Professional Documents

Culture Documents

API Compressors Sealing Systems

Uploaded by

RajagopalCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

API Compressors Sealing Systems

Uploaded by

RajagopalCopyright:

Available Formats

API CENTRIFUGAL COMPRESSOR OIL SEALS AND SUPPORT SYSTEMS

TYPES, SELECTION, AND FIELD TROUBLESHOOTING

by

Ed Wilcox

Senior Staff Engineer

Conoco, Inc.

Westlake, Louisiana

Ed Wilcox is a Senior Staff Engineer with

Conoco, Inc., in Westlake, Louisiana, where

he is the Reliability Engineer for ExcelParalubes, a joint venture between Conoco

and Pennzoil. He also provides technical

support for the adjacent Conoco Refinery.

His responsibilities include maintenance,

troubleshooting, and specification of

rotating equipment.

Mr. Wilcox received his BSME degree

from the University of Missouri-Rolla and

MSME degree from Oklahoma State University. He has also done

post graduate work at the Georgia Institute of Technology in the

areas of machinery vibration, lubrication, and rotordynamics. He

is a Vibration Institute certified Level III Vibration Specialist, a

member of STLE, and a registered Professional Engineer in the

State of Oklahoma.

ABSTRACT

Even though dry gas seals for centrifugal compressors are

becoming more popular, knowledge and understanding of oil seals

and their associated support systems are still very important. Many

existing compressors still have oil seals; likewise, dry gas seals

have pressure and surface velocity limitations that prevent them

from being applied to all applications. The author describes the two

most common types of API oil seals so that users can understand

the fundamentals of each. Likewise, the strengths and weaknesses

for each seal type are listed so users can have input into

specification of their seals dependent upon their particular

application. Examples are given of problematic seal designs and

the changes made to improve them. The support systems for each

type of oil seal are described, along with ways to specify the best

system for different applications. A step-by-step method is given

for troubleshooting seals and their support systems in the field.

Case studies of problematic oil seal systems with solutions are

presented.

Figure 1. Combined Lube and Seal Oil System.

FACE CONTACT TYPE OIL SEALS

Face contact oil seals are similar to pump seals where two radial

faces (one stationary and one rotating, items 15 and 21,

respectively, in Figure 2) provide the seal between the process gas

and seal oil. The stationary face moves axially with the compressor

rotor. A small amount of seal oil is forced between the two sealing

faces to provide lubrication and cooling, because the seal oil is at a

higher pressure than the process gas (typically the seal oil

differential pressure is 40 to 80 psid). This contaminated or sour

seal oil comes in contact with the process gas and is drained away

to the seal oil traps for reclamation or disposal. Sour oil leakage

rates are typically five to 10 gallons per day (gpd) per seal. A

labyrinth seal (item 9) prevents the oil from entering the

compressor. The stationary face has a secondary seal (item 12),

normally made from a compatible elastomer. The secondary seal

must slide on the seal housing or stationary face as the rotor floats

axially. Springs (item 10) are used to load the seal faces in addition

to the hydraulic load, as well as when the seal oil system is not in

operation. The springs are almost always located on the stationary

INTRODUCTION

Compressor oil seals are designed around the principle of

forcing oil into the compressor seals at a higher pressure than the

process gas to prevent the gas from escaping from the pressure

casing. In fact, compressor oil seals are not gas seals at all, but

rather liquid seals designed to minimize the amount of seal oil that

passes into the compressor. The seal oil is normally supplied from

a combined lube and seal oil system, an example of one such

system is shown in Figure 1. This system is designed to keep the

seal oil pressure above the sealed gas pressure.

Oil seals are generally grouped into two different groups: face

contact seals and floating ring seals. The two different types have

different strengths and weaknesses that make them attractive

and/or applicable to different applications. Likewise, their

associated seal oil support systems are quite different.

225

226

PROCEEDINGS OF THE 29TH TURBOMACHINERY SYMPOSIUM

Sweet oil

return

face due to the high shaft rotational speeds encountered in

compressors (i.e., high rotational speeds would cause springs to

deflect and result in an unstable seal). Face seals have maximum

surface velocity and sealing pressure limitations (Table 1).

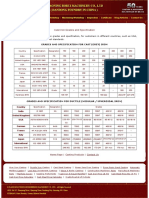

Table 1. Approximate Pressure and Velocity Limitations of Face

Contact Seals.

Maximum Surface Velocity (fps)

Maximum Sealed Pressure (psia)

300

500-1500

A floating bushing seal (item 27, Figure 2) is normally used on

the atmospheric or outer side of the seal to keep the seal housing

pressurized. The seal oil that passes through the outer seal is

drained directly back to the lube oil reservoir because it has not

come in contact with the process gas. For this reason, it is called

uncontaminated or sweet seal oil. The bushing seal clearance is

sized to maintain the correct differential pressure on the process

seal while at the same time providing enough flowrate through the

seal housing to cool the seal (normally around five to 10 gpm).

Alternatively, some seal designs use a second contact seal on the

atmospheric side (Figure 3). This is usually required at high

surface velocities, if the oil flow cannot be controlled adequately

enough with a bushing seal. Depending upon the seal design and

application, the sweet seal oil flow may require a separate drain to

the reservoir. The flow through this separate drain is either

restricted by an orifice or regulated by a control valve to maintain

the seal oil differential pressure.

(Sweet Oil Drain)

Sour oil

drain

(Reference Gas)

Seal oil

Supply

Sweet oil

drain

Figure 3. Double Mechanical Contact Seal. (Courtesy of Flowserve)

Atmosphere

Process

Gas

Atmosphere

Process

Gas

(Sour Oil Drain)

Figure 2. Mechanical Contact Seal. (Courtesy of Kaydon Ring and

Seal)

To lower the relative surface velocity between the rotating and

stationary faces, some face type oil seals include a floating

nonmetallic ring (usually carbon, item 1, Figure 4) between the two

faces. This ring normally spins at approximately one-half the shaft

rotational speed. This lowers the relative velocity between the seal

faces to approximately half of the shaft speed. The carbon ring is

normally scalloped on the inside diameter to make sure a pressure

differential does not exist across it and pressed inside a steel ring

(Figure 5). However, the lower velocity does not come without a

cost, it does add an additional sealing face that can leak as well.

Face seals provide positive shutoff; i.e., they will contain the

process gas if the seal oil differential is lost. This is very important

in hazardous applications, even if buffer gas is used on the seals.

Positive shutoff is maintained by the springs as well as a set of

Figure 4. Contact Seal with Center Carbon Ring. (Courtesy of

Elliott Co.)

shutdown pistons (item 14, Figure 6). If the seal oil pressure

differential drops to a few psid, the pistons will move in the

outboard direction and push the seal retainer against the rotating

seat. Alternatively, some seal designs incorporate a separate sealing

face for shutdown protection (item 1, Figure 7). This design

prevents process gas from escaping by closing the additional seal

face on the outside of the contact seal. At the same time it pushes

the contact seal together.

