Professional Documents

Culture Documents

Summary of Findings and Outcome of The HAZOP Study

Uploaded by

dhanu_lagwankarOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Summary of Findings and Outcome of The HAZOP Study

Uploaded by

dhanu_lagwankarCopyright:

Available Formats

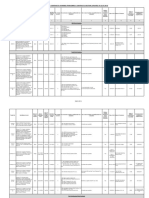

SUMMARY OF FINIDINGS & OUTCOME OF THE HAZOP

STUDY

Sr.

No.

Observation

Action Recommended

01

As of now process is not

defined,

only

facilities

HAZOP were carried out.

NFIL has to carried out,

process HAZOP based on the

process. And has to prepare

SOPs for respective process.

02

SPCPL to ensure that all the

interlocks and

safety

parameters to be covered in

DCS

Following major safety

points were discussed in

hydrogenation reaction

area.

Followings

safety

precautions were taken.

03

Separate cooling water

line with On/OFF valve to

be provided on inlet &

outlet of external coil. will

operate

based

on

interlocks from DCS.

Steam control & ON/OFF

valve will operate based

on interlocks from DCS.

ON/OFF valve is provided

on hydrogen line and will

be operated based on

interlocks from DCS.

SPCPL to check

specification.

Locate water pot at 5 mtr

or mezzanine level inside

the hydrogenation area,

1. Pressurization & Loss

of strength due to

high temp.

2. To control heating

rate in reactor.

3. Reaction

exotherm,

Due

to

excess

addition of hydrogen.

4. On/off valves on LPS

line and hydrogen

line were fail to close

top, whereas on/off

valves on cold utility

line were fail to open

type.

DCS HAZOP to be carried

out with DCS vendor.

SPCPL to provide separate

interlock

list

to

DCS

vendor

as

discussed

during HAZOP study.

valve

provision of local level

indicator

and

pressure

gauge,

SPCPL

to

incorporate it in layout

and P&ID and NFIL to

incorporate in operational

SOP.

5. Reverse flow of water

from hydrogen vent

line.

To be confirm during PSSR.

6. Venting of hydrogen

will

be

at

safe

location.

04

Following major safety

points were discussed in

Intermediate

glass

reactor.

1

Pressurization & Loss

of strength due to

high temp.

Followings

safety

precautions were taken.

Steam control & ON/OFF

valve will operate based

on interlocks from DCS.

ON/OFF valve is provided

on hydrogen line and will

be operated based on

interlocks from DCS.

SPCPL

to

incorporate

Additional

temperature

transmitter on vapour line.

Vent is connected directly

to

Scrubber,

Scrubber

running status will be

provided in DCS. NFIL to

generate venting SOP.

Pressure safety valve to be

provided on utility supply

line after isolation valve,

which will operation on

required utility pressure,

SPCPL to incorporate in

P&ID.

To control heating

rate in reactor.

Malfunctioning

temperature

transmitter

reactor.

of

on

Due to pressurization

or gas venting /

Vacuum at the end of

batch,

hazardous

gases will be present

and will get released

in atm.

High

pressure

at

utility side will break

the tubes in glass

condensers, result in

cross contamination.

05

Gas leakages

plant

inside

06

NFIL

have

to

following SOPs

the

prepare

1. SOPs as per process

2. Operation

start-up

SOP

3. Operational SOP

4. Venting SOP

5. Safety SOP

6. Equipment

&

Instrument calibration

& maintenance SOP.

7. Material loading and

unloading SOP

to

be

Hydrogen, oxygen and

bromine gas detection

system is provided

NFIL has to prepare all these

documents,

based

on

process.

08

Motor no alarm

provided on DCS

SPCPL to incorporate in DCS

09

Design calculation back for

all safety installation like

Rupture disk, Safety valve

etc

SPCPL to provide the design

backup

10

Hydrogen & other gas bank

system to be shown in

layout

SPCPL

layout

11

NFIL have to carry out the

Process HAZOP as per the

products

NFILs has to prepare process

HAZOP and SOPs as per

product.

to

incorporate

in

Only facility HAZOP is carried out for typical high pressure hydrogenation

reactor, Intermediate glass reactor, and CF system.

Same philosophy will be carried out for other equipments.

HAZOP study is done based on approved Piping and instrumentation

diagrams (P&IDs) & approved facility layout. In addition to this HAZOP,

study to be done considering specific product manufacturing since facility

will be used for multipurpose application.

NFIL has to carry out process HAZOP as per specified product and

prepared the operational SOPs as per requirement.

