Professional Documents

Culture Documents

Experiment Shearing Forces

Uploaded by

AnushaBheenuckCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Experiment Shearing Forces

Uploaded by

AnushaBheenuckCopyright:

Available Formats

Shearing Force in Beams Experiment

Group 2

Table of Contents

List of Tables ................................................................................................................................................ 2

List of Figures ............................................................................................................................................... 3

1.

Abstract ................................................................................................................................................. 4

2.

Introduction ........................................................................................................................................... 4

3.

Literature review ................................................................................................................................... 5

4.

Methodology ......................................................................................................................................... 6

4.1.

Apparatus used .............................................................................................................................. 6

4.2.

Procedures ..................................................................................................................................... 7

5.

Results ................................................................................................................................................... 8

6.

Discussion ........................................................................................................................................... 11

7.

Limitations........................................................................................................................................... 11

8.

Recommendations ............................................................................................................................... 12

9.

Health and safety................................................................................................................................. 12

10.

Dissemination of knowledge ........................................................................................................... 13

11.

Applications in real life ................................................................................................................... 16

12.

Contribution of team members ...................................................................................................... 17

13.

Conclusion ....................................................................................................................................... 17

Shearing Force in Beams Experiment

Group 2

List of Tables

Table 1........................................................................................................................................................... 8

Table 2........................................................................................................................................................... 8

Table 3........................................................................................................................................................... 9

Table 4......................................................................................................................................................... 10

Table 5......................................................................................................................................................... 11

Table 6......................................................................................................................................................... 11

Table 7......................................................................................................................................................... 15

Table 8......................................................................................................................................................... 15

Shearing Force in Beams Experiment

Group 2

List of Figures

Figure 1 ......................................................................................................................................................... 5

Figure 2 ......................................................................................................................................................... 8

Figure 3 ....................................................................................................................................................... 13

Figure 4 ....................................................................................................................................................... 14

Figure 5 ....................................................................................................................................................... 17

Shearing Force in Beams Experiment

Group 2

1. Abstract

When simply supported beams are loaded two main forces are created, bending and shear. These forces

are internal and cannot easily be seen. This experiment brings these internal forces from inside the beam

to outside the beam so that students can visually see the beam deflecting and shear forces acting.

Each beam is simply supported on vertical supports which can be easily moved to create varying support

positions and beam spans. At the cut section, bearings in one beam straddle a vertical bearing track in

the mating beam. This ensures free vertical movement for monitoring shear forces. Although beam

bending is permitted, it is counteracted by the bearings and a tension spring supported horizontally from

underneath the beams.

2. Introduction

When a beam is loaded the forces cause the beam to bend and to undergo vertical displacement. These

effects are due to vertical component of forces acting perpendicular to the longitudinal axis of the beam.

The vertical displacement tends to shear the beam. Shear means relative movement between two parts of

a structural member.

Any beam must be designed in such a way that it can resist shear and bending.

Moving loads on beams are common features of design. Many road bridges are constructed from beam,

and as such have to be designed to carry a knife edge load, or a string of wheel loads, or a uniformly

distributed load, or perhaps the worst combination of all three. The method of solving the problem is to

use influence lines, i.e., shear force diagrams.

Shearing Force in Beams Experiment

Group 2

3. Literature review

The determination of shear force in a member in civil engineering is the basic part of structural analysis.

Shear force is defined as the pair of internal forces at any portion in a member that are formed to resist the

load being transferred at that point to maintain equilibrium. Shear force in a member is calculated on a

shear force diagram. We can use this diagram to calculate bending moment in a section. These diagrams

can be used to easily determine the type, size, and material of a member in a structure so that a given set

of loads can be supported without structural failure. Another application of shear and moment diagrams is

that the deflection of a beam can be easily determined using the moment area method.

