Professional Documents

Culture Documents

Dry Dock

Uploaded by

Eman MousaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Dry Dock

Uploaded by

Eman MousaCopyright:

Available Formats

Dry dock

Diaphragm wall - Sheet piling - Ground anchors - Civil works - Equipment

CONCARNEAU DRY DOCK

CONCARNEAU - FRANCE

Design and construction as main contractor of dry dock,

length 130m, width 27m, depth 10.80m

he target contract for

construction

of

the

Concarneau dry dock was

performed by a consortium of

Soletanche Bachy and Le Pape

(excavation and fill). The site

was a lagoon fed by a stream

and open to the sea. The dock

was needed to suit modern

requirements, to supplement a

boat hoist and slipway already

in operation at Concarneau.

Design

The dry dock is 130m long, 27m

wide and 10.80m deep, controlled on the seaward side by a

trolley-mounted sliding gate.

The remote end has a spiral

access ramp for more efficient

operational use by the commercial companies operating there.

A pump room is provided to

control washwater and gate

leakage. Three pumps can discharge up to 4000 m3 per hour

to dewater the dock in four

hours when a ship is being docked. There are all the usual

fittings conventionally found

in harbours works such as

bollards, capstans and winches.

A390

Dry dock and port

OWNER:

CHAMBRE DE COMMERCE ET D'INDUSTRIE DE QUIMPER

ENGINEER:

CHAMBRE DE COMMERCE ET D'INDUSTRIE DE QUIMPER

MAIN CONTRACTOR:

SOLETANCHE BACHY / LE PAPE

CLASSIFICATION SOCIETY:

BUREAU VERITAS

PERIOD:

APRIL 2000 TO DECEMBER 2001

CONSTRUCTION COST:

11.5 MILLION EUROS

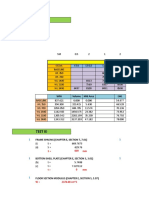

MAIN WORKS QUANTITIES:

Diaphragm wall: 4800 m2

Earthmoving: 220,000 m3

2

Sheet piling: 1200 m

Strip drains: 60,000 m

Ground anchors: 106

Drained raft: 4000 m2

Tie beams: 228t

Civil works: RC raft (4000 m3), spiral access ramp, capping beam, pump room,

L walls, etc.

Facilities: Control building, perimeter road, services (water, electricity, gas)

Equipment: Sliding dock gate, bollards, winches, pumps (35-4000 m3/hr), capstans, keel blocks, etc.

Typical section

Works

One of the challenges facing the

weight of the fill gradually expelled

consortium was how to deal with the

the water from the mud through

mud covering the lagoon bed to

sumps collecting the water in the

The floor is a drained raft to prevent

depths of up to 7 metres, considering

free-draining layer. Settlement of

the build-up of uplift. Works on the

that the finished dock was to be

approximately one metre was obser-

dock entrance proceeded behind a

surrounded by earth platforms for

ved before construction work proper

watertight cofferdam built in the port:

normal harbour operations, with a

could commence.

pump room, floor under the gate, gate

Sinking strip drains

specified bearing capacity of at least

recess (rock excavation with shotcrete

3 tonnes per square metre. Excavation

and nail support). The contract requi-

of the mud would have been difficult

red a turnkey graving facility, and

and disposal even more problematical,

ancillary works included a perimeter

and it was decided to consolidate it in

road around the dock, drinking water,

situ by preloading. Apart from the

electricity and gas supply, fire-figh-

excavation for the dock itself, there-

ting system, two-storey control buil-

fore, all the mud has been left in

ding and all fittings for ship docking

place. An interceptor channel was dug

(keel blocks, winched cradles, etc.).

to divert the river around the lagoon,

One of the last operations was assem-

then the lagoon was emptied to

Diaphragm wall and sheet pile driving

bly of the dock gate, by assembling

four caissons to form a single unit

expose the mud. A geotextile was laid

over the whole area and covered with

The dock sidewalls were built as

28m long, 11m high and 4m thick,

the same thickness of free-draining

diaphragm walls, tied back at the

weighing 170 tonnes. The gate was

gravel. Strip drains were sunk from

top with passive anchors to sheet

launched by a nearby boat hoist,

this platform down to bedrock in a

piling and fixed at the bottom by the

towed to station and sunk onto its trol-

1-metre square array. The subsequent

concrete floor of the dock.

leys, standing ready on their rail tracks.