Following drawings were refer for preparation of HAZOP report

Equipment layout

Men material movement layout

Hazardous area classification layout

HVAC classification layout

Safety shower & fire exit layut

Fire hydrant layout

Gas detection system layout

P&ID

Parameters covered in HAZOP reports are as follows

Flow

Temperature

Pressure

Level

Contamination

Relief

Electrical

Corrosion

You might also like

- Thermal (Steam) Power Plants Mainly Consists of 4 CircuitsDocument100 pagesThermal (Steam) Power Plants Mainly Consists of 4 CircuitsNikhil Patidar100% (1)

- Environmental Protection in The Field of Thermal Power PlantDocument21 pagesEnvironmental Protection in The Field of Thermal Power PlantGoverdhan ShresthaNo ratings yet

- Statutory Compliance Report Factories Act 1948Document6 pagesStatutory Compliance Report Factories Act 1948Vidya AdsuleNo ratings yet

- EHS Guidelines+101 WebinarDocument36 pagesEHS Guidelines+101 WebinarRashedul KarimNo ratings yet

- Energy SavingDocument34 pagesEnergy SavingSankaran_Nair_3051100% (1)

- Quotation Air Curtains EI-2019!5!596241Document2 pagesQuotation Air Curtains EI-2019!5!596241Ratnakar SeethiniNo ratings yet

- WESM Participant Handbook Vol3Document18 pagesWESM Participant Handbook Vol3Leizza Ni Gui DulaNo ratings yet

- Air PollutionDocument6 pagesAir PollutionBhavesh BhoeeNo ratings yet

- Arci Ele Final Boq, Specs and Data's 11.10.2014Document230 pagesArci Ele Final Boq, Specs and Data's 11.10.2014madhav0303No ratings yet

- Valuation of Furniture at Contractor Main Camp Mankulam: No Describtion Unit Qty Unit Price (RS.) Value (RS.)Document2 pagesValuation of Furniture at Contractor Main Camp Mankulam: No Describtion Unit Qty Unit Price (RS.) Value (RS.)ලහිරු විතානාච්චිNo ratings yet

- CVC Guidelines On Public ProcurementDocument105 pagesCVC Guidelines On Public ProcurementDeepesh SirohiaNo ratings yet

- Tech DiagramDocument1 pageTech DiagramFerry LaviantoNo ratings yet

- LOI P&R Infraproject LTDDocument6 pagesLOI P&R Infraproject LTDRamesh SinghNo ratings yet

- BUA AREAS On 6th Sept 2013Document14 pagesBUA AREAS On 6th Sept 2013Sachin ShindeNo ratings yet

- IFC EHS Guidelines, Project Finance and Environmental Impact Assessments PDFDocument21 pagesIFC EHS Guidelines, Project Finance and Environmental Impact Assessments PDFleonelNo ratings yet

- COC CLS - Healthy Safety EnvironmentDocument121 pagesCOC CLS - Healthy Safety Environmentaristian27No ratings yet

- Slab N ConduitsDocument54 pagesSlab N ConduitsSachin ShindeNo ratings yet

- Slab CycleDocument2 pagesSlab CycleSudarshan ManeNo ratings yet

- PNC Infratech Limited Emerges The Lowest Bidder For Airport Runway Project at Air Force Station, Kanpur (Company Update)Document2 pagesPNC Infratech Limited Emerges The Lowest Bidder For Airport Runway Project at Air Force Station, Kanpur (Company Update)Shyam SunderNo ratings yet

- Exposure AssessmentDocument83 pagesExposure AssessmenttommyNo ratings yet

- Approved Document FDocument22 pagesApproved Document FAnonymous NcB95G6XwNo ratings yet

- Budget Excel FileDocument83 pagesBudget Excel FilervkheavenNo ratings yet

- Environment PollutionDocument14 pagesEnvironment Pollutionapi-37312570% (1)

- Letter To Court. 10 June 2014Document2 pagesLetter To Court. 10 June 2014Shijo ThomasNo ratings yet

- Labour: Se. No Description UnitDocument2 pagesLabour: Se. No Description Unitලහිරු විතානාච්චිNo ratings yet

- RFP For AWOS IndiaDocument68 pagesRFP For AWOS IndiaanupamkhannaNo ratings yet

- Cooper - Fps Boq-EdwardsDocument34 pagesCooper - Fps Boq-EdwardsSudeep Sudhakara MenonNo ratings yet

- 7203 - Pyrotek - Without OLD PDFDocument55 pages7203 - Pyrotek - Without OLD PDFAditya TubachiNo ratings yet