Figure 1

If we consider the cantilever beam above with a load, P N acting on the beam end, we can see the shear

forces with equal magnitude, Q N acing in opposite directions at section BC. These forces arise as

explained below:

At section AB the net force acting is Q N upwards. In order to bring equilibrium we need a

downward force of equal magnitude, Q N. This shear force is provided by the other section of

the beam, i.e., CD.

At section CD the net force acting is QN downwards. So in order to bring equilibrium we need

an upward shear force of QN. This shear force is provided by the other section of the beam, i.e.,

AB.

Shearing Force in Beams Experiment

Group 2

4. Methodology

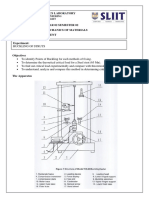

4.1.Apparatus used

Beam

Hangers

Spring Balance

Spirit Level

Measuring tape

Loads

Shearing Force in Beams Experiment

Group 2

4.2. Procedures

Part 1

1. The beam is installed 300mm from cut part to support A and 600mm from cut part to support B.

2. Initially the beam is made horizontal by tightening/releasing the underslung spring below it,

accordingly to the bubble in the spirit level so that it is central.

3. The height of the Newton meter is adjusted so that the part A and B of the beam are at same level.

4. A measuring tape is used for measurement; a hanger is positioned at the middle of the 300mm

member A1 (A) of beam and another at the middle of the 600mm member B1 of beam. (B)

5. A hanger is positioned on member A just near the cut part of the beam.

6. The initial reading is recorded on the Newton meter.

7. A load of 10N is first placed on hanger (A).

8. The deflection of the beam is observed.

9. The underslung spring and height of Newton meter is used to level the beam so as to counter the

bending moment formed initially.

10. The final value of the Newton meter is recorded.

11. The load is removed.

12. Procedures 3-10 are repeated for the 2 other positions of the beam

Part 2

1. The members distances and position of hangers are unchanged.

2. The beam is made horizontal with the spirit level.

3. The initial reading on Newton meter is noted.

4. 10N force is placed on each hanger.

5. The beam is levelled.

6. The final reading on Newton meter is recorded.

7. The load is removed.

8. The experiment is repeated with loads of 15 N and 20 N.

Shearing Force in Beams Experiment

Group 2

D

C

B

B1

A1

Figure 2

A1-short member

B1-long member

A-Midpoint of short member

B-Midpoint of long member.

5. Results

Part 1:

Position of 10N load

600mm from Left support (B)

300mm from Left support (D)

150mm form Left Support (A)

When placed at C

Initial

reading/N

1.50

2.00

2.00

Final

reading/N

5.50

9.25

0.75

No reading

Shear force

at C/N

-1.25

7.25

4.00

Table 1

Part 2:

Load on hangers/N

5

10

15

Initial reading/N

2.00

2.00

2.00

Final reading/N

6.50

11.00

17.00

Shear force at C/N

4.50

9.10

15.00

Table 2

Shearing Force in Beams Experiment

Group 2

Theoretical shear force diagrams

Position of 10N load

A

Shear force diagram and force at C

SF/N

The theoretical SF at C is +3.33 N

B

SF/N

The theoretical SF at C is 6.67 N

C

SF/N

Theoretical SF at C is -1.67 N

Table 3

Shearing Force in Beams Experiment

Group 2

Part 2

Load on hangers

5

SF diagrams and force at C

SF/N

Theoretical SF at C is 4.17N

10

SF/N

Theoretical sf at C is 8.33N

15

SF/N

Theoretical SF at C is 12.5N

Table 4

10

Shearing Force in Beams Experiment

Group 2

6. Discussion

We have shown above how we reached the magnitude of shear force at the point C (cut end of beam) in

the diagram. There is small difference in values between the calculated value and experimental value due

to the limitations in experiment as shown below. When the load is shifted to position C, the section A of

the beam moves upward hence we could not take the any reading on the newton meter. The Newton meter

can measure only tensile forces and the shear force is negative at this position and hence compressive.