Capping beam and sidewalls

A390

Dock after pouring reinforced

concrete floor

You might also like

- EVALUATING THE MERITS OF A BUNKER CLAIM Illustrated PDFDocument25 pagesEVALUATING THE MERITS OF A BUNKER CLAIM Illustrated PDFJuan Enrique Vergel MarinNo ratings yet

- Buckling of Columns PDFDocument11 pagesBuckling of Columns PDFAhmedHatifNo ratings yet

- Using The Moody DiagramDocument6 pagesUsing The Moody DiagramDorothy AmpomahNo ratings yet

- Resistance (MA R) 1: The Power Necessary To Overcome This Resistance Is Called The) WhereDocument11 pagesResistance (MA R) 1: The Power Necessary To Overcome This Resistance Is Called The) Wheresupriadi90315No ratings yet

- Sites Default Files Technip Publications Attachments Skandi Achiever WEBDocument4 pagesSites Default Files Technip Publications Attachments Skandi Achiever WEBimperitusNo ratings yet

- Brief Presentation of Ut-Design UT 739 L: Multifunctional, Deep Water Anchor Handling, Tug, Supply and Service VesselDocument32 pagesBrief Presentation of Ut-Design UT 739 L: Multifunctional, Deep Water Anchor Handling, Tug, Supply and Service VesselCinthia Lidia Hidrogo PaulinoNo ratings yet

- Crest Radiant 3 9535357 Anchor Handling VesselDocument1 pageCrest Radiant 3 9535357 Anchor Handling VesselAndi IrfanNo ratings yet

- 12217-1 Worksheet 1-2-3-4-5Document7 pages12217-1 Worksheet 1-2-3-4-5yunus ahmet ilhanNo ratings yet

- Platform Supply Vessel ULSTEIN PX121Document6 pagesPlatform Supply Vessel ULSTEIN PX121maria_bustelo_2No ratings yet

- DS120m Diving Support Vessel Armon PDFDocument3 pagesDS120m Diving Support Vessel Armon PDFJorge Ricardo AlcivarNo ratings yet

- Harvard Semester 4Document255 pagesHarvard Semester 4Ricky PrabowoNo ratings yet

- Orca Energy SpecDocument2 pagesOrca Energy SpecHanWee LowNo ratings yet

- Offshore Support VesselsDocument7 pagesOffshore Support VesselsCriss MadNo ratings yet

- Dulam 2016 Spec Sheet Oceanic Installer 03Document2 pagesDulam 2016 Spec Sheet Oceanic Installer 03HajeeNo ratings yet

- Hydrodynamic Response of A Floating Dry DockDocument17 pagesHydrodynamic Response of A Floating Dry DockJayapal RajanNo ratings yet

- Sea Jack: Technical Specifi CationsDocument2 pagesSea Jack: Technical Specifi Cationsronny-suNo ratings yet

- Suez Canal Transit MiniguideDocument34 pagesSuez Canal Transit MiniguideNikhilVinayNo ratings yet

- 1989 MODU CodeDocument97 pages1989 MODU CodeChris EdwardsNo ratings yet

- Ferries PDFDocument25 pagesFerries PDFletathienNo ratings yet

- Skandi ArcticDocument4 pagesSkandi ArcticnebulaequinoxNo ratings yet

- Lecture 05Document35 pagesLecture 05Junaid JavaidNo ratings yet

- Mud Barge Sea ChestDocument1 pageMud Barge Sea ChestAstri NgentNo ratings yet

- Devlopment of The Rêvo Wasp 743 PDFDocument14 pagesDevlopment of The Rêvo Wasp 743 PDFrobertoNo ratings yet

- 30mt Multi Purpose Vessel SpecDocument2 pages30mt Multi Purpose Vessel Specmariners123No ratings yet

- Test Ii: WPA Volume Mid Area LWLDocument9 pagesTest Ii: WPA Volume Mid Area LWLMark Lester AndayaNo ratings yet

- Thesis RGdeJongDocument108 pagesThesis RGdeJongNaval2014DNNo ratings yet

- Naval Architecture Term 1Document23 pagesNaval Architecture Term 1Lahiru Chamara JayasingheNo ratings yet

