Professional Documents

Culture Documents

2012 05 31FIS EM en

Uploaded by

kktttOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2012 05 31FIS EM en

Uploaded by

kktttCopyright:

Available Formats

Extracts from our product range

Description

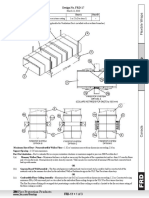

FIS EM 390 S

093 048 D, GB, F, NL, E, P

1 cartridge 390 ml + 2 mixing nozzles

Injection mortar

FIS EM 390 S

093 049 GB, CZ, PL, GR, RC, ROK

1 cartridge 390 ml + 2 mixing nozzles

Injection mortar

FIS EM 390 S

502 289 RUS, LT, LV, EST, UA, KZ

1 cartridge 390 ml + 2 mixing nozzles

Injection mortar

FIS EM 585 S

508 831 D, GB, F, NL, E, P

1 cartridge 585 ml + 2 mixing nozzles

Injection mortar

FIS EM 585 S

509 266 GB, PRC, RU, ROK, CZ, PL

1 cartridge 585 ml + 2 mixing nozzles

Injection mortar

FIS EM 1100 S

096 865 D, F, I, GB, E, P, NL, RC, PL, J, CZ, ROK

1 cartridge 1100 ml + 2 mixing nozzles

Injection mortar

in a box

FIS EM 390 S HWK 040 038 GB, CZ, PL, GR, RC, ROK

20 cartridges 390 ml + 20 mixing nozzles

Injection mortar

in a box

FIS EM 390 S HWK 501 808 D, GB, F, NL, E, P

20 cartridges 390 ml + 20 mixing nozzles

Injection mortar in a bucket

FIS EM 390 S

503 024 D, GB, F, NL, E, P

16 cartridges 390 ml + 16 mixing nozzles

Mixing nozzle

for FIS EM 390 S

FIS SE

096 448 -

10 mixing nozzles for FIS EM 390 S

Comments

Threaded rod

FIS A

M 8 - M 30

Threaded rod

RG M

M 8 - M 30

Internal threaded anchor

RG MI

M 8 - M 20

Rebar anchor

FRA

M 12 - M 24

Description

Cleaning brush

Art. No.

BS

Brush extension

508 791

Compressed air cleaning gun

093 286

Easy and reliable to use

420 mm long, required for deep drillholes

Injection adaptors are required for drillholes deeper than 250 mm and for hole

diameters 40 mm, and for overhead installations.

The complete product range can be found in the current main catalogue

048 983

1000 mm long, required for deep drillholes 150 mm, for FIS EM 390 S and

FIS EM 585 S

Extension hose 15 mm

001 498

1900 mm long, required for deep drillholes 150 mm, for FIS EM 585 S and

FIS EM 1100 S

Application equipment

Extremest conditions

fischerwerke GmbH & Co. KG

Weinhalde 1418 72178 Waldachtal

Germany

Phone +49 7443 12-0

Fax +49 7443 12-4220

www.fischer.de

fischer

FIS EM Injection System

Comments

FIS extension hose 9 mm

Your fischer partner:

Maximum safety

The complete product range can be found in the current main catalogue

The complete product range can be found in the current main catalogue

Injection adaptors

FRA rebar anchor

Contents

Injection mortar

Description

Rebar steel

Languages on the label

The complete product range of hand-held dispenser, cordless dispenser and compressed air dispenser can be found in the current main catalogue

Flexible, economic, approved for tension zone.

XXXXXX (1) 05/2010 P-MPS/RC Printed in Germany Subject to change without notice.

Injection mortar

FIS EM 390 S

Art. No.

fischer FIS EM Injection System:

For maximum performance in concrete.

fischer FIS EM Injection System.

Flexible and simply good.

Applications

Fixing of heavy structural steel structures, silos, masts, metal

chimneys, high-bay racking, impact protection, noise barries.

