez-Boza, P. Attane, C. GallegosShovon HalderNo ratings yet

- Materials 14 01162Document16 pagesMaterials 14 01162Mihai Edward GheorgheNo ratings yet

- Sol GelDocument23 pagesSol GelSharana basavaNo ratings yet

- Hierarchically Porous Materials From Layer-By-Layer Photopolymerization of High in Ternal Phase EmulsionsDocument6 pagesHierarchically Porous Materials From Layer-By-Layer Photopolymerization of High in Ternal Phase Emulsionsphani12_chem5672No ratings yet

- 90-Mechanical and Rheological PPties of Epoxidized Soybean Oil Plasticized PLA 2009Document7 pages90-Mechanical and Rheological PPties of Epoxidized Soybean Oil Plasticized PLA 2009TOUFIKNo ratings yet

- Composites Science and Technology: SciencedirectDocument9 pagesComposites Science and Technology: SciencedirectMaha LakshmiNo ratings yet

- Starch MD2020Document10 pagesStarch MD2020Poornima RNo ratings yet

- SCF PolyDocument7 pagesSCF PolyAde AnjaniNo ratings yet

- Project Catalogue 2023 4 SemesterDocument10 pagesProject Catalogue 2023 4 Semestereman hussainNo ratings yet

- Materials Today: Proceedings: Nor Amira Othman, Fatmawati Adam, Nur Hidayah Mat YasinDocument6 pagesMaterials Today: Proceedings: Nor Amira Othman, Fatmawati Adam, Nur Hidayah Mat YasinMarlyn Julieth España PeñaNo ratings yet

- Thermoplastic FoamDocument22 pagesThermoplastic FoamKeo SokhimNo ratings yet

- Polymers: Numerical Studies of The Viscosity of Reacting Polyurethane Foam With Experimental ValidationDocument14 pagesPolymers: Numerical Studies of The Viscosity of Reacting Polyurethane Foam With Experimental ValidationmgrubisicNo ratings yet

- Effect of Melt Jet Spinning Process On Poly (Lactic Acid) Disposable Nonwoven Fabric ProductionDocument7 pagesEffect of Melt Jet Spinning Process On Poly (Lactic Acid) Disposable Nonwoven Fabric Productionkareem0109393No ratings yet

- Chemical Engineering and Processing: Process Intensi FicationDocument7 pagesChemical Engineering and Processing: Process Intensi FicationrukwavuNo ratings yet

- Architecture Control of Three-Dimensional Polymeric Scaffolds For Soft Tissue Engineering. I. Establishment and Validation of Numerical ModelsDocument9 pagesArchitecture Control of Three-Dimensional Polymeric Scaffolds For Soft Tissue Engineering. I. Establishment and Validation of Numerical ModelsHutsDMNo ratings yet

- TF4L3 We 889ar PDFDocument229 pagesTF4L3 We 889ar PDFFelipe ChimborazoNo ratings yet

- Chem M5 ColloidsDocument19 pagesChem M5 ColloidsEstrie Niku Sanes JaleerNo ratings yet

- CG 2015193 01 B 1 SprinklersDocument2 pagesCG 2015193 01 B 1 SprinklersIskandar HasibuanNo ratings yet

- Ringfeder Fricton Spring Manual (2019)Document3 pagesRingfeder Fricton Spring Manual (2019)Guang ChenzNo ratings yet

- Klüberlub NH1 11-222 EN enDocument2 pagesKlüberlub NH1 11-222 EN enKamila AriasNo ratings yet

- Airsep VisionAire Concentrator - Service ManualDocument46 pagesAirsep VisionAire Concentrator - Service Manualfrankj1100% (1)

- Waste Heat Recovery at Compressor Stations: The Path Towards Novel and High-Impact Technologies and Their ImplementationDocument33 pagesWaste Heat Recovery at Compressor Stations: The Path Towards Novel and High-Impact Technologies and Their ImplementationraaaghaffarNo ratings yet

- Terracycle Opportunities at UW - Stout: A Feasibility StudyDocument36 pagesTerracycle Opportunities at UW - Stout: A Feasibility StudyAlakesh GangwalNo ratings yet

- Pakyaw RatesDocument36 pagesPakyaw RatesKesMercado100% (5)

- Rotary ScrubberDocument2 pagesRotary ScrubberTamal Tanu RoyNo ratings yet

- Air CompressorDocument48 pagesAir CompressorMarius Condurache0% (1)

- Cable Selection and Wiring SystemDocument34 pagesCable Selection and Wiring SystemMuhammad Faiz bin Ahmad Shafi0% (1)

- BMP - Powder MetallurgyDocument71 pagesBMP - Powder Metallurgymantra2010No ratings yet

- TLCDocument6 pagesTLCDoni DermawanNo ratings yet

- 11.asphalt Mix CuringDocument3 pages11.asphalt Mix CuringGiorgos Siorentas100% (1)

- Nalgene Plastics Tech Guide 0209Document64 pagesNalgene Plastics Tech Guide 0209bkorecNo ratings yet

- Polycab India Limited Test Report: Tested By: Yugdip Uttekar Approved By: Kajal SaluiDocument1 pagePolycab India Limited Test Report: Tested By: Yugdip Uttekar Approved By: Kajal SaluiAshwin SupeNo ratings yet

- Challenges and Opportunities of Solid Waste Collector in Case of Yeka Sub City by KENEAN BEDANEDocument73 pagesChallenges and Opportunities of Solid Waste Collector in Case of Yeka Sub City by KENEAN BEDANETigist HaileNo ratings yet

- Sil 26-0233eDocument13 pagesSil 26-0233eKhaled ElmabroukNo ratings yet

- Engine Parts MaterialsDocument4 pagesEngine Parts Materialsmy generalNo ratings yet

