Professional Documents

Culture Documents

Ucsi University B.Eng (Hons) in Chemical Engineering Course Outline

Uploaded by

tkjingOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ucsi University B.Eng (Hons) in Chemical Engineering Course Outline

Uploaded by

tkjingCopyright:

Available Formats

UCSI UNIVERSITY

B.ENG (HONS) IN CHEMICAL ENGINEERING

COURSE OUTLINE

Course Name

Course Code

Name(s) of Academic

Staff:

Category

Rationale

for

the

inclusion of the course in

the programme

Credit hour

Pre-requisite

Synopsis

Course Learning

Outcome ( CLO)

Transferrable Skills

Delivery Method

Assessment Methods and

Types

References

Reaction Engineering and Design

EP 319

Engr. Noor Rosyidah Sajuni/ Engr. Mubarak/ Prof Hikmat

Core

The course will enable the students to acquire the knowledge of reaction kinetics

basic concept, derivation of rate expressions from reaction mechanisms and

equilibrium or steady state assumptions, isothermal and non-isothermal, ideal and

non-ideal, adiabatic and non-adiabatic of batch and flow reactors. At the end of this

course, students will be able to design reactors for heterogeneous reactions and

optimise operating conditions.

4

Mass Transfer, Heat Transfer, Fluid mechanics, Surface Chemistry & Catalysis

The basic concepts of chemical rate processes are applied to the theory of the

design and operation of the various types of commercial reactors for both catalytic

reactions. Topics covered include mole balances, rate laws and stoichiometry,

collection and analysis of rate data, multiple reactors and reactions, isothermal and

non-isothermal, ideal and non-ideal reactor design, catalysis and catalytic reactors

in details.

Upon the completion of this course, students will be able to :

CLO 1: Determine the reactor size for a given chemical reaction. (C4, PLO2).

CLO 2: Determine the reaction rate and reaction order for elementary reactions.

(C4, PLO2).

CLO 3: Design batch and continuous reactors using differential and integral

methods. (C5, PLO4).

CLO 4: Calculate the selectivity and reactant conversion for reactions in

single/multiple reactors. (C4, PLO2).

CLO 5: Determine rate law and rate limiting step in catalytic reactor design.

(C4, PLO2).

Thinking and scientific skills, problem analysis

Lecture and Practical

Type of Assessment

Assessment Methods

Percentage (%)

Test

20

Written tests

Mid-term examination

20

Final examination

50

Lab experimentations

Lab reports

10

The course has four assessment components as described above.

Test: The test will usually have 3 to 4 questions of 1 hour duration.

Mid-term exam: it will be conducted on week 7-8 of the semester. .

Laboratory component: it is compulsory to attend all the lab sessions; failing to do

so may result in complete failure in the subject. The student will carry out the

experiments described below and submit a report to the lab tutor at the end of the

semester.

Final Exam: It will consist of 6 main questions. Students must answer 5 of the 6

questions. The duration of the exam will be 3 hours.

1.

2.

3.

Fogler, H.S., Elementary of Chemical Reaction Engineering, 4th edition.

Upper Saddle River: Pearson Education Inc., 2006.

Levenspeil, O., Chemical Reaction Engineering, 3rd edition. New York: Wiley,

2006.

Smith, J.M., Chemical Engineering Kinetics, 3rd ed. New York: McGraw-Hill,

2009.

4.

Carberry, J.J., Chemical & Catalytic Reaction Engineering. McGraw Hill,

2004.

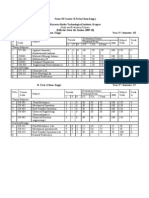

COURSE/SUBJECT OUTCOMES PROGRAM OUTCOMES MATRIX

Course Learning Outcomes (CLO)

Assessment

Determine the reactor size for a given chemical reaction. (C4, PLO 2)

Test

Final Exam

Determine the reaction rate and reaction order for elementary reactions.