Advantages at a glance

Approved for cracked and non-cracked

concrete

Example: Variable embedment depths and

variable loads

(using example of

threaded rod M16)

Advantages

Highest permissible loads up to 400 kN

Variable embedment depth from

4 x to 20 x bar diameter

Efficient and time-saving:

Due to the variable embedment depths from 4 ds to 20 ds

(ds = diameter of steel part) the anchor lengths can be optimally

adjusted to the load. Drilling and installation times are

minimised.

Injection mortar

FIS EM 390 S

Suitable in addition to the approval

even for diamond drilling and

underwater installations

hef= 80 mm (5 ds)

FIS EM for multiple combination options:

Threaded rods FIS A or RG M from M8 to M30

Internal threaded anchor RG MI from M8 to M20

Rebar steel from 8 to 40

FRA Rebar anchor M12 to M24

Successful in series:

No setting tools required for installation and the extended

processing times are optimal for series installation

hef= 125 mm

hef= 320 mm (20 ds)

Simple and cost-effective:

FIS EM can be used with fischer standard threaded rods FIS A

and RG M in cracked and non-cracked concrete.

Extended processing times ideal for

serial installation

Diverse and user-friendly:

FIS EM is suitable in addition to the approval, even for diamond

drilling and underwater installations and at the same time seals

off the drillhole.

Approvals

ETA 10/0012:

Optimum series installation

ETA 09/0089:

COMPUFIX design software makes the design and construction easier

Makes it possible to design and

construct safe, economic fixings

quickly and without extensive

effort.

An automatic calculation immediately informs you of the effect of

the change you have made.

The user-friendly Windows

Vista interfaces enables it to

be used intuitively, without a long

training.

Use the 3D navigation to easily

rotate, swivel, tilt and zoom your

designs in space.

An automatic Input Wizard assists you with detailed information and tips.

Verifiable printout.

Free download under:

www.fischer.de

European Technical Approval for post-installed rebar

connections according to EN 1992-1-1:2004 (Eurocode 2)

Z-21.8-1874:

M16

European Technical Approval

170 mm

Maximum loads

M12

160 mm

Flexible anchorings

M10

European Technical Approval for anchoring in cracked and

non-cracked concrete (Option 1) with threaded rods, internal

threaded anchors, rebar steel and rebar anchors

200 mm

Internal threaded

anchor RG MI

10.2

kN

Example: Variable concrete thicknesses

and

Bond stress

different

thread

sizes

under

the

(with variable concrete thicknesses)

same load

140 mm

Threaded rod

FIS A / RG M

17.5

kN

170 mm

FRA Rebar anchor

44.7

kN

Temperature resistant:

FIS EM is approved for temperatures from 40 C to +72 C.

Thus it convinces with its excellent bond strength.

125 mm

Rebar steel

National German Approval of the Deutsches Institut fr

Bautechnik (DIBt) for post-installed rebar connections, according to DIN 1045-1:2008-08 with fire test, according to

DIN 4102 for fire ratings up to R 180 (= 180 minutes)

ICC ESR-1990:

Approval of the International Code Council Evaluation Service

(ICC-ES), USA in compliance with 2006 IBC and 2006 IRC

17.5

kN

17.5

kN

17.5

kN

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Technical Report WritingDocument15 pagesTechnical Report WritingkktttNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- A Review On Pavement Porous Concrete Using Recycled Waste MaterialsDocument9 pagesA Review On Pavement Porous Concrete Using Recycled Waste MaterialsOM YeimyNo ratings yet

