Professional Documents

Culture Documents

Us2960824 PDF

Uploaded by

grigOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Us2960824 PDF

Uploaded by

grigCopyright:

Available Formats

Nov.

22, 1960

'

.H. PLUMMER

2,960,824

ROCKET swam FOR GAS mama ,

Filed Aug. 1, 1955

'

2 Shuts-Sheet 1

Z T

32

22

2/

24

Z7 29 a

3 on

_'

3/

as

/6

'

42/441

' y,

,-~'J"

"I'M __,,'-'-'-"

/2

70.

////I~~~~~~~ __

25

I //l, I

~~~~

c we"

coco

as

43

/20

1-

I7

/5

0,,

L

'

3"

'

0.1

,0

--

2 0-

35

28}

63

45

H. PLUMMEIR

INVEN TOR.

BY

ATTORNEY

Nov. 22,1960

H. PLU-MMER v- -

2,960,824

ROCKET STARTER FOR GAS mama

Filed Aug. 1, 1955'

,

2 Sheets-Sheet 2

ILPLUMMER

JNVENTOR.

BY

ATTORNEY

United States Patent O?ice

.1

2,960,824

Patented Nov. 22, 1960

2

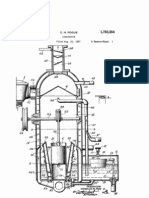

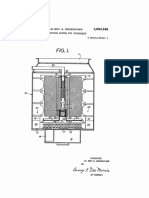

Fig. 6 is a sectional view on an enlarged scale :show

ing the rocket ?ring squib and circuit.

92,960,824

The engine illustrated is of the jet type and comprises

an enclosed sheet metal casing 10 which is substantially

ROKET STARTER FOR GAS TURBINE

Ilarold Plummer, La Jolla, Calif., assignor to Rohr Air

symmetrical about a horizontal airis 11 of a power shaft

craft Corporation, Chula Vista, Calif., a corporation of

California

Filed Aug. 1, 1955, Ser. No. 525,461

5 Claims. (Cl. 6039.14)

12, the casing having a cylindrical front portion 13, an

intermediate cylindrical portion 14 of larger diameter,

and a Venturi tube 15 having a constricted circular

portion 16 spaced from the downstream end 17 of the

10 casing. At its upstream end the engine has at its center

a convex nose 18 which de?ects the entering air into an

axial multistage air compressor 19 of known type. The

rotor 20 of the compressor has secured to its periphery

a number of sets of curved blades 21 between which are

This invention relates to the use of a solid propellant 15 mounted the sets of stationary blades 22 which are sup

fuel charge for substantially increasing the air supply and

ported at their outer ends by section 13 of the casing.

After the compressed air leaves compressor 19, it travels

also the ?ow of exhaust gas through the tail pipe of a

between casing 10 and an interior shell 23 which has an

gas turbine engine at starting.

inwardly converging wall portion 24, a cylindrical center

Rocket assists in the form of Jato bottles mounted

on airplanes at points remote from the jet engines have 20 wall portion 25 and an outwardly diverging wall 26, the

downstream end of which supports a ring of spaced apart

been used to accelerate the plane at take-off. When

turbine stator blades 27 of gas turbine 28. Blades 27'

such a rocket is used at starting, the drag or work of

de?ect the hot combustion gases against a set of curved

forcing air through the turbine has to be ?rst overcome

turbine blades 29, the latter blades being secured to the

by the rocket so that a substantial delay results before

the gas turbine becomes e?icient and overcomes its own 25 periphery of rotor 30 which is attached to the end of

shaft 12. It will be understood that shaft 12 is supported

starting air drag. The gas turbine therefore does not

for free rotation by spaced apart thrust bearings of any

known type (not shown). Eight fuel burners 31 are

shown for generating the hot combustion gases which

According to my invention, the rocket is placed cen

trally inside the upstream end of the tail pipe and is ?red 30 propel the airplane while cruising, these burners being

assist the rocket e?iciently until after the airplane has

reached take-oif speed.

