Professional Documents

Culture Documents

NO.06BMethod Statement For Gravity Retaining Walls Using C20 Contrete Rev.a

Uploaded by

isurupushOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

NO.06BMethod Statement For Gravity Retaining Walls Using C20 Contrete Rev.a

Uploaded by

isurupushCopyright:

Available Formats

Matara- Kataragama Railway Extension Project (Phase 1) Sri

Lanka Matara-Beliatta Sector

Matara-Kataragama Railway Extension Project

Matara-Beliatta Sector (Phase 1)

(DK0+44 ~ DK26+461)

Method statement for Construction of Concrete Gravity Retaining Walls

MS- 06B

Rev. A

Contractor : China National Machinery Imp. & Exp. Corp.

No

REV.A

Date

2014.3.4

Prepared

LiBO

Checked

Zhong Xiang

Approved

He peizhi

Remark

Matara- Kataragama Railway Extension Project (Phase 1) Sri

Lanka Matara-Beliatta Sector

CONTENT

1.0 Purpose of Method Statement

2.0 Relevant documents and Standards

3.0 Responsibilities for activity Describe within this Method Statement

4.0 Detailed method of carrying out method statement activity

5.0 QA & QC measures

6.0 HSE Measures

Appendix 1 .RETAINING WALL FORMWORK

Appendix.2. Relevant Chinese material specification

Matara- Kataragama Railway Extension Project (Phase 1) Sri

Lanka Matara-Beliatta Sector

Method statement for Construction of Concrete Gravity Retaining Walls

1.0 Purpose of Method Statement

This method statement provides the details of the materials; the equipment, the procedure and

relevant documents related to the construction of concrete gravity retaining wall from DK 0+044 ~

DK 26+461

2.0 Relevant documents and Standards

2.1 Typical drawings SLR-CMC-D-EAW-SD-07

2.2 Working drawings for Gravity Retaining wall

3.0 Responsibilities for activity Describe within this Method Statement

Construction manager, section manager, section engineer, and other relevant personnel within whose

scope of works shall be responsible for referred construction activities in to the construction of

gravity retaining wall from DK 0+044 ~ DK 26+461 shall carry out according to the method

stipulated in this statement unless otherwise changed by the Engineer.

4.0 Detailed method of carrying out method statement activity

4.1 General construction requirements

Embedded depth for gravity retaining wall in embankment fill slope is not less than 1.0m

Matara- Kataragama Railway Extension Project (Phase 1) Sri

Lanka Matara-Beliatta Sector

Notes

b is the width, H denotes the height, 1:n denotes the slope gradient. The values of b, H and n are

indicated in the drawings of different construction sites.

If the height of the retaining wall is higher than 3.0m, protective railing will be provided.

The embedded depth of retaining wall in cutting areas will be not less than 1.2m, below the shoulder

or the berm of side the ditch and not less than 0.2m below base of the side ditch.

Matara- Kataragama Railway Extension Project (Phase 1) Sri

Lanka Matara-Beliatta Sector

If the retaining wall is in the inclined ground the embedded depth is not less than 1.0m for soil and

weak rock, and the horizontal distance between toe to the embedded ground surface shall be 1.5m to

2.5m. For the hard rock embedment depth will be not less than 1m, the horizontal distance between

toe to the embedded ground surface shall be 0.6m 1.5m. If the gradient of the slope is greater than

5%, the base of the retaining wall will be stepped.

If the wall height is greater than 6m, C20 rubble concrete will be used for the construction. If the

wall height is less than 6m, M10 Cement mortar will be used.

0.1m dia. PVC pipe drain holes will be provided in wall arrange in 2m X 2m grid. The inner end of

PVC pipe is wrapped with geotextile. The first raw of drain holes will be 0.3m higher than ground or

shoulder level. 0.3m thick, filter gravel/sand layer will be constructed between embankment or slope

surface and inner surface of gravity retaining wall. 0.5m thick compacted impermeable clay layer

will be provided in at each ends of the filter layer, 0.5m below from the original ground level at the

bottom and 0.5m from top of the retaining wall.