Balance

Seal balance or balance ratio is the ratio of the seal face closing

area to seal face contact area (Figures 8 and 9, and Equation (1)).

API CENTRIFUGAL COMPRESSOR OIL SEALS AND SUPPORT SYSTEMS

TYPES, SELECTION, AND FIELD TROUBLESHOOTING

227

Balance ratios for compressor oil seals typically range from 60 to

80 percent, which means that there is a slight closing bias. Leakage

rates for compressors are much higher than pumps (typically

gallons per day for compressors compared to parts per million

(ppm) for pumps) because the faces require more lubrication and

cooling. Typically, most compressor seals are designed for a

complete liquid film across the entire seal face, in comparison to

pumps where it is common for the sealed liquid to vaporize at the

inside diameter of the seal faces. The liquid film provides for a

much longer operating life.

Balance = B =

2

2

closin g area ro rb

=

.

contact area r 2 r 2

o

i

Oil

(1)

Process gas

Figure 5. Relief on Inside Diameter of Center Carbon Ring.

ro

r

ri

Figure 8. Balance Dimensions for Outside Pressurized Face Seal.

Oil

Process gas

ro

ri

Figure 9. Balance Dimensions for Outside Pressurized Seal.

Seal Face Loading

Figure 6. Contact Seal Showing Shutdown Piston. (Courtesy of

Elliott Co.)

The hydraulic axial load on the seal faces is a function of the seal

balance, face orientation, differential pressure, and pressure profile

across the seal faces (Figure 10). The shape of the pressure profile

across the seal faces is a function of the seal face orientation. The

seal faces are never exactly parallel. A divergent face profile is

unstable and results in face wear and short run-life. The parallel or

slightly convergent face profile results in lower leakage rates and is

the normal design case (Table 2).

Figure 10. Axial Hydraulic Load Distribution on Face Seal.

Figure 7. Contact Seal Showing Alternate Shutdown Piston

Design. (Courtesy of Dresser-Rand)

A nonparallel face orientation is not due solely to manufacturing

tolerances or installation errors. The seal face runs warmer on the

inside diameter because the oil film is thinner on the inside than the

outside (Figure 11). Additionally, there is a large temperature

gradient in the axial direction as well. These temperature gradients

tend to deflect the seal faces in a convergent direction (Figure 12).

Likewise, pressure induces moments on the stationary seal faces that

tips or deflects the seal faces (Figure 13). Since the stationary face

pivots on the secondary seal, the distance from the seal face to the

secondary seal affects face orientation and as a result the seal face

loading (SFL) (i.e., as the rotor shifts axially, the pressure effects

228

PROCEEDINGS OF THE 29TH TURBOMACHINERY SYMPOSIUM

Table 2. Seal Face Orientations.

Face

Orientation

Stability

Leakage

Life

Parallel

Stable but very

difficult to obtain

exactly.

Hydrodynamic lift

only produced by

surface roughness.

Low

Long

Converging

Stable produces

hydrodynamic lift

Low/Moderate

Long, assuming

faces do not touch.

Maybe the result of

temperature effects

in seal

Unstable no

hydrodynamic lift

Diverging

Will cause wear on

OD and result in

failure or parallel

Slightly higher than

parallel because

hydrodynamic

pressure causes K to

be higher.

Very Low

Short

At first but wear

occurs resulting in

higher leakage.

on the stationary face can change). This sensitivity to axial location

can be eliminated by fixing the secondary seal in the stationary

face instead of on the seal carrier (Figure 14). The temperature and

pressure effects are normally designed to oppose each other such

that the face orientation is parallel or slightly convergent.

Figure 14. Contact Seal with Secondary Sealing Element Fixed.

The hydraulic load along with the spring load are added together

to provide the seal face loading (Equation (2)). The pressure profile

across the seal faces is commonly approximated as linear, which

results in K = 0.5.

SFL = PSPRING POIL (B K)

Leakage

Sour oil leakage for mechanical contact type seals is normally

five to 10 gpd per seal. Typical axial clearances between seal faces

are only 0.0001 to 0.0005 inch. Therefore, only small increases in

this clearance can cause high leakage rates. Equation (3) gives an

estimate of the leakage rate between two radial faces, assuming the

oil film thickness is uniform across the seal (i.e., the faces are

parallel). Note: the flowrate is proportional to the cube of the axial

clearance (h).

Q=

Figure 11. Typical Temperature Gradients in Contact Seals.

(Courtesy of Burgmann Seals)

Seal oil

-----

----++++

shrinking

++++

(2)

rmh3p

.

6r

(3)

As an example, a cracked gas compressor was recently

consuming approximately 750 gpd (from one end only). To

determine if the problem could be caused by the face seals

hanging up, a calculation was made to determine the amount

of axial clearance required for this leakage rate. Equation (3)

can be rearranged to give the clearance for a given leakage rate

(Equation (4)).

h=3

6Q

.

r

(4)

expansion

Process Gas

Process Gas

Figure 12. Effects of Temperature Gradients on Seal Face

Orientation. (Courtesy of Burgmann Seals)

Figure 13. Effect of Pressure on Seal Face Orientation.

For a 6.75 inch seal with 45 psid seal oil differential and using

100 SSU oil at an estimated inlet temperature of 110F, the axial

clearance (h) required for the actual leakage of 750 gpd is only

0.0015 inch! Considering that this particular compressor floated 2

to 3 mils axially every day because of load swings, it seemed very

plausible that the leakage was a result of a stationary face hung up

on the seal carrier. This estimate was further backed up by the fact

that the seal balance was very low, approximately 50 percent. If the

pressure gradient across the seal face is assumed linear (i.e., K =

0.5), a 50 percent balance results in the SFL to be provided only by

the spring load (i.e., B K = 0 in Equation (2)). In other words, if

the seal faces are disturbed from their equilibrium condition, the

only restoring force is that applied by the springs. This makes the

seal very susceptible to build up between the stationary face and

the seal carrier, which might keep the seal faces further apart when

the rotor shifts axially.

One of the largest weaknesses of the face contact seal is the

dynamic gasket on the stationary face. The gasket is required to

slide back and forth on the seal carrier or seal ring as the rotor

moves axially. This motion can wear a groove in the seal carrier,

API CENTRIFUGAL COMPRESSOR OIL SEALS AND SUPPORT SYSTEMS

TYPES, SELECTION, AND FIELD TROUBLESHOOTING

229

which can cause the stationary face to hang up, Likewise, dirty

seal oil or other contaminants can build up in the area between the

stationary face and the seal housing and hang up the stationary face

(Figure 16). Either of these situations can cause the seal leakage

rate to increase dramatically. This weakness is especially acute on

compressors that have large swings in load (which results in large

amounts of axial travel).