The Newton meter do not enable us to measure this force.

Part 1

A

B

C

Theoretical value/N

1.67

6.67

3.33

Experimental value/N

1.25

7.25

4.00

Table 5

Part 2

Load

5

10

15

Theoretical value/N

5.83

8.33

17.5

Experimental value/N

4.50

9.10

15.00

Table 6

7. Limitations

1)

The pointer of the spring balance was too large.

2)

The loads may have not been well centered on the hanger.

3)

It was difficult to align the two sections A and B. It was done visually.

4)

Hangers were wide and thus were not placed at exact distances

5)

The beam was not exactly 900mm. The cut has a length.

6)

Friction might occur with the ball bearings at the cut.

11

Shearing Force in Beams Experiment

Group 2

8. Recommendations

A digital force display meter could be used for more accurate results

Known loads could have been firstly hung to the spring balance to check if it is not damaged.

A compression spring balance could have been used when the spring balance shows no reading

(when in compression).

Oil could have been applied to the ball bearings at the cut to eliminate friction.

Grooves could be made at the positions where the hangers were to be suspended.

9. Health and safety

Loads should be handled with care. Shock resisting materials could be placed beneath load

hangers if loads were to fall.

Gloves should be used when handling the beam and hangers as pointy ends can cause injuries.

Readings should be taken when beam is at rest.

12

Shearing Force in Beams Experiment

Group 2

10. Dissemination of knowledge

Shear force in a beam are forces generated in the beam by the applied loads and by the supports. The

forces due to reaction at support push up and forces due to applied forces pushes down.

Shear force act along the beam depending on the type of load applied and the reaction at support.

The drawing below shows the shear force diagram for different type of loads on a simply supported beam.

For this experiment we are using a simple beam with off-set point load.

Figure 3

13

Shearing Force in Beams Experiment

Group 2

For this experiment we are using a simple beam with off-set point load.

The apparatus used is as shown below.

Figure 4

The beam is cut 300mm from the right hand side of the support and 600mm from the left hand side of the

support. The apparatus is set up such as the shear force in the beam can be shown and read from the

spring balance attached to the end of left hand side beam.

For the first part the load is applied at different position on the beam:

1) In the middle of the part B of the Beam.

2) In the middle of part A of the Beam

3) In the groove at D

The theoretical values of the shear force which would be obtained at the point D when the beam is loaded

at those three positions is calculated using the laws of statics. The experimental value is obtained from the

spring balance when the beam is levelled.

14

Shearing Force in Beams Experiment

Group 2

The results are shown in the table below:

A

B

C

Theoretical value value/N

1.67

6.67

3.33

Experimental value/N

1.25

7.25

4.00

Table 7

The maximum difference between the theoretical and experimental values of shear force is:

7.25 - 6.67 = - 0.58 N

The maximum percentage difference is (0.58/6.67)% = 8.70%

From this set of reading we can deduce that the theoretical shear force at the section is similar to the

experimental shear force we obtained.

For the second part, the hangers are not moved from their position in the Part 1.

The experiment is carried out in with 3 different loads, 10N, 15N and 20N, which are placed on all the

three hangers.

The results are displayed in the table below.

Load

5

10

15

Theoretical value/N

5.83

8.33

17.5

Experimental value/N

4.50

9.10

15.00

Table 8

The maximum difference between the theoretical and experimental values is:

17.5 15.0 = 2.5N

The percentage difference in the reading is: (2.5/15.00)% = 16.67%

15

Shearing Force in Beams Experiment

Group 2

11. Applications in real life

Bending Moment and Shear diagrams are always used by structural engineers or anyone dealing with

forces in materials. In steel beam design, bending moment tells the structural engineer what is the lightest

shape I can use to carry this bending moment. Shear strength of steel beams are high and typically can be

overlooked if there isnt and special loading condition that warrants a look such as a column sitting at the

middle of a beam or near the support. At the support, the shear stresses are at its highest and any load near

this point would raise a red flag to check the capacity of the steel beam. In concrete, everything has to be

checked because concrete is design for bending and the internal couple within the beam must resist the

external bending moment placed on it. In addition, the shear in concrete has to be check to make sure it

has the capacity and if it doesnt, stirrups are used to raise the shear capacity to at or above the ultimate

strength design of the section. In any case, steel stirrups are always placed in concrete beams. Also, if an

engineer is doing a moment frame in concrete or steel, they have to understand how bending moments

and shear should look like in the frame. In todays world, the structural engineer uses software to do all

the calculation but if they do not know what a bending moment or shear diagram looks like in a loading

condition, the analysis is null. Bending moment and shear diagrams are used all the time by engineers

design bridges, buildings, boats, cars, planes and any type of structure that has to resist forces.

16

Shearing Force in Beams Experiment

Group 2

12. Contribution of team members

Task Allocation for SHEAR FORCE

Work to be

submitted on

Work

submitted on

Abstract, Introduction,

Limitation,

recommendation,health and

Kavish, Rujub

safety, dissemination of

and Saif

knowledge.contribution of team

members and conclusion

16.04.15

16.04.15

Anusha,

Abhishek and

Lionel

15.04.15

18.04.15

Task

Literature Review,

Methodology and results

Student

Figure 5

13. Conclusion

From the results of the experiment we can deduce that the experimental values of shear force are in

agreement with the theoretical values calculated. There is a small percentage error in the reading which

may be due to several limitations in this experiment; however the results are in consistent with the

expected results. The experiment could be repeated with more loads to better compare the results. Overall

the experiment was a success and help us a lot to better understand the action of shear force a beam and

how to apply this knowledge in practice.

17

You might also like

- s2 Bending MomentDocument22 pagess2 Bending MomentismailNo ratings yet

- Bending Moment Beam LabDocument14 pagesBending Moment Beam LabMorapedi D. KealebogaNo ratings yet

- Shear Force Experiment - 2Document6 pagesShear Force Experiment - 2Mohamad Afiq Afandi100% (1)

- Shear ForceDocument22 pagesShear ForceGregory MillerNo ratings yet

- Applied Strength Lab 3 The Thick CylinderDocument14 pagesApplied Strength Lab 3 The Thick CylinderSims Gift ShibaNo ratings yet

- EXPERIMENTAL BEAMSDocument10 pagesEXPERIMENTAL BEAMSNurul NadhirahNo ratings yet

- Shear Force and Bending MomentDocument5 pagesShear Force and Bending MomentSudarshan DukeNo ratings yet

- S3-Deflection in Beam and CantileverDocument97 pagesS3-Deflection in Beam and CantileverBruh100% (1)

- Discussion For Shear Centre LabDocument2 pagesDiscussion For Shear Centre Labkevinblache67% (3)

- Lab 2 - Maxwell-Betti Reciprocal Theorem FinalDocument2 pagesLab 2 - Maxwell-Betti Reciprocal Theorem FinalCarlo Santos50% (2)

- Shear Force in Beam ExperimentDocument2 pagesShear Force in Beam ExperimentaQuAmiRaNo ratings yet

- Topic 3: Shear Force of A BeamDocument19 pagesTopic 3: Shear Force of A BeamhafizNo ratings yet

- Deflection of A Simply Supported BeamDocument15 pagesDeflection of A Simply Supported Beamshuqing heongNo ratings yet

- Shear Force & Bending Moment TestDocument11 pagesShear Force & Bending Moment TestKalaiArasanNo ratings yet

- Charpy TestDocument10 pagesCharpy TestAsad AliNo ratings yet

- Som 4Document11 pagesSom 4Ronaldo Ulisi100% (1)

- SHEAR CENTRE Lab ReportDocument16 pagesSHEAR CENTRE Lab ReportAthirah Dinata100% (2)