At the sites where ground water development is high, the filter layer thickness will be increased to

0.5m. At the slopes where it is very hard to excavate (eg: hard weathered rock) or coarse-grained

sandy back fills or slopes the filter later will be omitted.

4.2 Materials

4.2.1 C 20 Rubble concrete

4.2.2 Ladder Rebar (see attached drawing)

4.2.3 100mm dia. gauge 600 or above PVC pipe for drain holes

4.2.4 Gravel and sand filter materials

4.3 Preparation

After the setting out for foundation, the excavation will be carried out until design level reached. The

dynamic cone penetration test, at least 1 per every 30m segment will be carried out to assess the

bearing capacity of in-situ soil. If the bearing capacity is not sufficient, additional excavation will be

carried out to sound bearing strata. The additional excavation depth will be back filled with

compacted rubble stone.

After excavation, the foundation pit will be continuously de water, so the bearing stratum will not

allow getting soaked.

The base trench will be excavated section by section or at different locations. Continuous excavation

of a long section that will influence the stability of Embankment slope is strictly forbidden. The

maximum length of wall section is 30m.

Matara- Kataragama Railway Extension Project (Phase 1) Sri

Lanka Matara-Beliatta Sector

4.4 Wall construction

A). Form work

The formwork will be timber, steel or any other material approved by the Engineer. Timber forms

will be of approved quality, well seasoned and of uniform thickness, sound, free from warps, loose

knots, twists, wavy edges, saps and shakes or other defects affecting the strength of the form work

and appearance of the finished surface of the retaining wall. Metal sheets use for formwork will be

kept free from rust and dents with no surface blemishes that will impair the concrete surface finish.

The supports and scaffoldings will be of metal, sawn timber, round timber or of any other material

approved by the Engineer.

The temporary staging will be provided to enable the constructional operations to be performed in

the required sequence and in a safe manner. The false work will be properly constructed to provide

the necessary rigidity and to carry out loads, which will be required to support. Where necessary it

will include safe walkways to enable Engineer to inspect the form work, reinforcement and

concreting.

All formwork will be constructed that there will be no loss of materials from the fresh concrete.

Forms will be mortar tight, will be made sufficiently rigid by the use of ties and bracing to prevent

any displacement or sagging, and will be capable of withstanding all incidentals loading during

concreting.

Where internal ties, they will be extracted without damage to the concrete to a depth of at least

25mm from the finished concrete surface and the resulting holes filled with mortar. No permanently

embedded nuts will have less than 25mm concrete cover from finished concrete surface.

Immediately before concreting, the forms will be thoroughly cleaned either by water jetting or by

any other suitable method, temporary openings being provided for the purpose. Inside surfaces will,

if necessary coated with an approved material such as mould oil to prevent adhesion of the concrete.

This material will not be allowed to come in to contact with the reinforcement.

No concrete pouring will be carried out unless the Engineer has inspected and approved the

formwork, false work and reinforcement.

The engineer will be informed in advance as to when the formwork removed. The minimum period

between concreting and formwork removal for gravity retaining wall will be 01 day.

B). Concreting

The concerting of the retaining wall will be integrally done as possible. The retaining wall will be

supported using prop supports adequately until embankment filling behind the retaining wall

completes. The prop supports will be re adjusted as the embankment filling progress.

Matara- Kataragama Railway Extension Project (Phase 1) Sri

Lanka Matara-Beliatta Sector

The sections will be separated using settlement joints. The length of section will be 10m or as

specified in working drawings. The base trench will be excavated to the required level and pass the

bearing capacity test prior to the base construction. Formwork will be installed as per the design

drawing. Concrete should be uniformly produced and transported to site by truck mixer.

The concrete will be delivered to site and discharge within one and half hours after addition of

cement to the aggregates. Each batch of concrete delivered will be accompanied with batch ticket

bearing complete batching information. The temperature of fresh concrete will be maintained less

than 32C. The addition of water after initial mixing will not allowed. The concrete that is not within

the specified consistency limits at the time of placement will not be used.