(C4, PLO2)

Test

Final Exam

Lab reports

Test

Mid Term

Final Exam

Lab reports

Mid Term

Final Exam

Lab reports

Mid Term

Final Exam

Design batch and continuous reactors using differential and integral methods.

(C5, PLO4)

Calculate the selectivity and reactant conversion for reactions in single/multiple reactors.

(C4, PLO2).

Determine rate law and rate limiting step in catalytic reactor design.

(C4, PLO2).

Topic/Content

1.Introduction

Definition of reaction rate. The general mole balance. Types of reactor in industry. Definition of conversion.

Design equation for batch and flow systems. Reactor in series. Space velocity and space time.

2. Rate Laws and Stoichiometry

Part 1: Rate Laws. Relative Rates of Reaction. The reaction order and Power Law Model. Elementary Reactions.

Non-Elementary Rate Laws.

Part 2: Stoichiometry. Batch System Stoichiometric Table. Flow System Stoichiometric Table.

3. Isothermal Reactor Design

Concept of ideal reactors, Development of design equations for isothermal reactor (batch, CSTR and PFR).

Introduction for space time () and Damkohler number. Tubular Reactors. Pressure drop in reactors. Reversible

reactions.

4. Multiple Reactors And Multiple Reactions

Design for multiple reactor systems. Reactors in series and parallel, Types of multiple reactions selectivity and

yield. Parallel Reactions. Reactions in Series. Condition for maximizing yields and selectivity for parallel

reactions and series reactions.

5. Collection and Analysis of Rate Data

Differential and integral method for batch reactor data. Method of initial rates. Method of half lives.

6.Nonisothermal And Non-Ideal Reactor Design

Non-isothermal reactors, The energy balance, Adiabatic operation

Non-ideal rectors: importance and interpretation of Residence Time Distribution. C, E & F curves & statistical

interpretation. RTD for Ideal Reactors. Tanks in series model. Dispersion model.

7. Catalysis And Catalytic Reactors

Catalysts, Steps in catalytic reactions, Synthesis rate law, mechanism and rate-limiting step, Catalyst

deactivation.

You might also like

- Chemical Reactor Analysis and Applications for the Practicing EngineerFrom EverandChemical Reactor Analysis and Applications for the Practicing EngineerNo ratings yet

- CDB2043 Course Outline and Planning Sept 2015Document4 pagesCDB2043 Course Outline and Planning Sept 2015chiang95No ratings yet

- V Sem Scheme - Syllabus081117030234Document13 pagesV Sem Scheme - Syllabus081117030234Aditya GuptaNo ratings yet

- Gujarat Technological UniversityDocument3 pagesGujarat Technological UniversityShilen PatelNo ratings yet

- SyllabusDocument22 pagesSyllabusSohael AftabNo ratings yet

- National University of Sience and TechnologyDocument3 pagesNational University of Sience and TechnologypalesaNo ratings yet

- Course Code: CHE 401 Course Title: Reaction Engineering Term: January 2019Document2 pagesCourse Code: CHE 401 Course Title: Reaction Engineering Term: January 2019Md Abid AfridiNo ratings yet

- Che 308 Chemical Reaction EngineeringDocument4 pagesChe 308 Chemical Reaction EngineeringskwerbukopieNo ratings yet

- Course Syllabus PENG 361Document2 pagesCourse Syllabus PENG 361absinitNo ratings yet

- Gujarat Technological University: W.E.F. AY 2018-19Document4 pagesGujarat Technological University: W.E.F. AY 2018-19HirenNo ratings yet

- National University of EngineeringDocument2 pagesNational University of EngineeringMarco A. Castillo LudeñaNo ratings yet

- 10100Document42 pages10100احمد الدلالNo ratings yet

- Chemical Reaction Engineering: RD THDocument2 pagesChemical Reaction Engineering: RD THAmol RastogiNo ratings yet

