Professional Documents

Culture Documents

FL - Air Duct Accessories

Uploaded by

Art JamesOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FL - Air Duct Accessories

Uploaded by

Art JamesCopyright:

Available Formats

Royal Commission - Yanbu

January 2012

SECTION 23 33 00

AIR DUCT ACCESSORIES

PART 1 - GENERAL

1.1

RELATED DOCUMENTS

A.

1.2

Drawings and general provisions of the Contract, including General and Supplementary

Conditions and Division 01 Specification Sections, apply to this Section.

SUMMARY

A.

Section Includes:

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

B.

Related Requirements:

1.

2.

3.

1.3

Backdraft and pressure relief dampers.

Barometric relief dampers.

Manual volume dampers.

Control dampers.

Fire dampers.

Ceiling radiation dampers.

Smoke dampers.

Combination fire and smoke dampers.

Corridor dampers.

Flange connectors.

Duct silencers.

Turning vanes.

Remote damper operators.

Duct-mounted access doors.

Flexible connectors.

Flexible ducts.

Duct security bars.

Duct accessory hardware.

Section 23 37 23 "HVAC Gravity Ventilators" for roof-mounted ventilator caps.

Section 28 31 11 "Digital, Addressable Fire-Alarm System" for duct-mounted fire and

smoke detectors.

Section 28 31 12 "Zoned (DC-Loop) Fire-Alarm System" for duct-mounted fire and

smoke detectors.

ACTION SUBMITTALS

A.

Product Data: For each type of product.

1.

23 33 00 rev 1

For duct silencers, include pressure drop and dynamic insertion loss data.

breakout noise calculations for high transmission loss casings.

PAGE 1 OF 26

Include

Contract No.

RC - Yanbu

B.

Air Duct Accessories

LEED Submittals:

1.

2.

C.

Product Data for Prerequisite IEQ 1: Documentation indicating that units comply with

ASHRAE 62.1, Section 5 - "Systems and Equipment."

Product Data for Prerequisite EA 2: Documentation indicating that duct insulation Rvalues comply with tables in ASHRAE/IESNA 90.1, Section 6 - "Heating, Ventilating,

and Air Conditioning."

Shop Drawings: For duct accessories.

attachments to other work.

1.

Include plans, elevations, sections, details and

Detail duct accessories fabrication and installation in ducts and other construction.

Include dimensions, weights, loads, and required clearances; and method of field

assembly into duct systems and other construction. Include the following:

a.

b.

c.

d.

e.

f.

1.4

January 2012

Special fittings.

Manual volume damper installations.

Control-damper installations.

Fire-damper, smoke-damper, combination fire- and smoke-damper, ceiling, and

corridor damper installations, including sleeves; and duct-mounted access doors

and remote damper operators.

Duct security bars.

Wiring Diagrams: For power, signal, and control wiring.

INFORMATIONAL SUBMITTALS

A.

Coordination Drawings: Reflected ceiling plans, drawn to scale, on which ceiling-mounted

access panels and access doors required for access to duct accessories are shown and

coordinated with each other, using input from Installers of the items involved.

B.

Source quality-control reports.

1.5

CLOSEOUT SUBMITTALS

A.

1.6

Operation and Maintenance Data:

maintenance manuals.

For air duct accessories to include in operation and

MAINTENANCE MATERIAL SUBMITTALS

A.

Furnish extra materials that match products installed and that are packaged with protective

covering for storage and identified with labels describing contents.

1.

23 33 00 rev 1

Fusible Links: Furnish quantity equal to [10] <Insert number> percent of amount

installed.

PAGE 2 OF 26

Contract No.

RC - Yanbu

Air Duct Accessories

January 2012

PART 2 - PRODUCTS

2.1

ASSEMBLY DESCRIPTION

A.

Comply with NFPA 90A, "Installation of Air Conditioning and Ventilating Systems," and with

NFPA 90B, "Installation of Warm Air Heating and Air Conditioning Systems."

B.

Comply with SMACNA's "HVAC Duct Construction Standards - Metal and Flexible" for

acceptable materials, material thicknesses, and duct construction methods unless otherwise

indicated. Sheet metal materials shall be free of pitting, seam marks, roller marks, stains,

discolorations, and other imperfections.

2.2

MATERIALS

A.

Galvanized Sheet Steel: Comply with ASTM A 653/A 653M.

1.

2.

Galvanized Coating Designation: [Z180] [Z275].

Exposed-Surface Finish: Mill phosphatized.

B.

Stainless-Steel Sheets: Comply with ASTM A 480/A 480M, Type 304, and having a [No. 2]

<Insert finish designation> finish for concealed ducts and <Insert finish designation> finish

for exposed ducts.

C.

Aluminum Sheets: Comply with ASTM B 209M, Alloy 3003, Temper H14; with mill finish for

concealed ducts and standard, 1-side bright finish for exposed ducts.

D.

Extruded Aluminum: Comply with ASTM B 221M, Alloy 6063, Temper T6.

E.

Reinforcement Shapes and Plates: Galvanized-steel reinforcement where installed on

galvanized sheet metal ducts; compatible materials for aluminum and stainless-steel ducts.

F.

Tie Rods: Galvanized steel, 6-mm minimum diameter for lengths 900 mm or less; 10-mm

minimum diameter for lengths longer than 900 mm.

2.3

BACKDRAFT AND PRESSURE RELIEF DAMPERS

A.

Manufacturers: Subject to compliance with requirements, [provide products by the following]

[provide products by one of the following] [available manufacturers offering products that may

be incorporated into the Work include, but are not limited to, the following]:

B.

Basis-of-Design Product: Subject to compliance with requirements, provide [product

indicated on Drawings] <Insert manufacturer's name; product name or designation> or

comparable product by one of the following:

1.

<Insert manufacturer's name>.

C.

Description: Gravity balanced.

D.

Maximum Air Velocity: [5.1 m/s] [6.4 m/s] [10 m/s] [15 m/s] <Insert value>.

23 33 00 rev 1

PAGE 3 OF 26

Contract No.

RC - Yanbu

Air Duct Accessories

E.

Maximum System Pressure: [0.25 kPa] [0.5 kPa] [0.8 kPa] [1.5 kPa] <Insert value>.

F.

Frame: Hat-shaped, [1.3-mm- thick, galvanized sheet steel] [2.4-mm- thick, galvanized sheet

steel] [1.6-mm- thick extruded aluminum] [0.8-mm- thick stainless steel] [1.3-mm- thick

stainless steel], with welded corners or mechanically attached[ and mounting flange].

G.

Blades: Multiple single-piece blades, [center pivoted,] [off-center pivoted,] [end pivoted,]

maximum 150-mm width, [0.6-mm- thick, roll-formed aluminum] [1.2-mm- thick aluminum

sheet] [noncombustible, tear-resistant, neoprene-coated fiberglass] with sealed edges.

H.

Blade Action: Parallel.

I.

Blade Seals: [Felt] [Vinyl foam] [Extruded vinyl, mechanically locked] [Neoprene,

mechanically locked].

J.

Blade Axles:

1.

2.

Material: [Nonferrous metal] [Galvanized steel] [Plated steel] [Stainless steel]

[Nonmetallic] [Aluminum].

Diameter: [5 mm] <Insert value>.

K.

Tie Bars and Brackets: [Aluminum] [Galvanized steel].

L.

Return Spring: Adjustable tension.

M.

Bearings: [Steel ball] [or] [synthetic pivot bushings].

N.

Accessories:

1.

2.

3.

4.

5.

Adjustment device to permit setting for varying differential static pressure.

Counterweights and spring-assist kits for vertical airflow installations.

Electric actuators.

Chain pulls.

Screen Mounting: Front mounted in sleeve.

a.

b.

6.

7.

8.

9.

2.4

January 2012

Sleeve Thickness: 1.0 mm minimum.

Sleeve Length: 152 mm minimum.

Screen Mounting: Rear mounted.

Screen Material: [Galvanized steel] [Aluminum].

Screen Type: [Bird] [Insect].

90-degree stops.

BAROMETRIC RELIEF DAMPERS

A.

Manufacturers: Subject to compliance with requirements, [provide products by the following]

[provide products by one of the following] [available manufacturers offering products that may

be incorporated into the Work include, but are not limited to, the following]:

23 33 00 rev 1

PAGE 4 OF 26

Contract No.

RC - Yanbu

B.

Air Duct Accessories

January 2012

Basis-of-Design Product: Subject to compliance with requirements, provide [product

indicated on Drawings] <Insert manufacturer's name; product name or designation> or

comparable product by one of the following:

1.

<Insert manufacturer's name>.

C.

Suitable for horizontal or vertical mounting.

D.

Maximum Air Velocity: [5.1 m/s] [16.4 m/s] [10 m/s] [13 m/s] <Insert value>.

E.

Maximum System Pressure: [0.5 kPa] [0.8 kPa] [1.5 kPa] [2.5 kPa] <Insert value>.

F.

Frame: Hat-shaped, [1.3-mm- thick, galvanized sheet steel] [2.4-mm- thick, galvanized sheet

steel] [1.6-mm- thick extruded aluminum] [0.8-mm- thick stainless steel] [1.3-mm- thick

stainless steel], with welded corners or mechanically attached[ and mounting flange].

G.

Blades:

1.

2.

3.

4.

5.

Multiple, [0.6-mm- thick, roll-formed aluminum] [1.2-mm- thick aluminum sheet].