- Potential Utilization of Waste Material For Sustainable Development in Construction IndustryDocument4 pagesPotential Utilization of Waste Material For Sustainable Development in Construction IndustrykktttNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Waste Management: Sathish Paulraj Gundupalli, Subrata Hait, Atul ThakurDocument9 pagesWaste Management: Sathish Paulraj Gundupalli, Subrata Hait, Atul ThakurkktttNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Characterizing The Generation and Flows of Construction and Demolition 2017Document9 pagesCharacterizing The Generation and Flows of Construction and Demolition 2017Natalia SandovalNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Articulo 5Document11 pagesArticulo 5Manuelita Huamán GonzálesNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Docslide - Us - Aisc360 05 Direct Analysis Method 5631036e010f2 PDFDocument12 pagesDocslide - Us - Aisc360 05 Direct Analysis Method 5631036e010f2 PDFNguyen Duc CuongNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Lec 1 - Surveying Drafting & Computations-1Document35 pagesLec 1 - Surveying Drafting & Computations-1kktttNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Lec 1 - Surveying Drafting & ComputationsDocument9 pagesLec 1 - Surveying Drafting & ComputationsTalha Bin TahirNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Construction Surveying or Building SurveyingDocument21 pagesConstruction Surveying or Building SurveyingkktttNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Department of Civil Engineering: Course Code: Ce2122 Course Title: Advance Engineering SurveyingDocument46 pagesDepartment of Civil Engineering: Course Code: Ce2122 Course Title: Advance Engineering SurveyingkktttNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- SAP2000 Tutorial 2015 PDFDocument9 pagesSAP2000 Tutorial 2015 PDFAnonymous EhjsAEyHrBNo ratings yet

- Lec 1 - Surveying Drafting & Computations-2Document18 pagesLec 1 - Surveying Drafting & Computations-2kktttNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Scholarship Cover Letter FormatDocument1 pageScholarship Cover Letter FormatkktttNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Qa QC Guidelines PDFDocument13 pagesQa QC Guidelines PDFkktttNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Size Effect On Shear Strength PF FRP Reinforced ConcreteDocument39 pagesSize Effect On Shear Strength PF FRP Reinforced ConcretekktttNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Technical Writting and Presentation Skills PDFDocument1 pageTechnical Writting and Presentation Skills PDFkktttNo ratings yet

- Evaluation of Minimum Shear Reinforcement in Reinforced Concrete BeamsDocument8 pagesEvaluation of Minimum Shear Reinforcement in Reinforced Concrete BeamsChetan B ArkasaliNo ratings yet

- Design Guidelines For Community Infrastructure of Rural AreasDocument102 pagesDesign Guidelines For Community Infrastructure of Rural AreaskktttNo ratings yet

- Analysis of Wind Loads On Buildings and Signs A Computer Program Based On Asce 7Document9 pagesAnalysis of Wind Loads On Buildings and Signs A Computer Program Based On Asce 7noumanNo ratings yet

- CH 6 - Bolt ConnectionsDocument45 pagesCH 6 - Bolt ConnectionskktttNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Tension Members & Connections: Lecture NotesDocument2 pagesTension Members & Connections: Lecture NotesAndrei AevoaieNo ratings yet

- Span-To-Depth Ratio Effect On Shear Strength of Deep BeamsDocument12 pagesSpan-To-Depth Ratio Effect On Shear Strength of Deep BeamsHanumaNo ratings yet

- MDOT QAQCProcessGuide 120511 7Document21 pagesMDOT QAQCProcessGuide 120511 7Dan CosacNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- CH 8 - Welded ConnectionsDocument49 pagesCH 8 - Welded ConnectionskktttNo ratings yet

- National University of Sciences and TechnologyDocument2 pagesNational University of Sciences and TechnologykktttNo ratings yet

- Building Drifts in ETABSDocument9 pagesBuilding Drifts in ETABSkktttNo ratings yet

- Structural Analysis and ControlDocument24 pagesStructural Analysis and ControlkktttNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Tank Steel CalculationDocument6 pagesTank Steel CalculationkktttNo ratings yet

- Anchor BoltDocument8 pagesAnchor Boltazwan50% (2)

- Muttenz Industrial ChimneyDocument12 pagesMuttenz Industrial ChimneyAlin ApoNo ratings yet

- Chapter 4 Deflection and BucklingDocument64 pagesChapter 4 Deflection and BucklingHamlity SaintataNo ratings yet

- DOS - Steel Bridge - Lecture 2Document22 pagesDOS - Steel Bridge - Lecture 2M Sajjad TufailNo ratings yet

- Work Instruction Page 1 of 2 Contiguous Bored Piles InstallationDocument7 pagesWork Instruction Page 1 of 2 Contiguous Bored Piles InstallationMuhammad Syahmi Adli SamNo ratings yet

- HBY - Ground Floor - Incoming Products PDFDocument1 pageHBY - Ground Floor - Incoming Products PDFsupportLSMNo ratings yet