Figure 16. Wear on Load Face of a Bushing Atmospheric Seal.

Figure 15. Stationary Face with Build Up on Sour Side (Inside

Diameter).

Materials

The seal face materials are very similar to those seen in pump

seals. Nickel or antimony bonded carbon is commonly used as

stationary face material. Likewise, silicon carbide, tungsten

carbide, or surface-hardened steel is used for rotating seats. The

faces are lapped to a surface flatness of approximately 106

inches. Secondary seals are normally made from Teflon or Viton

depending on the process. The metal parts are normally 316 SS,

Inconel or Hastelloy depending upon the corrosive nature of the

gas.

differential pressure controller on the seal oil supply to maintain

the required seal oil supply pressure. The reference gas pressure is

normally supplied from the process gas side of the labyrinth seal

shown in Figure 2, note the port labeled control gas. This gas

reference pressure should always be located between the seal and

the buffer gas port. Likewise it should always be obtained from the

end of the compressor with the highest pressure (i.e., discharge or

interstage suction) to prevent balance piston problems from

starving one side of the compressor for oil. The sweet oil is drained

back to the reservoir through either the atmospheric seal and/or a

separate orificed drain. The sour oil is drained away to the seal

traps.

Gas Reference

DPC

Seal Oil

Supply

Rotordynamic Effects

Face Contact Seal Oil Systems

The most common seal oil system for face contact oil seals is

forward pressure control (Figure 17). This system uses a

Sour

Oil

Sour

Oil

Clean Oil

to

Reservoir

Sweet Oil

Balance Connection

Sweet Oil

The process side of contact seals (with or without a center

carbon ring) has very little rotordynamic effect on the compressor

rotor. Because the differential pressure across the process side is

typically low (< 100 psid), there is very little frictional radial load

carrying capability in the contact seal. Without the frictional

radial load, the seal cannot develop stiffnesses that contribute to

the rotordynamics of the system. In contrast, the atmospheric

side, which is normally a bushing style, can affect the

rotordynamics of the compressor. Depending upon the

differential pressure, balance, L/D ratio, and shaft clearance, the

atmospheric ring can lock up in an eccentric position and

produce marginal amounts of destabilizing cross-coupled

stiffness. However, this can be avoided by designing the

atmospheric ring to reduce its frictional load (i.e., lapping faces,

decreasing balance ratio) and by reducing the L/D ratio. In

contrast, if the axial load on the atmospheric ring is too low,

fretting can occur (Figure 16). The atmospheric ring also

produces a great amount of direct damping that helps to stabilize

the rotor.

Gas to

Flare

Sour

Oil

Figure 17. Contact Seal Oil System, Forward Pressure Control.

An alternate seal oil system for face contact oil seals is the

backpressure control shown in Figure 18. The system uses a

differential pressure controller as well, but is placed on the sweet

oil drain back to the reservoir (i.e., the control oil port on Figure

2). Normally an adjustable flow controller is required on the supply

oil line as well. This is normally set at a fixed amount determined

by the seal vendor.

230

PROCEEDINGS OF THE 29TH TURBOMACHINERY SYMPOSIUM

reduce the amount of seal oil that is exposed to the process. To

further reduce the sour leakage, a windback groove may be cut into

the inside diameter of the inner ring (Figure 21). This causes the

inner ring to pump the seal oil back toward the outer ring. Likewise,

for applications where the process gas may corrode the babbitt,

aluminum may be sprayed on the inside diameter of the inner ring.

Typical sour oil leakage rates are approximately 10 to 25 gpd.

Gas Reference

FC

Seal Oil

Supply

Gas Reference

LC

OVHD

SEAL

OIL

TANK

Seal Oil

Supply

Gas to

Flare

LT

LC1

Sweet Oil

Sour

Oil

To

Reservoir

Sour

Oil

DPC

Sweet Oil

Balance Connection

LC2

15

Sour

Oil

Figure 18. Contact Seal Oil System, Back Pressure Control.

Balance Connection

FLOATING RING TYPE OIL SEALS

Floating ring oil seals typically comprise two to four stationary

rings in a seal housing that are allowed to float radially with the

shaft (Figure 19). There is normally only one ring on the process

side of the seal, with varying numbers of rings on the atmospheric

side (but normally not more than three). Unlike face seals, floating

ring seals have no pressure or speed limitations. There are two

sealing surfaces on floating rings: the radial face that slides on the

seal housing and the clearance between the shaft sleeve and the

seal ring. The radial face is usually lapped to an 8 to 15 rms finish.

Likewise, the inside diameter of the rings is normally lined with a

thin layer of babbitt (approximately 0.010 to 0.060 inch deep). The

seal sleeves (or shaft) that the seal rings run on are normally hardsurfaced by weld overlay (typical hardness of 50 to 60 Rockwell

C). Axial clearance between the rings and the seal housing is

normally 0.010 to 0.020 inch per ring.

Inner Labyrinth

Seal

Buffer gas

injection

(optional)

Clean Oil

to

Reservoir

Gas to

Flare

T

Sour

Oil

Figure 20. Seal Oil System with Overhead Seal Oil Tank, Floating

Ring Seals.

Seal oil supply enters

between inner and

outer rings

Process

Gas

Atmosphere

Outer Labyrinth

seal

Sour oil drained

away between

inner ring and

Inner seal ring

Outer seal ring

Figure 19. Floating Ring Oil Film Seal. (Courtesy of Dresser-Rand)

The seal oil is supplied between the inner and outer rings (Figure

19). The differential pressure across the inner ring (which is on the

process gas side) is normally very low, around 5 psid. This

differential is normally maintained by elevating a seal oil tank

approximately 15 ft above the shaft centerline and connecting the

sealed gas reference pressure to the top of the tank (Figure 20). The

seal oil supply is either pumped up to the seal oil tank and then

gravity fed down into the compressor or connected to a drain off the

bottom of the seal oil tank such that the supply pressure is set by the

tank. The inner ring normally has the tightest clearance

(approximately 0.0005 to 0.001 inch/inch of shaft diameter) to

Figure 21. Inner Ring with Windback Groove.