- Chemical Engineering Iit RoorkeeDocument69 pagesChemical Engineering Iit RoorkeeZaid ImranNo ratings yet

- Ench4rt Outline 2012Document5 pagesEnch4rt Outline 2012thirushkaNo ratings yet

- Heterogeneous Reactor DesignDocument267 pagesHeterogeneous Reactor DesignS S S REDDY100% (1)

- CHEM2002 Unit Outline 2012Document8 pagesCHEM2002 Unit Outline 2012Nishanthini SuppiahNo ratings yet

- Lesson Plan CHE433 - 030314Document8 pagesLesson Plan CHE433 - 030314ShahrizatSmailKassimNo ratings yet

- Kinetic Reactor Design Lecture Note 1-1Document31 pagesKinetic Reactor Design Lecture Note 1-1Khairul Imran AzmanNo ratings yet

- 4rth Sem SyllabusDocument11 pages4rth Sem SyllabusChaitanyaNo ratings yet

- FALLSEM2023-24 BCHE303L TH VL2023240100107 2023-04-29 Reference-Material-IDocument29 pagesFALLSEM2023-24 BCHE303L TH VL2023240100107 2023-04-29 Reference-Material-Isaswata299No ratings yet

- Basic Thermodynamics (BTME-305-18)Document14 pagesBasic Thermodynamics (BTME-305-18)Surjit Kumar GandhiNo ratings yet

- University of Petroleum & Energy Studies College of Engineering Studies Dehradun Course PlanDocument7 pagesUniversity of Petroleum & Energy Studies College of Engineering Studies Dehradun Course PlanSwapnil TripathiNo ratings yet

- Course Syllabus (Mechanical Engineering Program) : T.D. Eastop& A. McconkeyDocument6 pagesCourse Syllabus (Mechanical Engineering Program) : T.D. Eastop& A. McconkeyGordon ChaiNo ratings yet

- Gujarat Technological University: W.E.F. AY 2018-19Document4 pagesGujarat Technological University: W.E.F. AY 2018-19MohitSathwara 2609No ratings yet

- M.tech. Chemical Engineering SyllabusDocument10 pagesM.tech. Chemical Engineering SyllabusvkpaithankarNo ratings yet

- ACF DesignDocument5 pagesACF DesignRonald ManyamaNo ratings yet

- Course Syllabus Physical CheDocument7 pagesCourse Syllabus Physical CheOsama MohsinNo ratings yet

- Chemical Reaction Engineering-IIDocument3 pagesChemical Reaction Engineering-II2020001873.gcetNo ratings yet

- Gujarat Technological University Chemical Engineering (05) : Physical and Inorganic Chemistry B.E. 4 SemesterDocument4 pagesGujarat Technological University Chemical Engineering (05) : Physical and Inorganic Chemistry B.E. 4 SemesterNitin DubeyNo ratings yet

- FIRST NOTES January 2021Document37 pagesFIRST NOTES January 2021vivaline AchiengNo ratings yet

- Chemical Reaction Engineering and Thermodynamics PDFDocument2 pagesChemical Reaction Engineering and Thermodynamics PDFErj DaniyaroffNo ratings yet

- Module Description Thermal Chemistry Spring 20212022Document2 pagesModule Description Thermal Chemistry Spring 20212022wongnick150No ratings yet

- Learning Outcomes G12Document12 pagesLearning Outcomes G12Mohamed HussainNo ratings yet

- Chemical and Materials Engineering Department: Course SyllabiDocument35 pagesChemical and Materials Engineering Department: Course SyllabiAbdullah SalemNo ratings yet

- Course Syllabi ABET New PlanDocument60 pagesCourse Syllabi ABET New PlanFarooq AhmadNo ratings yet

- CMO 24 s2008 Annex III Course Specification For The BSECEDocument37 pagesCMO 24 s2008 Annex III Course Specification For The BSECEEunice Jane Bolgado-DoctorNo ratings yet