Maximum Width: 150 mm.

Action: Parallel.

Balance: Gravity.

[Eccentrically pivoted] [Off-center pivoted] [End pivoted].

H.

Blade Seals: [Vinyl] [Neoprene].

I.

Blade Axles:

[Nonmetallic].

J.

Tie Bars and Brackets:

1.

2.

[Galvanized steel] [Nonferrous metal] [Plated steel] [Stainless steel]

Material: [Aluminum] [Galvanized steel].

Rattle free with 90-degree stop.

K.

Return Spring: Adjustable tension.

L.

Bearings: [Synthetic] [Stainless steel] [Bronze].

M.

Accessories:

1.

2.

3.

2.5

Flange on intake.

Adjustment device to permit setting for varying differential static pressures.

<Insert accessories>.

MANUAL VOLUME DAMPERS

A.

Standard, Steel, Manual Volume Dampers:

1.

23 33 00 rev 1

Manufacturers: Subject to compliance with requirements, [provide products by the

following] [provide products by one of the following] [available manufacturers

PAGE 5 OF 26

Contract No.

RC - Yanbu

Air Duct Accessories

2.

offering products that may be incorporated into the Work include, but are not

limited to, the following]:

Basis-of-Design Product: Subject to compliance with requirements, provide [product

indicated on Drawings] <Insert manufacturer's name; product name or

designation> or comparable product by one of the following:

a.

3.

4.

5.

b.

c.

b.

B.

Multiple or single blade.

Parallel- or opposed-blade design.

Stiffen damper blades for stability.

[Galvanized] [Stainless]-steel, 1.62 mm thick.

Blade Axles: [Galvanized steel] [Stainless steel] [Nonferrous metal].

Bearings:

a.

9.

Frame: Hat-shaped, [2.4-mm- thick, galvanized sheet steel] [1.3-mm- thick

stainless steel].

Mitered and welded corners.

Flanges for attaching to walls and flangeless frames for installing in ducts.

Blades:

a.

b.

c.

d.

7.

8.

<Insert manufacturer's name>.

Standard leakage rating[, with linkage outside airstream].

Suitable for horizontal or vertical applications.

Frames:

a.

6.

January 2012

[Oil-impregnated bronze] [Molded synthetic] [Oil-impregnated stainless-steel

sleeve] [Stainless-steel sleeve].

Dampers in ducts with pressure classes of 750 Pa or less shall have axles full

length of damper blades and bearings at both ends of operating shaft.

Tie Bars and Brackets: Galvanized steel.

Standard, Aluminum, Manual Volume Dampers:

1.

2.

Manufacturers: Subject to compliance with requirements, [provide products by the

following] [provide products by one of the following] [available manufacturers

offering products that may be incorporated into the Work include, but are not

limited to, the following]:

Basis-of-Design Product: Subject to compliance with requirements, provide [product

indicated on Drawings] <Insert manufacturer's name; product name or

designation> or comparable product by one of the following:

a.

3.

4.

5.

6.

23 33 00 rev 1

<Insert manufacturer's name>.

Standard leakage rating[, with linkage outside airstream].

Suitable for horizontal or vertical applications.

Frames: Hat-shaped, 2.5-mm- thick, aluminum sheet channels; frames with flanges for

attaching to walls and flangeless frames for installing in ducts.

Blades:

PAGE 6 OF 26

Contract No.

RC - Yanbu

Air Duct Accessories

a.

b.

c.

d.

e.

7.

8.

C.

Multiple or single blade.

Parallel- or opposed-blade design.

Stiffen damper blades for stability.

Roll-Formed Aluminum Blades: 2.5-mm- thick aluminum sheet.

Extruded-Aluminum Blades: 1.2-mm- thick extruded aluminum.

Blade Axles: [Galvanized steel] [Stainless steel] [Nonferrous metal].

Bearings:

a.

b.

9.

January 2012

[Oil-impregnated bronze] [Molded synthetic] [Stainless-steel sleeve].

Dampers in ducts with pressure classes of 750 Pa or less shall have axles full

length of damper blades and bearings at both ends of operating shaft.

Tie Bars and Brackets: Aluminum.

Low-Leakage, Steel, Manual Volume Dampers:

1.

2.

Manufacturers: Subject to compliance with requirements, [provide products by the

following] [provide products by one of the following] [available manufacturers

offering products that may be incorporated into the Work include, but are not

limited to, the following]:

Basis-of-Design Product: Subject to compliance with requirements, provide [product

indicated on Drawings] <Insert manufacturer's name; product name or

designation> or comparable product by one of the following:

a.

3.

4.

5.

6.

Comply with AMCA 500-D testing for damper rating.

Low-leakage rating[, with linkage outside airstream,] and bearing AMCA's Certified

Ratings Seal for both air performance and air leakage.

Suitable for horizontal or vertical applications.

Frames:

a.

b.

c.

d.

7.

Multiple or single blade.

Parallel- or opposed-blade design.

Stiffen damper blades for stability.

[Galvanized] [Stainless], roll-formed steel, 1.62 mm thick.

Blade Axles: [Galvanized steel] [Stainless steel] [Nonferrous metal].

Bearings:

a.

23 33 00 rev 1

[Hat] [U] [Angle] shaped.

[2.4-mm- thick, galvanized sheet steel] [1.3-mm- thick stainless steel].

Mitered and welded corners.

Flanges for attaching to walls and flangeless frames for installing in ducts.

Blades:

a.

b.

c.

d.

8.

9.

<Insert manufacturer's name>.

[Oil-impregnated bronze] [Molded synthetic] [Oil-impregnated stainless-steel

sleeve] [Stainless-steel sleeve].

PAGE 7 OF 26

Contract No.

RC - Yanbu

Air Duct Accessories

b.

10.

11.

12.

13.

Dampers in ducts with pressure classes of 750 Pa or less shall have axles full

length of damper blades and bearings at both ends of operating shaft.

Blade Seals: [Felt] [Vinyl] [Neoprene].

Jamb Seals: Cambered [stainless steel] [aluminum].

Tie Bars and Brackets: [Galvanized steel] [Aluminum].

Accessories:

a.

D.

January 2012

Include locking device to hold single-blade dampers in a fixed position without

vibration.

Low-Leakage, Aluminum, Manual Volume Dampers:

1.

2.

Manufacturers: Subject to compliance with requirements, [provide products by the

following] [provide products by one of the following] [available manufacturers

offering products that may be incorporated into the Work include, but are not

limited to, the following]:

Basis-of-Design Product: Subject to compliance with requirements, provide [product

indicated on Drawings] <Insert manufacturer's name; product name or

designation> or comparable product by one of the following:

a.

3.

4.

5.

6.

7.

Comply with AMCA 500-D testing for damper rating.

Low-leakage rating[, with linkage outside airstream,] and bearing AMCA's Certified

Ratings Seal for both air performance and air leakage.

Suitable for horizontal or vertical applications.

Frames: [Hat] [U] [Angle]-shaped, 2.5-mm- thick, aluminum sheet channels; frames

with flanges for attaching to walls and flangeless frames for installing in ducts.

Blades:

a.

b.

c.

d.

8.

9.

b.

[Oil-impregnated bronze] [Molded synthetic] [Oil-impregnated stainless-steel

sleeve] [Stainless-steel sleeve].

Dampers in ducts with pressure classes of 750 Pa or less shall have axles full

length of damper blades and bearings at both ends of operating shaft.

Blade Seals: [Felt] [Vinyl] [Neoprene].

Jamb Seals: Cambered [stainless steel] [aluminum].

Tie Bars and Brackets: [Galvanized steel] [Aluminum].

Accessories:

a.

23 33 00 rev 1

Multiple or single blade.

Parallel- or opposed-blade design.

Roll-Formed Aluminum Blades: 2.5-mm- thick aluminum sheet.

Extruded-Aluminum Blades: 1.2-mm- thick extruded aluminum.

Blade Axles: [Galvanized steel] [Stainless steel] [Nonferrous metal].

Bearings:

a.

10.

11.

12.

13.

<Insert manufacturer's name>.

Include locking device to hold single-blade dampers in a fixed position without

vibration.

PAGE 8 OF 26

Contract No.

RC - Yanbu

E.

Air Duct Accessories

Jackshaft:

1.

2.

3.

F.

Size: [13-mm] [25-mm] diameter.

Material: Galvanized-steel pipe rotating within pipe-bearing assembly mounted on

supports at each mullion and at each end of multiple-damper assemblies.

Length and Number of Mountings: As required to connect linkage of each damper in

multiple-damper assembly.

Damper Hardware:

1.

2.

3.

2.6

January 2012

Zinc-plated, die-cast core with dial and handle made of 2.4-mm- thick zinc-plated steel,

and a 19-mm hexagon locking nut.

Include center hole to suit damper operating-rod size.

Include elevated platform for insulated duct mounting.

CONTROL DAMPERS

A.

Manufacturers: Subject to compliance with requirements, [provide products by the following]

[provide products by one of the following] [available manufacturers offering products that may

be incorporated into the Work include, but are not limited to, the following]:

B.

Basis-of-Design Product: Subject to compliance with requirements, provide [product

indicated on Drawings] <Insert manufacturer's name; product name or designation> or

comparable product by one of the following:

1.

<Insert manufacturer's name>.

C.

Low-leakage rating[, with linkage outside airstream,] and bearing AMCA's Certified Ratings

Seal for both air performance and air leakage.

D.

