Professional Documents

Culture Documents

MEP R ES 006 Corrugated Plate Intercept Separator

Uploaded by

imyourscinCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MEP R ES 006 Corrugated Plate Intercept Separator

Uploaded by

imyourscinCopyright:

Available Formats

Doc.

No : MEP-R-ES-006

CORRUGATED PLATE INTERCEPT

SEPARATOR

Rev 0

page 1 of 6

Rev Date : 25 July 2005

PT. MEDCO E&P INDONESIA

STANDARD SPECIFICATION

FOR

CORRUGATED PLATE INTERCEPT SEPARATOR

MEP-R-ES-006, Corrugated Plate Intercept Separator, rev 0, 25 July 2005

Custodian: Surface Engineering

Doc. No : MEP-R-ES-006

CORRUGATED PLATE INTERCEPT

SEPARATOR

Rev 0

page 2 of 6

Rev Date : 25 July 2005

TABLE OF CONTENTS

PAGE

1

SCOPE

1.1

1.2

3

3

General

Item Definition

CODES AND STANDARDS

2.1

2.2

2.3

3

3

4

General Standards

Specific Standards and Codes

Applicable COMPANY Specifications

DESIGN AND FABRICATION

3.1

3.2

3.3

4

5

6

Process Design

Mechanical Design

Materials

INSPECTION AND TESTING

4.1

4.2

6

6

General

Hydrotest

DOCUMENTATION

PREPARATION FOR SHIPMENT

WARRANTY

MEP-R-ES-006, Corrugated Plate Intercept Separator, rev 0, 25 July 2005

Custodian: Surface Engineering

Doc. No : MEP-R-ES-006

CORRUGATED PLATE INTERCEPT

SEPARATOR

Rev 0

page 3 of 6

Rev Date : 25 July 2005

1

SCOPE

1.1

General

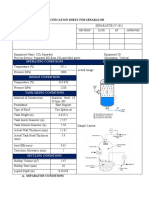

This general specification covers the minimum technical requirements for the

design, manufacture, and testing of corrugated plate interceptors (CPI). For a

specific CPI this specification shall be used in conjunction with the project

specifications and data sheets for that CPI. Any exceptions to the requirements of

this specification shall be submitted in writing for resolution by the COMPANY.

1.2

Item Definition

The corrugated plate interceptor separates solids and oil from produced water prior

to disposal or further treatment. The corrugated plate interceptor includes the

tanks, plates, support structure, and instrumentation necessary for processing and

controlling the flow of treated water. The CPI shall be capable of processing a fluid

of the composition specified on the data sheets at the pressures, temperatures,

and capacities specified at site conditions as described in MEP-G-ES-001, General

Technical Conditions for Tender and Purchase of Equipment and Materials.

CODES AND STANDARDS

2.1

General Standards

The Vendor shall consider the most recent issue of the applicable standards and

codes by the following associations and approval bodies as part of this

specification:

-

2.2

American National Standards Institute (ANSI)

American Petroleum Institute (API)

American Society for Testing and Materials (ASTM)

American Society of Mechanical Engineers (ASME)

Specific Standards and Codes

American National Standards Institute (ANSI)

B16.5 Pipe flanges and Flanged Fittings

American Petroleum Institute (API)

STD 650

Welded Steel Tanks for Oil Storage

American Society for Testing and Materials (ASTM)

MEP-R-ES-006, Corrugated Plate Intercept Separator, rev 0, 25 July 2005

Custodian: Surface Engineering

Doc. No : MEP-R-ES-006

CORRUGATED PLATE INTERCEPT

SEPARATOR

Rev 0

page 4 of 6

Rev Date : 25 July 2005

A53

Specification for Pipe, Steel, Black and Hot-Dipped, Zinc-Coated Welded

and Seamless

A283 Specification for Low and Intermediate Tensile Strength Carbon-Silicon

Steel Plates. Shapes, and Bars

American Society of Mechanical Engineers (ASME)

Section VIII

2.3

Pressure Vessels

Applicable COMPANY Specifications

The following COMPANY specifications are referenced in this specification.