- Anchor Chain Locker Volume CalculationDocument1 pageAnchor Chain Locker Volume Calculationbasant_konatNo ratings yet

- Assignment 1 (Ship Resistance)Document1 pageAssignment 1 (Ship Resistance)KikiNo ratings yet

- Product Sheet Damen Modular Ferry 3710 Yn523024 08 2016Document2 pagesProduct Sheet Damen Modular Ferry 3710 Yn523024 08 2016leoschunckNo ratings yet

- Your Propulsion Experts: Nav Schottel NavigatorDocument8 pagesYour Propulsion Experts: Nav Schottel NavigatorMustafa TemelNo ratings yet

- Life-Saving Equipment SekociDocument16 pagesLife-Saving Equipment SekociChory P. Arista100% (1)

- Resume 2Document2 pagesResume 2Jonel TaburaNo ratings yet

- Aureus 15 May 18Document2 pagesAureus 15 May 18Noor Riz Al Jeffery IshakNo ratings yet

- Subsea Pipe Laying ShipsDocument8 pagesSubsea Pipe Laying ShipsMostafa Shawky El ShenawyNo ratings yet

- Shippaxguide16: Extract From The Annual Publication Shippax Guide 16. Presentation of ACL's ATLANTIC STARDocument68 pagesShippaxguide16: Extract From The Annual Publication Shippax Guide 16. Presentation of ACL's ATLANTIC STARЕгор Лядов100% (1)

- 2004-02-18 Stevns Power AHV AccidentDocument17 pages2004-02-18 Stevns Power AHV AccidentriggertroyNo ratings yet

- Volume IIDocument246 pagesVolume IIathanasios niotisNo ratings yet

- SeaBoats ID1127Document14 pagesSeaBoats ID1127nipper7No ratings yet

- Tech Data Sheet SAT System RaffaellaDocument13 pagesTech Data Sheet SAT System RaffaellaMarco VacchieriNo ratings yet

- Supertanker - Knock Nevis: Seawise Giant, Happy Giant, and Jahre VikingDocument16 pagesSupertanker - Knock Nevis: Seawise Giant, Happy Giant, and Jahre Vikingsan0zNo ratings yet

- SEATECH - Forum On Marine Blue Economy - Developing The Potential of Deep Seabed Mining What Trade-Offs With BiodiversityDocument20 pagesSEATECH - Forum On Marine Blue Economy - Developing The Potential of Deep Seabed Mining What Trade-Offs With BiodiversityDilip SarangdharNo ratings yet

- Truxor 09 ENG2 PDFDocument16 pagesTruxor 09 ENG2 PDFProjetos TonioloNo ratings yet

- Need For A Comprehensive "OSV Code": August 2011Document11 pagesNeed For A Comprehensive "OSV Code": August 2011stanescu mihaiNo ratings yet

- The Demise of EL FARO - A Wake Up Call For The World Merchant MarineDocument18 pagesThe Demise of EL FARO - A Wake Up Call For The World Merchant Marineshakeer tNo ratings yet

- Final GWS382Document30 pagesFinal GWS382cengiz kutukcuNo ratings yet

- Tractel Price List 2016 LR PDFDocument173 pagesTractel Price List 2016 LR PDFtangouzeNo ratings yet

- Saipem 3000Document8 pagesSaipem 3000Nkechi KokoNo ratings yet

- Ocean Tow GuidelinesDocument35 pagesOcean Tow Guidelinesfajee_faridNo ratings yet

- Vent SystemDocument5 pagesVent SystemNicu BîlhacNo ratings yet

- AMVER ReportingDocument33 pagesAMVER ReportingAaron Rizaga CarcuevaNo ratings yet

- Brochure Armada Condor Rev D3Document4 pagesBrochure Armada Condor Rev D3rammech85No ratings yet

- The Report September 2020Document112 pagesThe Report September 2020anacondamarineNo ratings yet

- Hydodynamic Loads During The Deployment of ROVs - P.sayerDocument6 pagesHydodynamic Loads During The Deployment of ROVs - P.sayerDavid ThomsonNo ratings yet

- 2data Anchor Windlass CapstanDocument56 pages2data Anchor Windlass CapstanFrank RoperNo ratings yet