Frames:

1.

2.

3.

E.

Blades:

1.

2.

3.

4.

5.

6.

F.

Multiple blade with maximum blade width of [152 mm] [200 mm].

[Parallel] [Parallel- and opposed] [Opposed]-blade design.

[Galvanized-steel] [Stainless steel] [Aluminum].

[1.62 mm thick single skin] [or] [1.9-mm- thick dual skin].

Blade Edging: [Closed-cell neoprene] [PVC].

Blade Edging: Inflatable seal blade edging, or replaceable rubber seals.

Blade Axles: 13-mm- diameter; [galvanized steel] [stainless steel] [nonferrous metal]; bladelinkage hardware of zinc-plated steel and brass; ends sealed against blade bearings.

1.

G.

[Hat] [U] [Angle] shaped.

[2.4-mm- thick, galvanized sheet steel] [1.3-mm- thick stainless steel].

[Mitered and welded] [Interlocking, gusseted] corners.

Operating Temperature Range: From minus 40 to plus 93 deg C.

Bearings:

23 33 00 rev 1

PAGE 9 OF 26

Contract No.

RC - Yanbu

Air Duct Accessories

1.

2.

3.

2.7

January 2012

[Oil-impregnated bronze] [Molded synthetic] [Oil-impregnated stainless-steel

sleeve] [Stainless-steel sleeve].

Dampers in ducts with pressure classes of 750 Pa or less shall have axles full length of

damper blades and bearings at both ends of operating shaft.

Thrust bearings at each end of every blade.

FIRE DAMPERS

A.

Manufacturers: Subject to compliance with requirements, [provide products by the following]

[provide products by one of the following] [available manufacturers offering products that may

be incorporated into the Work include, but are not limited to, the following]:

B.

Basis-of-Design Product: Subject to compliance with requirements, provide [product

indicated on Drawings] <Insert manufacturer's name; product name or designation> or

comparable product by one of the following:

1.

<Insert manufacturer's name>.

C.

Type: [Static] [Dynamic] [Static and dynamic]; rated and labeled according to UL 555 by an

NRTL.

D.

Closing rating in ducts up to [1-kPa] <Insert value> static pressure class and minimum [10m/s] <Insert value> velocity.

E.

Fire Rating: [1-1/2] [and] [3] hours.

F.

Frame: [Curtain type with blades inside airstream] [Curtain type with blades outside airstream]

[Multiple-blade type] [Curtain type with blades outside airstream except when located behind

grille where blades may be inside airstream]; fabricated with roll-formed, 0.85-mm- thick

galvanized steel; with mitered and interlocking corners.

G.

Mounting Sleeve: Factory- or field-installed, galvanized sheet steel.

1.

2.

Minimum Thickness: [1.3 mm] [3.5 mm] [or] [9.9 mm] thick, as indicated, and of

length to suit application.

Exception: Omit sleeve where damper-frame width permits direct attachment of

perimeter mounting angles on each side of wall or floor; thickness of damper frame must

comply with sleeve requirements.

H.

Mounting Orientation: Vertical or horizontal as indicated.

I.

Blades: Roll-formed, interlocking, [0.61-mm] [0.85-mm-] thick, galvanized sheet steel. In

place of interlocking blades, use full-length, 0.85-mm- thick, galvanized-steel blade connectors.

J.

Horizontal Dampers: Include blade lock and stainless-steel closure spring.

K.

Heat-Responsive Device: Replaceable, [74 deg C] [100 deg C] <Insert temperature> rated,

fusible links.

L.

Heat-Responsive Device: [Electric] [Pneumatic], [resettable] [replaceable] link and switch

package, factory installed, [74 deg C] [and] [100 deg C] <Insert temperature> rated.

23 33 00 rev 1

PAGE 10 OF 26

Contract No.

RC - Yanbu

2.8

Air Duct Accessories

January 2012

CEILING RADIATION DAMPERS

A.

Manufacturers: Subject to compliance with requirements, [provide products by the following]

[provide products by one of the following] [available manufacturers offering products that may

be incorporated into the Work include, but are not limited to, the following]:

B.

Basis-of-Design Product: Subject to compliance with requirements, provide [product

indicated on Drawings] <Insert manufacturer's name; product name or designation> or

comparable product by one of the following:

1.

C.

<Insert manufacturer's name>.

General Requirements:

1.

2.

Labeled according to UL 555C by an NRTL.

Comply with construction details for tested floor- and roof-ceiling assemblies as

indicated in UL's "Fire Resistance Directory."

D.

Frame: Galvanized sheet steel, round or rectangular, style to suit ceiling construction.

E.

Blades: Galvanized sheet steel with refractory insulation.

F.

Heat-Responsive Device: Replaceable, [74 deg C] [100 deg C] <Insert temperature> rated,

fusible links.

G.

Fire Rating: [1] [2] [3] <Insert number> hours.

2.9

SMOKE DAMPERS

A.

Manufacturers: Subject to compliance with requirements, [provide products by the following]

[provide products by one of the following] [available manufacturers offering products that may

be incorporated into the Work include, but are not limited to, the following]:

B.

Basis-of-Design Product: Subject to compliance with requirements, provide [product

indicated on Drawings] <Insert manufacturer's name; product name or designation> or

comparable product by one of the following:

1.

<Insert manufacturer's name>.

C.

General Requirements: Label according to UL 555S by an NRTL.

D.

Smoke Detector: Integral, factory wired for single-point connection.

E.

Frame: Hat-shaped, 2.4-mm- thick, galvanized sheet steel, with [welded] [interlocking,

gusseted] [or] [mechanically attached] corners[ and mounting flange].

F.

Blades: Roll-formed, horizontal, [interlocking] [overlapping], [0.85-mm-] [1.6-mm] thick,

galvanized sheet steel.

G.

Leakage: [Class I] [Class II] <Insert class>.

23 33 00 rev 1

PAGE 11 OF 26

Contract No.

RC - Yanbu

Air Duct Accessories

January 2012

H.

Rated pressure and velocity to exceed design airflow conditions.

I.

Mounting Sleeve: Factory-installed, [1.0-mm-] [1.3-mm-] thick, galvanized sheet steel; length

to suit wall or floor application[ with factory-furnished silicone calking].

J.

Damper Motors: [Modulating] [or] [two-position] action.

K.

Comply with NEMA designation, temperature rating, service factor, enclosure type, and

efficiency requirements for motors specified in Section 23 05 13 "Common Motor

Requirements for HVAC Equipment."

1.

2.

3.

4.

5.

6.

7.

L.

Accessories:

1.

2.

2.10

Motor Sizes: Minimum size as indicated. If not indicated, large enough so driven load

will not require motor to operate in service factor range above 1.0.

Controllers, Electrical Devices, and Wiring: Comply with requirements for electrical

devices and connections specified in [Section 23 09 00 "Instrumentation and Control

for HVAC."] Section <Insert Section number> "<Insert Section title>."

Permanent-Split-Capacitor or Shaded-Pole Motors: With oil-immersed and sealed gear

trains.

Spring-Return Motors: Equip with an integral spiral-spring mechanism where indicated.

Enclose entire spring mechanism in a removable housing designed for service or

adjustments. Size for running torque rating of 17 N x m and breakaway torque rating of

17 N x m.

Outdoor Motors and Motors in Outdoor-Air Intakes: Equip with O-ring gaskets designed

to make motors weatherproof. Equip motors with internal heaters to permit normal

operation at minus 40 deg C.

Nonspring-Return Motors: For dampers larger than 2.3 sq. m, size motor for running

torque rating of 17 N x m and breakaway torque rating of 34 N x m.

Electrical Connection: [115 V, single phase, 60 Hz] <Insert values>.

Auxiliary switches for [signaling] [fan control] [or] [position indication].

[Momentary test switch] [Test and reset switches], [damper] [remote] mounted.

COMBINATION FIRE AND SMOKE DAMPERS

A.

Manufacturers: Subject to compliance with requirements, [provide products by the following]

[provide products by one of the following] [available manufacturers offering products that may

be incorporated into the Work include, but are not limited to, the following]:

B.

Basis-of-Design Product: Subject to compliance with requirements, provide [product

indicated on Drawings] <Insert manufacturer's name; product name or designation> or

comparable product by one of the following:

1.

<Insert manufacturer's name>.

C.

Type: Dynamic; rated and labeled according to UL 555 and UL 555S by an NRTL.

D.

Closing rating in ducts up to [1-kPa] <Insert value> static pressure class and minimum [10m/s] <Insert value> velocity.

23 33 00 rev 1

PAGE 12 OF 26

Contract No.

RC - Yanbu

Air Duct Accessories

January 2012

E.

Fire Rating: [1-1/2] [and] [3] hours.

F.

Frame: Hat-shaped, 2.4-mm- thick, galvanized sheet steel, with [welded] [interlocking,

gusseted] [or] [mechanically attached] corners[ and mounting flange].

G.

Heat-Responsive Device: [Resettable] [Replaceable], [74 deg C] [100 deg C] rated, [fusible

links] [fire-closure device].

H.

Heat-Responsive Device: [Electric] [Pneumatic] resettable [link] [device] and switch

package, factory installed, rated.

I.

Smoke Detector: Integral, factory wired for single-point connection.

J.

Blades: Roll-formed, horizontal, [interlocking] [overlapping], [1.6-mm-] [0.85-mm-] thick,

galvanized sheet steel.

K.

Leakage: [Class I] [Class II] <Insert class>.