MEP-G-ES-001

MEP-G-ES-002

MEP-S-ES-002

MEP-P-ES-001

MEP-P-ES-003

MEP-G-ES-008

General Technical Conditions for Tender and Purchase of

Equipment and Materials.

Requirements for Third Party Inspection

Structural Steel Construction

Piping Material Specification

Fabricated Piping and Inspection

Surface Preparation, Painting and Galvanizing

DESIGN AND FABRICATION

3.1

Process Design

3.1.1

The C.P.I. shall remove oil and suspended solids from effluent water

produced by oil and gas processing facilities. The unit shall include a tank

and packs of tilted corrugated plates inside the tank.

3.1.2

Oil in the water may be formed of fine emulsion. The produced water will

enter the C.P.I. unit from a produced water break drum (for degassing

process) by means of gravity flow. The flow may be turbulent with high

velocity.

3.1.3

In the C.P.I., the oily water velocity shall be reduced to permit the drops of

oil to separate and slowly rise to the surface. The C.P.I. shall be designed

such that oil droplets attach themselves to the underside of the plates in the

C.P.I. unit and rise by virtue of their lower specific gravity. The C.P.I. unit

shall include gutters which are designed to collect the oil droplets which

accumulate at the top of the plates. The gutters shall channel the

separated oil out of the water flow, eliminating any chance of reentrainment.

MEP-R-ES-006, Corrugated Plate Intercept Separator, rev 0, 25 July 2005

Custodian: Surface Engineering

Doc. No : MEP-R-ES-006

CORRUGATED PLATE INTERCEPT

SEPARATOR

Rev 0

page 5 of 6

Rev Date : 25 July 2005

3.2

3.1.4

The velocity of the flow through the corrugated plates shall not exceed 2.5

ft/min. The Reynolds number shall not exceed 400.

3.1.5

Vendor shall guarantee that the C.P.I. unit will produce effluent of the

specified quality above process conditions and table 1, Corrugated Plate

Intercept Separator.

Mechanical Design

3.2.1

The corrugated plate interceptor (C.P.I.) unit shall be rectangular, skid

mounted and fabricated in accordance with API-650, Welded Steel Tanks

for Oil Storage.

3.2.2

The unit shall have inspection manholes installed at the tank side wall and

on top of the unit.

3.2.3

Nozzles of the unit shall include but not be limited to water inlet and outlet

nozzles, oil outlet, vent, sludge drain, cleaning nozzles for water jet, etc.

3.2.4

A device to change the turbulent flow to laminar shall be provided.

3.2.5

A manual adjustable flow device shall be provided.

3.2.6

A daniel level gauges with gauge cocks shall be provided.

3.2.7

All piping installation shall comply with MEP-P-ES-003, Fabricated Piping

and Inspection.

3.2.8

The unit shall be equipped with ladders and platforms, including railing, all

in accordance with MEP-S-ES-002, Structural Steel Construction.

Platforms shall be fabricated of galvanized, non-slip type gratings.

3.2.9

Painting and coating of the unit shall be in accordance with

MEP-G-ES-008, Surface Preparation, Painting and Galvanizing.

3.2.10

All internal wetted metal shall be epoxy coated and suitable for operation

up to the maximum working temperature specified on the data sheet. The

coating shall be applied to comply with MEP-G-ES-008, Surface

Preparation, Painting and Galvanizing.

3.2.11

The C.P.I. Separator shall be installed above ground, skid mounted on an

oil-field type skid to rest on a concrete pad.

MEP-R-ES-006, Corrugated Plate Intercept Separator, rev 0, 25 July 2005

Custodian: Surface Engineering

Doc. No : MEP-R-ES-006

CORRUGATED PLATE INTERCEPT

SEPARATOR

Rev 0

page 6 of 6

Rev Date : 25 July 2005

3.3

Materials

3.3.1

The C.P.I. tank shall be fabricated from carbon steel with a minimum

corrosion allowance of 1/8 inch (3 mm) for all wetted surfaces.