at the same time that the turbine is started so very

quickly thereafter the thrust from the turbine exhaust

assists the rocket in securing take-off before the airplane

reaches its maximum speed. This provides a more rapid

of similar construction and each having a spray nozzle

32 which directs a spray of liquid fuel into a combustion

chamber 33 and ignition means (not shown) operable in

association with initial supply of the fuel in a well known

acceleration of the airplane so that a shorter runway is 35 manner. The wall of this chamber is tapered, as shown,

and is provided with a number of small holes 34 which

required for take-off.

admit the compressed air to the combustion zone in the

An object of the invention is the provision of a rocket

chamber. Gasoline, kerosene or other liquid fuel is

unit in place of the conventional turbine starting unit,

supplied to the nozzles 32 from a circular pipe 35 which

encircles casing 10 and is connected to the individual

nozzles by short connectors 36. The fuel is supplied

A further object is to provide a hollow support in the

from a storage tank (not shown) on the airplane to pipe

tailpipe to insulate, enclose and support a container in

35 through a supply pipe 36 and adjustable valve 37

which the propellant charge is disposed, the container

which is opened and closed by rotating a lever 38 through

having one or more ?lling openings through which a

second charge may be inserted after the ?rst has been 45 an angle of the order of 90 degrees. Lever 38 is con

nected with the operating handle 39 of a switch 40 (Fig.

?red.

6) by any suitable linkage 41, indicated schematically

Another object is the provision of an electrical circuit

by the dash line.

for ?ring the charge, the circuit including a pair of con

The hot gases resulting from the combustion of the fuel

tacts which are automatically brought into engagement

with each other when the rocket unit is inserted in the 50 impinge against turbine blades 29 whose rotation rotates

shaft 12 which drives air compressor 19. After leaving

tailpipe.

the turbine the hot combustion gases pass through the

Another object is to provide a single control means

annular channel 42 lying between converging tube 15

located at a place convenient to the pilot for simulta

and the frusto-conical peripheral wall 43 of hollow rocket

neously ?ring the rocket and turning on the fuel for the

55 housing 44. From here the gases continue through tube

fuel nozzles of turbine.

15 where they are accelerated in accordance with my in

Further objects will become apparent as a description

vention and issue from tube end 17 as a propulsion jet

of the engine proceeds. For a better understanding of

which thrusts the engine forward. This forward thrust

the invention, reference is made to the accompanying

is transmitted to the nacelle 45 within which the engine is

drawings, in which:

which can easily be placed and fastened in position in

the upstream end of a jet engine tailpipe.

Fig. l is a view partly diagrammatic and partly in

section of a jet engine embodying the invention also

showing the nacelle of an airplane,

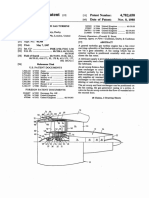

Fig. 2 is a diagrammatic view through the line 22 of

secured and to the airplane wing or fuselage (not shown)

which carries the nacelle in a known manner.

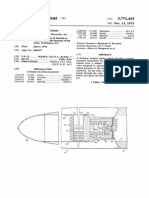

The upstream end of hollow rocket housing 44 (see

Fig. 4) is closed by a circular plate 46 having an offset

?ange 47 hermetically secured to wall 43 and the housing

Fig. 1,

65 has a cylindrical tube 48 whose upstream end is hermeti