- Chromatography ReviewerDocument4 pagesChromatography ReviewerAnthony Val RolunaNo ratings yet

- Paint Master Bonding Liquid - TDSDocument2 pagesPaint Master Bonding Liquid - TDSMichael JoudalNo ratings yet

- Title Description - Soda Ash+Document1 pageTitle Description - Soda Ash+glitterxinchauNo ratings yet

- Thermodynamics & IC Engines Lab ManualDocument170 pagesThermodynamics & IC Engines Lab ManualNABIL HUSSAINNo ratings yet

- Operating Instructions FOR Determination of Aggregate Impact Value ApparatusDocument2 pagesOperating Instructions FOR Determination of Aggregate Impact Value ApparatusAshish VermaNo ratings yet

- MdriveDocument104 pagesMdriveAlejandroSosaVieraNo ratings yet

- Electrochemistry SimulationDocument8 pagesElectrochemistry Simulationfaridbaik89No ratings yet

- Volumetric or Cubical Expansion Coefficients of LiquidsDocument1 pageVolumetric or Cubical Expansion Coefficients of LiquidsImmerNo ratings yet

- FMDS 03 10 - Installation & Maintenance of Fire Service MainsDocument59 pagesFMDS 03 10 - Installation & Maintenance of Fire Service MainsNazri Nawi100% (1)

- Brochure Cleaning Cationic Surfactant ThickenersDocument4 pagesBrochure Cleaning Cationic Surfactant Thickenersrachmi.kartiniNo ratings yet

- Process Plant Equipment: Operation, Control, and ReliabilityFrom EverandProcess Plant Equipment: Operation, Control, and ReliabilityRating: 5 out of 5 stars5/5 (1)

- Lees' Process Safety Essentials: Hazard Identification, Assessment and ControlFrom EverandLees' Process Safety Essentials: Hazard Identification, Assessment and ControlRating: 4 out of 5 stars4/5 (4)

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

- Guidelines for Chemical Process Quantitative Risk AnalysisFrom EverandGuidelines for Chemical Process Quantitative Risk AnalysisRating: 5 out of 5 stars5/5 (1)

- Sodium Bicarbonate: Nature's Unique First Aid RemedyFrom EverandSodium Bicarbonate: Nature's Unique First Aid RemedyRating: 5 out of 5 stars5/5 (21)

- The Perfumed Pages of History: A Textbook on Fragrance CreationFrom EverandThe Perfumed Pages of History: A Textbook on Fragrance CreationRating: 4 out of 5 stars4/5 (1)

- An Applied Guide to Water and Effluent Treatment Plant DesignFrom EverandAn Applied Guide to Water and Effluent Treatment Plant DesignRating: 5 out of 5 stars5/5 (4)

- Water-Based Paint Formulations, Vol. 3From EverandWater-Based Paint Formulations, Vol. 3Rating: 4.5 out of 5 stars4.5/5 (6)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsFrom EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNo ratings yet

- Well Control for Completions and InterventionsFrom EverandWell Control for Completions and InterventionsRating: 4 out of 5 stars4/5 (10)

- Pulp and Paper Industry: Emerging Waste Water Treatment TechnologiesFrom EverandPulp and Paper Industry: Emerging Waste Water Treatment TechnologiesRating: 5 out of 5 stars5/5 (1)

- Distillation Design and Control Using Aspen SimulationFrom EverandDistillation Design and Control Using Aspen SimulationRating: 5 out of 5 stars5/5 (2)

- Fun Facts about Hydrogen : Chemistry for Kids The Element Series | Children's Chemistry BooksFrom EverandFun Facts about Hydrogen : Chemistry for Kids The Element Series | Children's Chemistry BooksNo ratings yet

- Chemical Engineering Design: Principles, Practice and Economics of Plant and Process DesignFrom EverandChemical Engineering Design: Principles, Practice and Economics of Plant and Process DesignRating: 4 out of 5 stars4/5 (16)

- A New Approach to HAZOP of Complex Chemical ProcessesFrom EverandA New Approach to HAZOP of Complex Chemical ProcessesNo ratings yet

- The Periodic Table of Elements - Halogens, Noble Gases and Lanthanides and Actinides | Children's Chemistry BookFrom EverandThe Periodic Table of Elements - Halogens, Noble Gases and Lanthanides and Actinides | Children's Chemistry BookNo ratings yet

- Handbook of Cosmetic Science: An Introduction to Principles and ApplicationsFrom EverandHandbook of Cosmetic Science: An Introduction to Principles and ApplicationsH. W. HibbottRating: 4 out of 5 stars4/5 (6)

- Nuclear Energy in the 21st Century: World Nuclear University PressFrom EverandNuclear Energy in the 21st Century: World Nuclear University PressRating: 4.5 out of 5 stars4.5/5 (3)

- Bioinspired Materials Science and EngineeringFrom EverandBioinspired Materials Science and EngineeringGuang YangNo ratings yet

- The Stress Analysis of Pressure Vessels and Pressure Vessel Components: International Series of Monographs in Mechanical EngineeringFrom EverandThe Stress Analysis of Pressure Vessels and Pressure Vessel Components: International Series of Monographs in Mechanical EngineeringS. S. GillRating: 3.5 out of 5 stars3.5/5 (3)

- Coupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsFrom EverandCoupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsNo ratings yet

- Fundamentals of Risk Management for Process Industry EngineersFrom EverandFundamentals of Risk Management for Process Industry EngineersNo ratings yet

- Cathodic Protection: Industrial Solutions for Protecting Against CorrosionFrom EverandCathodic Protection: Industrial Solutions for Protecting Against CorrosionNo ratings yet