3.3.2

Corrugated plates shall be Vendor standard materials compatible with oil

and water and process conditions.

3.3.3

Piping shall conform to MEP-P-ES-001, Piping Material Specification,

Line Spec. 1B.

3.3.4

Valves shall conform to MEP-P-ES-005, Valve Specification, Line Spec.

1B.

INSPECTION AND TESTING

4.1

General

Quality assurance shall conform to the provisions of MEP-G-ES-001, General

Technical Conditions for Tender and Purchase of Equipment and Materials and

MEP-G-ES-002, Requirements for Third Party Inspection Services with the

following additional requirements.

4.2

Hydrotest

The corrugated plate interceptor shall be leak tested (hydrotest) in accordance with

API-650, Section 5.3.6. The test will be witnessed by COMPANY's representative.

DOCUMENTATION

Documentation requirements shall be as stated in MEP-G-ES-001, and supplemental

project provisions, if applicable.

PREPARATION FOR SHIPMENT

Preparation for shipping shall comply with the requirements of MEP-G-ES-001, as a

minimum. Additional requirements may be specified in project documents.

WARRANTY

Minimum warranty requirements are specified in MEP-G-ES-001. Additional requirements

may be specified in project document.

MEP-R-ES-006, Corrugated Plate Intercept Separator, rev 0, 25 July 2005

Custodian: Surface Engineering

You might also like

- Equipment DatasheetDocument9 pagesEquipment DatasheetBimal DeyNo ratings yet

- Wet Crude Tank CorrectedDocument36 pagesWet Crude Tank CorrectedssheafiNo ratings yet

- Mucog 1910502 Mec DS 055Document12 pagesMucog 1910502 Mec DS 055vinodNo ratings yet

- LPG loading pump mechanical data sheetDocument8 pagesLPG loading pump mechanical data sheetRudin Fahrudin RahmanNo ratings yet

- PSV Sizing For Fire SpreadsheetDocument2 pagesPSV Sizing For Fire SpreadsheetKrisTian EdogawaNo ratings yet

- Perancangan Plate Adn Frame HEDocument36 pagesPerancangan Plate Adn Frame HEDavid LambertNo ratings yet

- Filter Vessel Shell VelocityDocument12 pagesFilter Vessel Shell VelocityAye KyweNo ratings yet

- N2 Purging Demand Calculation Shutdown - Flare SystemDocument54 pagesN2 Purging Demand Calculation Shutdown - Flare SystemMoch FaridNo ratings yet

- P D S F O W T P P - 6006: Rocess UTY Pecification OR ILY Ater Reatment Ackage KDocument13 pagesP D S F O W T P P - 6006: Rocess UTY Pecification OR ILY Ater Reatment Ackage KHamid MansouriNo ratings yet

- Control Valve SizingDocument3 pagesControl Valve Sizingkaveh-bahiraeeNo ratings yet

- R2B-P3-206-02-P-HD-00205 - DATASHEETS FOR CONTROL VALVE, SLIDE, U-21000 - Rev.1Document21 pagesR2B-P3-206-02-P-HD-00205 - DATASHEETS FOR CONTROL VALVE, SLIDE, U-21000 - Rev.1Diana Paula Echartea MolinaNo ratings yet

- Specification Sheet For Separator: Operating Conditions SketchDocument12 pagesSpecification Sheet For Separator: Operating Conditions SketchAngelikaOdimer100% (1)

- Pressure Safety Valve Sizing Calculation Rev 01Document4 pagesPressure Safety Valve Sizing Calculation Rev 01Fari NazariNo ratings yet