- CMO 24 s2008 Annex III Course Specification For The BSECEDocument37 pagesCMO 24 s2008 Annex III Course Specification For The BSECEThea Marie SantarinNo ratings yet

- I. Understand The Applications of Engineering Thermodynamics in Real Life SituationsDocument18 pagesI. Understand The Applications of Engineering Thermodynamics in Real Life SituationstbnjhjlkkkkkkNo ratings yet

- Chet-106 Abet SyllabusDocument2 pagesChet-106 Abet Syllabusbbfe89f31eNo ratings yet

- Manual Lab 1Document82 pagesManual Lab 1AmroKashtNo ratings yet

- National University of Engineering College of Geological, Mining and Metallurgical Engineering Metallurgical Engineering ProgramDocument3 pagesNational University of Engineering College of Geological, Mining and Metallurgical Engineering Metallurgical Engineering ProgramJhair JhamidhNo ratings yet

- CMP 304: Chemical Reaction Engineering LabDocument2 pagesCMP 304: Chemical Reaction Engineering LabdevilNo ratings yet

- BTE - 3720 Course Outline Sem 2 15 - 16Document6 pagesBTE - 3720 Course Outline Sem 2 15 - 16Irfan MswNo ratings yet

- CRE Lab ManualDocument26 pagesCRE Lab ManualNaeem Ashraf0% (2)

- M.Tech (Full Time) - Chemical Engineering Curriculum & Syllabus 2013 - 2014Document40 pagesM.Tech (Full Time) - Chemical Engineering Curriculum & Syllabus 2013 - 2014hmasif456No ratings yet

- Chemistry Outline For Refresher Course UpdatedDocument5 pagesChemistry Outline For Refresher Course Updatedabhisheksingh89208No ratings yet

- ChE SyllabusDocument30 pagesChE SyllabusRavindra Kumar NiranjanNo ratings yet

- Engineering," Vol. 3, 3Document1 pageEngineering," Vol. 3, 3SHIVAM CHATURVEDI IET Lucknow StudentNo ratings yet

- Chemical Engineering of IIT RoorkeeDocument53 pagesChemical Engineering of IIT RoorkeeSandeep KumarNo ratings yet

- ChE SyllabusDocument30 pagesChE SyllabusSubodh DwivediNo ratings yet

- Roorkee 3 RdsemDocument102 pagesRoorkee 3 RdsemPranav GuptaNo ratings yet

- Sem 6Document5 pagesSem 6Adawiyah Az-zahraNo ratings yet

- CH701 Chemical Reaction Engineering - II (3 0 2 4)Document2 pagesCH701 Chemical Reaction Engineering - II (3 0 2 4)ShreyashNo ratings yet

- Computer Applications in Process IndustriesDocument10 pagesComputer Applications in Process IndustriesNikhil Kumar ChennuriNo ratings yet

- Thermal and Fluids - Engineering Syllabus M. TechDocument59 pagesThermal and Fluids - Engineering Syllabus M. TechDamodar S PrabhuNo ratings yet

- ChE 106 Syllabus PDFDocument2 pagesChE 106 Syllabus PDFnadimNo ratings yet

- General Physics SylabusDocument5 pagesGeneral Physics SylabusTadesse AbateNo ratings yet

- LUMS EE - 1st Year Course OutlinesDocument36 pagesLUMS EE - 1st Year Course OutlinesAhsan Ahmed MoinNo ratings yet

- Ee PDFDocument2 pagesEe PDFDhenil Manubat0% (1)

- Adsorption and Desorption of MB From WastewaterDocument5 pagesAdsorption and Desorption of MB From WastewatertkjingNo ratings yet

- Adsorption of MB Onto ACDocument53 pagesAdsorption of MB Onto ACtkjingNo ratings yet

- Benefits of Green Tea PDFDocument7 pagesBenefits of Green Tea PDFThesdave SinghNo ratings yet