All mixed concrete will be placed and compacted in the formwork, using approved vibrators of the

internal, external, or screed types or combination of thereof depending on the type of Job.

After one layer of concrete 150-300mm rubble layer will be placed on top of paved concrete layer,

and cover with C20 concrete, compact adequately using poker vibrators until voids between rubbles

fully occupied with concrete. The maximum particle size of the rubble will be limit to 2/3 of the

width of the formwork, in any case the thickness of the retaining wall less than 400mm.

During continuous concrete pouring, fresh concrete will be poured on already laid concrete is less

than 30 minutes old and where this gap is exceeded further placing will be subjected to testing the

already placed concrete surface to be live. In the event of surface is not live, it shall be treated as a

construction joint and to be allowed to set.

All concrete will be placed in layers not more than 300mm. No concrete dropped from height greater

than about 1.5m except with a prior approval from the Engineer.

The freshly laid concrete will be kept undisturbed and protected from effects of sun and rain and

from drying out until it hardens. After hardened concrete will be cured for 7 days.

4..3 Backfilling

4.3.1 Backfilling of retaining wall base excavation

After construction of the base of retaining wall, the slopes of excavation pit will be trimmed or

prepared the gradients mentioned in the drawings. The materials for the backfilling will be soil

except peat and organic clay and free from timber and any other degradable materials. The

backfilling will be carried out in 150mm thick compacted layers using light compaction equipments.

The requirement for the compaction is to form a firm surface.

Matara- Kataragama Railway Extension Project (Phase 1) Sri

Lanka Matara-Beliatta Sector

4. 3.2 Embankment filling behind the retaining wall

The concerting of the retaining wall will be integrally done as possible. The retaining wall will be

supported using prop supports adequately until embankment filling behind the retaining wall

completes. The prop supports will be re adjusted as the embankment filling progress. The

embankment filling behind the retaining wall described in steps as follows;

Step 1: First layer of embankment will be laid, 0.3m thick and 0.3m high, impermeable clay layer

will be placed and compact, the embankment soil layer close to the retaining wall compact using

Light compaction equipment.

Step 2: Re adjust the prop supports to the wall on compacted embankment soil layer slightly away

from former prop position. Care shall be taken not to remove all prop supports in one time that

would affect stability of the wall. Place and compact embankment soil around earlier prop supports

to the specified density.

Step 3: Continue the procedure until filling and compaction completes up to the top of the retaining

wall. The Filer layer construction shall be carried out simultaneously with the embankment filling

behind the retaining wall.

Matara- Kataragama Railway Extension Project (Phase 1) Sri

Lanka Matara-Beliatta Sector

Construction Flow Chart for C20 rubble concrete Gravity retaining wall

Preparatio

n

Setting

Out

Base Trench

Excavation

Sub grade

Bearing

Capacity Test

Pass

Base Formwork

Fail

Analysis and

Solution

Settlement Joint

Construction

Base Rubble

Concreting

Base Pit

Backfilling

Wall Formwork &

Filter Layer

Construction

Wall Rubble

Concreting

Formwork

Removal &

Curing

Rebar Ladder, Weep hole,

Settlement Joint

Construction

Ancillary Work

Matara- Kataragama Railway Extension Project (Phase 1) Sri

Lanka Matara-Beliatta Sector

5.0 Quality assurance and Quality control measures

5.1 Bearing capacity check will be carried out after excavation to designed foundation level to

ensure that it meets the requirements given in the design.

5.2 All the materials will be check to confirm that they meet requirements

5.3 Mortar and C20 concrete will be in accordance with the approved mix design

5.4 Formworks are well prepared and fixed firmly

5.5 Concrete pouring and rubble masonry works strictly conform to the method statement

6. 0 HSE Measurements

6.1. Deep base pit with less stable slope should be excavated section by section or with intervals

between two sections. Moreover, temporary support structure should be strengthened

6.2. The location and height of the stockpiles of wasted soil after excavation should not influence the

stability of the base pit

6.3. The construction procedure should be arranged reasonably, and slope protection will be done to

prevent landslide or collapse;

6.4. Information about rainfall ought to be known timely to take protective measures preventing

newly constructed soil surface from being washed directly by raining.

