Professional Documents

Culture Documents

SPC CR UR 510 3 (Important)

Uploaded by

Aitazaz AhsanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SPC CR UR 510 3 (Important)

Uploaded by

Aitazaz AhsanCopyright:

Available Formats

$

GENERAL SPECIFICATION

AUSTENITIC STAINLESS STEELS FOR UREA PLANT

HIGH PRESSURE SECTION

SPC.CR.UR.510

Rev.03

September 2003

Form code : MDT.GG.QUA.0505 Sh. 01/Rev. 1.94

File code: spcgnrae.dot

Data file: spc_cr_ur_510_r03_e_f.doc

THE INFORMATION HEREIN AND IN THE FOLLOWING PAGES (N35 , COVER INCLUDING) CONTAINED IS SECRET, CONFIDENTIAL AND BELONGS TO SNAMPROGETTI WHICH HAS

PROVIDED IT SOLELY FOR AN EXPRESSLY RESTRICTED PRIVATE USE. ALL PERSONS, FIRMS OR CORPORATIONS WHO RECEIVE SUCH INFORMATION FROM SNAMPROGETTI SHALL

BE DEEMED BY THEIR ACT OF RECEIVING THE SAME TO HAVE AGREED TO BE OBLIGED TO KEEP IT SECRET AND CONFIDENTIAL, TO MAKE NO DUPLICATION OR OTHER DISCLOSURE

OR USE WHATSOEVER OF ANY OR ALL SUCH INFORMATION EXCEPT SUCH RESTRICTED USE AS IS EXPRESSLY AUTHORIZED IN WRITING BY SNAMPROGETTI AND SOLELY FOR THE

SCOPE AGREED THEREIN. IN CASE OF UNDUE DISCLOSURE AND/ OR ANY FAILURE TO OBSERVE THE ABOVE PROVISIONS, THE DEFAULTING PARTY SHALL BE RESPONSIBLE FOR ANY

AND ALL DAMAGES, WITHOUT LIMITATIONS.

SPC.CR.UR.510

Rev. 03

Date

Sep. 2003

Sheet 2 (24)

CONTENTS

1

GENERAL

1.1

Scope and field of application

1.2

Definitions

1.3

Abbreviations

1.4

Referenced Codes (always latest revision)

MATERIALS

2.1

General

2.2

316L UG stainless steel (UNS S31603)

2.3

25Cr-22Ni-2Mo alloy (UNS S31050)

ADDITIONAL REQUIREMENTS

3.1

Chemical analysis

3.2

Mechanical properties

TESTING AND CERTIFICATION OF MATERIAL

4.1

General criteria for sampling

4.2

Test samples and specimens

4.3

Microstructure examination

11

4.4

Corrosion test procedure

12

4.5

Flaw assessment test

14

Note 1: It is the sum of all defects found on 7 tube welds at all levels

14

4.6

15

Certification

WELDING

16

ADDITIONAL TESTS ON MATERIALS

23

6.1

Workshop check of ferrite

23

6.2

Non Destructive Examinations

23

TESTS ON PRODUCTION WELDS AND CONSUMABLES

24

7.1

General

24

7.2

Tube to tubesheet weld production mock up

24

Form code : MDT.GG.QUA.0515 Sh. 01/Rev. 1.94

File code: spcgnrae.dot

Data file: spc_cr_ur_510_r03_e_f.doc

This document is the property of Snamprogetti who will safeguard its rights according to the civil and penal provision of the law.

SPC.CR.UR.510

Rev. 03

Date

Sep. 2003

Sheet 3 (24)

ATTACHMENT 1

ATTACHMENT 2

ATTACHMENT 3

ATTACHMENT 4

ATTACHMENT 5

ATTACHMENT 6

ATTACHMENT 7

ATTACHMENT 8

ATTACHMENT 9

ATTACHMENT 10

Form code : MDT.GG.QUA.0515 Sh. 01/Rev. 1.94

File code: spcgnrae.dot

Data file: spc_cr_ur_510_r03_e_f.doc

This document is the property of Snamprogetti who will safeguard its rights according to the civil and penal provision of the law.

SPC.CR.UR.510

Rev. 03

Date

Sep. 2003

Sheet 4 (24)

GENERAL

1.1

Scope and field of application

1.1.1

This specification covers the requirements for austenitic stainless steel materials and relevant

welds in contact with the process fluid in the high pressure section of urea plants. These

requirements shall be considered in addition to the ones of the codes and standards applicable

to the product in question (equipment, piping components, plates, materials, testing, etc.). In

case of conflict with any of the above standards, this document prevails.

1.1.2

This specification takes into consideration both the 316L UG stainless steel (UNS S31603) and

the 25Cr-22Ni-2Mo type stainless alloy (UNS S31050).

1.2

Definitions

1.3

Owner:

The company that has placed the order to suppliers as permitted under

the license granted by Snamprogetti.

Supplier:

Before placing the order it means each of the potential supplier(s)

contacted; after placing the order, it means the selected supplier(s).

Snamprogetti:

Snamprogetti S.p.A., the licensor of the urea process.

316L UG:

urea grade modified 316L type austenitic stainless steel that shall meet

all the requirements of the AISI 316L (UNS S31603) material specification

and all the additional requirements mentioned in this specification.

sample

the piece of semifinished/ finished product (tube, plate, W.O., etc.) from

which the specimens to be tested are taken out

specimen

a piece of material obtained from the sample and actually subjected to the

destructive tests described below (corrosion test, metallography, etc.).

Abbreviations

AISI

ASME

ASTM

AWS

DIN

IIW

UG

UNS

W.O.

American Iron and Steel Institute

The American Society of Mechanical Engineers

American Society for Testing and Material

American Welding Society

Deutsches Institut fur Nrmung

International Institute of Welding

Urea Grade alloy

Unified Numbering System

Weld Overlay Deposit

Form code : MDT.GG.QUA.0515 Sh. 01/Rev. 1.94

File code: spcgnrae.dot

Data file: spc_cr_ur_510_r03_e_f.doc

This document is the property of Snamprogetti who will safeguard its rights according to the civil and penal provision of the law.

SPC.CR.UR.510

Rev. 03

Date

Sep. 2003

Sheet 5 (24)

1.4

Referenced Codes (always latest revision)

ASME Sect. VIII

Boiler and pressure vessel code - Pressure Vessel

ASME Sect. IX

Boiler and pressure vessel code qualifications

ASME Sect.V

Non Destructive Examination

ASME Sect. II Parts A & D

Materials

ASME Sect. II Part C

Specification for welding rods, electrodes and filler metals

EN 10204

Metallic materials Types of inspection documents

ASTM A262

Standard Practices for Detecting Susceptibility to Intergranular

Attack in Austenitic Stainless Steels

ASTM E562

Standard Test Method for Determining Volume Fraction by

Systematic Manual Point Count

AD MERKBLATTER

Complete Technical Rules for Pressure Vessels (English Edition)

Welding and brazing

Form code : MDT.GG.QUA.0515 Sh. 01/Rev. 1.94

File code: spcgnrae.dot

Data file: spc_cr_ur_510_r03_e_f.doc

This document is the property of Snamprogetti who will safeguard its rights according to the civil and penal provision of the law.

SPC.CR.UR.510

Rev. 03

Date

Sep. 2003

Sheet 6 (24)

MATERIALS

2.1

General

2.1.1

The list of suppliers and subvendors of plates, forgings, bars, piping and tubes for High

Pressure Urea equipment and piping to be operated in contact with the urea process fluid shall

be submitted to Snamprogetti for acceptance. For filler materials the provisions of chapter 5

shall be applied.

2.1.2

All semifinished products shall be supplied in the solution annealed condition. No heating over

400 C shall be allowed during machining or any other manufacturing activity, except welding.

If heating above 400 C cannot be avoided, a new solution annealing heat treatment shall then

be performed and new samples shall be taken and tested as described in chapter 4.

2.1.3

If, after solution annealing heat treatment, forgings or bars are submitted to machining and

more than 5 mm depth is removed from the side in contact with the process fluid, then a new

solution annealing heat treatment is required except for the 25Cr-22Ni-2Mo alloy provided that

the samples taken after machining satisfy the test requirements as per chapter 4.

2.1.4

All tubes and pipes shall be seamless type. Welded fittings are allowed provided that the

requirements of chapter 5 are met.

2.1.5

Cast parts and rod bars are not permitted unless approved by Snamprogetti.