The atmospheric side of the seal has a differential pressure equal

to the sealed gas pressure plus the seal oil differential pressure. It is

not uncommon for the atmospheric side of a floating ring seal to

have differential pressures in excess of several thousand psid. It just

depends upon the process conditions. The clearance between the

outer ring(s) and the seal sleeve is sized to provide enough oil flow

to cool the seal. The clearance is normally higher than the process

side (normally 0.001 to 0.003 inch/inch of shaft diameter). Higher

API CENTRIFUGAL COMPRESSOR OIL SEALS AND SUPPORT SYSTEMS

TYPES, SELECTION, AND FIELD TROUBLESHOOTING

pressure applications are normally designed with two or three outer

rings (or one ring with multiple grooves) to reduce the L/D ratio of

the rings. Normally, a compressed O-ring on the face of the inner

ring loads the inner and outer rings in the axial direction (item 5,

Figure 22). This axial loading is provided to help keep the inner ring

centered since it has very little differential pressure to hold it in

place. Because the compression of the O-ring is very important,

using the correct durometer is critical. Alternative seal designs use a

spring between the inner and outer rings to provide axial loading. The

spring is located between items 6 and 7 in Figure 23. This prevents

changes in axial loading due to O-ring degradation and also prevents

the O-ring from causing the inner ring to hang up in an eccentric

position. Normally the outer rings are loaded in the axial direction

by a substantial differential pressure. The radial sealing surface on

the outboard of the outer rings can easily wear in high-pressure

applications. For this reason, it is common for these contact surfaces

to be hard-surface coated (i.e., HVOF) (Figure 23). This produces

hardness values that are approximately 70 to 75 Rockwell C.

Process

Gas

Atmosphere

231

simplified combination of the conservation of mass and

momentum equations for a fluid (Equation (5)). For a centered ring

with constant viscosity and linear pressure drop, the leakage

between the ring and the rotating shaft can be approximated by

Equation (6). The net result is that the leakage between the floating

rings and shaft sleeve is proportional to the cube of the clearance.

h

h3 P

h3 P

h

1

=

2

2

6

z 6 z

R

Q=

Dh3P

L

(5)

(centered)

(6)

It is important for the floating ring seals to stay centered to reduce

the amount of leakage. The leakage rate for eccentric rings is

approximated by Equation (7).

Q=

Dh3P

3e2

1

L

2

(eccentric)

(7)

Neither floating ring nor pumping bushing seals provide positive

shutoff. If the seal oil pressure drops below the process gas

pressure, the process gas will escape down the shaft. For this

reason, they are not normally used for hazardous applications (i.e.,

H2S, acid gas).

Pumping Bushing Seal

Tilting pad

ring/bearing

Figure 22. Floating Ring Seal with Tilt-Pad on Outer Rings.

(Courtesy of Dresser-Rand)

Atmosphere

Process

Gas

Hard surfaced areas

A slight variation of the floating ring seal is the pumping

bushing seal. The straight inner ring is replaced with a conical

sleeve (Figure 24) or a radially stepped arrangement (Figure 25).

The pumping bushing design has larger radial clearances between

the stationary inner ring and the rotating member (typically 0.008

to 0.012 inch). The flow of sour oil into the compressor is retarded

by the dynamic pumping action of the cone or radial step, which

acts like an impeller. The sour leakage rate of the pumping bushing

seal is less than standard floating ring seals but more than contact

seals. Because of the larger radial clearance, the pumping bushing

seal may be considered less susceptible to contaminants in the seal

oil than standard floating ring seals. However, it is much more

sensitive to changes in rotational speed and axial misalignment due

to thermal growth. The pumping bushing seal requires flow

through seal oil, so its seal oil system is slightly more complicated

because it has an overhead seal oil tank and a back-pressure

controller (Figure 26). The flow-through oil is required to remove

the additional heat generated by the pumping bushing.

Figure 23. Floating Ring Seal with Hard Surfaced Faces.

(Courtesy of Dresser-Rand)

Because of the low differential pressure across the inner ring, the

correct operation of floating ring seals is very dependent upon the

condition of the balance piston seal (Figure 20). Besides

counteracting the thrust in the compressor, the balance piston seal

reduces the pressure on the discharge end seal to approximately

suction pressure. Normally, the differential pressure across the

balance line is less than 2 psid (even for high-pressure

applications). If the balance piston seal fails, the seal reference

pressure will rise as the balance cavity pressure rises. Because the

seals are supplied off a common header, this increases the

differential pressure across the inner ring in the suction end seal.

This will increase the sour oil leakage on the suction end. Note:

failure of the balance piston seal has much less effect on the oil

seals if the compressor is equipped with a seal equalizing line.

Leakage

The leakage through both the inner and outer rings is

approximately laminar due to the very small clearances. This flow

regime is modeled with the Reynolds equation, which is a

Inner ring

Atmosphere

Process

Gas

Rotating

Cone

Figure 24. High-Pressure Cone Seal with Multiple Outer Rings.

(Courtesy of Dresser-Rand)

232

PROCEEDINGS OF THE 29TH TURBOMACHINERY SYMPOSIUM

Radially stepped

inner ring

Figure 25. Pumping Bushing Seal. (Courtesy of Kaydon Ring and

Seal)

Figure 27. Typical Minimum Pressure Required for Floating Ring

Seals. (Courtesy of Dresser-Rand)

ring and the seal housing. In contrast, the outer rings can greatly

affect the rotordynamics of the system, especially if it is a highpressure application. The high differential pressure can cause large

radial frictional forces between the floating rings and the housing.

This can cause the rings to lock up in an eccentric radial position

and act like a straight journal bearing. This can produce large

amounts of destabilizing cross-coupled stiffness. This can be

reduced by various methods:

Lower the balanceAdjusting the balance so that the normal

load produced by the differential pressure is lower, resulting in

lower radial frictional loads. However, a minimum load is required

to keep the seal ring from fretting.

Hard

surface radial facesCoat the radial sealing faces to

reduce the coefficient of friction between the floating rings and

seal housing, thus reducing the tendency of the seal rings to lock

up in an eccentric position.

Increase

the number of segments in the seal landThis

increases the turbulence in the seals that reduces the cross-coupled

stiffness produced, but may reduce the direct damping as well. A

full rotordynamic study must be done to evaluate the effects of this

change.

Replace the inner ring of the outer ring group with a tilt-pad

ring/bearing (Figure 22)This tilt-pad seal produces less crosscoupled stiffness than the one-piece ring. The centered leakage rate

may be slightly higher, but since the seal tends to stay more

centered than conventional ring seals, the actual leakage may be

less.

A comparison of contact and floating ring seals is shown in

Table 3.

Figure 26. Seal Oil System for Pumping Bushing Seal. (Courtesy of

Dresser-Rand)

Floating ring seals normally require a minimum suction pressure

to ensure proper lubrication before starting the compressor (Figure

27). Obviously, this is more of a concern for high-pressure seals

designed to operate with high differentials across the outer rings.

Note that the minimum pressure is a function of the shaft rotational

speed.

Rotordynamic Effects

The rotordynamic effects of the floating ring seals are

similar to those of face seals, though floating ring seals tend to

have more rotordynamic problems due to their application in highpressure applications. The inner seal ring has very little effect on

the rotordynamics of the compressor because there is very little

differential pressure across the ring (< 5 psid). This normally

prevents the development of large frictional loads between the seal

Table 3. Comparison of Contact and Floating Ring Seals.