You might also like

- Laying of Wet Mix RoadbaseDocument4 pagesLaying of Wet Mix Roadbaseare_rail28100% (1)

- Retaining Wall Failures PDFDocument3 pagesRetaining Wall Failures PDFrockingjoe100% (1)

- Is 15058 2002Document12 pagesIs 15058 2002Santosh KumarNo ratings yet

- Elastic ShorteningDocument12 pagesElastic Shorteningo100% (1)

- C.C Road ConstructionDocument18 pagesC.C Road ConstructionJayesh GojiyaNo ratings yet

- 1.1 General: VOLUME III, Pavement Design Manual Part 3: Gravel Road Pavement Design GuideDocument27 pages1.1 General: VOLUME III, Pavement Design Manual Part 3: Gravel Road Pavement Design GuideMatumbi Naito100% (1)

- MS Basement Slab Casting (Completed)Document72 pagesMS Basement Slab Casting (Completed)Hafiz Kamarudin100% (2)

- Concrete Formwork and FinishesDocument15 pagesConcrete Formwork and FinishesIm Chinith100% (1)

- Construction JointsDocument4 pagesConstruction JointsAvelino De Leon Jr100% (1)

- 2016 06 22 Concrete Cold JointsDocument1 page2016 06 22 Concrete Cold JointskiranNo ratings yet

- Joints in Concrete Pavement Technical PaperDocument22 pagesJoints in Concrete Pavement Technical Paperphyo_thar_1100% (1)

- 6 - Plate Load TestDocument6 pages6 - Plate Load Testmido medo100% (1)

- 7.Ms-External Plaster WorkDocument6 pages7.Ms-External Plaster WorkShenbagaraja PandianNo ratings yet

- Ras Al Khaimah Structural Guidelines-2021-R3Document57 pagesRas Al Khaimah Structural Guidelines-2021-R3Mohamed987No ratings yet

- Standing Sawtooth Staircase Analysis Design and DetailingDocument8 pagesStanding Sawtooth Staircase Analysis Design and DetailingMahesh SNo ratings yet

- Creep and Shrinkage Prediction Model For Analysis and Design of Concrete Structures: Model B3Document77 pagesCreep and Shrinkage Prediction Model For Analysis and Design of Concrete Structures: Model B3Concepción de PuentesNo ratings yet

- Methodology For Calculating Life Expectancy of Existing StructuresDocument6 pagesMethodology For Calculating Life Expectancy of Existing StructuresganeshNo ratings yet

- Useful Guidelines For Design of RCC Slab Basic Rules For Slab DesignDocument7 pagesUseful Guidelines For Design of RCC Slab Basic Rules For Slab DesignUsman Shahid100% (1)

- Raft FoundationDocument3 pagesRaft FoundationDylan Ramasamy0% (2)

- Conquas: The Bca Construction Quality Assessment SystemDocument67 pagesConquas: The Bca Construction Quality Assessment SystemalfieNo ratings yet

- Hollow CoreDocument15 pagesHollow CoreBassem Muhanna100% (2)

- Curing ConcreteDocument10 pagesCuring ConcreteShariq KhanNo ratings yet

- UltraTech Fibrecon Presentation - MailerDocument26 pagesUltraTech Fibrecon Presentation - MailerVikas Singh100% (2)

- Raft FoundationDocument28 pagesRaft FoundationAashi Gupta100% (1)

- CM For Pile Cap Formwork Revise RE 12 Maret 2007 (Submitted)Document45 pagesCM For Pile Cap Formwork Revise RE 12 Maret 2007 (Submitted)Gangsar Lukmanjaya100% (1)

- Propping Brochure.9080815Document20 pagesPropping Brochure.9080815chillerz69No ratings yet

- Basement Water ProofingDocument35 pagesBasement Water ProofingSCOA crewNo ratings yet

- Hollow Core SpecificationsDocument8 pagesHollow Core SpecificationsJohn Carpenter100% (1)