2.1.6

When 316L UG material is required, the use of 25Cr-22Ni-2Mo material is allowed as an

alternative.

2.2

316L UG stainless steel (UNS S31603)

2.2.1

Stainless steel 316L UG type shall be in accordance with the ASME-(SA) specifications

applicable to the relevant semifinished products; it shall also meet the additional requirements

detailed in chapters 3 and 4.

2.3

25Cr-22Ni-2Mo alloy (UNS S31050)

2.3.1

Stainless steel 25Cr-22Ni-2Mo type shall be in accordance with the ASME-(SA) specifications

applicable to the relevant semifinished products; it shall also meet the additional requirements

detailed in chapters 3 and 4.

Form code : MDT.GG.QUA.0515 Sh. 01/Rev. 1.94

File code: spcgnrae.dot

Data file: spc_cr_ur_510_r03_e_f.doc

This document is the property of Snamprogetti who will safeguard its rights according to the civil and penal provision of the law.

SPC.CR.UR.510

Rev. 03

Date

Sep. 2003

Sheet 7 (24)

ADDITIONAL REQUIREMENTS

3.1

Chemical analysis

In the following paragraphs the chemical or additional chemical requirements for 316 UG

stainless steel and 25Cr-22Ni-2Mo alloy are reported. Any deviation from these requirements

shall be subject to Snamprogettis acceptance.

3.1.1

316L UG stainless steel

The 316L UG stainless steel base material shall have the following additional chemical

requirements:

C = 0.020 % max.

P = 0.015 % max.

S = 0.010 % max.

Ni > 13 %

N = 0.10 % max.

The carbon content restriction above does not apply to forgings provided no welding is

performed after the solution annealing heat treatment, not even for installation purposes.

3.1.2

25Cr-22Ni-2Mo stainless steel

The 25Cr-22Ni-2Mo stainless steel base material shall have the following chemical

composition:

Cr = 24 26 %

Ni = 21 23.5 %

Mo = 2 2.6 %

Mn = 1.5 2.0 %

N = 0.10 0.15 %

3.1.3

C = 0.020 % max.

P = 0.020 % max.

S = 0.010 % max.

Si = 0.40 % max.

B = 0.0015 % max.

W.O. deposit shall meet the following requirements for a depth of at least 3 mm (see

Attachment 8) from the as welded or machined surface:

Material type 316L UG:

C = 0.030 % max. (SAW-ESW-GTAW)

C = 0.040 % max. (SMAW)

Cr = 16.5 % min.

Ni = 15 % min.

Mo = 2.2 % min.

Form code : MDT.GG.QUA.0515 Sh. 01/Rev. 1.94

File code: spcgnrae.dot

Data file: spc_cr_ur_510_r03_e_f.doc

This document is the property of Snamprogetti who will safeguard its rights according to the civil and penal provision of the law.

SPC.CR.UR.510

Rev. 03

Date

Sep. 2003

Sheet 8 (24)

Material type 25Cr-22Ni-2Mo:

C = 0.030 % max. (SAW-ESW-GTAW)

C = 0.040 % max. (SMAW)

Cr = 24 % min.

Ni = 21 % min.

Mo = 1.9 % min.

and

Creq

Ni eq

%Cr + % Mo + 1,5% Si

1,20

% Ni + 30%C + 0,5% Mn

3.1.4

Chemical analysis at depth of 1 mm and 2 mm (see Attachment 8) shall also be performed

and reported for information.

3.2

Mechanical properties

The mechanical properties of 25Cr-22Ni-2Mo stainless steel, at room temperature, shall be as

follows:

Tensile strength

580 N/mm min.

Yield strength (0,2% offset)

270 N/mm min.

Elongation (l=5d)

30% min.

3.2.1

Short Time Tensile Test shall be performed/ certified at the design temperature (indicated on the

Snamprogetti process data sheet) for each heat of Urea Stripper heat exchanger tubes.

3.2.2

If the design is carried out in accordance with ASME code BPVC section VIII, for forgings the

code itself shall be applicable with reference to CODE CASE 2038.

3.2.3

For other requirements the relevant material/ product SA (ASME) specification shall be applied.

Form code : MDT.GG.QUA.0515 Sh. 01/Rev. 1.94

File code: spcgnrae.dot

Data file: spc_cr_ur_510_r03_e_f.doc

This document is the property of Snamprogetti who will safeguard its rights according to the civil and penal provision of the law.

SPC.CR.UR.510

Rev. 03

Date

Sep. 2003

Sheet 9 (24)

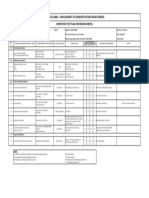

TESTING AND CERTIFICATION OF MATERIAL

4.1

General criteria for sampling

Product

Sampling for corrosion test

Sampling for metallographic examination

PLATES

One sample for each heat

One sample from each lot of no more

than 50 pieces of each heat and

(1)

same heat treatment

One sample for each plate

One sample from each lot of no more

than 50 pieces of each heat and

(1)

same heat treatment

One sample from each lot even if of more

than 50 pieces of each heat and

(1)

same heat treatment for bolts, nuts, and

forgings of small size (Dia. 219,1 mm).

One sample from each lot of 200 pieces

(1)

of each heat and same heat treatment

PIPING, FORGING

BOLTS, NUTS,

One sample for each heat

SMALL-SIZE FORGING

EXCHANGER TUBES

One sample for each heat

NOTE (1): definition of same heat treatment:

- If final heat treatment is in a batch-type furnace = in the same furnace charge

- If final heat treatment is in a continuos furnace = in the same furnace at the same

temperature, time at heat, and furnace speed.

4.2

Test samples and specimens

4.2.1

Samples for corrosion tests and microstructural examination shall be taken as per the above

table (base material) and from each weld test during the welding procedure qualification.

Overheating shall be avoided when cutting the specimens (thermal-cutting is not allowed).

Each sample shall be marked, by stamping, with proper identification traceability number.

4.2.2

The area of each sample shall be of 180 cm as a minimum (if not otherwise specified in this

document) and shall permit to take out with sufficient allowance the following specimens:

1 for check (chemical) analysis

1 for corrosion test (see para. 4.4)

1 for corrosion re-testing (if required)

3 for microstructure examination (see para. 4.3)

1 for metallography re-testing (if required)

4.2.3

Each specimen shall include the side that will be in contact with the process fluid if known

(consequently liner plates shall then be installed by exposing to the process fluid the side that

has been actually tested with positive results). Specimens for the corrosion test shall have an

2

area of approximately 30 32 cm , weight of 40 g minimum (100 g maximum) and, when

feasible, an approximately rectangular shape with dimensions of about 50 x 25 x 5 mm.

4.2.4

In the case of plates with thickness over 7 mm, the specimen shall be reduced to 5 mm by

machining material in excess on the opposite side from that (those) in contact with the process

fluid (avoiding overheating).

Form code : MDT.GG.QUA.0515 Sh. 01/Rev. 1.94

File code: spcgnrae.dot

Data file: spc_cr_ur_510_r03_e_f.doc

This document is the property of Snamprogetti who will safeguard its rights according to the civil and penal provision of the law.

SPC.CR.UR.510

Rev. 03

Date

Sep. 2003

Sheet 10 (24)

4.2.5

In the case of tubes with outside diameter less than 30 mm, the sample shall have a cylindrical

shape. In the case of tubes or pipes with outside diameter 30 mm, the sample shall be taken

with length "a" approximately equal to arc "b" (see Attachment 5).

4.2.6

If the pipe or tube thickness is over 7 mm, the specimen thickness shall be reduced to 5 mm

by machining material in excess on the opposite side from that (those) in contact with the

process fluid (avoiding overheating).

4.2.7

In the case of forgings or bars, if it is not possible to take a sample with the surface to be in

contact with the process fluid, the sample shall be taken from the core of the forging bar. Test

specimens shall be taken from the forging extension or by a representative specimen with the

same heat and heat treatment having maximum treated thickness size of those forgings.

4.2.8

In the case of special pieces (valves, thermocouples, fittings, instrument separators, etc.) the

supplier shall submit to Snamprogetti for acceptance an overall drawing showing the location

of the sample(s).