Construction

Seal oil dp

Leakage rates

Positive Shutoff

Rotordynamic

Effects

Pressure Limits

Speed Limits

Clearance

Seal oil system

Sensitive to axial

growth

Sensitive to speed

changes

Sensitive to

balance piston

problems

Mechanical

Contact

Maybe complex to

assemble

75-40 psid

5-10 gpd

Yes

Negligble

Floating Ring

Standard

Pumping Bushing

Very simple

Simple

500-1500 psi

300 ft/s

0.0001-0.0005 inch

DP control

Yes

5-10 psid

10-25 gpd

No

May be a problem

with high pressure

applications

None

None

0.0015-0.005 inch

Ovhd Tank

No

5-10 psid

10-15 gpd

No

May be a problem

with high pressure

applications

5000 psig

Yes

0.008-0.012 inch

Ovhd Tank w/ DP

Yes

Slightly

No

Yes

Very Little

Yes

Yes

API CENTRIFUGAL COMPRESSOR OIL SEALS AND SUPPORT SYSTEMS

TYPES, SELECTION, AND FIELD TROUBLESHOOTING

233

TROUBLESHOOTING GUIDELINES/STEPS

The first step to solving a seal problem is identifying the

problem, which is usually one of the following:

Cannot maintain seal oil differential pressure or seal oil tank level

Excessive sour seal oil consumption

Excessive sweet seal oil consumption

Performing the following guidelines/steps can help identify the

seal or seal system problem and provide valuable information for

design modifications that may be needed to improve the reliability

of the seal system.

1. Monitor sour oil consumption regularly (i.e., how fast is the

level dropping in the reservoir)If a degassing tank is used, shut

it off periodically to measure sour oil consumption. Even if the

degassing tank is working correctly, the amount of sour leakage

should be monitored.

2. Check seal oil differential pressure readingA differential

pressure gauge or transmitter should always be used, not two

separate pressure gauges. For contact seals verify that the seal oil

differential pressure is maintained at a constant value as the

process pressure changes. This is very important on startup, when

the process pressure may change rapidly. Likewise, for floating

ring seals, verify that the seal oil level in the overhead tank is not

fluctuating. A common problem is a plugged gas reference line,

which results in the seal oil differential pressure being either too

high or too low as the process changes.

3. Check oil quality, water content, viscosity, metal additives.

Improper seal oil (too light or too heavy) can cause the seals

to run hotter than design, resulting in higher wear and leakage.

OEMs usually recommend a certain viscosity range, typically 100

to 150 SSUs at the seal oil supply temperature. This may require

blending in a heavier oil during higher ambient temperatures if seal

oil cooling is a problem.

Water content should be kept below 50 ppm (below 10 ppm if

possible). Water will greatly reduce the viscosity of the oil.

Likewise, water may have metals or other contaminants that will

foul the seals (Figures 28 and 29).

Figure 29. Grooves in Shaft Sleeve Caused by Oil Rings Due to

Contaminated Seal Oil.

4. Measure seal oil supply flowratesNormally, seal oil systems

are designed to control the seal oil differential pressure, not the oil

flowrate. Likewise, the seal oil supply to the compressor is

normally common for both ends of the compressor (i.e., the seal oil

differential pressure is only controlled at one seal). Measuring the

flowrate to the seals at key locations can reveal problems in the seal

oil system.

Check seal oil control valve output. The output of the DPC

control valves in Figures 17 and 18 as well as the level control valve

in Figure 20 can be used to calculate the seal oil flowrate to the

seals, because the seal oil flowrate is not normally measured. The

flowrate through a control valve can be approximated by Equation

(8). Note: the value of Cv is dependent upon the valve position as

well. Figure 30 shows a typical Cv chart for different types of

control valves (this can be supplied by the valve manufacturer).

Bench testing the control valve (in a shop) and measuring the

flowrate and valve position can achieve the most accuracy.

P

Q = CV

Generally, oil additives are bad for seals. Metallic additives

can react with process gases and cause fouling at the seal faces.

Turbine oils, which normally contain only a small amount of

antifoam and antioxidation additives, are normally recommended.

Seal oil should contain less than 5 ppm zinc.

(% Open)

(8)

Cv Values

100

% Max Flow

80

60

40

20

0

0

20

40

60

80

100

Percent Open

Linear

Quick Opening

Equal Percent

Figure 30. Values of Cv for Three Types of Typical Control Valves.

Figure 28. Deposits on Shaft Sleeve Caused by Contaminated Seal

Oil (Amine and Water).

Measure the seal oil flow to each end of the compressor

using a nonintrusive flowmeter (ultrasonic is preferable). The

higher seal oil supply flow may not be the problem seal. Since

234

PROCEEDINGS OF THE 29TH TURBOMACHINERY SYMPOSIUM

both seals are normally supplied from a common header, if the

atmospheric seal fails on one end, it can starve the entire seal on

the other end. Knowing the supply flowrate can assist in

determining whether the excessive leakage is on the process or

atmospheric side. For example, the original seal oil flow diagram

for a wet gas compressor with contact seals is shown in Figure

31. The seal oil flowrates were measured at various locations and

are shown in Figure 32. As can be seen, nearly all the seal oil is

going to one side. This one-sided flowrate is confirmed by

observing the bearing oil drain on the end with a failed bushing

seal. The sight glass in the bearing drain was completely full.

Likewise, there was lube oil leaking from the coupling guard.

This was caused by the flowrate through the bushing exceeding

the drain capacity of the sweet oil drain and spilling over into the

coupling guard (Figure 33). Inspection of the seals showed

broken pieces of metal in the sweet oil drain (Figure 34). It was

determined that the broken pieces shown in Figure 34 were

pieces of the wavy spring used to provide a preload for the

atmospheric bushing seal (item 12, Figure 35). The spring failed

because it had spun with shaft (Figures 36 and 37). The broken

spring damaged the bushing as it was pushed out the atmospheric

bushing (Figure 38).

SEAL OIL

SUPPLY

20 gpm

20 gpm

BUSHING

SEAL

FACE

SEALS

TO SOUR

TRAPS

(10 gpd)

TO SOUR

TRAPS

(10 gpd)

14 gpm

Coupling

Guard

Gearbox

Oil level builds in bearing

housing and runs over into

coupling guard, causing

leak

To Lube Oil

Reservoir

Sight glass is completely full on

Drive End, less than half full on

Non-Drive End

BUSHING

SEAL

TO OIL

RESERVOIR

(6 gpm)

Seal oil supply

10-15 gpm

Normally

4 gpm, maybe

as high as 10

gpm

Figure 33. Oil Leaking from Coupling Guard Because of Failed

Atmospheric Bushing Seal.