- PSV Sizing: The Relief Load Can Be Calculated Directly, in Pounds Per Hour, From The Following RelationshipDocument4 pagesPSV Sizing: The Relief Load Can Be Calculated Directly, in Pounds Per Hour, From The Following RelationshipAfees OlajideNo ratings yet

- HDPE PipeDocument3 pagesHDPE PipechowdaryharshaNo ratings yet

- LP Gas Amine Contactor Process DataDocument6 pagesLP Gas Amine Contactor Process DataEddy RainNo ratings yet

- Calculate Pressure Drop in Basket & Tee Strainers ReferenceDocument5 pagesCalculate Pressure Drop in Basket & Tee Strainers Referencebrock100% (1)

- RTN - Ttu-V-2154-001-Ste-Cal-007 - 3B Capacity Calculation Sheet For PRV & VRVDocument15 pagesRTN - Ttu-V-2154-001-Ste-Cal-007 - 3B Capacity Calculation Sheet For PRV & VRVroronoa_zorro11No ratings yet

- Fluid Handling Engineers: U S Agency - Taco DivDocument5 pagesFluid Handling Engineers: U S Agency - Taco DivsitehabNo ratings yet

- PSV D-103Document24 pagesPSV D-103DIANTORONo ratings yet

- BFW Cooler Datasheet Rev-2Document3 pagesBFW Cooler Datasheet Rev-2Anonymous iCFJ73OMpDNo ratings yet

- PT Synergy Engineering: WarningsDocument1 pagePT Synergy Engineering: Warningsokky wddNo ratings yet

- Fuel gas filter sizing calculationDocument1 pageFuel gas filter sizing calculationIndraharja FerryNo ratings yet

- Loadsheet Demin Water Pump PU-1202 ABDocument13 pagesLoadsheet Demin Water Pump PU-1202 ABGunturMudaAliAkbarNo ratings yet

- Quick estimation compressor settle out conditionsDocument1 pageQuick estimation compressor settle out conditionsAhmed GattoufiNo ratings yet

- Oil Separator SizingDocument8 pagesOil Separator SizingDavid LambertNo ratings yet

- SCPF-PETW-LIS-P-01001 - Rev0 - Utility Consumption List - CPFDocument3 pagesSCPF-PETW-LIS-P-01001 - Rev0 - Utility Consumption List - CPFSEGUNNo ratings yet

- Wastewater Treatment Plant Design PDFDocument68 pagesWastewater Treatment Plant Design PDFmostafa1alaahobaNo ratings yet

- Valve Sizing Calculation8Document2 pagesValve Sizing Calculation8PIDNo ratings yet

- Open TankDocument27 pagesOpen Tankhgagselim2012No ratings yet

- MPCL Flare KOD Pump 11442-DS-103 - IFC2 18-06-2013Document2 pagesMPCL Flare KOD Pump 11442-DS-103 - IFC2 18-06-2013zohaib_farooqNo ratings yet

- Table Convert MMSCFD To SI SKG BetungDocument132 pagesTable Convert MMSCFD To SI SKG BetungGelorawan AditNo ratings yet

- PH2-03-PLG-GRS-DS-M-005 Rev.0 Vent StackDocument16 pagesPH2-03-PLG-GRS-DS-M-005 Rev.0 Vent StackRanu JanuarNo ratings yet

- Crude Tank Bund Wall CalculationDocument2 pagesCrude Tank Bund Wall Calculationharsh_1582No ratings yet

- OrificeDocument3 pagesOrificeandi_nuNo ratings yet

- Process Calculation For FREYLIT CPI Oil SeparatorDocument4 pagesProcess Calculation For FREYLIT CPI Oil SeparatorRajdeepsinhNo ratings yet

- Oil Water Separator SizingDocument6 pagesOil Water Separator SizingMohamed Mamdouh AbdelHameedNo ratings yet

- FGCP Line Sizing CalculationsDocument86 pagesFGCP Line Sizing CalculationsToyinNo ratings yet