Fig. 3 is a sectional view through the line 3-3 of

cally secured to plate 46. The downstream end of tube

Fig. 1,

48 has a vertical annular ?ange 49 whose periphery is

Fig. 4 is an enlarged view of portion of the turbine,

hermetically secured to the downstream end of wall 43.

the engine tailpipe with a rocket therein also showing

Flange 49 is tapped to receive the threaded ends of three

the electrical circuit for ?ring the rocket,

70 or more screws 50 which pass through an annular ?ange

51 on the end of rocket 52 and secure the rocket in

Fig. 5 is a rear view showing the center portion of

the rocket mounting of Fig. 4, and

place.

Rocket housing 44 is secured in place by six

2,960,824

tubes 53 whose outer ends are fastened to tube 15.

has to manipulate at take-off adds to the convenience,

Housing 44 is ?lled with heat insulating material 54

speed and safety of take-off.

such as asbestos, an insulated wire 55 passing from

switch 40 through one of the tubes 53 and terminating in

a metal contact v5,6 carried by a plug 57 made of insulating

material and screwed into a threaded hole in tube 48

(see Fig. 6). Current is supplied to contact 56 by any

suitable current source, such as a battery 58.

The

rocket contains a cylindrical propellant charge 59 which

A further advantage of the invention is that no addi

tional equipment need be provided on the airplane for

mounting the rocket 52 which is put in space within

frusto-conical wall 43 which would otherwise be wasted.

My rocket assist is also of much less weight and less

expensive to construct and install than the conventional

starting unit which must be carried on the airplane in

isignited at its rear face by a powder squib 6!} comprising 10 order to start the turbine away from the home airport.

a metal collar 61 attached to rocket 52 and having a de

pending wire 62. Collar 61 has a plug 63 of insulation

material seated in its upper end, the plug having a spring

After the airplane has landed and the engine stopped,

the screws 50 are loosened and the empty rocket 52 re

moved. Another full rocket may immediately be in

erted and the screws 50 tightened whereupon the engine

64 adapted to frictlonally engage contact 56 when the 15 may be restarted upon the pilots moving handle 39 to

cartridge is slid forward into the position shown in Fig.

restart the engine in the manner above described.

attached thereto, the spring having spaced apart leaves

4. The upper end of a wire 65 is attached to spring 64,

a spark passing in the gap between the bottom ends of

This invention may be embodied in other forms or

carried out in other ways without departing from the

wires 6265 to ignite the powder 66 in the squib when

spirit or essential characteristics thereof. The present

switch 40 is closed.

20 embodiment of the invention is therefore to be considered

At its forward end the cylindrical portion of rocket

as in all respects illustrated and not restrictive, the scope

52 is externally threaded to receive threaded closure cap

of the invention being indicated by the appended claims,

67, whose peripheral face has a sliding ?t in tube 48 to

and all changes which come within the meaning and

guide the rocket as the latter is moved in or out of the

range of equivalency of the claims are intended to be

25 embraced therein.

tube.

The charge 59 is preferably of the restricted burning

Having thus described my invention, what I claim as

type containing potassium perchlorate as an oxidizer and

new and useful and desire to secure by Letters Patent is:

a mixture of asphalt and oil as fuel. The constituents