- Formwork Tie BoltsDocument8 pagesFormwork Tie BoltsJoey SmitheyNo ratings yet

- Deck Slab Concreting - Aug 2011Document11 pagesDeck Slab Concreting - Aug 2011AlsonChinNo ratings yet

- 19.method Statement For R.C.C. Pile Cap WorksDocument3 pages19.method Statement For R.C.C. Pile Cap WorksShenbagaraja PandianNo ratings yet

- Group 2 - Quality ControlDocument94 pagesGroup 2 - Quality ControlZairah Ann Borja100% (1)

- Special Concretes and Concreting MethodsDocument26 pagesSpecial Concretes and Concreting MethodsSathish Selva100% (2)

- Repairing Methodology of Honeycombs in Concrete SurfaceDocument4 pagesRepairing Methodology of Honeycombs in Concrete Surfacejohn paul100% (1)

- Pile Instalation Methods 2Document9 pagesPile Instalation Methods 2Bright MuzaNo ratings yet

- Wall Form Work DesignDocument7 pagesWall Form Work Designdeanz_75No ratings yet

- Temperature Problems in Concreting: Main ReferenceDocument4 pagesTemperature Problems in Concreting: Main ReferenceMirosha NavaratnaNo ratings yet

- Jack Micro PDFDocument48 pagesJack Micro PDFHizbar ArsjadNo ratings yet

- Roofing Code of Practice PDFDocument379 pagesRoofing Code of Practice PDFAlejandro Segura Pereira100% (1)

- HW Retaining WallDocument76 pagesHW Retaining Wallrutuja100% (1)

- RaftDocument16 pagesRaftpoojaNo ratings yet

- Well FoundationDocument56 pagesWell FoundationSriram Nandipati67% (3)

- Honeycomb in ConcreteDocument2 pagesHoneycomb in ConcreteSaurav ShresthaNo ratings yet

- Form WorkDocument45 pagesForm WorkYatin BhutaniNo ratings yet

- Introduction To Shoring Systems - Cairo UniDocument24 pagesIntroduction To Shoring Systems - Cairo Uniأبو لينا الجميلةNo ratings yet

- HOLLOW-CORE SLAB SYSTEMS Information ManDocument36 pagesHOLLOW-CORE SLAB SYSTEMS Information ManEng.wissam Safaa100% (1)

- Setting and Hardening of ConcreteDocument30 pagesSetting and Hardening of ConcreteManjer123No ratings yet

- Concrete DetailingDocument13 pagesConcrete DetailingIyamperumal MurugesanNo ratings yet

- What Is Concrete Curing Compound?Document17 pagesWhat Is Concrete Curing Compound?SHAIK ASIMUDDIN100% (2)

- What Are The Methods of Concrete Crack RepairDocument11 pagesWhat Are The Methods of Concrete Crack RepairEvello MercanoNo ratings yet

- Method Statement For Grout ColumnDocument1 pageMethod Statement For Grout ColumnAlsonChin100% (1)

- CulvertsDocument18 pagesCulvertsAmmar A. Ali100% (1)

- 5.method Statement Shuttering and Form WorkDocument4 pages5.method Statement Shuttering and Form Workشاز إياس100% (1)

- Unbound Aggregates in RoadsFrom EverandUnbound Aggregates in RoadsR.H. JonesNo ratings yet

- Concrete Materials: Properties, Specifications, and TestingFrom EverandConcrete Materials: Properties, Specifications, and TestingRating: 4.5 out of 5 stars4.5/5 (5)

- Supervising Highway Engineer: Passbooks Study GuideFrom EverandSupervising Highway Engineer: Passbooks Study GuideNo ratings yet

- Handbook for Clerks of Works: Greater London Council Department of Architecture and Civic DesignFrom EverandHandbook for Clerks of Works: Greater London Council Department of Architecture and Civic DesignNo ratings yet

- MOH Ratnapura02Document29 pagesMOH Ratnapura02isurupushNo ratings yet

- Description Symbol Roadway Excavation Quantity: STATION - 4+010mDocument50 pagesDescription Symbol Roadway Excavation Quantity: STATION - 4+010misurupushNo ratings yet