L.

Rated pressure and velocity to exceed design airflow conditions.

M.

Mounting Sleeve: Factory-installed, [1.0-mm-] [1.3-mm-] thick, galvanized sheet steel; length

to suit wall or floor application[ with factory-furnished silicone calking].

N.

Master control panel for use in dynamic smoke-management systems.

O.

Damper Motors: [Modulating] [or] [two-position] action.

P.

Comply with NEMA designation, temperature rating, service factor, enclosure type, and

efficiency requirements for motors specified in Section 23 05 13 "Common Motor

Requirements for HVAC Equipment."

1.

2.

3.

4.

5.

6.

7.

Q.

Motor Sizes: Minimum size as indicated. If not indicated, large enough so driven load

will not require motor to operate in service factor range above 1.0.

Controllers, Electrical Devices, and Wiring: Comply with requirements for electrical

devices and connections specified in [Section 23 09 00 "Instrumentation and Control

for HVAC."] Section <Insert Section number> "<Insert Section title>."

Permanent-Split-Capacitor or Shaded-Pole Motors: With oil-immersed and sealed gear

trains.

Spring-Return Motors: Equip with an integral spiral-spring mechanism where indicated.

Enclose entire spring mechanism in a removable housing designed for service or

adjustments. Size for running torque rating of 17 N x m and breakaway torque rating of

17 N x m.

Outdoor Motors and Motors in Outdoor-Air Intakes: Equip with O-ring gaskets designed

to make motors weatherproof. Equip motors with internal heaters to permit normal

operation at minus 40 deg C.

Nonspring-Return Motors: For dampers larger than 2.3 sq. m, size motor for running

torque rating of 17 N x m and breakaway torque rating of 34 N x m.

Electrical Connection: 115 V, single phase, 60 Hz.

Accessories:

23 33 00 rev 1

PAGE 13 OF 26

Contract No.

RC - Yanbu

Air Duct Accessories

1.

2.

2.11

January 2012

Auxiliary switches for [signaling] [fan control] [or] [position indication].

[Momentary test switch] [Test and reset switches], [damper] [remote] mounted.

CORRIDOR DAMPERS

A.

Manufacturers: Subject to compliance with requirements, [provide products by the following]

[provide products by one of the following] [available manufacturers offering products that may

be incorporated into the Work include, but are not limited to, the following]:

B.

Basis-of-Design Product: Subject to compliance with requirements, provide [product

indicated on Drawings] <Insert manufacturer's name; product name or designation> or

comparable product by one of the following:

1.

<Insert manufacturer's name>.

C.

General Requirements: Label combination fire and smoke dampers according to UL 555 for 1hour or 1-1/2-hour rating by an NRTL.

D.

Heat-Responsive Device: Replaceable, [74 deg C] [100 deg C] rated, fusible links.

E.

Heat-Responsive Device: [Electric] [Pneumatic] resettable [link] [device] and switch

package, factory installed, rated.

F.

Frame: Hat-shaped, 2.4-mm- thick, galvanized sheet steel, with [welded] [interlocking,

gusseted] [or] [mechanically attached] corners[ and mounting flange].

G.

Blades: Roll-formed, horizontal, [interlocking] [overlapping], 0.85-mm- thick, galvanized

sheet steel.

H.

Mounting Sleeve: Factory-installed, [1.0-mm-] [1.3-mm-] thick, galvanized sheet steel; length

to suit wall or floor application.

I.

Damper Motors: [Modulating] [or] [two-position] action.

J.

Comply with NEMA designation, temperature rating, service factor, enclosure type, and

efficiency requirements for motors specified in Section 23 05 13 "Common Motor

Requirements for HVAC Equipment."

1.

2.

3.

4.

23 33 00 rev 1

Motor Sizes: Minimum size as indicated. If not indicated, large enough so driven load

will not require motor to operate in service factor range above 1.0.

Controllers, Electrical Devices, and Wiring: Comply with requirements for electrical

devices and connections specified in [Section 23 09 00 "Instrumentation and Control

for HVAC."] Section <Insert Section number> "<Insert Section title>."

Permanent-Split-Capacitor or Shaded-Pole Motors: With oil-immersed and sealed gear

trains.

Spring-Return Motors: Equip with an integral spiral-spring mechanism where indicated.

Enclose entire spring mechanism in a removable housing designed for service or

adjustments. Size for running torque rating of 17 N x m and breakaway torque rating of

17 N x m.

PAGE 14 OF 26

Contract No.

RC - Yanbu

Air Duct Accessories

5.

6.

7.

2.12

January 2012

Outdoor Motors and Motors in Outdoor-Air Intakes: Equip with O-ring gaskets designed

to make motors weatherproof. Equip motors with internal heaters to permit normal

operation at minus 40 deg C.

Nonspring-Return Motors: For dampers larger than 2.3 sq. m, size motor for running

torque rating of 17 N x m and breakaway torque rating of 34 N x m.

Electrical Connection: 115 V, single phase, 60 Hz.

FLANGE CONNECTORS

A.

Manufacturers: Subject to compliance with requirements, [provide products by the following]

[provide products by one of the following] [available manufacturers offering products that may

be incorporated into the Work include, but are not limited to, the following]:

B.

Basis-of-Design Product: Subject to compliance with requirements, provide [product

indicated on Drawings] <Insert manufacturer's name; product name or designation> or

comparable product by one of the following:

1.

<Insert manufacturer's name>.

C.

Description: [Add-on] [or] [roll-formed], factory-fabricated, slide-on transverse flange

connectors, gaskets, and components.

D.

Material: Galvanized steel.

E.

Gage and Shape: Match connecting ductwork.

2.13

DUCT SILENCERS

A.

Manufacturers: Subject to compliance with requirements, [provide products by the following]

[provide products by one of the following] [available manufacturers offering products that may

be incorporated into the Work include, but are not limited to, the following]:

B.

Basis-of-Design Product: Subject to compliance with requirements, provide [product

indicated on Drawings] <Insert manufacturer's name; product name or designation> or

comparable product by one of the following:

1.

C.

General Requirements:

1.

2.

3.

D.

<Insert manufacturer's name>.

Factory fabricated.

Fire-Performance Characteristics: Adhesives, sealants, packing materials, and accessory

materials shall have flame-spread index not exceeding 25 and smoke-developed index not

exceeding 50 when tested according to ASTM E 84.

Airstream Surfaces: Surfaces in contact with the airstream shall comply with

requirements in ASHRAE 62.1.

Shape:

1.

23 33 00 rev 1

Rectangular straight with splitters or baffles.

PAGE 15 OF 26

Contract No.

RC - Yanbu

Air Duct Accessories

2.

3.

4.

5.

January 2012

Round straight with center bodies or pods.

Rectangular elbow with splitters or baffles.

Round elbow with center bodies or pods.

Rectangular transitional with splitters or baffles.

E.

Rectangular Silencer Outer Casing: ASTM A 653/A 653M, [Z275] [Z180], galvanized sheet

steel, [0.85 mm] [1.02 mm] thick.

F.

Round Silencer Outer Casing: ASTM A 653/A 653M, [Z275] [Z180], galvanized sheet steel.

1.

2.

3.

4.

Sheet Metal Thickness for Units up to 600 mm in Diameter: 0.85 mm thick.

Sheet Metal Thickness for Units 660 through 1000 mm in Diameter: 1.02 mm thick.

Sheet Metal Thickness for Units 1060 through 1300 mm in Diameter: 1.3 mm thick.

Sheet Metal Thickness for Units 1370 through 1500 mm in Diameter: 1.62 mm thick.

G.

Inner Casing and Baffles: ASTM A 653/A 653M, [Z275] [Z180] galvanized sheet metal, 0.85

mm thick, and with 3-mm- diameter perforations.

H.

Special Construction:

1.

2.

Suitable for outdoor use.

High transmission loss[ to achieve STC 45].

I.

Connection Sizes: Match connecting ductwork unless otherwise indicated.

J.

Principal Sound-Absorbing Mechanism:

1.

2.

Controlled impedance membranes and broadly tuned resonators without absorptive

media.

[Dissipative] [Film-lined] type with fill material.

a.

b.

3.

K.

Lining: [None] [Mylar] [Tedlar] [Fiberglas cloth] <Insert material>.

Fabricate silencers to form rigid units that will not pulsate, vibrate, rattle, or otherwise react to

system pressure variations. Do not use mechanical fasteners for unit assemblies.

1.

2.

3.

L.

Fill Material: [Inert and vermin-proof fibrous material, packed under not less

than 5 percent compression] [Inert and vermin-proof fibrous material,

packed under not less than 15 percent compression] [Moisture-proof

nonfibrous material].

Erosion Barrier: Polymer bag enclosing fill, and heat sealed before assembly.

Joints: [Lock formed and sealed] [continuously welded] [or] [flanged connections].

Suspended Units: Factory-installed suspension hooks or lugs attached to frame in

quantities and spaced to prevent deflection or distortion.

Reinforcement: Cross or trapeze angles for rigid suspension.

Accessories:

1.

23 33 00 rev 1

Integral [1-1/2] [3]-hour fire damper with access door.[ Access door to be high

transmission loss to match silencer.]

PAGE 16 OF 26

Contract No.

RC - Yanbu

Air Duct Accessories

2.

3.

4.

M.

Factory-installed end caps to prevent contamination during shipping.

Removable splitters.

Airflow measuring devices.