4.2.9

In the case of welding procedure qualification tests for SAW/ ESW/ SMAW weld overlay (see

Attachment 1) three samples shall be taken:

-

4.2.10

sample S1 (Attachment 2) which shall include at least 2 bead overlap of adjacent beads

sample S2 (Attachment 3) which shall include stop and restart point of a bead

sample S3 (Attachment 4) which shall include beads deposited by manual welding with

SMAW and/ or GTAW on the automatic overlay, simulating repair if any.

The specimens obtained from each of the above samples shall be used as follows:

-

specimen(s) labeled A are to be used for metallographic analysis (one is for re-testing if

required)

specimen(s) labeled B are to be used for corrosion test

specimen labeled B1 is to be used for corrosion re-testing if required

specimen labeled C is to be used for macrographic examination

specimen labeled D is for chemical check analysis.

4.2.11

In the case of welding procedure qualification tests for additional automatic GTAW weld

overlay on liner plates or SAW/ ESW/ SMAW weld overlay, a sample of S1 type including at

least 2 bead overlap of adjacent beads (see Attachment 2) shall be taken out.

4.2.12

In the case of welding procedure qualification test for butt joints, the sample shall be as wide

as the face of weld in contact with the process fluid plus 12 mm (6 mm each side) and 5 mm

thick (see Attachment 6).

4.2.13

In the case of procedure qualification tests for welds between tube and tube-sheet, no. 2

mock-up shall be prepared. From the first one the specimens for corrosion test and

metallographic examination shall be obtained and they shall include 3 tubes in central position.

One central tube shall be used for the corrosion test, one shall be used for the metallographic

examination, one is for re-testing, if required (see Attachment 7 for details). The second mock-

Form code : MDT.GG.QUA.0515 Sh. 01/Rev. 1.94

File code: spcgnrae.dot

Data file: spc_cr_ur_510_r03_e_f.doc

This document is the property of Snamprogetti who will safeguard its rights according to the civil and penal provision of the law.

SPC.CR.UR.510

Rev. 03

Date

Sep. 2003

Sheet 11 (24)

up shall be prepared following Attachment 9 and it will be subject only to the flaw assessment

test as detailed in para 4.5.

4.2.14

The metallographic examination of the first mock-up shall be performed on the central tube

assembly previously longitudinally sectioned following 4 perpendicular directions starting from

the second weld pass stop as follows:

a) on 4 of the 8 surfaces obtained from the sectioning a macrographic examination shall be

performed in order to determine the extension of weld fusion (which shall not exceed at any

point 75 % of wall tube thickness), weld throat thickness (minimum weld throats of all sections

shall be not less than the specified tube wall thickness) and penetration.

b) the 4 remaining surfaces shall be used for the microstructural examination (one surface for

each of the 3 required etchings plus one for re-testing if required).

4.2.15

The surface to be in contact with the process fluid and the opposite one if not machined shall

remain in the "as received" condition.

4.2.16

The specimens shall not be subjected to any heat treatment before the test.

4.2.17

The remaining part of each sample after taking out the specimens, with the identification

number, shall be made available for five years (ex work delivery) at Suppliers care for further

Samprogetti investigation.

4.2.18

All tests described below (macrographic and micrographic examination, corrosion test, flaw

assessment, etc.) shall be performed and certified by a laboratory approved by Snamprogetti.

Laboratory shall officially inform Snamprogetti about any inconvenience (e.g. deviations from

the material requirements etc.) encountered during the tests as well as in case of re-testing.

4.3

Microstructure examination

4.3.1

The material (base, welds and weld overlay) used in contact with the process fluid shall be

subject to metallographic analysis following the methods detailed below. 3 (three)

metallographic specimens, each for any required etching, shall be obtained from each of the

sample(s) as detailed in para. 4.2.2 and 4.2.10. A fourth specimen shall be retained for retesting (if required). The re-use of the same metallographic specimen for two or more different

etchings is not allowed.

4.3.2

The metallography shall be considered preliminary to the corrosion test.

4.3.3

Presence of ferrite shall be evaluated by means of a ferritometer on each of the 3 specimens

before etching. Ferrite content shall not be greater than 0.6 % in all specimens except for

SMAW welds for which 1% is allowed.

4.3.4

The material microstructure shall be determined following ASTM A262 Practice A. Only a fully

austenitic step structure as defined in the above standard shall be considered acceptable. The

presence of any structure other than the step structure (e.g. ditch structure, interdendritic

ditches, end-grain pitting type I or II) is not allowed.

Form code : MDT.GG.QUA.0515 Sh. 01/Rev. 1.94

File code: spcgnrae.dot

Data file: spc_cr_ur_510_r03_e_f.doc

This document is the property of Snamprogetti who will safeguard its rights according to the civil and penal provision of the law.

SPC.CR.UR.510

Rev. 03

Date

Sep. 2003

Sheet 12 (24)

4.3.5

Presence of sigma phase shall be checked at 100x and 500x after electrolitic etching with

2

NaOH 10N at 3 V and 0.5 to 1 A/cm for 2 to 5 sec. Sigma phase shall be absent.

4.3.6

An etching with oxalic acid (10%, 6 V DC, 0.5 1 A/cm , 15 sec.) shall be performed and the

specimen shall be examined at 100x and 500x. Presence of any intergranular or intragranular

compounds or phases other than the austenitic phase is not allowed whatever their

composition might be and irrespective of their quantity, with the exception of the ferrite phase

within the limits stated in para. 4.3.3.

4.3.7

The material not in compliance with the above requirements shall be rejected.

4.4

Corrosion test procedure

4.4.1

The corrosion test, Huey type, shall be performed on the sample material that already resulted

acceptable after the microstructure examination detailed in para 4.3.

4.4.2

AISI 316L UG specimens shall be subjected to 5 test periods and the acid shall be renewed

each time. Each period shall last 48 hours actual boiling. 25Cr-22Ni-2Mo alloy shall be

subjected to 10 test periods at the same conditions as above.

4.4.3

The corrosion test shall shall follow the ASTM A262 Practice C with the following additions:

4.4.4

Only one specimen shall be tested in each flask.

4.4.5

A finger type refrigerator shall be used and it is necessary to check, by litmus paper, that no

acid vapours are released during testing.

4.4.6

The ratio of the solution volume to the sample area shall be 20 ml/cm as a minimum.

4.4.7

The flasks for Huey test shall be used only for this purpose.

4.4.8

The flask, refrigerator and specimen shall be carefully rinsed after each test cycle to remove all

the corrosion products (by means of a nonmetallic brush).

4.4.9

Before corrosion testing, the specimens shall be first degreased in acetone (chlorinated agents

are not allowed), pickled in boiling nitric acid (65%) for thirty minutes, and then rinsed; the

corrosion products shall be removed by nonmetallic brush.

4.4.10

After each test cycle and after rinsing, the specimens shall be dipped in acetone, dried by hot

air, and weighed (when cold).

4.4.11

The time between two cycles shall be as short as possible.

4.4.12

Besides the determination of the corrosion rate (for each cycle and for the overall periods)

obtained by weighting, it is also required to determine the maximum depth of attack by

examining under a microscope the edges of a specimen section (for details see note 5 of table

in para. 4.4.13)

Form code : MDT.GG.QUA.0515 Sh. 01/Rev. 1.94

File code: spcgnrae.dot

Data file: spc_cr_ur_510_r03_e_f.doc

This document is the property of Snamprogetti who will safeguard its rights according to the civil and penal provision of the law.

SPC.CR.UR.510

Rev. 03

Date

Sep. 2003

Sheet 13 (24)

4.4.13

The following table shows both the maximum corrosion rate and depht of attack allowed in

each test cycle and for the average of the results of all cycles, calculated according to ASTM

A262 Practice C:

Semifinished

product

Type of

material

Corrosion

rate

(mm/month)

Depth of

attack

(micron)

Plates, sheets,

bars,

tubes, pipes,

forgings

316L UG

0.025 (1) (2)

90 (4) (5)

25Cr-22Ni-2Mo

0.015 (1) (2)

70 (4) (5)

316L UG

0.025 (1) (3) (4)

90 (3) (4) (5)

25Cr-22Ni-2Mo

0.015 (1) (3) (4)

70 (3) (4) (5)

Welds and

W.O. surfacing

NOTES

General: the above limits are valid for each test cycle and for the average

of the results of all cycles.