- Schilling Rudder - Wikipedia, The Free EncyclopediaDocument3 pagesSchilling Rudder - Wikipedia, The Free EncyclopediaAhmad HajivandNo ratings yet

- RB - Aluminium A60 Hinged DoorDocument2 pagesRB - Aluminium A60 Hinged DoorHayden Kyle KeigleyNo ratings yet

- High Speed Towing Tank FacilityDocument4 pagesHigh Speed Towing Tank FacilityAnkit GhoshNo ratings yet

- Sheet PDFDocument8 pagesSheet PDFEman MousaNo ratings yet

- Pavement Subgrade, Unbound Materials, and Nondestructive TestingDocument22 pagesPavement Subgrade, Unbound Materials, and Nondestructive TestingEman MousaNo ratings yet

- Atterberg Limit ExperimentDocument6 pagesAtterberg Limit ExperimentsaravananveranNo ratings yet

- Kwon 2015Document7 pagesKwon 2015Eman MousaNo ratings yet

- Resilient Modulus of Crushed Granite Aggregate Base For Use in Mechanistic Pavement DesignDocument11 pagesResilient Modulus of Crushed Granite Aggregate Base For Use in Mechanistic Pavement DesignEman MousaNo ratings yet

- تمارين الرسم المدنى هندسة حورسDocument49 pagesتمارين الرسم المدنى هندسة حورسEman MousaNo ratings yet

- Kwon 2015Document7 pagesKwon 2015Eman MousaNo ratings yet

- Experiment 7-Atterberg LimitsDocument14 pagesExperiment 7-Atterberg LimitsJack RasalNo ratings yet

- CM Exercise 7Document2 pagesCM Exercise 7Eman MousaNo ratings yet

- IAM Beginners Guide Low 9Document32 pagesIAM Beginners Guide Low 9andcrisdanmat100% (1)

- Uu Test: - 200 Sample Area 100 Sample Volume 1.91 CM CMDocument13 pagesUu Test: - 200 Sample Area 100 Sample Volume 1.91 CM CMEman MousaNo ratings yet

- Manual 3D MoveDocument214 pagesManual 3D MoveVictor Hugo Iriondo100% (2)

- Flexible Pavement Modelling Using Kenlayer: Dr. Amin ChegenizadehDocument13 pagesFlexible Pavement Modelling Using Kenlayer: Dr. Amin ChegenizadehEman MousaNo ratings yet

- IAM Beginners Guide Low 9Document32 pagesIAM Beginners Guide Low 9andcrisdanmat100% (1)

- Slipway 2012 DecDocument1 pageSlipway 2012 DecEman MousaNo ratings yet

- Overview Presentation: 1. What Is Asset Management? 2. Why Asset Management?Document50 pagesOverview Presentation: 1. What Is Asset Management? 2. Why Asset Management?Edy SuprayitnoNo ratings yet

- Laboratory Testing Manual (2000) PDFDocument330 pagesLaboratory Testing Manual (2000) PDFandressaoliveira2301100% (8)

- Quiz ModelDocument1 pageQuiz ModelEman MousaNo ratings yet

- Dry DockDocument2 pagesDry DockEman MousaNo ratings yet

- Overview Presentation: 1. What Is Asset Management? 2. Why Asset Management?Document50 pagesOverview Presentation: 1. What Is Asset Management? 2. Why Asset Management?Edy SuprayitnoNo ratings yet

- 01 TRB 2009 Fatigue PaperDocument10 pages01 TRB 2009 Fatigue PaperEman MousaNo ratings yet

- Slipway 2012 DecDocument1 pageSlipway 2012 DecEman MousaNo ratings yet

- This Memo Has ExpiredDocument3 pagesThis Memo Has ExpiredEman MousaNo ratings yet

- Dry DockDocument2 pagesDry DockEman MousaNo ratings yet

- Quiz 10Document9 pagesQuiz 10Eman MousaNo ratings yet

- Quiz 10Document9 pagesQuiz 10Eman MousaNo ratings yet

- Faye Contd Is T ExtraDocument8 pagesFaye Contd Is T ExtraEman MousaNo ratings yet

- RV2Document12 pagesRV2Eman MousaNo ratings yet

- Trip Distribution: Theoretical BackgroundDocument70 pagesTrip Distribution: Theoretical BackgroundEman MousaNo ratings yet