Source Quality Control: Test according to ASTM E 477.

1.

2.

3.

N.

Testing [of mockups ]to be witnessed by Royal Commission.

Record acoustic ratings, including dynamic insertion loss and generated-noise power

levels with an airflow of at least 10-m/s face velocity.

Leak Test: Test units for airtightness at 200 percent of associated fan static pressure or

1500-Pa static pressure, whichever is greater.

Capacities and Characteristics:

1.

2.

3.

4.

5.

Configuration: [Straight] [90-degree elbow] <Insert configuration>.

Shape: [Rectangular] [Round].

Attenuation Mechanism: [Acoustical glass fiber] [Acoustical glass fiber with

protective film liner] [Helmholtz resonator mechanism with no internal media].

Maximum Pressure Drop: [0.09 kPa] <Insert value>.

Casing:

a.

b.

c.

6.

7.

8.

9.

10.

11.

12.

13.

Attenuation: [Standard] [High transmission loss].

Outer Material: [Galvanized steel] [Stainless steel] [Aluminum].

Inner Material: [Galvanized steel] [Stainless steel] [Aluminum].

Velocity Range: <Insert L/s> to <Insert L/s>.

End Connection: [25-mm slip joint] [Flange].

Length: <Insert mm>.

Face Dimension:

a.

b.

Width: <Insert mm>.

Height: <Insert mm>.

Face Velocity: <Insert m/s>.

Dynamic Insertion Loss: <Insert dBA>.

Generated Noise: <Insert dBA>.

Accessories:

a.

b.

2.14

January 2012

Access door.

Birdscreen.

TURNING VANES

A.

Manufacturers: Subject to compliance with requirements, [provide products by the following]

[provide products by one of the following] [available manufacturers offering products that may

be incorporated into the Work include, but are not limited to, the following]:

B.

Basis-of-Design Product: Subject to compliance with requirements, provide [product

indicated on Drawings] <Insert manufacturer's name; product name or designation> or

comparable product by one of the following:

23 33 00 rev 1

PAGE 17 OF 26

Contract No.

RC - Yanbu

Air Duct Accessories

1.

C.

January 2012

<Insert manufacturer's name>.

Manufactured Turning Vanes for Metal Ducts: Curved blades of galvanized sheet steel; support

with bars perpendicular to blades set; set into vane runners suitable for duct mounting.

1.

Acoustic Turning Vanes: Fabricate airfoil-shaped aluminum extrusions with perforated

faces and fibrous-glass fill.

D.

Manufactured Turning Vanes for Nonmetal Ducts: Fabricate curved blades of resin-bonded

fiberglass with acrylic polymer coating; support with bars perpendicular to blades set; set into

vane runners suitable for duct mounting.

E.

General Requirements: Comply with SMACNA's "HVAC Duct Construction Standards - Metal

and Flexible"; Figures 4-3, "Vanes and Vane Runners," and 4-4, "Vane Support in Elbows."

F.

Vane Construction: [Single] [Double] wall.

G.

Vane Construction: Single wall for ducts up to [1200 mm] <Insert dimension> wide and

double wall for larger dimensions.

2.15

REMOTE DAMPER OPERATORS

A.

Manufacturers: Subject to compliance with requirements, [provide products by the following]

[provide products by one of the following] [available manufacturers offering products that may

be incorporated into the Work include, but are not limited to, the following]:

B.

Basis-of-Design Product: Subject to compliance with requirements, provide [product

indicated on Drawings] <Insert manufacturer's name; product name or designation> or

comparable product by one of the following:

1.

<Insert manufacturer's name>.

C.

Description: Cable system designed for remote manual damper adjustment.

D.

Tubing: [Brass] [Copper] [Aluminum].

E.

Cable: [Stainless steel] [Steel].

F.

Wall-Box Mounting: [Recessed] [Surface].

G.

Wall-Box Cover-Plate Material: [Steel] [Stainless steel].

2.16

A.

DUCT-MOUNTED ACCESS DOORS

Manufacturers: Subject to compliance with requirements, [provide products by the following]

[provide products by one of the following] [available manufacturers offering products that may

be incorporated into the Work include, but are not limited to, the following]:

23 33 00 rev 1

PAGE 18 OF 26

Contract No.

RC - Yanbu

B.

Air Duct Accessories

Basis-of-Design Product: Subject to compliance with requirements, provide [product

indicated on Drawings] <Insert manufacturer's name; product name or designation> or

comparable product by one of the following:

1.

C.

<Insert manufacturer's name>.

Duct-Mounted Access Doors: Fabricate access panels according to SMACNA's "HVAC Duct

Construction Standards - Metal and Flexible"; Figures 7-2M, "Duct Access Doors and Panels,"

and 7-3, "Access Doors - Round Duct."

1.

Door:

a.

b.

c.

d.

e.

2.

3.

c.

d.

3.

4.

5.

6.

7.

8.

9.

A.

Access Doors Less Than 300 mm Square: No hinges and two sash locks.

Access Doors up to [460 mm] Square: [Two hinges] [Continuous] and two sash

locks.

Access Doors up to 600 by 1200 mm: [Three hinges] [Continuous] and two

compression latches[ with outside and inside handles].

Access Doors Larger Than 600 by 1200 mm: [Four hinges] [Continuous] and

two compression latches with outside and inside handles.

Pressure Relief Access Door:

1.

2.

2.17

Double wall, rectangular.

Galvanized sheet metal with insulation fill and thickness as indicated for duct

pressure class.

Vision panel.

Hinges and Latches: 25-by-25-mmbutt or piano hinge and cam latches.

Fabricate doors airtight and suitable for duct pressure class.

Frame: Galvanized sheet steel, with bend-over tabs and foam gaskets.

Number of Hinges and Locks:

a.

b.

D.

January 2012

Door and Frame Material: Galvanized sheet steel.

Door: [Single wall] [Double wall with insulation fill] with metal thickness applicable

for duct pressure class.

Operation: Open outward for positive-pressure ducts and inward for negative-pressure

ducts.

Factory set at [800 to 2000 Pa] [2500 Pa] <Insert value>.

Doors close when pressures are within set-point range.

Hinge: Continuous piano.

Latches: Cam.

Seal: Neoprene or foam rubber.

Insulation Fill: 25-mm- thick, fibrous-glass or polystyrene-foam board.

DUCT ACCESS PANEL ASSEMBLIES

Manufacturers: Subject to compliance with requirements, [provide products by the following]

[provide products by one of the following] [available manufacturers offering products that may

be incorporated into the Work include, but are not limited to, the following]:

23 33 00 rev 1

PAGE 19 OF 26

Contract No.

RC - Yanbu

B.

Air Duct Accessories

January 2012

Basis-of-Design Product: Subject to compliance with requirements, provide [product

indicated on Drawings] <Insert manufacturer's name; product name or designation> or

comparable product by one of the following:

1.

<Insert manufacturer's name>.

C.

Labeled according to UL 1978 by an NRTL.

D.

Panel and Frame: Minimum thickness [1.3-mm carbon] [1.1-mm stainless] steel.

E.

Fasteners: [Carbon] [Stainless] steel. Panel fasteners shall not penetrate duct wall.

F.

Gasket: Comply with NFPA 96; grease-tight, high-temperature ceramic fiber, rated for

minimum 1093 deg C.

G.

Minimum Pressure Rating: 2500 Pa, positive or negative.

2.18

FLEXIBLE CONNECTORS

A.

Manufacturers: Subject to compliance with requirements, [provide products by the following]

[provide products by one of the following] [available manufacturers offering products that may

be incorporated into the Work include, but are not limited to, the following]:

B.

Basis-of-Design Product: Subject to compliance with requirements, provide [product

indicated on Drawings] <Insert manufacturer's name; product name or designation> or

comparable product by one of the following:

1.

<Insert manufacturer's name>.

C.

Materials: Flame-retardant or noncombustible fabrics.

D.

Coatings and Adhesives: Comply with UL 181, Class 1.

E.

Metal-Edged Connectors: Factory fabricated with a fabric strip [89 mm] [146 mm] wide

attached to two strips of 70-mm- wide, 0.7-mm- thick, galvanized sheet steel or 0.8-mm- thick

aluminum sheets. Provide metal compatible with connected ducts.

F.

Indoor System, Flexible Connector Fabric: Glass fabric double coated with neoprene.

1.

2.

3.

G.

Outdoor System, Flexible Connector Fabric: Glass fabric double coated with weatherproof,

synthetic rubber resistant to UV rays and ozone.

1.

2.

3.

H.

Minimum Weight: 880 g/sq. m.

Tensile Strength: 84 N/mm in the warp and 63 N/mm in the filling.

Service Temperature: Minus 40 to plus 93 deg C.

Minimum Weight: 810 g/sq. m.

Tensile Strength: 93 N/mm in the warp and 77 N/mm in the filling.

Service Temperature: Minus 45 to plus 121 deg C.

High-Temperature System, Flexible Connectors: Glass fabric coated with silicone rubber.

23 33 00 rev 1

PAGE 20 OF 26

Contract No.

RC - Yanbu

Air Duct Accessories

1.

2.

3.

I.

J.

Glass fabric with chemical-

Minimum Weight: 474 g/sq. m.

Tensile Strength: 79 N/mm in the warp and 60 N/mm in the filling.

Service Temperature: Minus 55 to plus 260 deg C.