(1) If the corrosion rate exceeds the rate specified in the table or if the

corrosion rate in cycle 5 (cycle 10 for 25Cr-22Ni-2Mo alloy) exceeds

the one in cycle 4 (cycle 9 for 25Cr-22Ni-2Mo alloy) by more than 50%,

a second specimen taken from the same sample under examination

shall be re-tested with the same procedure. Only the result of re-testing

shall be taken into consideration. Further re-testings are not allowed.

(2) No deviations allowed.

(3) The heat affected zone and the bead overlap zone (for W.O.) shall also

be examined.

(4) Any deviation shall be subject to Snamprogettis acceptance.

(5) Depht of attack shall be determined after completion of the corrosion

test by taking a metallographic sample from the most corroded area, if

visible. The value shall be reffered to the deepest attack observed on

both the transverse and the longitudinal directions of the specimen.

Form code : MDT.GG.QUA.0515 Sh. 01/Rev. 1.94

File code: spcgnrae.dot

Data file: spc_cr_ur_510_r03_e_f.doc

This document is the property of Snamprogetti who will safeguard its rights according to the civil and penal provision of the law.

SPC.CR.UR.510

Rev. 03

Date

Sep. 2003

Sheet 14 (24)

4.5

Flaw assessment test

4.5.1

Samples to be tested shall be prepared in accordance with Attachment 9 (Procedure

Qualification Record) and Attachment 10 (production mock-up).

4.5.2

The tube protusion shall be machined down until the contact between tube face and the upper

weld toe. This surface shall be recorded as starting test level. The examination shall proceed

on repeated plane at 1 mm distance from each other till the tube gets lose.

4.5.3

Each level shall be prepared for etching and examined under a binocular microscope with

magnification from x15 to x25.

4.5.4

The following table gives the number and extension of the allowable defects:

Defect type

Cracks (2)

Pores

Wormholes

Slag inclusions

Fusion defects

Crater cracks

Burn through

Max. allowed number of

defects (1)

0

5

0

2

2

0

0

Max. dimensions allowed

0.6

0.6

2

-

Note 1: It is the sum of all defects found on 7 tube welds at all levels

Note 2: Any deviation shall be subject to Snamprogettis acceptance

4.5.5

The weld fusion depht shall have a regular profile and its extension shall never exceed the 75

% of the wall tube thickness at any point

4.5.6

No more than 1 defect per tube and per level is allowed. Any deviation shall be subject to

Snamprogettis acceptance.

4.5.7

Defects extended on different levels are not allowed.

4.5.8

A photograph shall be taken on each surface (scale 1:1) showing defects location, type and

extension.

4.5.9

Certification of the flaw assessment test shall be in accordance with para. 4.6.

Form code : MDT.GG.QUA.0515 Sh. 01/Rev. 1.94

File code: spcgnrae.dot

Data file: spc_cr_ur_510_r03_e_f.doc

This document is the property of Snamprogetti who will safeguard its rights according to the civil and penal provision of the law.

SPC.CR.UR.510

Rev. 03

Date

Sep. 2003

Sheet 15 (24)

4.6

Certification

4.6.1

The laboratory shall certify that the test results are in compliance or not in compliance with the

requirements of the present specification. The certification shall be made available to

Snamprogetti as soon as the certificate is issued. Certification shall include the following:

4.6.2

A photograph(s) showing the samples as received; the identification stamping on the

sample(s) shall be clearly visibile and readable.

4.6.3

The photomicrographs showing the materials microstructure after each etching. The photos

shall be of high quality and fully readable (e.g. laser prints on photographic quality paper, prints

from photo negatives etc.). B/W or color photocopies are not acceptable.

4.6.4

The etching details, the magnifications employed and a short but comprehensive comment by

a metallurgy specialist shall be reported in each caption. The result of the ferrite check on each

specimen shall also be reported.

4.6.5

The corrosion rates after each testing cycle and the average corrosion rate values shall be

reported.

4.6.6

As an option the testing certificate can be supplied in electronic (PDF) format provided the

above requirements are fully met.

4.6.7

Snamprogetti reserves the right to require to the Supplier (or the Owner) further testing or

investigation whenever Snamprogettis acceptance is required or the laboratory results are

controversial.

Form code : MDT.GG.QUA.0515 Sh. 01/Rev. 1.94

File code: spcgnrae.dot

Data file: spc_cr_ur_510_r03_e_f.doc

This document is the property of Snamprogetti who will safeguard its rights according to the civil and penal provision of the law.

SPC.CR.UR.510

Rev. 03

Date

Sep. 2003

Sheet 16 (24)

WELDING

5.1

Weldings and weld overlays shall be performed with special filler materials, low ferrite type,

approved by Snamprogetti. The approved filler materials for both 316L UG and 25Cr-22Ni-2Mo

alloys are listed below. Different filler materials or wire/stripflux combination shall not be used

unless approved by Snamprogetti.

316L UG

CLASS 25Cr-22Ni-2Mo

Electrodes

(Avesta) P6

(Thyssen) Thermanit 19/15 H

(Kobe Steel) NC 316 MF

(ESAB) 316 KCR

(Siderotermica) CITOXID B 316 LM

(VEW) FOX EASN 25 M

(Thyssen) Thermanit 25 / 22 H

(Soudometal) Soudinox LF

(Kobe Steel) NC 310 MF

(Esab) FILARC BM 310 Mo L

Wires

(Thyssen) Thermanit 19/15 H

(Kobe Steel) no. 4051

(Siderotermica) Siderfil 316 LM

(Thyssen) Thermanit 25/22 H

(Kobe Steel) TGS 310 MF

(Sandvik) 25-22-2 L Mn

(VEW) FOX EASN 25 MIG

Strips

(Sandvik) 20-16-3 L Mn with

(Soudometal) 12 b 316 LFT 2 flux

(Thyssen) 21.17.E with (Soudometal)

Rekord 13 BLFT flux

(Sandvik) 25-22-2 L Mn with

(Soudometal) Rekord 13 BLFT flux or

with (Sandvik) 31S flux

(Sandvik) 25-22-2 L Mn with

(Sandvik) 37 S flux (electroslag)

(Thyssen) 25-22 H with (Soudometal)

EST 122 flux (electroslag)

General note: the materials of class 25Cr-22Ni-2Mo can be used for welding of materials of

class 316L UG.

Form code : MDT.GG.QUA.0515 Sh. 01/Rev. 1.94

File code: spcgnrae.dot

Data file: spc_cr_ur_510_r03_e_f.doc

This document is the property of Snamprogetti who will safeguard its rights according to the civil and penal provision of the law.

SPC.CR.UR.510

Rev. 03

Date

Sep. 2003

Sheet 17 (24)

5.2

WPS/PQR applicable codes and additional required tests are summarized in the following

table:

Weld Overlay

Specimen

Applicable code (1)

Corrosion test

Chemical analysis

Microstructure

examination

B

D

Macroexamination

Flaw test

Sample S1

Sample

S2

Sample

S3

ASME IX

YES (para. 4.4)

ASME IX

ASME VIII Div. 2

Art. F3

YES (para. 4.4)

YES (para. 4.4)

NO

NO

YES (para. 4.3)

YES (para. 4.3)

YES (para. 4.3)

YES (3)

YES (para. 4.2.13)

NO

YES (para. 4.5)

YES (2)

NO

NO

Tube to

tubesheet

joints

YES (para. 3.1.3 and 3.1.4)

NO

Butt joints

NO

NO

NOTES: (1) Unless otherwise specified in the design code indicated in the purchase order.

(2)

For W.O. the macroexamination shall be performed only on sample S1. The purpose of

macroetching is to identify the sequence of the weld beads overlay and the location of the

heat affected region of each weld pass, due to the re-heating during the application of the

subsequent pass. Specimen B shall be taken out by the laboratory across the centerline

of the above mentioned area (see Attachment 2).

(3) Macroexamination to be performed to check weld structure, presence of slag porosity and

cracks in weld and heat affected zone.

5.3

PQR shall include the certification detailed in para. 4.6.

Form code : MDT.GG.QUA.0515 Sh. 01/Rev. 1.94

File code: spcgnrae.dot

Data file: spc_cr_ur_510_r03_e_f.doc

This document is the property of Snamprogetti who will safeguard its rights according to the civil and penal provision of the law.