- Vibration Lab 2 Belt Friction Lab ReportDocument15 pagesVibration Lab 2 Belt Friction Lab ReportYann YeuNo ratings yet

- Shear Force Lab ReportDocument8 pagesShear Force Lab ReportJack WillyNo ratings yet

- Lab8-Shear Force (New)Document15 pagesLab8-Shear Force (New)Nur Syamiza Zamri100% (1)

- Torsion Testing Experiment GuideDocument11 pagesTorsion Testing Experiment GuideAnoj pahathkumburaNo ratings yet

- Experiment 2 - Shear Force in BeamsDocument8 pagesExperiment 2 - Shear Force in BeamsSubuk T. Rathod100% (1)

- Rolling Disk Lab Report Applied DynamicsDocument7 pagesRolling Disk Lab Report Applied DynamicsAliNo ratings yet

- Lab Report - 2Document3 pagesLab Report - 2Gowtham Ragunathan100% (1)

- Shear Force Bending Moment Test ReportDocument5 pagesShear Force Bending Moment Test ReportZahed AbdAzizNo ratings yet

- Experiment 3 Reaction TurbineDocument20 pagesExperiment 3 Reaction TurbineAnonymous T7vjZG4ot100% (1)

- Torsion of Cylindrical RodsDocument16 pagesTorsion of Cylindrical RodsStephen Mirdo83% (18)

- 2 - Torsion TestDocument14 pages2 - Torsion TestKaarthiek Kanagasundaram KaarthiekNo ratings yet

- CVE 230. Lab Report 4 (Torsion Testing) .Document4 pagesCVE 230. Lab Report 4 (Torsion Testing) .Juan Villa100% (1)

- Experiment 1 (Practical 2)Document3 pagesExperiment 1 (Practical 2)Vimal Mathivanan50% (2)

- Structure Lab-Three Hinge ArcDocument13 pagesStructure Lab-Three Hinge ArcFendi Roon100% (1)

- Bending Moment in A Beam Lab Report - Green MechanicDocument9 pagesBending Moment in A Beam Lab Report - Green Mechanicmohdiqbal93No ratings yet

- Experiment 3 (A) : Cc205 Lab Mechanic of StructuresDocument5 pagesExperiment 3 (A) : Cc205 Lab Mechanic of StructuresZol HasNo ratings yet

- MEC424 Content TorsionDocument12 pagesMEC424 Content TorsionHaFiy HaZimNo ratings yet

- Module BDA27301 StaticsDocument39 pagesModule BDA27301 StaticsZarul IkramNo ratings yet

- Cable Suspension Experiment ReportDocument4 pagesCable Suspension Experiment ReportShiv Kumar Meena0% (1)

- Exp 5 - Deflection of Beam and CantileverDocument4 pagesExp 5 - Deflection of Beam and CantileverMohamadNaqiuddin0% (1)

- MMAN2400 - Beam Stress Lab ReportDocument5 pagesMMAN2400 - Beam Stress Lab ReportAnthony Lotfi100% (2)

- BENDING LAB 3..latestDocument28 pagesBENDING LAB 3..latestKabuki Mask100% (2)

- Structure CableDocument7 pagesStructure CableEriey ZuhairiNo ratings yet

- Torsion Experiment ReportDocument14 pagesTorsion Experiment ReportNbl KlfNo ratings yet

- Lab Report (Reaction of Forces On A Simply Supported Beam)Document10 pagesLab Report (Reaction of Forces On A Simply Supported Beam)Muhammad Abubakar Shahzad Talib ShahzadNo ratings yet

- Shear Centre of C-Channel SectionDocument12 pagesShear Centre of C-Channel SectionAshrafur Rahman100% (1)

- Central Deflection of A Simply Supported BeamDocument10 pagesCentral Deflection of A Simply Supported BeamwaqarNo ratings yet

- Cylinder Eccentric LoadDocument8 pagesCylinder Eccentric LoadKyle Mast100% (1)