- Design of Heat Exchangers (Shell Tube)Document59 pagesDesign of Heat Exchangers (Shell Tube)tkjingNo ratings yet

- Graphitic CorrosionDocument12 pagesGraphitic Corrosiontkjing100% (1)

- Heat Exchangers - Without VideoDocument29 pagesHeat Exchangers - Without VideotkjingNo ratings yet

- Closed Loop System AnalysisDocument23 pagesClosed Loop System AnalysistkjingNo ratings yet

- BriefingDocument26 pagesBriefingtkjingNo ratings yet

- Lecture 6Document48 pagesLecture 6tkjingNo ratings yet

- Group Assignment 1Document3 pagesGroup Assignment 1tkjingNo ratings yet

- Lab Manual 2015Document19 pagesLab Manual 2015tkjingNo ratings yet

- No One Is Allowed To Change His/Her AssignmentDocument2 pagesNo One Is Allowed To Change His/Her AssignmenttkjingNo ratings yet

- Chap 4 Isothermal Reactor Design (Student)Document101 pagesChap 4 Isothermal Reactor Design (Student)tkjingNo ratings yet

- EP314 Lab IntroductionDocument14 pagesEP314 Lab IntroductiontkjingNo ratings yet

- 1b. Introduction - Classification of InstrumentDocument30 pages1b. Introduction - Classification of Instrumenttkjing33% (6)

- 1c. Introduction - Instrument Characteristics (Intro and Static)Document45 pages1c. Introduction - Instrument Characteristics (Intro and Static)tkjingNo ratings yet

- Anita Bt. Abu Bakar Department of Chemical & Petroleum EngineeringDocument21 pagesAnita Bt. Abu Bakar Department of Chemical & Petroleum EngineeringtkjingNo ratings yet

- 1a. Introduction - Basic Concepts in InstrumentationDocument26 pages1a. Introduction - Basic Concepts in InstrumentationtkjingNo ratings yet

- Law of Contract - Part1 STD 2014Document60 pagesLaw of Contract - Part1 STD 2014tkjingNo ratings yet

- 1-Introduction (Class Rules Regulations)Document14 pages1-Introduction (Class Rules Regulations)tkjingNo ratings yet

- Chapter 2 - Conduction (A) - Steady StateDocument33 pagesChapter 2 - Conduction (A) - Steady StatetkjingNo ratings yet

- Law of Contract - STD Part2 2014Document44 pagesLaw of Contract - STD Part2 2014tkjingNo ratings yet

- Assignment 2013Document4 pagesAssignment 2013tkjingNo ratings yet

- EE203 Tutorial 5 Partial Differential EquationDocument1 pageEE203 Tutorial 5 Partial Differential EquationtkjingNo ratings yet

- Law of Contract - STD Part2 2014Document44 pagesLaw of Contract - STD Part2 2014tkjingNo ratings yet

- FM1 Assignment - AirAsiaDocument22 pagesFM1 Assignment - AirAsiatkjingNo ratings yet

- Lecture 9 - BA205Document28 pagesLecture 9 - BA205tkjingNo ratings yet

- EE203 Tutorial 2 ODEDocument2 pagesEE203 Tutorial 2 ODEtkjingNo ratings yet

- Daily Lesson Log 4Document5 pagesDaily Lesson Log 4Diane Marr Nicolas Dencio100% (2)

- Transient Stability of A Multi Machine Power System: Devender Kumar, Balwinder Singh SurjanDocument4 pagesTransient Stability of A Multi Machine Power System: Devender Kumar, Balwinder Singh SurjanVerruumm AmineNo ratings yet

- HISTOPATHDocument38 pagesHISTOPATHDennis Louis Montepio BrazaNo ratings yet

- Astro 429 Assignment 2 AlbertaDocument2 pagesAstro 429 Assignment 2 AlbertatarakNo ratings yet

- ABS Rules For Cable SizingDocument2 pagesABS Rules For Cable SizingMohammed JassimNo ratings yet