Thrust Limits: Combination coil spring and elastomeric insert with spring and insert in

compression, and with a load stop. Include rod and angle-iron brackets for attaching to fan

discharge and duct.

1.

2.

3.

4.

5.

6.

7.

2.19

Minimum Weight: 542 g/sq. m.

Tensile Strength: 50 N/mm in the warp and 32 N/mm in the filling.

Service Temperature: Minus 55 to plus 260 deg C.

High-Corrosive-Environment System, Flexible Connectors:

resistant coating.

1.

2.

3.

January 2012

Frame: Steel, fabricated for connection to threaded rods and to allow for a maximum of

30 degrees of angular rod misalignment without binding or reducing isolation efficiency.

Outdoor Spring Diameter: Not less than 80 percent of the compressed height of the

spring at rated load.

Minimum Additional Travel: 50 percent of the required deflection at rated load.

Lateral Stiffness: More than 80 percent of rated vertical stiffness.

Overload Capacity: Support 200 percent of rated load, fully compressed, without

deformation or failure.

Elastomeric Element: Molded, oil-resistant rubber or neoprene.

Coil Spring: Factory set and field adjustable for a maximum of 6-mm movement at start

and stop.

FLEXIBLE DUCTS

A.

Manufacturers: Subject to compliance with requirements, [provide products by the following]

[provide products by one of the following] [available manufacturers offering products that may

be incorporated into the Work include, but are not limited to, the following]:

B.

Basis-of-Design Product: Subject to compliance with requirements, provide [product

indicated on Drawings] <Insert manufacturer's name; product name or designation> or

comparable product by one of the following:

1.

C.

Noninsulated, Flexible Duct: UL 181, Class 1, 2-ply vinyl film supported by helically wound,

spring-steel wire.

1.

2.

3.

D.

<Insert manufacturer's name>.

Pressure Rating: 2500 Pa positive and 250 Pa negative.

Maximum Air Velocity: 20 m/s.

Temperature Range: Minus 23 to plus 71 deg C.

Noninsulated, Flexible Duct: UL 181, Class 1, black polymer film supported by helically

wound, spring-steel wire.

1.

23 33 00 rev 1

Pressure Rating: 1000 Pa positive and 125 Pa negative.

PAGE 21 OF 26

Contract No.

RC - Yanbu

Air Duct Accessories

2.

3.

E.

Pressure Rating: 1000 Pa positive and 125 Pa negative.

Maximum Air Velocity: 20 m/s.

Temperature Range: Minus 29 to plus 79 deg C.

Insulation R-Value: [Comply with ASHRAE/IESNA 90.1] <Insert value>.

Insulated, Flexible Duct: UL 181, Class 1, multiple layers of aluminum laminate supported by

helically wound, spring-steel wire; fibrous-glass insulation; [polyethylene] [aluminized] vaporbarrier film.

1.

2.

3.

4.

K.

Pressure Rating: 2500 Pa positive and 250 Pa negative.

Maximum Air Velocity: 20 m/s.

Temperature Range: Minus 23 to plus 71 deg C.

Insulation R-value: [Comply with ASHRAE/IESNA 90.1] <Insert value>.

Insulated, Flexible Duct: UL 181, Class 1, black polymer film supported by helically wound,

spring-steel wire; fibrous-glass insulation; [polyethylene] [aluminized] vapor-barrier film.

1.

2.

3.

4.

J.

Pressure Rating: 2280 Pa positive or negative.

Maximum Air Velocity: 25 m/s.

Temperature Range: Minus 73 to plus 224 deg C.

Insulated, Flexible Duct: UL 181, Class 1, 2-ply vinyl film supported by helically wound,

spring-steel wire; fibrous-glass insulation; [polyethylene] [aluminized] vapor-barrier film.

1.

2.

3.

4.

I.

Pressure Rating: 2500 Pa positive and 250 Pa negative.

Maximum Air Velocity: 20 m/s.

Temperature Range: Minus 29 to plus 99 deg C.

Noninsulated, Flexible Duct: UL 181, Class 0, interlocking spiral of aluminum foil.

1.

2.

3.

H.

Pressure Rating: 2500 Pa positive and 250 Pa negative.

Maximum Air Velocity: 20 m/s.

Temperature Range: Minus 29 to plus 99 deg C.

Noninsulated, Flexible Duct: UL 181, Class 1, aluminum laminate and polyester film with latex

adhesive supported by helically wound, spring-steel wire.

1.

2.

3.

G.

Maximum Air Velocity: 20 m/s.

Temperature Range: Minus 29 to plus 79 deg C.

Noninsulated, Flexible Duct: UL 181, Class 1, multiple layers of aluminum laminate supported

by helically wound, spring-steel wire.

1.

2.

3.

F.

January 2012

Pressure Rating: 2500 Pa positive and 250 Pa negative.

Maximum Air Velocity: 20 m/s.

Temperature Range: Minus 29 to plus 99 deg C.

Insulation R-value: [Comply with ASHRAE/IESNA 90.1] <Insert value>.

Insulated, Flexible Duct: UL 181, Class 1, aluminum laminate and polyester film with latex

adhesive supported by helically wound, spring-steel wire; fibrous-glass insulation;

[polyethylene] [aluminized] vapor-barrier film.

23 33 00 rev 1

PAGE 22 OF 26

Contract No.

RC - Yanbu

Air Duct Accessories

1.

2.

3.

4.

L.

Pressure Rating: 2280 Pa positive or negative.

Maximum Air Velocity: 25 m/s.

Temperature Range: Minus 29 to plus 121 deg C.

Insulation R-value: [Comply with ASHRAE/IESNA 90.1] <Insert value>.

Flexible Duct Connectors:

1.

2.

2.20

Pressure Rating: 2500 Pa positive and 250 Pa negative.

Maximum Air Velocity: 20 m/s.

Temperature Range: Minus 29 to plus 99 deg C.

Insulation R-value: [Comply with ASHRAE/IESNA 90.1] <Insert value>.

Insulated, Flexible Duct: UL 181, Class 0, interlocking spiral of aluminum foil; fibrous-glass

insulation; [polyethylene] [aluminized] vapor-barrier film.

1.

2.

3.

4.

M.

January 2012

Clamps: [Stainless-steel band with cadmium-plated hex screw to tighten band with

a worm-gear action] [Nylon strap] in sizes 75 through 460 mm, to suit duct size.

Non-Clamp Connectors: [Adhesive] [Liquid adhesive plus tape] [Adhesive plus sheet

metal screws].

DUCT SECURITY BARS

A.

Manufacturers: Subject to compliance with requirements, [provide products by the following]

[provide products by one of the following] [available manufacturers offering products that may

be incorporated into the Work include, but are not limited to, the following]:

B.

Basis-of-Design Product: Subject to compliance with requirements, provide [product

indicated on Drawings] <Insert manufacturer's name; product name or designation> or

comparable product by one of the following:

1.

<Insert manufacturer's name>.

C.

Description: [Field-fabricated] [Factory-fabricated and field-installed] [Field- or factoryfabricated and field-installed] duct security bars.

D.

Configuration:

1.

2.

3.

4.

5.

6.

23 33 00 rev 1

Frame: [51 by 6 mm flat frame] [64 by 64 by 6 mm angle] <Insert values>.

Sleeve: [0.1345-inch 3.4-mm] [4.8-mm] <Insert size>, [continuously welded] [bent]

steel frames with [25-by-25-by-4.8-mm] [38-by-38-by-3.2-mm] <Insert size> angle

frame [factory welded to 1 end] [furnished loose for field welding on other end]. To

be poured in place or set with concrete block or welded or bolted to wall, one side only.

Duct connections on both sides.

Horizontal Bars: [13 mm] [50 by 6 mm] <Insert values>.

Vertical Bars: [13 mm] [19 mm] [25 mm] [51 by 6 mm] <Insert value>.

Bar Spacing: [150 mm] <Insert value>.

Mounting: [Metal deck or roofing] [Bolted or welded] [Bolted or welded with

masonry anchors] [Ductwork or other framing] [Poured in place or set with

concrete block] [Welded or bolted to one wall (one side only] [Bar extends 150 mm

into wall].

PAGE 23 OF 26

Contract No.

RC - Yanbu

2.21

Air Duct Accessories

January 2012

DUCT ACCESSORY HARDWARE

A.

Instrument Test Holes: Cast iron or cast aluminum to suit duct material, including screw cap

and gasket. Size to allow insertion of pitot tube and other testing instruments and of length to

suit duct-insulation thickness.

B.

Adhesives: High strength, quick setting, neoprene based, waterproof, and resistant to gasoline

and grease.

PART 3 - EXECUTION

3.1

INSTALLATION

A.

Install duct accessories according to applicable details in SMACNA's "HVAC Duct

Construction Standards - Metal and Flexible" for metal ducts and in NAIMA AH116, "Fibrous

Glass Duct Construction Standards," for fibrous-glass ducts.

B.

Install duct accessories of materials suited to duct materials; use galvanized-steel accessories in

galvanized-steel and fibrous-glass ducts, stainless-steel accessories in stainless-steel ducts, and

aluminum accessories in aluminum ducts.

C.

Install [backdraft] [control] dampers at inlet of exhaust fans or exhaust ducts as close as

possible to exhaust fan unless otherwise indicated.

D.

Install volume dampers at points on supply, return, and exhaust systems where branches extend

from larger ducts. Where dampers are installed in ducts having duct liner, install dampers with

hat channels of same depth as liner, and terminate liner with nosing at hat channel.