- Chemical System Study Provides Overview of Production and Non-Production ChemicalsDocument45 pagesChemical System Study Provides Overview of Production and Non-Production ChemicalsTifano Khristiyanto100% (2)

- Frictional Head Loss Calculation in Pumping SystemsDocument1 pageFrictional Head Loss Calculation in Pumping Systemsaman vermaNo ratings yet

- CNG ADK 3,5 MMSCFD 13 Desember 2019 New Inlet Pressure with Heater After DiDocument1 pageCNG ADK 3,5 MMSCFD 13 Desember 2019 New Inlet Pressure with Heater After Dirandi martaNo ratings yet

- Motorised Valve: Instrument Datasheet Tag NoDocument1 pageMotorised Valve: Instrument Datasheet Tag Nokrishna kumarNo ratings yet

- API650SH" Sheet A Saved As 97-09-165 Page set-up"API650SH" A1/K44 A45/K86 A87/K130 A131/K146Document11 pagesAPI650SH" Sheet A Saved As 97-09-165 Page set-up"API650SH" A1/K44 A45/K86 A87/K130 A131/K146nassmechNo ratings yet

- 541-PC-1002 Utility Consumption Summary1Document3 pages541-PC-1002 Utility Consumption Summary1svnaik14No ratings yet

- Validated SheetDocument12 pagesValidated SheetrohitkushNo ratings yet

- Indra: SonatrachDocument9 pagesIndra: SonatrachhichamNo ratings yet

- Heat duty calculationDocument6 pagesHeat duty calculationwahyuriansyahNo ratings yet

- Condensed Flare DatasheetDocument4 pagesCondensed Flare Datasheetbraviross_418157489No ratings yet

- Orifice Sizing TemplateDocument2 pagesOrifice Sizing TemplaterajeevjayanathNo ratings yet

- UASB Booster Pressure CalculationDocument143 pagesUASB Booster Pressure CalculationJayakrishnan RadhakrishnanNo ratings yet

- Specification For Air Compressors and Air Dryer PackagesDocument21 pagesSpecification For Air Compressors and Air Dryer PackagesSudjono BroNo ratings yet

- Flare Sizing CalculationDocument2 pagesFlare Sizing Calculationkristian08No ratings yet

- Bundwall SampleDocument1 pageBundwall Samplewawen03No ratings yet

- Design of Atmospheric Tanks - API650Document25 pagesDesign of Atmospheric Tanks - API650Faizal CANo ratings yet

- Line Sizing For Liquid, (DO IT OWN)Document11 pagesLine Sizing For Liquid, (DO IT OWN)sumitNo ratings yet

- KU-TWK-10-ME-DTS-0304 Rev 2 Data Sheet For Common Electrostatic Coalescer Package PDFDocument7 pagesKU-TWK-10-ME-DTS-0304 Rev 2 Data Sheet For Common Electrostatic Coalescer Package PDFRexx Mexx100% (1)

- MEP-R-ES-007-Flare Stack, Flare Tip and Flame Front GeneratorDocument10 pagesMEP-R-ES-007-Flare Stack, Flare Tip and Flame Front GeneratorimyourscinNo ratings yet

- General Specification FOR Material, Fabrication and Installation of StructureDocument58 pagesGeneral Specification FOR Material, Fabrication and Installation of Structuredang_noex56% (9)

- STD Spec - Pig TrapsDocument10 pagesSTD Spec - Pig TrapsArun MishraNo ratings yet

- Flanged Joints, Gaskets, and Bolting: ScopeDocument20 pagesFlanged Joints, Gaskets, and Bolting: Scopebenedicto soto mestanzaNo ratings yet

- Asset Tracking TemplateDocument3 pagesAsset Tracking TemplateimyourscinNo ratings yet

- T Beam Check Fy FC Mu D A HF (As.) As B ADocument2 pagesT Beam Check Fy FC Mu D A HF (As.) As B APushed AsideNo ratings yet