- 1.bending Moment in A BeamDocument7 pages1.bending Moment in A BeamNur Syahirah Mohd NoorNo ratings yet

- ME2113-1 Lab Report DEFLECTION AND BENDING STRESSES IN BEAMSDocument8 pagesME2113-1 Lab Report DEFLECTION AND BENDING STRESSES IN BEAMSsteven mcqueen67% (15)

- Test Slender Column Strength & Buckling LoadsDocument6 pagesTest Slender Column Strength & Buckling LoadsAsad UzzamanNo ratings yet

- MECE 221 Lab Manual - Torsion of Rods & TubesDocument6 pagesMECE 221 Lab Manual - Torsion of Rods & TubesSam Hitchens Lesenyamotse100% (1)

- Bending MomentDocument17 pagesBending MomentEsyad E-chadNo ratings yet

- Experiment Center Pressure Lab ReportDocument9 pagesExperiment Center Pressure Lab ReportAyong Anis100% (4)

- Measure forces in loaded frame using roof trussDocument4 pagesMeasure forces in loaded frame using roof trussAhmed0% (1)

- Bending Moment in A BeamDocument12 pagesBending Moment in A BeamOdarie HunterNo ratings yet

- Impact of Jet Lab ReportDocument7 pagesImpact of Jet Lab ReportMohamad Hilmy HaririeNo ratings yet

- HP Lab Report TrifilarDocument11 pagesHP Lab Report TrifilarHorciuxes IraniNo ratings yet

- Hydraulic JumpDocument5 pagesHydraulic JumpKafeel Bichu0% (1)

- Buckling of Struts Lab GuideDocument6 pagesBuckling of Struts Lab GuideMohamed Zamri0% (1)

- Exp 1 G5Document24 pagesExp 1 G5Abdullah Helmi100% (1)

- Shearing Forces in BeamsDocument9 pagesShearing Forces in BeamsKheshav JhundooNo ratings yet

- Rolled Steel JoistsDocument20 pagesRolled Steel Joistsmanish dhariwalNo ratings yet

- Visual Inspection of TimberDocument1 pageVisual Inspection of TimberAnushaBheenuckNo ratings yet

- Tupperware Magazine 08.03.17Document6 pagesTupperware Magazine 08.03.17AnushaBheenuckNo ratings yet

- V Notch PracticalDocument13 pagesV Notch PracticalAnushaBheenuck0% (2)

- CBR FinalDocument11 pagesCBR FinalAnushaBheenuckNo ratings yet

- Permeability FinalDocument17 pagesPermeability FinalAnushaBheenuckNo ratings yet

- Fluids Past Papers PDFDocument65 pagesFluids Past Papers PDFAnushaBheenuckNo ratings yet

- A Summary For Simple Structural Design CalculationsDocument12 pagesA Summary For Simple Structural Design CalculationsAnushaBheenuckNo ratings yet

- Beam Reaction Experiment Group 2Document22 pagesBeam Reaction Experiment Group 2AnushaBheenuck100% (1)

- Concrete Design - David GarberDocument15 pagesConcrete Design - David GarberMMM-2012No ratings yet

- Seismic Ground Motion Maps and Risk CoefficientsDocument6 pagesSeismic Ground Motion Maps and Risk CoefficientsYaserNo ratings yet

- Physics Episode 6 PDFDocument42 pagesPhysics Episode 6 PDFRaging PhoenixNo ratings yet

- JR - STAR CO SUPER CHAINA (2022-23) - TEACHING, EXAM SCHEDULE & PAPER SETTING ALLOTMENT at AFTER IPE TO JUNE4TH - 24.03.23Document81 pagesJR - STAR CO SUPER CHAINA (2022-23) - TEACHING, EXAM SCHEDULE & PAPER SETTING ALLOTMENT at AFTER IPE TO JUNE4TH - 24.03.23amanit12345No ratings yet