- Iom Chia Hia Reader 2005-2007Document56 pagesIom Chia Hia Reader 2005-2007anon-481687No ratings yet

- Presentation Ron Water MeyerDocument22 pagesPresentation Ron Water MeyerGordon RudmanNo ratings yet

- IMS AustriaDocument14 pagesIMS Austriamarlene0601No ratings yet

- Painting Final E and F WingDocument20 pagesPainting Final E and F WingSachin ShindeNo ratings yet

- AL Aza'em Al Muttahida L.L.C Document Transmittal: Kind Attn: Mr. Sudheer Nair (Sr. Project Manager) ProjectDocument8 pagesAL Aza'em Al Muttahida L.L.C Document Transmittal: Kind Attn: Mr. Sudheer Nair (Sr. Project Manager) ProjectSwapnil KamerkarNo ratings yet

- Adv Ayment-Per GuaranteeDocument4 pagesAdv Ayment-Per Guaranteeලහිරු විතානාච්චිNo ratings yet

- Future European Refining Industry June2012 PDFDocument23 pagesFuture European Refining Industry June2012 PDFdiego.lopez1870No ratings yet

- BUA RateDocument4 pagesBUA RateSachin ShindeNo ratings yet

- Pre Qualification Record Geotechnical SurveyDocument36 pagesPre Qualification Record Geotechnical SurveySyed Adnan AqibNo ratings yet

- The Wealth of NationsDocument786 pagesThe Wealth of Nationsleosilveira100% (1)

- The Stage Gate Process For Product DevelopmentDocument6 pagesThe Stage Gate Process For Product DevelopmentScottNo ratings yet

- 20170201-FINAL EHS+Guidelines+for+Ports+Harbors+and+Terminals PDFDocument35 pages20170201-FINAL EHS+Guidelines+for+Ports+Harbors+and+Terminals PDFmarineconsultantNo ratings yet

- Electrical Works Technical Specifications (General) : Sr. No.D E S C R I P T I O N Page NoDocument17 pagesElectrical Works Technical Specifications (General) : Sr. No.D E S C R I P T I O N Page NonaveedfndNo ratings yet

- NCRMP Alibaug UGC Work Action PlanDocument14 pagesNCRMP Alibaug UGC Work Action PlanKULDEEP KUMAR50% (2)

- EmissionInventoryCO2JK PDFDocument102 pagesEmissionInventoryCO2JK PDFAnkit Singh ThakurNo ratings yet

- CTR-GM - General & Management (0.11)Document9 pagesCTR-GM - General & Management (0.11)Elias EliasNo ratings yet

- Hazard Communication: Objective of HAZCOM As Per OSHADocument4 pagesHazard Communication: Objective of HAZCOM As Per OSHAMewnEProwtNo ratings yet

- 250kva Quotation ETA RevisedDocument8 pages250kva Quotation ETA Revisedgopal kumarNo ratings yet

- Item Master Form: Tab/Side Buttons Field Group Field TypeDocument32 pagesItem Master Form: Tab/Side Buttons Field Group Field TypeniravmodyNo ratings yet

- DTR Plinth AnalysisDocument2 pagesDTR Plinth AnalysisRohan SinghNo ratings yet

- NuScale PresentationDocument33 pagesNuScale PresentationMark ReinhardtNo ratings yet

- PT Flat Slab & PT Slab With PTB Option Cost DetailsDocument1 pagePT Flat Slab & PT Slab With PTB Option Cost DetailsSwapnil KamerkarNo ratings yet

- Hazop Sheet - SSR-216Document10 pagesHazop Sheet - SSR-216dhanu_lagwankarNo ratings yet

- Condenser Flood TestDocument14 pagesCondenser Flood Testsrigirisetty208100% (1)

- Method of Statement For Precommissioning & Commissioning of ChillersDocument4 pagesMethod of Statement For Precommissioning & Commissioning of Chillersvin ssNo ratings yet

- Procedure For Condenser Flood Test and Vacuum Tightness TestDocument13 pagesProcedure For Condenser Flood Test and Vacuum Tightness TestJackSparrow86No ratings yet

- LPG Check ListDocument39 pagesLPG Check ListARUL SANKARANNo ratings yet

- 500 MW Volume 2Document319 pages500 MW Volume 2api-19984595100% (7)

- Section-IV Shutdown Rev4Document12 pagesSection-IV Shutdown Rev4Balasubramanian CNo ratings yet

- Carrier Transicold TECHLINE July2012Document4 pagesCarrier Transicold TECHLINE July2012Carlitos Enrique Corpus PonceNo ratings yet