SPC.CR.UR.510

Rev. 03

Date

Sep. 2003

Sheet 18 (24)

5.4

In addition to the provisions of the applicable codes the validity of the PQR is five years from

issue date and the following essential variables, if modified from what qualified during the

Procedure Qualification Record as indicated in the following tables, require the welding

qualification tests to be repeated:

PRESSURE/ NOT PRESSURE RETAINING WELDS

BUTT AND FILLET WELD

ACCEPTED WELDING PROCESSES

VARIABLES

Shielded Metal Arc Welding

Gas Tungsten Arc Welding

Heat input

Heat input or volume of the weld metal increased more than 10%

Interpass

An increase of interpass temperature

Welding position

A change in the welding position (a PQR done in 3G-5G-6G-vertical-uphill

progression qualify all other position except vertical-down progression)

Filler metal size

A change in filler metal size

Filler metals

A change in the type, manufacturer of filler metal and/or trade name

Form code : MDT.GG.QUA.0515 Sh. 01/Rev. 1.94

File code: spcgnrae.dot

Data file: spc_cr_ur_510_r03_e_f.doc

This document is the property of Snamprogetti who will safeguard its rights according to the civil and penal provision of the law.

SPC.CR.UR.510

Rev. 03

Date

Sep. 2003

Sheet 19 (24)

CORROSION RESISTANT WELD OVERLAY

ACCEPTED WELDING PROCESS

VARIABLES

Submerged Arc

Welding

Base Metal

Electroslag

welding

Gas

Tungsten Arc

Welding

A change in the P or Gr number

A change of 30 % in the base metal thickness

Base Metal thickness

current

A change of 10%

A change of

5%

A change of

10%

Current

density

2

(A/mm ) (strip welding)

A change of 10%

A change of

5%

Not required

Welding

intensity

Shielded metal arc

welding

Not required

Arc voltage

A change of 10%

Not required

Welding speed

A change of 5%

Not Required

An increase of heat input more than what qualified

Heat input or volume

of the weld metal

increase more than

5%

Heat input

Stick-out

Preheat and interpass

A change 2.5% of the strip/wire stickout with respect to PQR

A

change

2.5% of the

strip/wire

stick-out with

respect

to

PQR

(for

machine/

automatic

process)

Not applicable

A change in the preheat25C (first layer) and/or an increase of interpass temperature

(all layers)

Form code : MDT.GG.QUA.0515 Sh. 01/Rev. 1.94

File code: spcgnrae.dot

Data file: spc_cr_ur_510_r03_e_f.doc

This document is the property of Snamprogetti who will safeguard its rights according to the civil and penal provision of the law.

SPC.CR.UR.510

Rev. 03

Date

Sep. 2003

Sheet 20 (24)

CORROSION RESISTANT WELD OVERLAY

ACCEPTED WELDING PROCESS

VARIABLES

PWHT (on first layer)

Submerged Arc

Welding

Electroslag

welding

Gas Tungsten

Arc Welding

Shielded metal

arc welding

A change in the temperature (15C)

Bead overlap

A change +20%/ -0% of the overlap of

adjacent beads with respect to that

measured on PQR (applicable to first

and last layers)

A change +20%/ 0% of the overlap

of adjacent beads

with respect to that

measured on PQR

(applicable to first

and last layers (for

machine/

automatic process)

N/A

Bead width

A change +20%/ -0% of the bead width

with respect to that measured on PQR

(applicable to first and last layers)

A change +20%/ 0% of the bead

width with respect

to that measured

on PQR

(applicable to first

and last layers (for

machine/

automatic process)

N/A

Welding position

A change in the welding position

Filler metal size and/

or thickness

A change in filler metal size and/or thickness

Layer thickness (to be

specified in WPS/

PQR)

An increase in layer thickness (applicable to each layer)

Number of weld layers

A decrease in the number of weld layers with respect to PQR

Filler metals

Flux

A change in the type, manufacturer and/or trade name

A change in the type, manufacturer

and/or trade name

Not applicable

Form code : MDT.GG.QUA.0515 Sh. 01/Rev. 1.94

File code: spcgnrae.dot

Data file: spc_cr_ur_510_r03_e_f.doc

This document is the property of Snamprogetti who will safeguard its rights according to the civil and penal provision of the law.

SPC.CR.UR.510

Rev. 03

Date

Sep. 2003

Sheet 21 (24)

TUBE TO TUBESHEET WELDING

ACCEPTED WELDING PROCESS

VARIABLES

Orbital Gas Tungsten Arc Welding

Manufacturer, type/ model

of welding machine

A change of manufacturer, type/model of welding machine to another.

Welding

program

(supplementary document

to be attached to the

WPS)

A change in any data included in the supplementary document specifying all

applicable equipment settings (pre-gas/post-gas/welding parameter for each

sector/etc.) to assure a consistent performance.

Base Metal: Tubesheet

(solid, W.O. or clad), Tube

(internal or external)

A change in the base metal type, grade or product form

Tubesheet (solid pressure

containment parts)

A change of 30% in the tubesheet (solid pressure containment parts) metal

thickness

Tubesheet (W.O., clad)

A decrease in the layer number and/or increase of layer thickness.

Shielding/Backing(inside

tube gas)/Trailing gas

A change/deletion in the gas composition and flow rate used

Tubes

Tube holes

Clearance between tubes

and tube holes

Positioning system

Non fusible electrodes

A change in the manufacturer, wall thickness or diameter

A change in the pitch

The clearance between the outside surface of the tubes and the inside surfaces of

the tube holes shall not exceed clearance used in the welding qualification tests

A change in the positioning/centering system of the weld head on the tube sheet

A change in the type, size, tips shape/angle, protrusion from the torch

Welding position

A change in the welding position

Filler metal size

A change in filler metal size

Tubes protrusion

A change in the tube protrusion form tubesheet

Filler metals

Interpass

A change in the type, manufacturer and/or trade name

An increase of interpass temperature

Form code : MDT.GG.QUA.0515 Sh. 01/Rev. 1.94

File code: spcgnrae.dot

Data file: spc_cr_ur_510_r03_e_f.doc

This document is the property of Snamprogetti who will safeguard its rights according to the civil and penal provision of the law.

SPC.CR.UR.510

Rev. 03

Date

Sep. 2003

Sheet 22 (24)

5.5

The root pass on pipe butt joints shall be carried out by argon gas welding and with backing gas

inside the pipe.

5.6

Weld overlays shall be performed with at least two layers in the case of automatic process,

(except strip weld overlay on liner plates) and at least three layers in the case of manual welding:

in any case, at least two layers shall be performed with low ferrite filler in compliance with para.

5.1.

5.7

Stress relieving heat treatment shall be carried out after first barrier layer before to start with the

further corrosion resistant layer.

5.8

The weld face in contact with the process fluid shall be adequately smooth, free from undercuts or

defects.

5.9

No grinding will be allowed, except on tube sheets or for removing local defects or discontinuities.

5.10

Care shall be taken during fabrication to avoid iron contamination of the austenitic surfaces by

tools (grinding wheels, brushes, clamps, etc.).

5.11

The grinding wheels must not have been previously used on ferritic steels and the brushes must

have austenitic stainless steel wires.

5.12

Weld overlay deposit on 25Cr-22Ni-2Mo liner plates shall be performed by providing a forced

back water cooling circulation system during weld operations in order to keep interpass

temperatures lower than 50C. Automatic interpass temperature control shall be adopted.

5.13

Electrodes for manual welding or weld overlay shall have a diameter not greater than 4 mm

(preferably 3.25 mm max.) and, where possible, shall be used with stringer bead technique.

5.14

All the welds of internal parts to the lining shall be performed by full-penetration welding

procedure.

Form code : MDT.GG.QUA.0515 Sh. 01/Rev. 1.94

File code: spcgnrae.dot

Data file: spc_cr_ur_510_r03_e_f.doc

This document is the property of Snamprogetti who will safeguard its rights according to the civil and penal provision of the law.

SPC.CR.UR.510

Rev. 03

Date

Sep. 2003

Sheet 23 (24)

ADDITIONAL TESTS ON MATERIALS

6.1

Workshop check of ferrite

In addition to the requirements of para 4.3.3 the ferrite content shall also be checked in the

workshop by magnetic permeability measurement by means of appropriate portable equipment

previously calibrated and certified per AWS A4.2. An annual calibration certification shall be

available to the Snamprogetti inspector. Prior to use in production, instrument calibration shall

be verified with IIW secondary weld metal standards (0 - 15 % ferrite range).

This check shall be carried out on each plate or forging and on at least one every 50 pipes or

tubes from the same heat and heat treatment and on one bolt and one nut for every lot and

every size from the same heat and heat treatment (for definition of same heat treatment see

Note 1 in para. 4.1).