1. An engine adapted to generate a gaseous jet of high

are mixed while hot and the hot black liquid may be cast

velocity comprising, in combination: a long tubular en

30

into a cylindrical mold to provide a solid charge which

closing casing having an inwardly converging outlet por

will enter the rocket when closure cap 67 is removed

tion terminating in a discharge ori?ce, the length of said

before the rocket has been put in tube 15. An alterna

converging portion being substantially greater than the

tive method for charging the rocket is to unscrew a

diameter of said discharge ori?ce; a gas turbine mounted

threaded plug 68 from a threaded opening 69 in the wall

in said casing and having a rotor rotatable about an axis

of the rocket and pour the hot black liquid through open 35 in alignment with said discharge ori?ce; a set of spaced

ing 69 while the rocket is resting on closure cap 67 with

apart turbine blades attached to the periphery of said

its axis vertical. A propellant charge of the above com

rotor; a plurality of fuel burners including spray nozzles

position burns at a rate of substantially 1.5 inches per

in said casing upstream of said turbine blades; a conduit

second so a charge 45 inches long would burn for 30

connected to said nozzles to supply liquid fuel thereto;

seconds, the combustion gases issuing from the rocket

a valve in said conduit to regulate the ?ow of fuel to

at a velocity of from 5,000 to 5,600 feet per second.

said nozzles; a long mass of restricted burning solid

To start the engine, the airplane pilot moves handle

propellant within the converging portion of said casing

39, which is located in the cockpit within convenient

and in alignment with the axis of said rotor, the down

reach, to close switch 43 and simultaneously open fuel

stream end of said propellant being spaced a substantial

valve 37. The closure of switch 40 causes a spark in the

distance upstream from said discharge ori?ce; a container

gap between the ends of wires 62 and 65, thereby ?ring

surrounding said propellant mass and having an outlet

the squib 60 and igniting propellant charge 59. The

portion constructed to direct the hot gas generated by

hot gases from this charge at once commence passing

the combustion of said propellant toward said discharge

through Venturi tube 15 and issuing from its end 17 to

ori?ce at high velocity; electrically operated means for

provide a large forward thrust. The hot gases also

igniting said propellant at the downstream end thereof;

cause tube 15 to function as a jet pump, causing a large

an electrical circuit including a switch connected to en

volume of air to be drawn through the compressor and

support combustion in the combustion chambers 33.

ergize said electrically operated means; and a movable

control member operatively connected to said switch

The hot combustion gases at once cause turbine blades

and valve and constructed to open said valve and close

29 to rotate and the gases pass through channel 42 and 55 said switch in response to movement of said control

tube 15 to add to the forward thrust. As the turbine

member in one direction.

speeds up, air compressor 19 supplies an increasing

2. A gas turbine having a rotor provided with a set

volume of air to burn the additonal fuel supplied by valve

of rotor blades, a set of fuel burners including spray

37 as this valve is further opened by movement of handle

nozzles disposed upstream from said blades and means

39 toward its ?nal position at which the valve is fully 60 for supplying liquid fuel to said nozzles; a long tubular

open and the turbine is operating at full speedv During