- Operational Control Procedures BhelDocument124 pagesOperational Control Procedures BhelKrishnan Rajappan100% (3)

- Appendix-1 (HAZOPWorksheets)Document37 pagesAppendix-1 (HAZOPWorksheets)zohaib_farooq100% (1)

- Installation, Operation, and Maintenance Manual: Sample ValvesDocument11 pagesInstallation, Operation, and Maintenance Manual: Sample Valvesdhanu_lagwankarNo ratings yet

- Risk Management in Sterile EnvironmentsDocument30 pagesRisk Management in Sterile Environmentsdhanu_lagwankarNo ratings yet

- Boiler Capcity-F&A 100 Deg CDocument3 pagesBoiler Capcity-F&A 100 Deg CAgeng Firstyan BagaskoroNo ratings yet

- Structural Integrity Assessment Report PDocument126 pagesStructural Integrity Assessment Report Pdhanu_lagwankarNo ratings yet

- Tech Specs For Nitrogen GeneratorDocument5 pagesTech Specs For Nitrogen Generatordhanu_lagwankarNo ratings yet

- PortfolioDocument2 pagesPortfoliodhanu_lagwankarNo ratings yet

- Rooftop Pipe Support EBookDocument22 pagesRooftop Pipe Support EBookdhanu_lagwankarNo ratings yet

- Care That Inspires Innovation: Cipla Limited Annual Report 2021-22Document392 pagesCare That Inspires Innovation: Cipla Limited Annual Report 2021-22dhanu_lagwankarNo ratings yet

- ELmach QuoteDocument2 pagesELmach Quotedhanu_lagwankarNo ratings yet

- Automatically Controlled Air Cooled Condenser With Backlit Displays Dramatically Reduces Testing TimesDocument6 pagesAutomatically Controlled Air Cooled Condenser With Backlit Displays Dramatically Reduces Testing Timesdhanu_lagwankarNo ratings yet

- Understanding Valves and Their Role in Mechanical IntegrityDocument13 pagesUnderstanding Valves and Their Role in Mechanical Integritydhanu_lagwankarNo ratings yet

- Impact AssessmentDocument18 pagesImpact Assessmentdhanu_lagwankarNo ratings yet

- MAHAVIR - 24 (21) ValveDocument3 pagesMAHAVIR - 24 (21) Valvedhanu_lagwankarNo ratings yet

- WBSDocument287 pagesWBSdhanu_lagwankarNo ratings yet

- FAT-Compounding Isolator 100 L Compounding VesselDocument33 pagesFAT-Compounding Isolator 100 L Compounding Vesseldhanu_lagwankarNo ratings yet

- Articulo Concept SelectionDocument14 pagesArticulo Concept Selectiondhanu_lagwankarNo ratings yet

- Scope Statement Structure PaintDocument4 pagesScope Statement Structure Paintdhanu_lagwankarNo ratings yet

- DQ - CRAB For Lyo LoadingDocument30 pagesDQ - CRAB For Lyo Loadingdhanu_lagwankarNo ratings yet

- OQ COMPOUNDING 100 Ltrs ISOLATORDocument28 pagesOQ COMPOUNDING 100 Ltrs ISOLATORdhanu_lagwankarNo ratings yet

- Conceptual Design Deliverables Latest Rev2Document14 pagesConceptual Design Deliverables Latest Rev2dhanu_lagwankarNo ratings yet

- Analysis For Boiler and Pre-Treatment SystemDocument2 pagesAnalysis For Boiler and Pre-Treatment Systemdhanu_lagwankarNo ratings yet

- URS - Ampoule Labelling MachineDocument15 pagesURS - Ampoule Labelling Machinedhanu_lagwankarNo ratings yet

- Way To Select An ACDocument1 pageWay To Select An ACdhanu_lagwankarNo ratings yet

- Dokumen - Tips Building Projects Pdri Automated Excel Spreadsheet WeightedDocument6 pagesDokumen - Tips Building Projects Pdri Automated Excel Spreadsheet Weighteddhanu_lagwankarNo ratings yet

- 12C 004 01 Asset Tag and Equipment Label Guidance 7.0 RedactedDocument20 pages12C 004 01 Asset Tag and Equipment Label Guidance 7.0 Redacteddhanu_lagwankarNo ratings yet

- Factories Act 1948Document68 pagesFactories Act 1948Sreelakshmi KambapuNo ratings yet

- Risk Engineering Position Paper 01 Atmospheric Storage Tanks 2015Document28 pagesRisk Engineering Position Paper 01 Atmospheric Storage Tanks 2015SardeniantoNo ratings yet