6.2

Non Destructive Examinations

6.2.1

The tubes for heat exchangers shall be 100% tested with ultrasonics and eddy currents in

accordance with ASTM A 450.

6.2.2

For eddy current test the calibration tube shall contain all the following discontinuities to

establish the minimum degree of sensitivity for rejection of tubes:

6.2.3

a longitudinal notch on a radial plane parallel to the tube axis on the outside surface,

having a length of 6.35 mm, maximum width 0.8 mm, and depth 10% of the tube

thickness but not less than 0.1 mm.

a circumferential notch on a transverse plane to the longitudinal axis of the tube, having a

depth of 10% of the tube thickness but not less than 0.1 mm.

Three or more through holes, equally spaced circumferentially around the tube and

longitudinally separated by a sufficient distance to allow distinct identification of the signal

from each hole. The diameter of hole shall not be larger than 0.8 mm.

For ultrasonic examination, the calibration tube shall contain all the following discontinuities to

establish the minimum degree of sensitivity for rejection of tubes:

-

a longitudinal notch on a radial plane parallel to the tube centre line, having a depth 5% of

the tube thickness but not less than 0.1 mm; on both the outside and inside surface

a transverse notch, tangent to the surface and perpendicular to the longitudinal centre line

of the tube, having a depth 5% of the tube thickness but not less than 0.1 mm., on both

the outside and inside surface

Form code : MDT.GG.QUA.0515 Sh. 01/Rev. 1.94

File code: spcgnrae.dot

Data file: spc_cr_ur_510_r03_e_f.doc

This document is the property of Snamprogetti who will safeguard its rights according to the civil and penal provision of the law.

SPC.CR.UR.510

Rev. 03

Date

Sep. 2003

Sheet 24 (24)

TESTS ON PRODUCTION WELDS AND CONSUMABLES

7.1

General

7.1.1

Welding consumables (electrodes, wires, rods, strips and fluxes) shall be certified for the

different heats/lots according to EN 10204 type 3.1.B. Snamprogetti and the owner reserves

the right to request a chemical check analysis on production welds.

7.1.2

Butt welds shall be fully radiographed (if physically feasible).

7.1.3

All welds and weld overlay deposit top layer shall be examined by dye penetrants, if possible

on the side in contact with the process fluid or, if this is impracticable, on the outside.

7.1.4

After final machining (if any) the last tubesheet W.O. layer deposited shall have a minimum

thickness of 3 mm. Along this thickness the chemical composition shall be in compliance with

the requirements of para. 3.1.3. Supplier shall maintain full traceability of fulfiment of this

requirement. Traceability data sheet shall be submitted to Snamprogetti inspector for review.

7.1.5

If the above requirement cannot be warranted by the supplier an additional weld overlay layer,

other than that qualified on PQR, shall be deposited.

7.1.6

After machining of tubesheet weld overlay and before drilling operations a chemical sample

shall be taken as per Attachment 8.

7.1.7

All the welds of internal parts to the lining shall be examined by dye penetrants after each

welding pass.

7.2

Tube to tubesheet weld production mock up

7.2.1

Supplier shall provide no. 3 representatives production mock-up to verify the tube to tubesheet

weld as per Attachment 9 and 10.

7.2.2

Mock-up shall be realised applying the same production tube sheet configuration, materials

and welding parameters except for the carbon steel plate material on which the thickness

should be reduced to a value equal at least the 30% of the original.

7.2.3

The frequency welding cycle verification shall be as follows:

a) No. 1 mock-up before starting any production welds

b) No. 1 mock-up around middle production

c) No. 1 mock-up before completion of the last 100 welds

7.2.4

On the mock-up 7.2.3 (a) an additional impediment shall be located in order to simulate the

peripheral tubesheet configuration (see Attachment 10).

7.2.5

Each tube samples shall have a minimum lenght of 100 mm.

Form code : MDT.GG.QUA.0515 Sh. 01/Rev. 1.94

File code: spcgnrae.dot

Data file: spc_cr_ur_510_r03_e_f.doc

This document is the property of Snamprogetti who will safeguard its rights according to the civil and penal provision of the law.

SPC.CR.UR.510

Rev. 03

Date

Sep. 2003

Sheet 25 (24)

7.2.6

Each tube weld sample shall be examined as per para 4.5.

Revision memorandum

Novembre 1984

August 1993

September 1995

September 2003

Issue

Rev. 01.

Rev. 02.

Modified para 2.3.2 specifying the yeld strenght at 0,2% offset. Updated the list of approved filler

materials of table 3.5.1.a . Conversion in Word of the whole document.

Rev. 03.

General revision

Form code : MDT.GG.QUA.0515 Sh. 01/Rev. 1.94

File code: spcgnrae.dot

Data file: spc_cr_ur_510_r03_e_f.doc

This document is the property of Snamprogetti who will safeguard its rights according to the civil and penal provision of the law.

SPC.CR.UR.510

Rev. 03

Date

Sep. 2003

Sheet 1 (1)

ATTACHMENT 1

Form code : MDT.GG.QUA.0515 Sh. 01/Rev. 1.94

File code: spcgnrae.dot

Data file: spc_cr_ur_510_r03_e_f.doc

This document is the property of Snamprogetti who will safeguard its rights according to the civil and penal provision of the law.

SPC.CR.UR.510

Rev. 03

Date

Sep. 2003

Sheet 1 (1)

ATTACHMENT 2

Form code : MDT.GG.QUA.0515 Sh. 01/Rev. 1.94

File code: spcgnrae.dot

Data file: spc_cr_ur_510_r03_e_f.doc

This document is the property of Snamprogetti who will safeguard its rights according to the civil and penal provision of the law.

SPC.CR.UR.510

Rev. 03

Date

Sep. 2003

Sheet 1 (1)

ATTACHMENT 3

Form code : MDT.GG.QUA.0515 Sh. 01/Rev. 1.94

File code: spcgnrae.dot

Data file: spc_cr_ur_510_r03_e_f.doc

This document is the property of Snamprogetti who will safeguard its rights according to the civil and penal provision of the law.

SPC.CR.UR.510

Rev. 03

Date

Sep. 2003

Sheet 1 (1)

ATTACHMENT 4

Form code : MDT.GG.QUA.0515 Sh. 01/Rev. 1.94

File code: spcgnrae.dot

Data file: spc_cr_ur_510_r03_e_f.doc

This document is the property of Snamprogetti who will safeguard its rights according to the civil and penal provision of the law.

SPC.CR.UR.510

Rev. 03

Date

Sep. 2003

Sheet 1 (1)

ATTACHMENT 5

Form code : MDT.GG.QUA.0515 Sh. 01/Rev. 1.94

File code: spcgnrae.dot

Data file: spc_cr_ur_510_r03_e_f.doc

This document is the property of Snamprogetti who will safeguard its rights according to the civil and penal provision of the law.

SPC.CR.UR.510

Rev. 03

Date

Sep. 2003

Sheet 1 (1)

ATTACHMENT 6

Form code : MDT.GG.QUA.0515 Sh. 01/Rev. 1.94

File code: spcgnrae.dot

Data file: spc_cr_ur_510_r03_e_f.doc

This document is the property of Snamprogetti who will safeguard its rights according to the civil and penal provision of the law.

SPC.CR.UR.510

Rev. 03

Date

Sep. 2003

Sheet 1 (1)

ATTACHMENT 7

The arrows indicate the sectioning planes

Form code : MDT.GG.QUA.0515 Sh. 01/Rev. 1.94

File code: spcgnrae.dot

Data file: spc_cr_ur_510_r03_e_f.doc

This document is the property of Snamprogetti who will safeguard its rights according to the civil and penal provision of the law.

SPC.CR.UR.510

Rev. 03

Date

Sep. 2003

Sheet 1 (1)

ATTACHMENT 8

Form code : MDT.GG.QUA.0515 Sh. 01/Rev. 1.94

File code: spcgnrae.dot

Data file: spc_cr_ur_510_r03_e_f.doc

This document is the property of Snamprogetti who will safeguard its rights according to the civil and penal provision of the law.

SPC.CR.UR.510

Rev. 03

Date

Sep. 2003

Sheet 1 (1)

ATTACHMENT 9

Tubes To Tube Sheet Welds Qualification Procedure Test

Form code : MDT.GG.QUA.0515 Sh. 01/Rev. 1.94

File code: spcgnrae.dot

Data file: spc_cr_ur_510_r03_e_f.doc

This document is the property of Snamprogetti who will safeguard its rights according to the civil and penal provision of the law.