casing enclosing said rotor blades and nozzles, said cas

the short interval while the turbine rotor 30 is speeding

ing having a long inwardly tapering portion which ter

up, the conical jet 70 (Fig. l) of combustion gases issuing

minates at its downstream end in a constricted discharge

from rocket 52 at high speed exert a suction effect on

ori?ce in alignment with said rotor; a hollow rocket

the gas in annular channel 42 thus decreasing the back 65 housing within the tapering portion of said casing and

pressure on the turbine blades and increasing the power

developed by the engine.

With the usual Jato assist mounted on the airplane at a

distance from the engine, the pilot has to manipulate

two separate controls to ?re the Jato and feed fuel

to the engine at starting. With my invention the start

supported thereby, said rocket housing having a long

interior wall concentric with the axis of said rotor; a

long hollow metallic container insertable through said

discharge ori?ce and having its major portion disposed

within said interior wall, said container being readily

attachable to and detachable from said rocket housing

ing operation is simpli?ed in that the pilot has to move

through said ori?ce and having a solid closure member

only a single control, 39. This is desirable since any

secured across its upstream end; a long mass of restricted

method which decreases the number of controls the pilot 75 burning solid propellant within, said container forgenerat:

2,960,824

5

ing a jet of hot combustion gas having a velocity greater

than 3,000 feet per second, said container having at its

downstream end a ?ared portion spaced upstream from

said discharge ori?ce by a distance at least twice the

diameter of said discharge ori?ce, said ?ared portion

being shaped to direct said jet of hot gas directly toward

ing to supply fuel for combustion with said volume of

air to generate hot gaseslto drive said turbine and com

pressor and on further opening of the valve after clos

ing of the switch to provide additional fuel to said bum

ers for combustion with the increased volume of air

supplied thereto by said compressor.

said discharge ori?ce.

'3. A turbine as claimed in claim 2, in which said solid

closure member has a peripheral ?ace in sliding contact

with the inner face of said interior Wall to guide said 10

metallic container upstream into said rocket housing.

4. A turbine as claimed in claim 2 in which said

rocket housing is provided with an inwardly sloping ex

terior conical wall whose distance from the tapering

portion of said tubular casing progressively increases 15

as said discharge ori?ce is approached; and a mass of

heat insulating material substantially ?lling the space

between said conical wall and the long interior wall of

said rocket housing.

5. An engine as claimed in claim 1 and further com 20

prising a compressor coupled to said turbine for rotation

therewith and having a large volume of air drawn there

through and into said burners by jet pump action of said

high velocity gas, said valve being constructed on open

References Cited in the ?le of this patent

UNITED STATES PATENTS

2,399,542

2,411,552

2,422,744

Collins ______________ __ Apr. 30, 1946

New ________________ __ Nov. 26, 1946

ONeil ______________ .._ June 24, 1947

2,440,305

2,610,464

2,645,999

Skinner ______________ __ Apr. 27, 1948

Knoll ______________ __ Sept. 16, 1952

Bogard ______________ __ July 21, 1953

2,676,457

2,695,366

2,735,263

2,769,305

Kramer ______________ __ Apr. 27,

Co?ey ______________ __ Nov. 23,

Charsha?an __________ __ Feb. 21,