- Glenmark Sustainability Report FY 2020 21Document126 pagesGlenmark Sustainability Report FY 2020 21dhanu_lagwankarNo ratings yet

- TMS1647 Plant and Equipment Tag Numbering Rev06Document17 pagesTMS1647 Plant and Equipment Tag Numbering Rev06abdelhalimNo ratings yet

- Pid Legend PDFDocument1 pagePid Legend PDFSocMed Dtk UI0% (1)

- Plant Manager Sample Resume From Freedom ResumesDocument2 pagesPlant Manager Sample Resume From Freedom ResumesFreedom ResumesNo ratings yet

- OLADE, Palcee - Latin American and Caribbean Energy Efficiency Program, July 2013Document65 pagesOLADE, Palcee - Latin American and Caribbean Energy Efficiency Program, July 2013Detlef LoyNo ratings yet

- DNV Os 101Document80 pagesDNV Os 101preceptiveinquirerNo ratings yet

- SCO and ProceduresDocument9 pagesSCO and ProceduresAngel LealNo ratings yet

- Andrew CNT 200Document2 pagesAndrew CNT 200sfynksNo ratings yet

- 19 Sept PagesDocument8 pages19 Sept PagesBalaNo ratings yet

- Talesun Corporate PPT VF FM May2019Document66 pagesTalesun Corporate PPT VF FM May2019api-511578545No ratings yet

- Genius SW-HF 5.1 5000.rarDocument26 pagesGenius SW-HF 5.1 5000.rarzzorox100% (3)

- Engine TechnologyDocument96 pagesEngine TechnologyBorborean Andrei TiberiuNo ratings yet

- Almig Screw Air CompDocument8 pagesAlmig Screw Air CompMohamed HarbNo ratings yet

- L&T SHE ProgramDocument42 pagesL&T SHE Programkanakarao150% (2)

- High Performance Condenser Tube Cleaning SystemDocument5 pagesHigh Performance Condenser Tube Cleaning SystemKrizia Meiahn CatalonNo ratings yet

- The Hydrogen Standard Issue 1Document28 pagesThe Hydrogen Standard Issue 1rriveram1299No ratings yet

- Boiler ErectionDocument44 pagesBoiler ErectionS.KAMBAN100% (1)

- Vacuum Parts - Part of The Uni FamilyDocument2 pagesVacuum Parts - Part of The Uni FamilyLogist ChinaNo ratings yet

- Blaze Tech Company ProfileDocument19 pagesBlaze Tech Company ProfileBLAZE TECHNo ratings yet

- Common Rail BrizgaljkeDocument8 pagesCommon Rail BrizgaljkeJovo PavlovicNo ratings yet

- c87 MZ P Mach Zen Pet User Guide PDFDocument12 pagesc87 MZ P Mach Zen Pet User Guide PDFpvekzNo ratings yet

- Building Blocks of PINCH Technology-Lect 8 PDFDocument8 pagesBuilding Blocks of PINCH Technology-Lect 8 PDFSukanta K. DashNo ratings yet

- Interruptor PowellDocument72 pagesInterruptor Powelljhon_angulo_3No ratings yet

- 2019 Environment Safety Social Data Report OptimisedDocument22 pages2019 Environment Safety Social Data Report OptimisedAminul IslamNo ratings yet

- Tishman Speyer RFP ResponseDocument49 pagesTishman Speyer RFP ResponseNat LevyNo ratings yet

- Indian Coal and It'S Use S: Presented byDocument19 pagesIndian Coal and It'S Use S: Presented bySiddharth KishanNo ratings yet

- List of Contracts AwardedDocument21 pagesList of Contracts AwardedShailesh GangNo ratings yet

- 2015-5-15 ASA Best Practice ESDDocument12 pages2015-5-15 ASA Best Practice ESDPIYUSH100% (1)

- Bharat Heavy Electricals LimitedDocument21 pagesBharat Heavy Electricals LimitedKiruthika BaskarNo ratings yet

- Suppliers Rating Evaluation: Apo Cement CorporationDocument1 pageSuppliers Rating Evaluation: Apo Cement CorporationAljon Angeles Tan100% (1)

- O9 Orcun KokturkDocument15 pagesO9 Orcun KokturkRajKumar KalimuthuNo ratings yet

- FINAL ABM and Fauquier County Public Schools Energy Study AgreementDocument14 pagesFINAL ABM and Fauquier County Public Schools Energy Study AgreementFauquier NowNo ratings yet

- Steel ContactsDocument16 pagesSteel ContactssimaproindiaNo ratings yet