TO OIL

RESERVOIR

(6 gpm)

14 gpm

DPC

TO OIL

RESERVOIR

Figure 31. Design Flowrates for Contact Seal Oil System.

SEAL OIL

SUPPLY

30-34 gpm

6-10 gpm

BUSHING

SEAL

BUSHING

SEAL

FACE

SEALS

TO OIL

RESERVOIR

(20-26 gpm)

TO SOUR

TRAPS

(10 gpd)

TO SOUR

TRAPS

(~700 gpd)

14 gpm

Figure 34. Metal Fragments Removed from Contact Seal Sweet Oil

Drain.

TO OIL

RESERVOIR

(6 gpm)

0 gpm

DPC

TO OIL

RESERVOIR

Figure 32. Measured Flowrates for Contact Seal Oil System with

Failed Atmospheric Seal.

Compare the sour seal oil flowrates (either through flow sight

glasses or by monitoring how fast the levels rise in the seal oil

traps).

Figure 35. Cross-Section of Contact Seal Showing Wavy Spring.

API CENTRIFUGAL COMPRESSOR OIL SEALS AND SUPPORT SYSTEMS

TYPES, SELECTION, AND FIELD TROUBLESHOOTING

235

Compare the sour oil drain temperatures on both ends of the

machine. Typically, the hottest sour drain indicates the highest sour

oil flow. The flow through the sour oil drain is normally low

enough that the line is relatively cool. Increased sour oil leakage

will cause it to warm up.

Compare the sweet oil drain temperatures on both ends of the

compressor. In contrast to the sour drains mentioned above, the

cooler sweet oil drain is many times the problem (higher flow

dilutes temperature rise in seal). For example, the seal oil pump for

a high-pressure barrel compressor was having trouble maintaining

a level in the seal oil overhead tank. The measured seal oil supply

rate indicated that the discharge end seal was consuming

approximately three times as much seal oil as the suction end

(Figure 39). Even though the gas on the discharge seal is much

hotter (there was no buffer gas), the sweet oil drain on the

discharge end was 30F cooler because of the higher flowrate.

Figure 36. Wavy Spring Showing Wear on High Spots Caused by

Spring Spinning.

Design flowrates

shown in ( )

21 (12) gpm

5 (6) gpm

16 (6) gpm

115 F

145 F

Clean Oil

to

Reservoir

Clean oil

to

reservoir

Gas to

Flare

T

Sour

Oil

Figure 37. Closeup of Wear on Wavy Spring.

Figure 39. Floating Ring Seals with High Sweet Oil Leakage.

5. Check buffer gas differential pressure

Too lowIf a buffer gas is used to isolate the seals from the

process gas, the buffer pressure is normally maintained at 3 to 5

psid above the process gas pressure (which should always be the

balance piston end of the compressor). Too little buffer gas

differential pressure can allow the process gas to migrate into the

seals, which may foul the sour seal oil. Adequate buffer gas

differential can be verified by sampling the seal gas off the sour

traps. If it contains process gas, the differential is too low.

Too highToo much buffer gas differential pressure ( > 5

psid) can cause a venturi-type effect in the compressor (Figure 40).

This can result in sour oil being ingested into the compressor

instead of draining to the sour traps.

Figure 38. Damage to Bushing Seal Caused by Broken Wavy

Spring.

6. Check differential pressure between seal cavities (Figure

41)Most compressor OEMs design the balance piston for a

differential of less than 2 psid. If the balance piston seal

begins to wear, this differential can go up, which can be very

detrimental for floating ring seals, which typically operate with

only 5 psid across the process ring. As mentioned above, the gas

reference pressure should always be connected to the highpressure end of the compressor. Increasing the balance line

differential causes the low-pressure seal to have a higher seal oil

differential pressure, which will increase its sour oil leakage.

Likewise, if for some reason the gas reference is on the lowpressure seal, increased balance line differential can cause the gas

236

PROCEEDINGS OF THE 29TH TURBOMACHINERY SYMPOSIUM

Draws sour

oil into

compressor

Vent to atmosphere or

low pressure recovery

vessel

High buffer gas

velocity,

Sour oil from

seal traps

Shaft

Oil Level

Oil Seal

Process

Gas

HTR

Secondary drain

off bottom of tank

for disposal

Buffer

gas

Figure 40. Effects of Excessive Buffer Gas on Sour Oil Leakage.

pressure on the high-pressure side to exceed the seal oil pressure.

This will cause the seal to overheat and fail. As mentioned above,

a seal equalization line will prevent this problem. Even though

contact seals operate with a much higher seal oil differential

pressure, the seal traps should still operate at the same pressure. If

they do not it probably indicates a problem with the sealing

system.

Return to

reservoir

8. Verify that the seal oil traps are properly ventedIf the seal oil

traps are not vented properly, the sour seal oil will be ingested into

the compressor. This can easily happen if the sour oil trap vents are

not routed to a low-pressure destination such as the flare header. It

is common for the vents off high-pressure sour oil traps to be

routed to an alternate destination to recover the gas. If the

destination pressure increases or the suction pressure of the

compressor decreases, the traps will not work correctly. An

example is a recycle hydrogen compressor in a Gulf Coast refinery

that always consumed large amounts of seal oil on unit startup until

the unit lined out and then it would quit. The problem only

occurred during startup because the sour oil traps were vented to

the plant fuel gas system. This was an adequate design as long as

the process unit was operating properly and the suction pressure of

the compressor was sufficiently above the fuel gas pressure to vent

the sour oil traps. However, on startup the fuel gas system created

enough backpressure on the oil traps to prevent the traps from

working properly.

9. Determine if the compressor has been pressurized without the

seal oil system in serviceIf the compressor has been pressurized

before the seal oil system was in operation (i.e., the seal oil

differential pressure was negative), the process gas may have

pushed trash into the space between the seal faces (contact seals)

or between the floating rings and the seal sleeves.

DPG

LC

Heavier liquids

that have a

flash point

above tank

temperature

Figure 42. Typical Seal Oil Degassing Tank.

Sour oil

to traps

Ball float that

controls drain

valve in top of

standpipe

T

LC

Figure 41. Measuring Differential Pressure Between Seal Oil

Traps.

7. Verify that degassing tank is working properlyMany systems

today have a seal oil degassing tank, which takes the sour oil from

the seal oil traps, heats it to approximately 180F, and vents off any

light hydrocarbons or water (Figure 42). One word of caution,

some hydrocarbons can collect in the drum that have a flashpoint

above 180F. Likewise, most amines (MDEA for sure) have a

flashpoint over 250F and will collect at the bottom of the

degassing tank. After a period of time, the level of heavier

contaminants will rise until they reach the level of the standpipe

and are drained into the reservoir. For this reason, the drain off the

bottom of the tank should be opened at least once a shift by

operations to drain away any contaminants collecting there. A

faulty or poorly designed degassing tank can contaminate a seal oil

reservoir in a matter of days, which is much faster than the

intervals plants sample their lube oil for analysis. Nitrogen

sparging can be used to improve the efficiency of the degassing

tank. It reduces the partial pressure of H2S in the tank, which

lowers the H2S concentration in the oil. Degassing tanks should

always be vented to atmosphere if at all possible.