- ER - Akarella Padiyawatta RoadDocument28 pagesER - Akarella Padiyawatta RoadisurupushNo ratings yet

- Description Symbol Roadway Excavation Quantity: STATION - 4+510mDocument50 pagesDescription Symbol Roadway Excavation Quantity: STATION - 4+510misurupushNo ratings yet

- Revised ERDocument16 pagesRevised ERisurupushNo ratings yet

- Road Defects DetailsDocument1 pageRoad Defects DetailsisurupushNo ratings yet

- Work Programme (R 2) New 11Document5 pagesWork Programme (R 2) New 11isurupushNo ratings yet

- Substructure33-2 5Document24 pagesSubstructure33-2 5isurupushNo ratings yet

- Substructure33-2 5Document24 pagesSubstructure33-2 5isurupushNo ratings yet

- Helakanda Bridge SubstructureDocument325 pagesHelakanda Bridge SubstructureisurupushNo ratings yet

- Substructure33-2 10Document27 pagesSubstructure33-2 10isurupushNo ratings yet

- Substructure33-2 10Document27 pagesSubstructure33-2 10isurupushNo ratings yet

- Design of Substructure 4 PileDocument328 pagesDesign of Substructure 4 PileisurupushNo ratings yet

- Balibathgoda BOQDocument33 pagesBalibathgoda BOQisurupushNo ratings yet

- DDDDDDocument66 pagesDDDDDisurupushNo ratings yet

- Helakanda BODocument103 pagesHelakanda BOisurupushNo ratings yet

- Table: Element Forces - Frames Frame Station Outputcase Casetype P V2 V3 T M2Document38 pagesTable: Element Forces - Frames Frame Station Outputcase Casetype P V2 V3 T M2isurupushNo ratings yet

- Table: Element Forces - Frames Frame Station Outputcase Casetype P V2 V3 T M2Document38 pagesTable: Element Forces - Frames Frame Station Outputcase Casetype P V2 V3 T M2isurupushNo ratings yet

- Survey Progress at 26th HmayDocument10 pagesSurvey Progress at 26th HmayisurupushNo ratings yet

- Table: Element Forces - Frames Frame Station Outputcase Casetype P V2 V3Document96 pagesTable: Element Forces - Frames Frame Station Outputcase Casetype P V2 V3isurupushNo ratings yet

- ResultsDocument646 pagesResultsisurupushNo ratings yet

- NameDocument1 pageNameisurupushNo ratings yet

- DDDDDDocument66 pagesDDDDDisurupushNo ratings yet

- 1Document10 pages1isurupushNo ratings yet

- Grade 1 ActivitiesDocument3 pagesGrade 1 ActivitiesisurupushNo ratings yet

- New Format For The Progress ReportDocument26 pagesNew Format For The Progress ReportisurupushNo ratings yet

- English Language Has Five Vowels Namely A, E, I, O, U. Following Activities To Be Done As Per The Given Instructions Using These 5 VowelsDocument3 pagesEnglish Language Has Five Vowels Namely A, E, I, O, U. Following Activities To Be Done As Per The Given Instructions Using These 5 VowelsisurupushNo ratings yet

- Grade 1 ActivitiesDocument3 pagesGrade 1 ActivitiesisurupushNo ratings yet

- Correspondence Subject FilingDocument2 pagesCorrespondence Subject FilingisurupushNo ratings yet

- 555Document1 page555isurupushNo ratings yet

- Park Lane 21-2-2014 (JB) (2014 - 03 - 21 05 - 45 - 57 UTC)Document30 pagesPark Lane 21-2-2014 (JB) (2014 - 03 - 21 05 - 45 - 57 UTC)Thomas JohnsonNo ratings yet

- Processing of Pulp of Various Cultivars of Guava (Psidium Guajava L.) ForDocument9 pagesProcessing of Pulp of Various Cultivars of Guava (Psidium Guajava L.) Forsadbad6No ratings yet

- Geography Notes - EcosystemsDocument12 pagesGeography Notes - EcosystemsBlessing ErenNo ratings yet