1.

2.

Install steel volume dampers in steel ducts.

Install aluminum volume dampers in aluminum ducts.

E.

Set dampers to fully open position before testing, adjusting, and balancing.

F.

Install test holes at fan inlets and outlets and elsewhere as indicated.

G.

Install fire[ and smoke] dampers according to UL listing.

H.

Install duct security bars. Construct duct security bars from 4.18-mmsteel sleeve, continuously

welded at all joints and 13-mm- diameter steel bars, 150 mm o.c. in each direction in center of

sleeve. Weld each bar to steel sleeve and each crossing bar. Weld 63-by-63-by-6-mm steel

angle to 4 sides and both ends of sleeve. Connect duct security bars to ducts with flexible

connections. Provide 300-by-300-mm hinged access panel with cam lock in duct in each side of

sleeve.

I.

Connect ducts to duct silencers [with flexible duct connectors] [rigidly].

J.

Install duct access doors on sides of ducts to allow for inspecting, adjusting, and maintaining

accessories and equipment at the following locations:

1.

23 33 00 rev 1

On both sides of duct coils.

PAGE 24 OF 26

Contract No.

RC - Yanbu

Air Duct Accessories

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

Upstream[ and downstream] from duct filters.

At outdoor-air intakes and mixed-air plenums.

At drain pans and seals.

Downstream from manual volume dampers, control dampers, backdraft dampers, and

equipment.

Adjacent to and close enough to fire or smoke dampers, to reset or reinstall fusible links.

Access doors for access to fire or smoke dampers having fusible links shall be pressure

relief access doors and shall be outward operation for access doors installed upstream

from dampers and inward operation for access doors installed downstream from dampers.

At each change in direction and at maximum 15-m spacing.

Upstream[ and downstream] from turning vanes.

Upstream or downstream from duct silencers.

Control devices requiring inspection.

Elsewhere as indicated.

K.

Install access doors with swing against duct static pressure.

L.

Access Door Sizes:

1.

2.

3.

4.

5.

6.

January 2012

One-Hand or Inspection Access: 200 by 125 mm.

Two-Hand Access: 300 by 150 mm.

Head and Hand Access: 460 by 250 mm.

Head and Shoulders Access: 530 by 355 mm.

Body Access: 635 by 355 mm.

Body plus Ladder Access: 635 by 430 mm.

M.

Label access doors according to Section 23 05 53 "Identification for HVAC Piping and

Equipment" to indicate the purpose of access door.

N.

Install flexible connectors to connect ducts to equipment.

O.

For fans developing static pressures of 1250 Pa and more, cover flexible connectors with loaded

vinyl sheet held in place with metal straps.

P.

Connect terminal units to supply ducts[ directly or] with maximum [300-mm] <Insert value>

lengths of flexible duct. Do not use flexible ducts to change directions.

Q.

Connect diffusers or light troffer boots to ducts[ directly or] with maximum [1500-mm]

<Insert value> lengths of flexible duct clamped or strapped in place.

R.

Connect flexible ducts to metal ducts with [adhesive] [liquid adhesive plus tape] [draw bands]

[adhesive plus sheet metal screws].

S.

Install duct test holes where required for testing and balancing purposes.

T.

Install thrust limits at centerline of thrust, symmetrical on both sides of equipment. Attach

thrust limits at centerline of thrust and adjust to a maximum of 6-mm movement during start

and stop of fans.

23 33 00 rev 1

PAGE 25 OF 26

Contract No.

RC - Yanbu

3.2

Air Duct Accessories

January 2012

FIELD QUALITY CONTROL

A.

Tests and Inspections:

1.

2.

3.

4.

5.

Operate dampers to verify full range of movement.

Inspect locations of access doors and verify that purpose of access door can be

performed.

Operate fire, smoke, and combination fire and smoke dampers to verify full range of

movement and verify that proper heat-response device is installed.

Inspect turning vanes for proper and secure installation.

Operate remote damper operators to verify full range of movement of operator and

damper.

END OF SECTION 23 33 00

23 33 00 rev 1

PAGE 26 OF 26

Contract No.

You might also like

- Project Standard Specification: Duct Accessories 15820 - Page 1/9Document9 pagesProject Standard Specification: Duct Accessories 15820 - Page 1/9adel rihanaNo ratings yet

- Roof Hatch SpecificationsDocument5 pagesRoof Hatch SpecificationsMØhãmmed ØwięsNo ratings yet

- MH Galvanized Chain Link Fence SpecificationDocument9 pagesMH Galvanized Chain Link Fence Specificationyamanta_rajNo ratings yet

- Spec 3parts 6500 enDocument5 pagesSpec 3parts 6500 enCesar BosqueNo ratings yet

- Air Outlets Accessories Compliance SheetsDocument12 pagesAir Outlets Accessories Compliance Sheetsabdalrahmanshahee99No ratings yet

- Duct FittingsDocument31 pagesDuct FittingsSam Jose100% (7)

- Astm F567Document4 pagesAstm F567RUI MIGUEL SILVANo ratings yet

- Air CurtainsDocument5 pagesAir Curtainsadel rihanaNo ratings yet

- Vents and StacksDocument5 pagesVents and Stacksadel rihanaNo ratings yet

- ITCC in Riyadh Residential Complex J10-13300 08470-1 Revolving DoorsDocument16 pagesITCC in Riyadh Residential Complex J10-13300 08470-1 Revolving DoorsuddinnadeemNo ratings yet

- Chain Link Fence and Gates 32-31-13Document14 pagesChain Link Fence and Gates 32-31-13melvinkorahNo ratings yet

- Overhead Coiling Doors SpecificationDocument14 pagesOverhead Coiling Doors Specificationomar shadyNo ratings yet

- Section 233300-Air Duct Accessories (Kbe Damper)Document12 pagesSection 233300-Air Duct Accessories (Kbe Damper)Li LiuNo ratings yet

- 3046 IFC Specification 1 of 4 Divisions of Acoustic LouversDocument4 pages3046 IFC Specification 1 of 4 Divisions of Acoustic Louverskhalid husseinNo ratings yet

- Crown Home Piping ExpansionDocument5 pagesCrown Home Piping ExpansionWaleed Abd El-HamiedNo ratings yet

- Steel Silo Specifications for Mymensingh Rice ProjectDocument3 pagesSteel Silo Specifications for Mymensingh Rice ProjectCelltron SolutionsNo ratings yet

- Paper Supplies Store AT Berkat AL Awamer: Qatar International Islamic Bank (QIIB)Document7 pagesPaper Supplies Store AT Berkat AL Awamer: Qatar International Islamic Bank (QIIB)Congson JeffNo ratings yet

- SPC Occ 221319 MeDocument9 pagesSPC Occ 221319 Metarekhisham1234No ratings yet

- PLUMBINGDocument5 pagesPLUMBINGhadjie ansayNo ratings yet

- HVAC Ductwork and Casings GuideDocument10 pagesHVAC Ductwork and Casings GuidemanikantanNo ratings yet

- SECTION 07 72 00 Roof AccessoriesDocument8 pagesSECTION 07 72 00 Roof AccessoriesJuanPaoloYbañezNo ratings yet

- Domingo Pua 10190-CubiclesDocument9 pagesDomingo Pua 10190-Cubiclesjuristdaneniel.domingoNo ratings yet

- Metal Doors and Frames - MSTDocument14 pagesMetal Doors and Frames - MSTwafikmh4No ratings yet

- 23 11 23 Facility Natural-Gas PipingDocument19 pages23 11 23 Facility Natural-Gas PipingKak SofiNo ratings yet

- Metal Building Specification GuideDocument7 pagesMetal Building Specification GuideXX9No ratings yet

- I-Sys Ss Csi Section 05 15 00 SpecDocument8 pagesI-Sys Ss Csi Section 05 15 00 SpecEmil John BaticulaNo ratings yet

- Rectangular Ducts and FittingsDocument31 pagesRectangular Ducts and FittingsSreejith MpNo ratings yet

- Duct Accessories Specification GuideDocument0 pagesDuct Accessories Specification GuidemanikantanNo ratings yet

- ITCC in Riyadh Residential Complex J10-13300 08120-1 Aluminum Doors and FramesDocument6 pagesITCC in Riyadh Residential Complex J10-13300 08120-1 Aluminum Doors and FramesuddinnadeemNo ratings yet

- Specification Facta For Access Hatches (Access Covers)Document20 pagesSpecification Facta For Access Hatches (Access Covers)mochammad yudyanto100% (1)

- Summary of Chain Link Fence UpdatesDocument11 pagesSummary of Chain Link Fence UpdatesAnonymous vh1f95o8No ratings yet

- Split-System Air ConditioningDocument6 pagesSplit-System Air Conditioningadel rihanaNo ratings yet

- Roof Specialties for Alamein Downtown TowersDocument6 pagesRoof Specialties for Alamein Downtown TowersWENDING HUNo ratings yet

- SECTION 09 2200 Metal Support AssembliesDocument5 pagesSECTION 09 2200 Metal Support AssembliesShajit KumarNo ratings yet

- A 822 - 90 r00 Qtgymi9bodiyts1sruqDocument5 pagesA 822 - 90 r00 Qtgymi9bodiyts1sruqsachinguptachdNo ratings yet

- Project Standard Specification: Meters and Gages 15122 - Page 1/10Document10 pagesProject Standard Specification: Meters and Gages 15122 - Page 1/10adel rihanaNo ratings yet