10. Check performance of seal oil pumpA lack of seal oil

differential may be caused by insufficient seal oil pump

performance. The easiest method to determine if the seal oil pump

is performing well is to switch to the spare. Normally both pumps

will not be deteriorated at the same time. Use the flowrate

measured in step 4 above as well as the motor amps to determine

if the pump is performing correctly. Likewise, verify that the seal

oil temperature is below 110F. Especially in high-pressure units,

the slippage through a positive displacement pump is greatly

affected by the oil temperature (i.e., viscosity).

11. Check discharge check valve on spare seal oil pumpA

leaking discharge check valve on the spare seal oil pump may

cause the seal oil flow to the compressor to be low and result in a

lower than normal seal oil differential. This can be confirmed by

blocking in the discharge of the spare pump and/or the flow

measurements made in step 4.

12. Check all spillbacksThe system pressure controller on the

lube and/or seal system will normally spillback to the reservoir. If

this controller is flowing too much or too little, it can cause either

inadequate flow or excessive seal oil differential pressure and

cause the compressor seal leakage to increase.

13. Check that gas pressure gauges do not have liquid legsAll

gas pressure instrumentation should be located above the shaft

centerline of the compressor to prevent liquid build up in the tubing

that could affect the readings.

API CENTRIFUGAL COMPRESSOR OIL SEALS AND SUPPORT SYSTEMS

TYPES, SELECTION, AND FIELD TROUBLESHOOTING

NOMENCLATURE

B

Cv

e

h

K

L

P

Q

r

=

=

=

=

=

=

=

=

=

Balance ratio

Control valve flow coefficient

Eccentricity ratio

Seal clearance

Seal face pressure gradient, dP/dh

Seal land length

Pressure, psi

Leakage flowrate

Radius

Subscripts

b = Balance

i = Inside

o = Outside

Symbols

= Viscosity

BIBLIOGRAPHY

Bloch, H. P., 1979, Reclaiming Compressor Seal Oil,

Compressor Handbook for the Processing Industries,

Hydrocarbon Processing, pp. 179-182.

Brown, M., 1995, Seals and Sealing Handbook, Fourth Edition,

Oxford, United Kingdom: Elsevier Advanced Technology.

Buck, G. S., Jr., 1978, The Role of Hydraulic Balance in

Mechanical Pump Seals, Proceedings of the Seventh

Turbomachinery Symposium, Turbomachinery Laboratory,

Texas A&M University, College Station, Texas, pp. 133-138.

Lesiecki, G., 1977, Evaluation of Liquid Film Seals, Associated

Systems and Process Considerations, Proceedings of the Sixth

Turbomachinery Symposium, Turbomachinery Laboratory,

Texas A&M University, College Station, Texas, pp. 145-148.

237

Lewis, R. A., 1977, Mechanical Contact Shaft Seal, Proceedings

of the Sixth Turbomachinery Symposium, Turbomachinery

Laboratory, Texas A&M University, College Station, Texas,

pp. 149-152.

Nelson, W. E., 1979, Compressor Seal Fundamentals,

Compressor Handbook for the Processing Industries,

Hydrocarbon Processing, pp. 72-77.

Salisbury, R. J. and Forsthoffer, W. E., Sept/Oct 1994,

Troubleshooting Centrifugal Compressor Oil Seal Problems,

Turbomachinery International.

Salisbury, R. J., Stack, R., and Sassos, M. J., 1984, Lubrication

and Seal Oil Systems, Proceedings of the Thirteenth

Turbomachinery Symposium, Turbomachinery Laboratory,

Texas A&M University, College Station, Texas, pp. 151-178.

Schmal, R. J., 1977, A Discussion of Turbine and Compressor

Sealing Devices and Systems, Proceedings of the Sixth

Turbomachinery Symposium, Turbomachinery Laboratory,

Texas A&M University, College Station, Texas, pp. 153-170.

ACKNOWLEDGEMENTS

The paper would not have been possible without the significant

techinical contributions of Ron Fox, Jr., of Dresser-Rand.

Likewise, the following individuals provided excellent reviews

of the paper that increased its quality as well: Ted Gresh and Jerry

Rodriguez of Elliott Co., David Lowe of Flowserve, Dennis

Schaibly of Kaydon Ring and Seal, John Eeds of Exxon-Mobil,

and Alan Lebeck of MSTI.

238

PROCEEDINGS OF THE 29TH TURBOMACHINERY SYMPOSIUM

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Nutrition For AthletesDocument37 pagesNutrition For AthletesAnonymous e1sArVj5zl100% (1)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Ul 854 - 2014 PDFDocument64 pagesUl 854 - 2014 PDFDouglasNo ratings yet

- Dna60 PDFDocument15 pagesDna60 PDFAc IdNo ratings yet

- Cast Iron Grades and SpecificationDocument1 pageCast Iron Grades and SpecificationRajagopal100% (1)

- Optibelt Compact Catalogue Power TransmissionDocument45 pagesOptibelt Compact Catalogue Power TransmissionvietkhamNo ratings yet

- Witness Testing of API 610 Centrifugal Pumps and API 611 Steam TurbinesDocument9 pagesWitness Testing of API 610 Centrifugal Pumps and API 611 Steam Turbinessiva242245No ratings yet

- AlphaRex3 UreDocument11 pagesAlphaRex3 UreRajagopalNo ratings yet

- Sealing Systems Impact Energy EfficiencyDocument20 pagesSealing Systems Impact Energy EfficiencyRajagopalNo ratings yet

- (ARTICLE) Gas Turbine DegradationDocument36 pages(ARTICLE) Gas Turbine DegradationFrancisco Baptista100% (1)

- Article Understanding and Preventing Turbine OverspeedDocument14 pagesArticle Understanding and Preventing Turbine OverspeedTan Nguyen HuuNo ratings yet

- Avoiding The Pitfalls of Viscosity-Starved MachinesDocument1 pageAvoiding The Pitfalls of Viscosity-Starved MachinesRajagopalNo ratings yet

- SA Steam GenerationDocument6 pagesSA Steam GenerationRajagopalNo ratings yet

- Solving Super-Synchronous Vibration On A Double Suction PumpDocument35 pagesSolving Super-Synchronous Vibration On A Double Suction PumpRajagopal100% (1)

- Alpharex3 Time Switch Brochure 03Document16 pagesAlpharex3 Time Switch Brochure 03RajagopalNo ratings yet