- Formula SheetDocument16 pagesFormula SheetgwerNo ratings yet

- Advanced Automatic ControlDocument26 pagesAdvanced Automatic Controlabdullah 3mar abou reashaNo ratings yet

- Flexowell® Replacement-Belts enDocument3 pagesFlexowell® Replacement-Belts enrererererererererereNo ratings yet

- Review of Henry Vyverberg, Historical Pessimism in The French EnlightenmentDocument4 pagesReview of Henry Vyverberg, Historical Pessimism in The French EnlightenmentRalph EllectualNo ratings yet

- Board ManualDocument190 pagesBoard ManualkmalNo ratings yet

- Okumas Guide To Gaijin 1Document90 pagesOkumas Guide To Gaijin 1Diogo Monteiro Costa de Oliveira SilvaNo ratings yet

- Angle of Elevation and Depression For Video LessonDocument35 pagesAngle of Elevation and Depression For Video LessonAlma Delos ReyesNo ratings yet

- Architecture of HimalayasDocument3 pagesArchitecture of HimalayasAndrea CaballeroNo ratings yet

- Rig 166 Data SheetDocument2 pagesRig 166 Data SheetEstuardo OlanNo ratings yet

- Manuel Alava 01-12-10 PLDocument3 pagesManuel Alava 01-12-10 PLAshley RodriguezNo ratings yet

- ITAD BIR RULING NO. 026-18, March 5, 2018Document10 pagesITAD BIR RULING NO. 026-18, March 5, 2018Kriszan ManiponNo ratings yet

- Grade 6 2nd Periodical Test With TOS Answer Keys MATH 1 PDFDocument6 pagesGrade 6 2nd Periodical Test With TOS Answer Keys MATH 1 PDFmafeh caranogNo ratings yet

- Tugas Topic 4 Devi PermatasariDocument8 pagesTugas Topic 4 Devi PermatasariMartinaNo ratings yet

- Sample Paper English: Kendriya Vidyalaya SangathanDocument7 pagesSample Paper English: Kendriya Vidyalaya SangathanVines and ScienceNo ratings yet

- Annals of The New York Academy of Sciences - 2023 - Hess - Accelerating Action To Reduce Anemia Review of Causes and RiskDocument13 pagesAnnals of The New York Academy of Sciences - 2023 - Hess - Accelerating Action To Reduce Anemia Review of Causes and RiskIdmNo ratings yet

- Unit II Construction PracticesDocument61 pagesUnit II Construction PracticesiploguNo ratings yet

- Required Obstacle ClearanceDocument14 pagesRequired Obstacle ClearancePero PericNo ratings yet

- Total Aircraft Washing System: Mudmaster Mudmaster MudliteDocument2 pagesTotal Aircraft Washing System: Mudmaster Mudmaster MudliteAli Abu ShhiwaNo ratings yet

- p14.6 - D.C. Motor - Igcse AidDocument2 pagesp14.6 - D.C. Motor - Igcse Aidrandom channelNo ratings yet

- Parasites in Reptile PDFDocument21 pagesParasites in Reptile PDFRamadhani SyafitriNo ratings yet

- An Automated Energy Meter Reading System Using GSM TechnologyDocument8 pagesAn Automated Energy Meter Reading System Using GSM TechnologyBarNo ratings yet

- Winter Solstice, CGW 2011Document38 pagesWinter Solstice, CGW 2011Lady HekateShadowMoonfire0% (1)

- Easy Guide For Fujitsu T901 LaptopDocument141 pagesEasy Guide For Fujitsu T901 LaptopElaineNo ratings yet

- MHFU Hunter RankDocument5 pagesMHFU Hunter RankGustin PrayogoNo ratings yet

- Strength of Materials: 2. Assume Missing Data, If Any, SuitablyDocument2 pagesStrength of Materials: 2. Assume Missing Data, If Any, SuitablynvnrevNo ratings yet