- 2mw Biomass Gasification Gas Power Plant ProposalDocument10 pages2mw Biomass Gasification Gas Power Plant ProposalimyourscinNo ratings yet

- Arita KatalogDocument58 pagesArita KatalogAhmed Beaet83% (6)

- As Built Drawing & Opname-Layout1Document1 pageAs Built Drawing & Opname-Layout1imyourscinNo ratings yet

- I Pekerjaan PersiapanDocument4 pagesI Pekerjaan PersiapanimyourscinNo ratings yet

- Tender SpecDocument8 pagesTender SpecimyourscinNo ratings yet

- DVS TechnicalDocument5 pagesDVS TechnicalimyourscinNo ratings yet

- E-03.0) General Static-Mixing Customer Specification QuestionnaireDocument2 pagesE-03.0) General Static-Mixing Customer Specification QuestionnaireimyourscinNo ratings yet

- Product ID Model Name Price CategoryDocument1 pageProduct ID Model Name Price CategoryimyourscinNo ratings yet

- Lap AirDocument36 pagesLap AirimyourscinNo ratings yet

- Flanged End Connection: Series F Carbon SteelDocument1 pageFlanged End Connection: Series F Carbon SteelimyourscinNo ratings yet

- Defect Report FormDocument1 pageDefect Report FormimyourscinNo ratings yet

- Stockcard DigitalDocument4 pagesStockcard DigitalGojali ZulfikarNo ratings yet

- Stuktur WWTP Tanpa Foot PlateDocument1 pageStuktur WWTP Tanpa Foot PlateimyourscinNo ratings yet

- 10 12691 Ajme-1-7-24 Fig - 1Document1 page10 12691 Ajme-1-7-24 Fig - 1imyourscinNo ratings yet

- D - Copy Dari Exhardisk 09.07.2015 - HHB Mech - As Built Drawing & Opname CoverDocument1 pageD - Copy Dari Exhardisk 09.07.2015 - HHB Mech - As Built Drawing & Opname CoverimyourscinNo ratings yet

- DMRDocument5 pagesDMRimyourscinNo ratings yet

- Perhitungan Beban Listrik UTSDocument5 pagesPerhitungan Beban Listrik UTSimyourscinNo ratings yet

- Fundamentals, Present and Future Perspectives of ElectrocoagulationDocument12 pagesFundamentals, Present and Future Perspectives of ElectrocoagulationimyourscinNo ratings yet

- Stockcard DigitalDocument4 pagesStockcard DigitalGojali ZulfikarNo ratings yet

- Iiii Iiii: IF (C117 C114 "Ok!") )Document1 pageIiii Iiii: IF (C117 C114 "Ok!") )imyourscinNo ratings yet

- DMRDocument5 pagesDMRimyourscinNo ratings yet

- 7300DDocument12 pages7300DimyourscinNo ratings yet

- 10 12691 Ajme-1-7-24 Fig - 1Document1 page10 12691 Ajme-1-7-24 Fig - 1imyourscinNo ratings yet

- 7300DDocument12 pages7300DimyourscinNo ratings yet

- Bq-Gedung-Pusbindiklat 20121121163219 0Document151 pagesBq-Gedung-Pusbindiklat 20121121163219 0zaereject18No ratings yet

- StressAnalysisReportfromInventor2009 PDFDocument8 pagesStressAnalysisReportfromInventor2009 PDFDelian KurniawanNo ratings yet

- DVS TechnicalDocument5 pagesDVS TechnicalimyourscinNo ratings yet

- 7300DDocument12 pages7300DimyourscinNo ratings yet

- Year 4 Spellings Unit 1 - 12Document2 pagesYear 4 Spellings Unit 1 - 12Bagelicius Carry it with styleNo ratings yet

- Lab Task # 2 Introduction To Programming With PythonDocument5 pagesLab Task # 2 Introduction To Programming With PythonMaryamNo ratings yet