- Premium Shell Vitrea Oils for Industrial ApplicationsDocument3 pagesPremium Shell Vitrea Oils for Industrial ApplicationsRajagopalNo ratings yet

- Emergency Conversion Pack VOL380 Data SheetDocument1 pageEmergency Conversion Pack VOL380 Data SheetRajagopalNo ratings yet

- Gas Turbines Emissions and Control GEDocument36 pagesGas Turbines Emissions and Control GECarlos SopasNo ratings yet

- Steel Technical CablesDocument37 pagesSteel Technical Cablesgreat2007No ratings yet

- Technical Information: 1. Hoist RopesDocument17 pagesTechnical Information: 1. Hoist RopesvikasgahlyanNo ratings yet

- Aaf En7792012Document6 pagesAaf En7792012Bruno GuedesNo ratings yet

- T8T5 Emergency Conversion PackDocument1 pageT8T5 Emergency Conversion PackRajagopalNo ratings yet

- SKF Stroboscopes TKRS SeriesDocument2 pagesSKF Stroboscopes TKRS SeriesRajagopalNo ratings yet

- Dodge Sleevoil RTLDocument12 pagesDodge Sleevoil RTLRajagopalNo ratings yet

- Ge Runout BasicsDocument14 pagesGe Runout BasicsRajagopal100% (1)

- Bearing Life TimeDocument83 pagesBearing Life TimeFadoooll100% (1)

- SumitomoDocument271 pagesSumitomoRajagopal60% (5)

- Honeycomb Seal Effect On Rotor Response To UnbalanceDocument12 pagesHoneycomb Seal Effect On Rotor Response To UnbalanceRajagopal100% (1)

- Choose a Dust Collection SystemDocument5 pagesChoose a Dust Collection SystemRajagopalNo ratings yet

- GTL TechnologyDocument11 pagesGTL TechnologyRajagopal100% (1)

- Tp022 - Turbomaquinas y ResonanciaDocument20 pagesTp022 - Turbomaquinas y Resonanciaalex roNo ratings yet

- Bearing Life TimeDocument83 pagesBearing Life TimeFadoooll100% (1)

- Original Gasket Technology GuideDocument40 pagesOriginal Gasket Technology GuideAtty AttyNo ratings yet

- GTL TechnologyDocument11 pagesGTL TechnologyRajagopal100% (1)

- The Design, Development and Future of Electric Vehicle: Prof. Eric ChengDocument18 pagesThe Design, Development and Future of Electric Vehicle: Prof. Eric ChengDeepak ChaurasiaNo ratings yet

- Kaplan Turbine Working As A Propeller CFD InvestigDocument11 pagesKaplan Turbine Working As A Propeller CFD InvestigclaudehackerNo ratings yet

- Ama Drainer & Ama Porter: Vertical Monobloc Dewatering PumpsDocument2 pagesAma Drainer & Ama Porter: Vertical Monobloc Dewatering Pumpssmita reddyNo ratings yet

- 6-Achs SPMT 210.12.4 G4 6-Axle SPMT 210.12.4 G4: Scheuerle-Fahrzeugfabrik GMBHDocument22 pages6-Achs SPMT 210.12.4 G4 6-Axle SPMT 210.12.4 G4: Scheuerle-Fahrzeugfabrik GMBHsrikanthc8550% (2)

- Distillation and Vapor Pressure Test of Gasoline Fuel: Fuels TestedDocument3 pagesDistillation and Vapor Pressure Test of Gasoline Fuel: Fuels TestedReyes, Ishmael Edward John U.No ratings yet

- Annual Syllabus 9 & 10Document6 pagesAnnual Syllabus 9 & 10Kumar SiddhantNo ratings yet

- CV - Alok Singh - Tech HSE & Loss Prevention Engineer (May-2018)Document5 pagesCV - Alok Singh - Tech HSE & Loss Prevention Engineer (May-2018)toalok4723No ratings yet

- Energy Consumption Benchmark Guide: Cement Clinker ProductionDocument14 pagesEnergy Consumption Benchmark Guide: Cement Clinker ProductionVisnu SankarNo ratings yet

- Delta Ia-Mds Vfd-Ed Um en 20150910-1Document280 pagesDelta Ia-Mds Vfd-Ed Um en 20150910-1FahadNo ratings yet

- 001 NemDocument4 pages001 NemNg Han PeiNo ratings yet

- Solar Refrigerator SpecsDocument4 pagesSolar Refrigerator SpecsFaisal Bin FaheemNo ratings yet

- Transport Phenomena: Instructor: Assistant Professor Department of Chemical Engineering, BUET, Dhaka-1000Document21 pagesTransport Phenomena: Instructor: Assistant Professor Department of Chemical Engineering, BUET, Dhaka-1000touhidNo ratings yet

- MVDC-Connected Offshore Wind Power Hybrid Resonant ConverterDocument4 pagesMVDC-Connected Offshore Wind Power Hybrid Resonant ConverterBrightworld ProjectsNo ratings yet

- Final Directory Handbook For ADIPEC 2023Document54 pagesFinal Directory Handbook For ADIPEC 2023Zharif ZainiNo ratings yet

- YM80SA Abrasive Belt Polishing Machine-Operation ManualDocument7 pagesYM80SA Abrasive Belt Polishing Machine-Operation ManualAgha Ali KhanNo ratings yet

- Energy Conservation Oppurtunities in Boiler SystemDocument34 pagesEnergy Conservation Oppurtunities in Boiler SystemSiddharth Jain67% (3)

- Site Effect Evaluation Using Spectral Ratios With Only One StationDocument15 pagesSite Effect Evaluation Using Spectral Ratios With Only One StationJavier MtNo ratings yet

- ABB Terminal BlocksDocument236 pagesABB Terminal BlocksBenoit LefebvreNo ratings yet

- Lab 5Document9 pagesLab 5Cem UsmangilNo ratings yet

- Fluid MechDocument10 pagesFluid MechPrasant KumarNo ratings yet

- Edited Economics AsDocument476 pagesEdited Economics AsShakeela ShanmuganathanNo ratings yet

- O359h MilDocument90 pagesO359h MilNisar AhmedNo ratings yet

- 320, 320L Medicion de Presiones Bomba Hidraulica PDFDocument181 pages320, 320L Medicion de Presiones Bomba Hidraulica PDFrprim100% (2)

- Lightning Protection System Design PDFDocument46 pagesLightning Protection System Design PDFhportezNo ratings yet

- Hum BirdDocument179 pagesHum BirdSuman ChhetryNo ratings yet

- Optical Properties of MaterialDocument63 pagesOptical Properties of MaterialNoviNo ratings yet

- WCR For Canon Motor Relay FailureDocument1 pageWCR For Canon Motor Relay FailureIqmal WahabNo ratings yet