Chernowitz __________ __ Nov. 6,

1,075,034

622,029

France _______________ .. Apr. 7, 1954

Great Britain _________ __ Apr. 26, 1949

1954

1954

1956

1956

FOREIGN PATENTS

You might also like

- SU Carbs TuningDocument13 pagesSU Carbs TuningXDBDNo ratings yet

- Jan. 4, L 1966 T. W. Spack 3,227,148Document6 pagesJan. 4, L 1966 T. W. Spack 3,227,148MainAvelNo ratings yet

- Experimental Investigation of The Influence of Fouling On Compressor Cascade Characteristics and Implications For Gas Turbine Performance by Fouflias Et Al (2010)Document12 pagesExperimental Investigation of The Influence of Fouling On Compressor Cascade Characteristics and Implications For Gas Turbine Performance by Fouflias Et Al (2010)wolf_nsNo ratings yet

- Manrose Vent Axia Ventilation Fan CatalogueDocument92 pagesManrose Vent Axia Ventilation Fan CatalogueEngJtonui100% (1)

- Piston Engines, GasTurbine Engines, Propellers PDFDocument141 pagesPiston Engines, GasTurbine Engines, Propellers PDFAakash SawaimoonNo ratings yet

- PIM130B1 - Honeywell AGT1500 Archived 03 2009 PDFDocument10 pagesPIM130B1 - Honeywell AGT1500 Archived 03 2009 PDF13421301508No ratings yet

- DGS SealDocument87 pagesDGS SealAhtsham Ahmad50% (2)

- Chapter Four: Steam TurbineDocument23 pagesChapter Four: Steam Turbineserverbek0527No ratings yet

- Basic of Gas Turbine Operating and Maintenance ConsiderationsDocument36 pagesBasic of Gas Turbine Operating and Maintenance Considerationssarizal100% (1)

- Charles Nelson Pogue - US Patent - 1759354Document18 pagesCharles Nelson Pogue - US Patent - 1759354PM100% (1)

- Chapter No 3 Air CompressorsDocument59 pagesChapter No 3 Air Compressorsahsan8arshad-4No ratings yet

- Experiment of Refrigeration and Air ConditioningDocument30 pagesExperiment of Refrigeration and Air ConditioningNitin KumarNo ratings yet

- US4143639 Friction Heat Space Heater, Eugene FrenetteDocument6 pagesUS4143639 Friction Heat Space Heater, Eugene FrenetteBastien Gall de SilléNo ratings yet

- H. O. Pedersen Etal: 2 Sheets-Sheet 1 Filed March 20, 1962Document4 pagesH. O. Pedersen Etal: 2 Sheets-Sheet 1 Filed March 20, 1962Josh FullerNo ratings yet

- Bob Neal Overunity Compression Unit - US2030759Document5 pagesBob Neal Overunity Compression Unit - US2030759John CarterNo ratings yet

- Charles Nelson Pouge (US Pat. 1750354)Document5 pagesCharles Nelson Pouge (US Pat. 1750354)GaleriaTechniki.PLNo ratings yet

- GT LL: NN W///, WM)Document5 pagesGT LL: NN W///, WM)lfilippiniNo ratings yet

- US2525422Document6 pagesUS2525422Rambabu ChNo ratings yet

- In The DrawingsDocument8 pagesIn The DrawingsLalit KumarNo ratings yet

- Aug. 26, 1969 R. M. Lockwood ETAL 3,462,955: Filed June 29, 1967Document4 pagesAug. 26, 1969 R. M. Lockwood ETAL 3,462,955: Filed June 29, 1967billy dillpickerNo ratings yet

- United States Patent (191: McguganDocument6 pagesUnited States Patent (191: McguganJamesStenhouseNo ratings yet

- Us3771455 PDFDocument3 pagesUs3771455 PDFdgfsduuwioNo ratings yet

- Jan. 7, 1936. C. N. Pogue 2,026,798: Filed Sept. 27, 1935 2. Sheets-Sheet LDocument6 pagesJan. 7, 1936. C. N. Pogue 2,026,798: Filed Sept. 27, 1935 2. Sheets-Sheet LJesus ValleNo ratings yet

- US5231917 - Wobble PistonDocument5 pagesUS5231917 - Wobble PistondevheadbotNo ratings yet

- Byyeqwla: 2 I / I I VDocument5 pagesByyeqwla: 2 I / I I VaegosmithNo ratings yet

- Us 3690255Document5 pagesUs 3690255wewewewNo ratings yet

- Err-Easels - / ' Ma. Ma @&?7hii?%: March 3, 1936. G, Gimera Et Al 2,032,695Document3 pagesErr-Easels - / ' Ma. Ma @&?7hii?%: March 3, 1936. G, Gimera Et Al 2,032,695RakeshNo ratings yet