SPC.CR.UR.510

Rev. 03

Date

Sep. 2003

Sheet 1 (1)

ATTACHMENT 10

Form code : MDT.GG.QUA.0515 Sh. 01/Rev. 1.94

File code: spcgnrae.dot

Data file: spc_cr_ur_510_r03_e_f.doc

This document is the property of Snamprogetti who will safeguard its rights according to the civil and penal provision of the law.

You might also like

- Vortex Gasket PDFDocument13 pagesVortex Gasket PDFmansurudinNo ratings yet

- JW Inmarco Flexible Pure Graphite Gasket SheetDocument2 pagesJW Inmarco Flexible Pure Graphite Gasket SheetNilesh NarkhedeNo ratings yet

- Cylinders Shall Be Produced As Per IS 7285 and Approved by Chief Controller of ExplosiveDocument1 pageCylinders Shall Be Produced As Per IS 7285 and Approved by Chief Controller of ExplosiveAlanka Prasad100% (1)

- Fs Api6fb FlexproDocument10 pagesFs Api6fb FlexproRatheesh VidyadharanNo ratings yet

- Flange Weld Build UpDocument2 pagesFlange Weld Build UpMohd Shafuaaz KassimNo ratings yet

- ASTM A312 2014 Specification For Seamless and Welded Austenitic Stainless Steel Pipe PDFDocument4 pagesASTM A312 2014 Specification For Seamless and Welded Austenitic Stainless Steel Pipe PDFanon_295291420No ratings yet

- Failure Analysis of Condenser Tubes - MP Dec. 2012Document4 pagesFailure Analysis of Condenser Tubes - MP Dec. 2012MarioNo ratings yet

- Pump SpecificationDocument6 pagesPump SpecificationPrabha KaranNo ratings yet

- Bis 4041 - Refractory Terminology PDFDocument19 pagesBis 4041 - Refractory Terminology PDFMayank KumarNo ratings yet

- Din en 1320-1996Document18 pagesDin en 1320-1996edcam13No ratings yet

- Titanium Grades PDFDocument7 pagesTitanium Grades PDFMatt AgonyaNo ratings yet

- Astm A744-A744m 2010Document6 pagesAstm A744-A744m 2010Júlio RosaNo ratings yet

- SCWI BokDocument2 pagesSCWI Bokshganesh81No ratings yet

- In-Service Inspection For Coal Handling Plant of Thermal Power Stations Using NDTDocument4 pagesIn-Service Inspection For Coal Handling Plant of Thermal Power Stations Using NDTPravivVivpraNo ratings yet

- Article 312 Inspection and Repair of Shell and Tube Heat ExchangersDocument12 pagesArticle 312 Inspection and Repair of Shell and Tube Heat ExchangersasifNo ratings yet

- Astm 20M PDFDocument33 pagesAstm 20M PDFDee DeeNo ratings yet

- Spe 77 - 307Document5 pagesSpe 77 - 307Dunamis Joe100% (1)

- Online Leak Sealing TenderDocument10 pagesOnline Leak Sealing TenderchennaiNo ratings yet

- Boroscope InspectiónDocument14 pagesBoroscope InspectiónXiomara Hurtado FloresNo ratings yet

- Asme b16.25 Buttwelding EndsDocument22 pagesAsme b16.25 Buttwelding Endsgst ajahNo ratings yet

- Grating Weight - CalculationDocument1 pageGrating Weight - CalculationMuthuram NNo ratings yet

- TPI For Pressure VesselDocument10 pagesTPI For Pressure VesselBhavani Prasad100% (2)

- Ansi/I - 75.08.06-2002Document16 pagesAnsi/I - 75.08.06-2002Yatã SantojaNo ratings yet

- PWHT For Shell Nozzle of Steel Storage Tanks-21Document27 pagesPWHT For Shell Nozzle of Steel Storage Tanks-21الGINIRAL FREE FIRE100% (1)

- Asme BPVC - Ssc.iv - Ii.v.ix - Xiii-2023Document42 pagesAsme BPVC - Ssc.iv - Ii.v.ix - Xiii-2023mmendozagNo ratings yet

- Pages Welding High Strength Bolts: Anchor Bolt and Construction Fastener ManufacturerDocument4 pagesPages Welding High Strength Bolts: Anchor Bolt and Construction Fastener ManufacturermauricioveracorreaNo ratings yet

- Ibr FormsDocument117 pagesIbr Formsshivabtowin3301No ratings yet

- Floating Flange Rubber Expansion Joints: Series 980Document8 pagesFloating Flange Rubber Expansion Joints: Series 980Roland Bon IntudNo ratings yet

- Mega - Check - Cleaner - MSDS English VerDocument8 pagesMega - Check - Cleaner - MSDS English Vermaxpan maxNo ratings yet

- Stud Welding Procedure Specification WpsDocument2 pagesStud Welding Procedure Specification WpsEnrique Santiago BenavidesNo ratings yet

- Tank Case StudyDocument2 pagesTank Case Studykaryantoherlambang100% (1)

- ASME Sec VIII Div 1 Ed 2010 471 PDFDocument9 pagesASME Sec VIII Div 1 Ed 2010 471 PDFStephen Maloba100% (1)

- Shielded Metal Arc Welding: by Lakhveer SinghDocument77 pagesShielded Metal Arc Welding: by Lakhveer Singhਲਖਵੀਰ ਸਿੰਘ ਖਾਨਾNo ratings yet

- Passivation Test ASTM A 967Document3 pagesPassivation Test ASTM A 967Zeeshan KhanNo ratings yet

- INSPECT HEAT EXCHANGERDocument82 pagesINSPECT HEAT EXCHANGERBalaji VenkatesanNo ratings yet

- API 510 PWHT RequirementsDocument30 pagesAPI 510 PWHT RequirementsKandregula Mohan BabuNo ratings yet

- TighteningofStructuralBolts 31-35Document5 pagesTighteningofStructuralBolts 31-35masaud akhtarNo ratings yet

- IBR QualificationDocument12 pagesIBR Qualificationsanjayyadav2009100% (2)

- WI-INSP-04 R0 Work Instruction-Agitator InspDocument2 pagesWI-INSP-04 R0 Work Instruction-Agitator InspRakesh MishraNo ratings yet

- ITP For Drum Screen InspectionDocument1 pageITP For Drum Screen InspectionkapsarcNo ratings yet

- Install, operate and maintain microfinish ball valvesDocument14 pagesInstall, operate and maintain microfinish ball valvesrajputashiNo ratings yet

- Percentage Wall Reduction Is The Most FrequentlyDocument4 pagesPercentage Wall Reduction Is The Most Frequentlysanketpavi21No ratings yet

- Helium leak test procedureDocument7 pagesHelium leak test procedureChandrasekhar mishraNo ratings yet

- Inspection of Heat ExchangerDocument83 pagesInspection of Heat ExchangerRaghavanNo ratings yet

- PFI ES 2 2000 Method of Dimensioning Piping AssembliesDocument4 pagesPFI ES 2 2000 Method of Dimensioning Piping AssembliesedwinNo ratings yet

- Hydrostatic Test Procedure: 1. ScopeDocument5 pagesHydrostatic Test Procedure: 1. ScopeHassan SleemNo ratings yet

- Water Soluble Penetrant Test ProcedureDocument7 pagesWater Soluble Penetrant Test ProcedureTahseen Ahmed100% (1)

- Helium Leak Detection of Shell & Tube Heat ExchangerDocument1 pageHelium Leak Detection of Shell & Tube Heat ExchangerGetapo RaminNo ratings yet

- Astm A516 Grade 70Document1 pageAstm A516 Grade 70Javier Caamaño VillafañeNo ratings yet

- Chapter IX Expansion Joints TrainingDocument29 pagesChapter IX Expansion Joints Trainingvarma101100% (1)

- NBIC Part 2 PDFDocument12 pagesNBIC Part 2 PDFjhonjimenez87No ratings yet

- Guideline For Boiler InspectionsDocument53 pagesGuideline For Boiler Inspectionsmkarahan100% (1)

- Acoustic Emission Testing of Pressure Vessel - ASME Section V, ASNT - 24 Feb 2011Document84 pagesAcoustic Emission Testing of Pressure Vessel - ASME Section V, ASNT - 24 Feb 2011concord1103No ratings yet