- Models - Mems.thermal Actuator Tem ParameterizedDocument16 pagesModels - Mems.thermal Actuator Tem ParameterizedIonescu ViorelNo ratings yet

- Engineering Statics FundamentalsDocument28 pagesEngineering Statics FundamentalsurwaNo ratings yet

- Table 1-Typical Rubber Properties Used in The Oil WellDocument8 pagesTable 1-Typical Rubber Properties Used in The Oil WellabodolkuhaaNo ratings yet

- Prof. Dr.-Ing. Habil. Holm Altenbach, - Mechanics of Composite Structural Elements-Springer-Verlag BerliDocument487 pagesProf. Dr.-Ing. Habil. Holm Altenbach, - Mechanics of Composite Structural Elements-Springer-Verlag BerliJohan100% (1)

- CH 01Document95 pagesCH 01김인웅No ratings yet

- Acoustics of Organ PipesDocument10 pagesAcoustics of Organ PipesNicola BurattiNo ratings yet

- PDF 5Document17 pagesPDF 5James BundNo ratings yet

- SME1306 - Theory of VibrationsDocument35 pagesSME1306 - Theory of Vibrationsu2b11517No ratings yet

- What Is The Electron SpinDocument92 pagesWhat Is The Electron SpinTomás Andres Veliz CamposNo ratings yet

- Strength of Materials 1 DiscussionDocument36 pagesStrength of Materials 1 DiscussionsadonNo ratings yet

- SPIT Fix-II Zinc CoatedDocument4 pagesSPIT Fix-II Zinc CoatedAhmed SakrNo ratings yet

- ELL 100 Introduction To Electrical Engineering: Ecture Lectromechanical Nergy OnversionDocument60 pagesELL 100 Introduction To Electrical Engineering: Ecture Lectromechanical Nergy OnversionmwasahaNo ratings yet

- Magnetic Brake 3dDocument6 pagesMagnetic Brake 3dalino4uNo ratings yet

- Linear Elastic Fracture Mechanics (LEFM) TopicsDocument19 pagesLinear Elastic Fracture Mechanics (LEFM) TopicsChimwemwe KaongaNo ratings yet

- Gravitation 5Document1 pageGravitation 5Aishwarya ShuklaNo ratings yet

- Energy Transport EquationDocument4 pagesEnergy Transport EquationFranklin PraveenNo ratings yet

- M M M M M: HapterDocument20 pagesM M M M M: HapterAnnNo ratings yet

- MDB Midterm Exam Me3bDocument3 pagesMDB Midterm Exam Me3bNavarro, Jherwin F.No ratings yet

- CBSE Class 11 Physics Notes - Work, Power and EnergyDocument12 pagesCBSE Class 11 Physics Notes - Work, Power and Energyrahul50% (2)

- CH4 Recommended Problems PDFDocument3 pagesCH4 Recommended Problems PDFnomio12No ratings yet

- Current Trends and Open Problems in Computational MechanicsDocument587 pagesCurrent Trends and Open Problems in Computational MechanicsShaerman ChenNo ratings yet

- Expressions for mass and momentum conservation in different coordinate systemsDocument2 pagesExpressions for mass and momentum conservation in different coordinate systemsTania NoorNo ratings yet

- Mem-402-Mos Final QB-2015Document9 pagesMem-402-Mos Final QB-2015Rohit DiwakarNo ratings yet

- Free-Fall Lab Report-4Document13 pagesFree-Fall Lab Report-4api-462582713No ratings yet

- Chodai - Buro Engineering Pte. LTD.: Fin Plate Connection Check (Single Line of Bolts)Document2 pagesChodai - Buro Engineering Pte. LTD.: Fin Plate Connection Check (Single Line of Bolts)hary9100100% (1)

- Thermodynamics Unit 1 NotesDocument49 pagesThermodynamics Unit 1 Noteskapilraj_mech100% (1)