- Sept. 13, 1966: J. Marsh EtalDocument4 pagesSept. 13, 1966: J. Marsh EtalwewewewNo ratings yet

- Us 3460614Document7 pagesUs 3460614scibduser001No ratings yet

- Carburador de Hidrógeno PatE8Document7 pagesCarburador de Hidrógeno PatE8Maximo CozzettiNo ratings yet

- Berthier Us1366863Document9 pagesBerthier Us1366863cll1968No ratings yet

- US3094165 Wheeler Manfac-PatentDocument7 pagesUS3094165 Wheeler Manfac-Patentsoubhadra nagNo ratings yet

- A Practical Guide To Free Energy' Devices: US Patent 642,434 12th November 1932 Inventor: Charles N. PogueDocument8 pagesA Practical Guide To Free Energy' Devices: US Patent 642,434 12th November 1932 Inventor: Charles N. PogueXavi Granados ContrerasNo ratings yet

- March 8, 1960 Y H. A. Longino 2,927,383: Filed June 3, 1958 2 Sheets-Sheet 1Document5 pagesMarch 8, 1960 Y H. A. Longino 2,927,383: Filed June 3, 1958 2 Sheets-Sheet 1david19775891No ratings yet

- S Chapter 27Document14 pagesS Chapter 27jesusalbeirourbanoviverosNo ratings yet

- United States Patent (19) : PerryDocument11 pagesUnited States Patent (19) : PerryDaniel MilanoNo ratings yet

- July 19, 1955: E. O. Seaver Rocket and Turbine Engine Combination For AircraftDocument4 pagesJuly 19, 1955: E. O. Seaver Rocket and Turbine Engine Combination For AircraftShubhamVishwakarmaNo ratings yet

- Filed Dec. 23, 1959: Aug. 15, 1961 L. A. Botkin 2,996,222Document4 pagesFiled Dec. 23, 1959: Aug. 15, 1961 L. A. Botkin 2,996,222sqmiNo ratings yet

- United States Patent (19) : SwearingenDocument6 pagesUnited States Patent (19) : SwearingenNicandroGonzalesNo ratings yet

- Buoyancy: The "Hidro" Self-Powered Generator of James KwokDocument14 pagesBuoyancy: The "Hidro" Self-Powered Generator of James KwokAlboresha RafidNo ratings yet

- 8%, ZGZFMWMD @144': June 4, 1968 R. E. Roy 3,386,336Document9 pages8%, ZGZFMWMD @144': June 4, 1968 R. E. Roy 3,386,336tyrer567899No ratings yet

- (1966, May 3) US3248803 Rotary Drum Heat ExchangerDocument6 pages(1966, May 3) US3248803 Rotary Drum Heat ExchangeraegosmithNo ratings yet

- Us 2397941Document3 pagesUs 2397941monem2014No ratings yet

- CarburettorsDocument3 pagesCarburettorsAlejandro GonzalezNo ratings yet

- Byfwf p41 ': March 7, 1961 O. Danyluke 2,973,909Document5 pagesByfwf p41 ': March 7, 1961 O. Danyluke 2,973,909KrozeNo ratings yet

- United States Patent: (72) 3,195,589 7/1965 Houda, Jr..................... 141/82 XDocument6 pagesUnited States Patent: (72) 3,195,589 7/1965 Houda, Jr..................... 141/82 XMustafa ŞENNo ratings yet

- CarburettorsDocument4 pagesCarburettorsAlejandro GonzalezNo ratings yet

- US2736306 Ice PatentDocument4 pagesUS2736306 Ice PatentJosh KertoNo ratings yet

- Thrust Reverser GEDocument14 pagesThrust Reverser GEMarco Raneo PezzanoNo ratings yet

- Wwkzii: Jan. 10, 1933. R. H. FarwellDocument3 pagesWwkzii: Jan. 10, 1933. R. H. Farwellmonem2014100% (1)

- Reciprocating EngineDocument4 pagesReciprocating EnginePaulFerryNo ratings yet

- CarburettorsDocument4 pagesCarburettorsAlejandro GonzalezNo ratings yet

- R.T MM MS: ' Filed July 28, 1965Document6 pagesR.T MM MS: ' Filed July 28, 1965Alexcel CorporalNo ratings yet

- Rig-E???': Gill!Document6 pagesRig-E???': Gill!luiscremaschiNo ratings yet

- April 5, 1966 B. Weiser 3,243,910: Filed Feb. 2, 1965Document4 pagesApril 5, 1966 B. Weiser 3,243,910: Filed Feb. 2, 1965fgrt490No ratings yet

- United States Patent: KiernanDocument12 pagesUnited States Patent: KiernanharisupayNo ratings yet

- 2,418,540 April 8, 1947.: R. E. BresslerDocument5 pages2,418,540 April 8, 1947.: R. E. Bresslerricva_rjNo ratings yet