- SPC - CR - UR - 510 - 3, Urea GradeDocument35 pagesSPC - CR - UR - 510 - 3, Urea Gradesaadpervaiz14No ratings yet

- InsulationDocument63 pagesInsulationSH1961No ratings yet

- Mil STD 870cDocument13 pagesMil STD 870cKrishnan DandapaniNo ratings yet

- 02 Samss 012Document9 pages02 Samss 012slan79bisNo ratings yet

- Mil DTL 24211CDocument8 pagesMil DTL 24211CmurphygtNo ratings yet

- AMS2411Document9 pagesAMS2411Pankaj Shah100% (1)

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- 2Document6 pages2bestread67No ratings yet

- 4 SimplificationDocument9 pages4 SimplificationsrinivasmicNo ratings yet

- Ex.1:Find The Average of All Prime Numbers Between 30 andDocument3 pagesEx.1:Find The Average of All Prime Numbers Between 30 andz1y280% (5)

- Ecat 2014Document12 pagesEcat 2014Aitazaz AhsanNo ratings yet

- Design of Pile FoundationsDocument186 pagesDesign of Pile Foundationsroborocks100% (1)

- Aiche-35-010 Removing The Failed WeldDocument11 pagesAiche-35-010 Removing The Failed WeldAitazaz AhsanNo ratings yet

- DocumentDocument1 pageDocumentAitazaz AhsanNo ratings yet

- A Kalina Cycle Application For Power Generation PDFDocument10 pagesA Kalina Cycle Application For Power Generation PDFAitazaz AhsanNo ratings yet

- Physics: © The PreceptorDocument10 pagesPhysics: © The PreceptorAitazaz AhsanNo ratings yet

- © The Preceptor: PhysicsDocument12 pages© The Preceptor: PhysicsAitazaz AhsanNo ratings yet

- Ecat 2013 FinalDocument7 pagesEcat 2013 FinalAitazaz AhsanNo ratings yet

- Ecat 2011Document5 pagesEcat 2011Aitazaz AhsanNo ratings yet

- Heat ExchangerDocument4 pagesHeat ExchangerAitazaz AhsanNo ratings yet

- © The Preceptor: PhysicsDocument10 pages© The Preceptor: PhysicsAitazaz AhsanNo ratings yet

- GeomatryDocument4 pagesGeomatryAitazaz AhsanNo ratings yet

- P4 High Frequency WordsDocument86 pagesP4 High Frequency WordsAitazaz AhsanNo ratings yet

- NDocument14 pagesNAitazaz Ahsan100% (1)

- GAT 5th JanDocument22 pagesGAT 5th JanAitazaz Ahsan100% (2)

- Profit Loss Problems SolutionsDocument7 pagesProfit Loss Problems SolutionsAitazaz AhsanNo ratings yet

- Final Thesis, Solar Dish Engine System 1 Uet TaxilaDocument114 pagesFinal Thesis, Solar Dish Engine System 1 Uet TaxilaAitazaz Ahsan100% (6)

- Previous GAT QuestionsDocument8 pagesPrevious GAT QuestionsAhmad NaumanNo ratings yet

- Time and Work ProblemsDocument13 pagesTime and Work ProblemsAitazaz AhsanNo ratings yet

- Share & Stock Problem SolutionsDocument8 pagesShare & Stock Problem SolutionsAitazaz AhsanNo ratings yet

- Clocks Problem SolutionsDocument16 pagesClocks Problem SolutionsAitazaz AhsanNo ratings yet

- Previous GATDocument23 pagesPrevious GATAitazaz Ahsan100% (1)

- GAT Analytical ReasoningDocument272 pagesGAT Analytical ReasoningMuzaffar Iqbal90% (10)

- Aberration: Frequently Used Vocabulary in GAT GeneralDocument10 pagesAberration: Frequently Used Vocabulary in GAT GeneralAitazaz Ahsan0% (1)

- Tips For ProbabilityDocument2 pagesTips For ProbabilityAitazaz AhsanNo ratings yet

- AverageDocument4 pagesAverageAitazaz AhsanNo ratings yet

- Principles of Brazing and Soldering: Joining TechnologyDocument26 pagesPrinciples of Brazing and Soldering: Joining Technologyyared Belete100% (1)

- Filler MetalsDocument28 pagesFiller MetalsPeerasak ArunNo ratings yet

- 20 Samss 001Document9 pages20 Samss 001asimazami690% (1)

- Aluminum Selection ChartDocument1 pageAluminum Selection ChartFahri Risfa ZulfiNo ratings yet

- WPS No. 1.203 Rev. 4 GTAW Welding Process SpecificationDocument2 pagesWPS No. 1.203 Rev. 4 GTAW Welding Process SpecificationbeyNo ratings yet

- Code Ref.Document155 pagesCode Ref.Selvakpm06No ratings yet

- Aws d1.8Document48 pagesAws d1.8fima20130% (1)

- 5 B503 Rev 5Document2 pages5 B503 Rev 5beyNo ratings yet

- Welding Workshop - Welding TechniquesDocument2 pagesWelding Workshop - Welding TechniquesFarid Ahmed KhwajaNo ratings yet

- PT Prakarsalanggeng Welder Qualification TestDocument24 pagesPT Prakarsalanggeng Welder Qualification Testmuhammad rizalNo ratings yet

- Usability Designators FCAWDocument5 pagesUsability Designators FCAWAnonymous dh6DITNo ratings yet

- Defense Scrap Yard HandbookDocument251 pagesDefense Scrap Yard HandbookAFLAC ............0% (1)

- Applying TIG Welding TechniquesDocument104 pagesApplying TIG Welding Techniqueshema_avraoNo ratings yet

- Boosting Business with Isuzu Pick-Up TrucksDocument10 pagesBoosting Business with Isuzu Pick-Up TrucksPradip GoswamiNo ratings yet

- A5 10-A5 10M-1999 - R2007PVDocument7 pagesA5 10-A5 10M-1999 - R2007PVfeni4kaNo ratings yet

- Welding Class 1Document73 pagesWelding Class 1omkardashetwarNo ratings yet

- AWS A5.8-92 Specification For Filler Metals For BrazingDocument33 pagesAWS A5.8-92 Specification For Filler Metals For BrazingFRANCISCO TORRES100% (2)

- Brazing: Brazing Is A Joining Process Whereby A NonDocument23 pagesBrazing: Brazing Is A Joining Process Whereby A Nonshayan sohailNo ratings yet

- Electric-Fusion-Welded Austenitic Chromium-Nickel Alloy Steel Pipe For High-Temperature ServiceDocument6 pagesElectric-Fusion-Welded Austenitic Chromium-Nickel Alloy Steel Pipe For High-Temperature Serviceluis100% (1)

- EPT 09 T 04 Piping ConstructionDocument30 pagesEPT 09 T 04 Piping Constructionnwosu_dixon100% (1)

- ASME IX Sample WPS GTAW SMAWDocument1 pageASME IX Sample WPS GTAW SMAWDeepak ShrivastavNo ratings yet

- WPS, PQR, WPQ PoojaDocument10 pagesWPS, PQR, WPQ PoojaRajmahesh Dakhore100% (1)

- Module 6 PDFDocument180 pagesModule 6 PDFyoustruelyNo ratings yet

- BPVC Ix qw-483 PDFDocument2 pagesBPVC Ix qw-483 PDFEmma DNo ratings yet

- Códigos de SoldaduraDocument16 pagesCódigos de SoldadurarenemolinaledezmaNo ratings yet

- Dad Workshop TechnologyDocument10 pagesDad Workshop TechnologyArif ZafryNo ratings yet

- Aws d1.1 WPS, PQR & WQTDocument4 pagesAws d1.1 WPS, PQR & WQTWeld Bro SandeepNo ratings yet

- Soldering, Brazing, Braze Welding, Wearfacing: TopicsDocument42 pagesSoldering, Brazing, Braze Welding, Wearfacing: Topicsyared BeleteNo ratings yet

- 12 - Exhibit C Sp-Welding of Pipelines &facilitiesDocument13 pages12 - Exhibit C Sp-Welding of Pipelines &facilitiesMoaatazz Nouisri100% (1)

- Welder Qualifications ProcedureDocument32 pagesWelder Qualifications ProcedureghanicwiNo ratings yet