- Calaveras Big Trees: State ParkDocument5 pagesCalaveras Big Trees: State Parkapi-287723993No ratings yet

- Knee-Brace Systems For Wind Bracing Farm Buildings: A B S HDocument9 pagesKnee-Brace Systems For Wind Bracing Farm Buildings: A B S HAmey GudigarNo ratings yet

- The Minorcan Legacyibit The Minorcan Legacy and Its Influence On Floridas Wine CultureDocument51 pagesThe Minorcan Legacyibit The Minorcan Legacy and Its Influence On Floridas Wine CultureKonstantinos MantasNo ratings yet

- Radiata: JAS Log Volume Estimates of New Zealand Pine and Douglas-Fir LogsDocument5 pagesRadiata: JAS Log Volume Estimates of New Zealand Pine and Douglas-Fir LogsASEPNo ratings yet

- Qcs External WorksDocument26 pagesQcs External Workschucan14100% (1)

- 2012 WFCM Changes PDFDocument3 pages2012 WFCM Changes PDFHyunkyoun JinNo ratings yet

- Pterocarpus Marsupium Roxb.Document4 pagesPterocarpus Marsupium Roxb.Settipalli Ram SuryaNo ratings yet

- Cargill Sustainable Palm Oil Action Plan and Progress UpdateDocument24 pagesCargill Sustainable Palm Oil Action Plan and Progress Updatebionus10No ratings yet

- 03 Properties of Wood and Structural Wood ProductsDocument62 pages03 Properties of Wood and Structural Wood ProductswalaywanNo ratings yet

- Agro Textiles PRDocument24 pagesAgro Textiles PRsanketvaliaNo ratings yet

- How To Build A Garden SwingDocument76 pagesHow To Build A Garden SwingНикола НешићNo ratings yet

- lc4 Final Digital BookDocument44 pageslc4 Final Digital Bookapi-253241414No ratings yet

- Andaman and Nicobar IslandsDocument3 pagesAndaman and Nicobar IslandsDivya SharmaNo ratings yet

- Income Generating Activities of Community Forest User Group in NepalDocument76 pagesIncome Generating Activities of Community Forest User Group in NepalhariramharikrishnaNo ratings yet

- ON NATIONAL PARKS RoseDocument19 pagesON NATIONAL PARKS RoseNancy KhuralNo ratings yet

- Effects of DeforestationDocument2 pagesEffects of Deforestationakhileshmoney100% (1)

- EIA Report - Special Investigation-Hydropwer Irrawaddy-Ayeyawady Bassin - Engl nr.2Document291 pagesEIA Report - Special Investigation-Hydropwer Irrawaddy-Ayeyawady Bassin - Engl nr.2Pugh JuttaNo ratings yet

- المواصفات العامة للطرق والجسور- نهائيDocument350 pagesالمواصفات العامة للطرق والجسور- نهائيAnmar Al-Adly100% (1)

- The ABCs of PlantsDocument35 pagesThe ABCs of PlantspopaflorianNo ratings yet

- Different Tobacco Smoking Pipe TypesDocument37 pagesDifferent Tobacco Smoking Pipe TypesSlow to See FreeNo ratings yet

- Slime MoldsDocument2 pagesSlime MoldsjoeNo ratings yet

- Doterra Arborvitae Essential OilDocument1 pageDoterra Arborvitae Essential OilAlexandru Eduard RotaruNo ratings yet

- The Evolution of Bridge ConstructionDocument17 pagesThe Evolution of Bridge Constructiontntran91No ratings yet

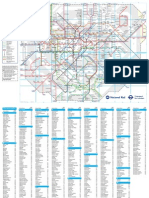

- London Rail and Tube Services MapDocument2 pagesLondon Rail and Tube Services MapKarthik SubramanianNo ratings yet

- Jean Giorno - The Man Who Planted TreesDocument46 pagesJean Giorno - The Man Who Planted TreesStephen Thorpe100% (1)

- Forest Society ColonialismDocument20 pagesForest Society ColonialismnandinisundarNo ratings yet

- The Vowels RulesDocument11 pagesThe Vowels RulesKelly MasonNo ratings yet