- Transport ADRDocument3 pagesTransport ADRZbinca CristianNo ratings yet

- Isuzu 4be1 Engine Manual KolesooreDocument5 pagesIsuzu 4be1 Engine Manual KolesooreRaymart Dealca75% (8)

- Accounting QuestionsDocument16 pagesAccounting QuestionsPrachi ChananaNo ratings yet

- Communication To Offer-ContractsDocument20 pagesCommunication To Offer-ContractsAarif Mohammad BilgramiNo ratings yet

- Optical Current TransformerDocument22 pagesOptical Current TransformerchallaramcharanreddyNo ratings yet

- Guillang Vs Bedania and SilvaDocument2 pagesGuillang Vs Bedania and Silvajdg jdgNo ratings yet

- Ahi Evran Sunum enDocument26 pagesAhi Evran Sunum endenizakbayNo ratings yet

- Tower BridgeDocument6 pagesTower BridgeCalvin PratamaNo ratings yet

- Project Human Resource Management Group PresentationDocument21 pagesProject Human Resource Management Group Presentationjuh1515100% (1)

- GSM Controlled RobotDocument33 pagesGSM Controlled RobotAbhishek KunalNo ratings yet

- GT Reading Test 5, 2Document2 pagesGT Reading Test 5, 2Muzammel Hossian MatinNo ratings yet

- Teaching Strategies, Styles and Qualities of ADocument6 pagesTeaching Strategies, Styles and Qualities of AjixNo ratings yet

- Snmpwalk Westermo DSL ModemDocument24 pagesSnmpwalk Westermo DSL ModemAexNo ratings yet

- Rules and Regulations Governing Private Schools in Basic Education - Part 2Document103 pagesRules and Regulations Governing Private Schools in Basic Education - Part 2Jessah SuarezNo ratings yet

- Garden Profile NDocument19 pagesGarden Profile NParitosh VermaNo ratings yet

- Indiabulls PILDocument64 pagesIndiabulls PILPGurus100% (1)

- Time-Series Forecasting: 2000 by Chapman & Hall/CRCDocument9 pagesTime-Series Forecasting: 2000 by Chapman & Hall/CRCeloco_2200No ratings yet

- Power GREPDocument392 pagesPower GREPCeles NubesNo ratings yet

- Subject: Industrial Marketing Topic/Case Name: Electrical Equipment LTDDocument4 pagesSubject: Industrial Marketing Topic/Case Name: Electrical Equipment LTDRucha ShirudkarNo ratings yet

- ImpulZ DocumentationDocument9 pagesImpulZ DocumentationexportcompNo ratings yet

- IS301 P1 Theory June 2021 P1 TheoryDocument20 pagesIS301 P1 Theory June 2021 P1 Theory50902849No ratings yet

- Ti - e - Protegol 32-97 Jan 08Document3 pagesTi - e - Protegol 32-97 Jan 08A MahmoodNo ratings yet

- Violence Against NursesDocument22 pagesViolence Against NursesQuality Assurance Officer Total Quality ManagementNo ratings yet

- Thoughts On Iphone Demand - Update On Delivery Times, Carrier IncentivesDocument10 pagesThoughts On Iphone Demand - Update On Delivery Times, Carrier Incentivesalpha123@tutopiaNo ratings yet

- Relevé: Partie 6: Vidéo "Le Blues en Jazz"Document1 pageRelevé: Partie 6: Vidéo "Le Blues en Jazz"santiagoNo ratings yet

- Zeb OSARSInstallDocument128 pagesZeb OSARSInstallThien TranNo ratings yet

- Department of Agrarian Reform Adjudication Board (Darab) : PetitionDocument3 pagesDepartment of Agrarian Reform Adjudication Board (Darab) : PetitionDe Dios JVNo ratings yet

- Want To Buy & Sell Expired Domain Names-Follow These 3 StepsDocument6 pagesWant To Buy & Sell Expired Domain Names-Follow These 3 StepsEmiemNo ratings yet

- Penn State: The Dickinson School of LawDocument88 pagesPenn State: The Dickinson School of LawHafiz UmmarNo ratings yet

- DS Introduction To TreeDocument23 pagesDS Introduction To TreePrashant JainNo ratings yet