- Alloy Temperature ChartDocument2 pagesAlloy Temperature ChartDaymer AularNo ratings yet

- Fen Do LiteDocument2 pagesFen Do LiteArmie May RicoNo ratings yet

- Hvac Boq - R0 - 2914Document46 pagesHvac Boq - R0 - 2914Vikash TiwariNo ratings yet

- Literature Study: by Kataru Lohith Krishna Reg No:RA1811201010070Document10 pagesLiterature Study: by Kataru Lohith Krishna Reg No:RA181120101007099 kingsNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Diagnose and Repair Engine Forced-Induction SystemsDocument87 pagesDiagnose and Repair Engine Forced-Induction SystemslittleprayerbyjacksNo ratings yet

- Comparative Analysis of Green Building Rating Systems and Codes - 1Document46 pagesComparative Analysis of Green Building Rating Systems and Codes - 1Rohit TirkeyNo ratings yet

- Design of Steel Structures: Mahmud Dwaikat Assistant Professor Civil Engineering Dept. An-Najah National UniversityDocument32 pagesDesign of Steel Structures: Mahmud Dwaikat Assistant Professor Civil Engineering Dept. An-Najah National Universityप्रभु नाथ सिंहNo ratings yet

- Nfpa 24Document16 pagesNfpa 24Sreenath S KallaaraNo ratings yet

- Fibre Reinforced ConcreteDocument23 pagesFibre Reinforced ConcreteGaurav SinghNo ratings yet

- C. Emsco FB-1600 Parts ListDocument14 pagesC. Emsco FB-1600 Parts Listluis mateosNo ratings yet

- Structural Standard Details: Construction NotesDocument4 pagesStructural Standard Details: Construction Notesjohn rey toledo100% (1)

- Description of PremisesDocument2 pagesDescription of PremisesRio KelsonNo ratings yet

- RCC Question BankDocument3 pagesRCC Question BankPurab PatelNo ratings yet

- Spec Sheet - American StandardDocument2 pagesSpec Sheet - American StandardJohn Enrick ManuelNo ratings yet

- FRD17Document3 pagesFRD17Raul FloresNo ratings yet

- Stemmann-Technik: Maintenance Instruction For Slipring Assembly MS7,2 - 300-300-10 Art. No. 6253620Document2 pagesStemmann-Technik: Maintenance Instruction For Slipring Assembly MS7,2 - 300-300-10 Art. No. 6253620Miguel RodriguezNo ratings yet

- DEP 30.10.05.11-Gen Plant Model Construction and ReviewDocument28 pagesDEP 30.10.05.11-Gen Plant Model Construction and ReviewSd Mahmood100% (1)

- Transmital Letter of Core Samples - JDT (South)Document1 pageTransmital Letter of Core Samples - JDT (South)Nscr GpiNo ratings yet

- IK - Manufacturers - XLSX 7 19 18Document428 pagesIK - Manufacturers - XLSX 7 19 18Naveen TripuraneniNo ratings yet

- Surface Driller Equipment Paper NO. 1.: All Questions Require Only ONE Answer Unless Otherwise StatedDocument22 pagesSurface Driller Equipment Paper NO. 1.: All Questions Require Only ONE Answer Unless Otherwise StatedandrzemaNo ratings yet

- ValvesDocument46 pagesValvesashirNo ratings yet

- Katalog Onaji 2021Document6 pagesKatalog Onaji 2021adityhot100% (1)

- KBK Installations: KBK II Extending CranesDocument2 pagesKBK Installations: KBK II Extending CranesMAGST100% (1)

- Rheomac® 707Document4 pagesRheomac® 707M HAFEEZ RAJANo ratings yet

- University of Chicago Press Fall 2009 Distributed TitlesFrom EverandUniversity of Chicago Press Fall 2009 Distributed TitlesRating: 1 out of 5 stars1/5 (1)

- University of Chicago Press Fall 2009 CatalogueFrom EverandUniversity of Chicago Press Fall 2009 CatalogueRating: 5 out of 5 stars5/5 (1)