- 08 63 00 PDFDocument11 pages08 63 00 PDFAnonymous hk1fhAkwyNo ratings yet

- Metal Locker Installation GuideDocument9 pagesMetal Locker Installation GuideBack to SumateraNo ratings yet

- Metal Duct SpecificationDocument12 pagesMetal Duct Specificationadel rihanaNo ratings yet

- Fan SpecificationsDocument12 pagesFan SpecificationsFalak KhanNo ratings yet

- Tube Reduction ProcedureDocument4 pagesTube Reduction Procedurejcarlos7411No ratings yet

- Section 221513 - General-Service Compressed-Air Piping.1Document9 pagesSection 221513 - General-Service Compressed-Air Piping.1jkhgvdj mnhsnjkhgNo ratings yet

- Cable TraysDocument4 pagesCable TraysMohammed Hussain OMNo ratings yet

- Division 8 - Doors and Windows Section 08111 - Steel Doors and Frames Part 1 - GeneralDocument10 pagesDivision 8 - Doors and Windows Section 08111 - Steel Doors and Frames Part 1 - GeneralOrin Orang InsyafNo ratings yet

- Manual For Duct Work SpecificationsDocument18 pagesManual For Duct Work SpecificationsAmos OchienoNo ratings yet

- CVS3 HVAC Duct Metal Work Specifications FINALDocument8 pagesCVS3 HVAC Duct Metal Work Specifications FINALMohammed MohieNo ratings yet

- Ductworks - RevDocument6 pagesDuctworks - RevLuis Gabriel BautistaNo ratings yet

- Metal Building Guide Specs PerformanceDocument10 pagesMetal Building Guide Specs Performanceyogesh100% (1)

- Section 09111 Non-Load-Bearing Steel Framing Part 1Document94 pagesSection 09111 Non-Load-Bearing Steel Framing Part 1jacksondcplNo ratings yet

- Pacific Stair SpecificationDocument3 pagesPacific Stair SpecificationCharlene De AsisNo ratings yet

- FL - Aluminum Doors and WindowsDocument9 pagesFL - Aluminum Doors and WindowsAmro Ahmad AliNo ratings yet

- Vibration Isolation - RevDocument3 pagesVibration Isolation - RevLuis Gabriel BautistaNo ratings yet

- Furring For Gypsum Board CeilingsDocument4 pagesFurring For Gypsum Board Ceilingsjack.simpson.changNo ratings yet

- Hot-rolled steel product catalogueDocument30 pagesHot-rolled steel product catalogueShankar PranavNo ratings yet

- Break ElongationDocument3 pagesBreak ElongationPHILIPANTHONY MASILANGNo ratings yet

- ITCC in Riyadh Residential Complex J10-13300 10200-1 Louvers and VentsDocument6 pagesITCC in Riyadh Residential Complex J10-13300 10200-1 Louvers and VentsuddinnadeemNo ratings yet

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Dimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyFrom EverandDimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyNo ratings yet

- Manila Bulletin-1Document86 pagesManila Bulletin-1Art JamesNo ratings yet

- Manila Bulletin-2Document48 pagesManila Bulletin-2Art JamesNo ratings yet

- PIc F 8159estimateDUCTDocument26 pagesPIc F 8159estimateDUCTArt JamesNo ratings yet

- Stock S Current Price Buy Below Price Target Price Expected Growth Action To Take AC AP CEB EEI Fgen LRI MBT MEG MER SMPHDocument1 pageStock S Current Price Buy Below Price Target Price Expected Growth Action To Take AC AP CEB EEI Fgen LRI MBT MEG MER SMPHArt JamesNo ratings yet

- FL - Hvac Water TreatmentDocument28 pagesFL - Hvac Water TreatmentArt JamesNo ratings yet

- FL - Heat Exchangers For HvacDocument11 pagesFL - Heat Exchangers For HvacArt JamesNo ratings yet

- Radiant Heating Electric CablesDocument7 pagesRadiant Heating Electric CablesArt JamesNo ratings yet

- TOC-Specs (May. 07)Document6 pagesTOC-Specs (May. 07)Art JamesNo ratings yet

- DUCT Calculation 8159Document16 pagesDUCT Calculation 8159Art JamesNo ratings yet

- Section 01150Document27 pagesSection 01150Art JamesNo ratings yet

- FL - Facility Liquefied-Petroleum Gas PipingDocument41 pagesFL - Facility Liquefied-Petroleum Gas PipingArt JamesNo ratings yet

- FL - Evaporative Refrigerant CondensersDocument19 pagesFL - Evaporative Refrigerant CondensersArt JamesNo ratings yet

- FL - Unit HeatersDocument13 pagesFL - Unit HeatersArt JamesNo ratings yet

- FL - Exp Fittings and Loops For HVAC PipingDocument8 pagesFL - Exp Fittings and Loops For HVAC PipingArt JamesNo ratings yet

- FL - General-Duty Valves For Hvac PipingDocument61 pagesFL - General-Duty Valves For Hvac PipingArt JamesNo ratings yet

- FL - Computer-Room Air-ConditionersDocument16 pagesFL - Computer-Room Air-ConditionersArt JamesNo ratings yet

- HVAC Casings for Yanbu Royal CommissionDocument12 pagesHVAC Casings for Yanbu Royal CommissionArt JamesNo ratings yet

- RC-Yanbu Escutcheon SpecDocument3 pagesRC-Yanbu Escutcheon SpecArt JamesNo ratings yet

- FL - Hvac Power VentilatorsDocument16 pagesFL - Hvac Power VentilatorsArt JamesNo ratings yet

- Date: 22 October 2008 Pic G-1613004: Ro Water Treatment Plant For Hemodialysis UseDocument1 pageDate: 22 October 2008 Pic G-1613004: Ro Water Treatment Plant For Hemodialysis UseArt JamesNo ratings yet

- Ventilation System Specs for Wet Well KioskDocument1 pageVentilation System Specs for Wet Well KioskArt JamesNo ratings yet

- 15652-Central Air Conditioning EquipmentDocument19 pages15652-Central Air Conditioning EquipmentArt JamesNo ratings yet

- Fire PumpDocument6 pagesFire PumpArt JamesNo ratings yet

- Total LoadDocument1 pageTotal LoadArt JamesNo ratings yet

- BS 8010-2.8 1992 Amendment PDFDocument2 pagesBS 8010-2.8 1992 Amendment PDFArt JamesNo ratings yet

- Check List IndexDocument2 pagesCheck List IndexArt JamesNo ratings yet

- Fire FightingDocument8 pagesFire FightingArt JamesNo ratings yet

- Every Electrical Component Has A Rated Steady State Current Specified at A Certain Ambient TemperatureDocument1 pageEvery Electrical Component Has A Rated Steady State Current Specified at A Certain Ambient TemperatureArt JamesNo ratings yet

- BS 5345-4 1977 PDFDocument18 pagesBS 5345-4 1977 PDFArt JamesNo ratings yet

- 514Document8 pages514hubert_veltenNo ratings yet

- Spring GradesDocument2 pagesSpring GradesReddy Sadhana0% (1)

- GIS 46-010-New Pressure VesselsDocument87 pagesGIS 46-010-New Pressure VesselsPippo Pippo100% (1)

- PAUT for Heavy Wall Austenitic SS WeldsDocument10 pagesPAUT for Heavy Wall Austenitic SS WeldsrupamNo ratings yet

- 1700 Series - Tech Specification (02-2020)Document72 pages1700 Series - Tech Specification (02-2020)Jiieee YpNo ratings yet

- Corrosion Rate Experiment of Steel and Stainless SteelDocument4 pagesCorrosion Rate Experiment of Steel and Stainless SteelNurul HusnaNo ratings yet

- 01 EJS Metal Technical CatalogDocument85 pages01 EJS Metal Technical CatalogGicuNo ratings yet

- Needle ValvesDocument38 pagesNeedle ValvesRavichandran MohanNo ratings yet

- SS304 Spec SheetDocument9 pagesSS304 Spec Sheetjeff501No ratings yet

- Float Tape Level Gauges 1 PDFDocument3 pagesFloat Tape Level Gauges 1 PDFpippalla aswiniNo ratings yet

- Pressure GaugesDocument36 pagesPressure GaugessenthilrsenthilNo ratings yet

- Materials Reliability Program A Review of Thermal Aging Embrittlement in Pressurized Water Reactors (MRP-80) PDFDocument116 pagesMaterials Reliability Program A Review of Thermal Aging Embrittlement in Pressurized Water Reactors (MRP-80) PDFJorge PerdigonNo ratings yet

- Microbiologically Influenced Corrosion (Mic)Document2 pagesMicrobiologically Influenced Corrosion (Mic)MohamedNo ratings yet

- Materials For SpacecraftDocument29 pagesMaterials For SpacecraftAhmed EsmatNo ratings yet

- Optimization of Cooling TowersDocument49 pagesOptimization of Cooling TowersKhalil LasferNo ratings yet

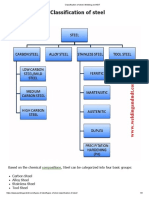

- Classification of Steel - Welding and NDTDocument3 pagesClassification of Steel - Welding and NDTAshif Iqubal100% (1)

- Manual and Semi-automatic Analysers Detect Copper and Silver CorrosionDocument1 pageManual and Semi-automatic Analysers Detect Copper and Silver CorrosionJorge EpbNo ratings yet