- NOV-9, 1943. A. Ca. Schneider: Planetary Turbine TransmissionDocument6 pagesNOV-9, 1943. A. Ca. Schneider: Planetary Turbine Transmissionbelchior alvaroNo ratings yet

- US2210720 Rocket PatentDocument3 pagesUS2210720 Rocket PatentGedi MinsterNo ratings yet

- Patented May 4:, 1915.: (Nven ForDocument4 pagesPatented May 4:, 1915.: (Nven Forbelchior alvaroNo ratings yet

- Electrolytic Carburetor by Charles H. Garrett (Patent)Document11 pagesElectrolytic Carburetor by Charles H. Garrett (Patent)max386No ratings yet

- US3200917Document5 pagesUS3200917张淼No ratings yet

- US1926463Document3 pagesUS1926463Kamal Vijay Ram R SNo ratings yet

- Jan. 16, 1962 J. A. Lyne 3:016w99l: Filed Jan. 26, 1959 2 Sheets-Sheet 1Document5 pagesJan. 16, 1962 J. A. Lyne 3:016w99l: Filed Jan. 26, 1959 2 Sheets-Sheet 1luiscremaschiNo ratings yet

- July 5, 1949. ' R. - Hasche - 2,475,282: Filed Jan. 21, 1946 ' 2 Sheets-Sheet 1Document5 pagesJuly 5, 1949. ' R. - Hasche - 2,475,282: Filed Jan. 21, 1946 ' 2 Sheets-Sheet 1Yanpiero BalladoresNo ratings yet

- The Petrol Engine: A Text-book dealing with the Principles of Design and Construction, with a Special Chapter on the Two-stroke EngineFrom EverandThe Petrol Engine: A Text-book dealing with the Principles of Design and Construction, with a Special Chapter on the Two-stroke EngineNo ratings yet

- Scientific American Supplement, No. 611, September 17, 1887From EverandScientific American Supplement, No. 611, September 17, 1887No ratings yet

- ND As332 FSX ManualDocument18 pagesND As332 FSX ManualVinicius LinsNo ratings yet

- HVAC Practical Journal PDFDocument43 pagesHVAC Practical Journal PDFMujjo SahbNo ratings yet

- CPL AGK Mar-2019Document116 pagesCPL AGK Mar-2019Abdullah Al-aminNo ratings yet

- Project ReportDocument85 pagesProject ReportSKZZZNo ratings yet

- SEMINAR On Engine FuelDocument35 pagesSEMINAR On Engine FuelThe Indian UnderdogNo ratings yet

- Unit I TurbomachinesDocument108 pagesUnit I Turbomachinespiravi66No ratings yet

- A Compressor Is A Mechanical Device That Increases The Pressure of ADocument9 pagesA Compressor Is A Mechanical Device That Increases The Pressure of AParth PatilNo ratings yet

- Understanding Surge: Figure 1: Examining The Characteristic CurveDocument5 pagesUnderstanding Surge: Figure 1: Examining The Characteristic Curvejanju81No ratings yet

- Multidimensional Flow Modeling of The Compression Test of A Gaede Pump Stage in The Viscous RegimeDocument9 pagesMultidimensional Flow Modeling of The Compression Test of A Gaede Pump Stage in The Viscous RegimeAsif HameedNo ratings yet

- Spillback CompressorDocument3 pagesSpillback CompressorpsaradaNo ratings yet

- FM 2e SI Chap14 LectureDocument123 pagesFM 2e SI Chap14 LectureJavinKhongNo ratings yet

- ch08 SorokesDocument12 pagesch08 SorokesNoureddine NdineNo ratings yet

- M14Document30 pagesM14Imran Amaleena100% (2)

- Friction Less Compressor TechnologyDocument33 pagesFriction Less Compressor Technologyaddy548767% (3)

- 101 Pressure Ratio Single Stage Centrifugal Compressor ProgramDocument434 pages101 Pressure Ratio Single Stage Centrifugal Compressor ProgramDavid BaylissNo ratings yet

- Partial Load Behavior of Gas Turbines - A Theoreti PDFDocument9 pagesPartial Load Behavior of Gas Turbines - A Theoreti PDFFuel45No ratings yet

- Laskos 2010 MS ThesisDocument142 pagesLaskos 2010 MS Thesiscepheid_luNo ratings yet

- ME 430 Project 2Document16 pagesME 430 Project 2Izzy MirandillaNo ratings yet

- Water Jet TrusmasterDocument5 pagesWater Jet TrusmasterSagita WidyatamaNo ratings yet

- V Semster 2018Document32 pagesV Semster 2018Sanjay CNo ratings yet

- Jet - Engine DGCA QuestionsDocument6 pagesJet - Engine DGCA Questionsstuartb4uNo ratings yet