- FMT ComputerDocument4 pagesFMT ComputerKenneth Delos SantosNo ratings yet

- Fourier Series Beku 2431 Laboratory ReportDocument5 pagesFourier Series Beku 2431 Laboratory ReportAzrul NizarNo ratings yet

- Supply Chain ManagementDocument62 pagesSupply Chain ManagementAjay KareNo ratings yet

- Google pricing templateDocument42 pagesGoogle pricing templatevinay_kNo ratings yet

- Allgon System Ab: Electrical Specifications Electrical SpecificationsDocument1 pageAllgon System Ab: Electrical Specifications Electrical SpecificationsРоманКочневNo ratings yet

- Math 7 Post TestDocument2 pagesMath 7 Post TestDonabel Carios100% (3)

- Cisco CCNA Security-SummaryDocument56 pagesCisco CCNA Security-Summaryhttp://utsit.blogspot.com.au/100% (2)

- Control Up To Six Hydraulic Functions With A Single Reel.: ApplicationsDocument2 pagesControl Up To Six Hydraulic Functions With A Single Reel.: Applicationsjads301179No ratings yet

- ACS 1000 Faults Alarms Classic0.1Document189 pagesACS 1000 Faults Alarms Classic0.1AbhishekDutta94% (16)

- UntitledDocument31 pagesUntitledSleepy AshNo ratings yet

- 5 Roll's Theorem.Document5 pages5 Roll's Theorem.Kavi SanjaiNo ratings yet

- FANUC Macro Interface ExpansionDocument10 pagesFANUC Macro Interface Expansionmahdi elmayNo ratings yet

- CHAPTER 12 - Memory Organization PDFDocument34 pagesCHAPTER 12 - Memory Organization PDFburaNo ratings yet

- BIM Ex PlanDocument40 pagesBIM Ex PlancoidoianhNo ratings yet

- Field Study 1 Episode 11Document31 pagesField Study 1 Episode 11Kent's LifeNo ratings yet

- Educational Technology: Meaning and NatureDocument275 pagesEducational Technology: Meaning and NatureammanapparaNo ratings yet

- Sylvie Nadeau (Editor) - Sustainable Development in Mechanical Engineering - Case Studies in Applied Mechanics (2015)Document179 pagesSylvie Nadeau (Editor) - Sustainable Development in Mechanical Engineering - Case Studies in Applied Mechanics (2015)Néstor CastellanosNo ratings yet

- Oracle SPARC Servers AssessmentDocument12 pagesOracle SPARC Servers AssessmentFazdlan FazNo ratings yet

- Seminar TopicsDocument11 pagesSeminar Topicsrameshchowdary113No ratings yet

- Polguide Final PalDocument15 pagesPolguide Final Paldeepak kumarNo ratings yet

- Entertainment News, Celebrity Gossip, Celebrity News - E! NewsDocument6 pagesEntertainment News, Celebrity Gossip, Celebrity News - E! NewsRas PutNo ratings yet

- AWS 110 WS Fatigue A10.1Document22 pagesAWS 110 WS Fatigue A10.1Richard Liu100% (1)

- Dell™ Ultrasharp™ 2001Fp LCD Display: QualityDocument1 pageDell™ Ultrasharp™ 2001Fp LCD Display: QualityAnonymous GBge2ED1ONo ratings yet

- 04 Power and RootDocument19 pages04 Power and RootAmit SinghNo ratings yet

- Compression: Safeen H. Rasool Assist. LecturerDocument16 pagesCompression: Safeen H. Rasool Assist. Lecturerasmahan abdulwahidNo ratings yet

- STR'L Calc. For Cuplock Scaffolding SystemDocument61 pagesSTR'L Calc. For Cuplock Scaffolding SystemZeeZ HNo ratings yet

- Application LetterDocument2 pagesApplication LetterShasha MahmudNo ratings yet

- Heat Pumps Noise Level CalcDocument10 pagesHeat Pumps Noise Level CalcZaid Al RayesNo ratings yet