Professional Documents

Culture Documents

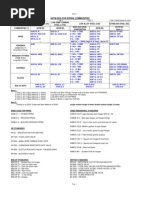

Element Standard Manufacturing Method: Piping Commodities

Uploaded by

Kamalakannan AyyaduraiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Element Standard Manufacturing Method: Piping Commodities

Uploaded by

Kamalakannan AyyaduraiCopyright:

Available Formats

Page 1 of 8

Piping commodities

Element

1 Pipe

SMLS

ERW

EFW

SAW

2 Fittings

2.1 Elbow

Large radius

Small radius

2.2 Reducer

Concentric

Eccentric

2.3 - Cap

2.4 Swage

2.5 Nipple

Standard

ASME B 36.10 (ferrite steel)

ASME B 36.19 (austenite steel)

Wrought means made from pipe

ASME B 16.11 Forged fittings (SW/TH)

ASME B 16.9 Wrought fittings (BE)

For LR same as above

For SR ASME B 16.28

SB Forging

LB Wrought

SB Forging

LB Wrought

MSS SP 95

MSS SP 95

2.6 Couplings (SB only)

Full Coupling

Half Coupling

2.7 Stub ends

2.8 Branches

2.8.1 Equal Tee

2.8.2 Reducing Tee

Manufacturing method

SB Forging

LB Wrought

Always Wrought

Made from pipe

Always Forged

MSS SP 43

SB SW reducer is always conc.

If ecc. is required then swage is used

Always Wrought

Forging & Wrought

Full Coupling To connect SB straight

pipe

Half Coupling For branching

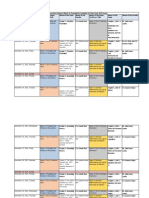

Page 2 of 8

2.8.3 Pipe weld

2.8.4 RF pipe weld

2.8.5 Letarol

2.8.6 O let fitting

Sockolet

Weldolet

Elbolet

Nippolet

Flangolet

Threadolet

Sweepolet

Latroolet

3 Flanges

3.1 on basis of type

SW

SO

WN

LJ(Lap Joint)

Blind

3.2 on basis of facing

FF

RF

RTJ

T & J (Tong & Groove)

MF ( Male & Female)

Forging & Wrought

MSS SP 97

ASME B 16.5 Up to 24

ASME B 16.47 Sr. A / Sr. B

26 ~ 48(only up to #3000 & weld neck

only)

Always Forged

Forged

ASME B 16.47 Sr. A Earlier name

MSS SP 44

ASME B 16.47 Sr. B - Earlier name API

605

Use

SW For low rating & SW

fittings are permitted

SO Low rating

WN High rating (#600 & above)

LJ Economical

Blind ----Use

FF Where bending property of material

is poor

Page 3 of 8

SW joints are not used in case of Cravec corrosion

For leak proof joint

- Flange should not fail in Bending

- Gasket should not fail in Compression

- Bolt should not fail in Tension

3.3 Gasket

Metallic ASME B 16.20

CAF Compressed asbestos fiber

Ex. Spiral wound, sheet metal, RTJ..

CNAF Compressed Non asbestos fiber

Non-metallic ASME B 16.21

Ex. CAF, CNAF, Graphite, PTFE

3.4 Bolt & Nut

Stud

ASME B 16.5

Machined

ASME B 18.2.1 & 18.2.2 gives manufacturing detail of bolt & nut

ASME B 16.5 gives length of bolt/stud , dia., no. of bolts/studs etc which is more important for piping engineer

3.5 Spectacle blind

or

Spacer & Blind

3.6 WN Flange with Jack screw (

4 & above)

4 Valves

4.1 Gate valve

Forged

Cast

Very large size

Symbolic Representation

ASME B 16.48

Made from plates

Forging

ASME B 16.34 design std.

API 598 / BS 6755 part.1 Testing std.

Forged API 602

Cast API 600

Very large size BSI 414

SB Forging

LB Casting

Page 4 of 8

4.2 Globe valve

Forged

Cast

4.3 Check valve

Lift type plug / ball

Swing type

Dual plate wafer / lug /

dual flange

4.4 Ball valve

4.4.1 On basis of bore

Full bore

Reduced bore

4.4.2 On basis of body

Single piece

Two piece

Three piece

4.4.3 Seating

Soft

Metal

4.4.4 Mounting of ball

Floating

Turnion mounting

Forged BS 5352

Cast BS 1873

Lift type BS 5352

Swing type BS 1868

Dual plate API 594

BS 5351

Lift type forging

Swing & Dual plate - casting

SB Forging

LB Casting

Page 5 of 8

4.5 Butterfly valve

Concentric

Eccentric double /

triple

Seating basis soft /

metal

Types of body end

wafer / lug / double

flanged

4.6 Plug valve

Lubricated

Non-lubricated

4.7 Needle valve

4.8 Foot valve

4.9 Diaphragm valve

Wire type pattern

Straight pattern

4.10 Piston valve

Flush button piston valve

Ram type piston valve

Glandless piston valve

(mainly used for steam

application)

4.11 Bellow seal valve

Gate

Globe

Concentric APS 609 cat. A

Eccentric APS 609 cat. B

Always Casting

APS 599

Cast & Forged

BS 1873

BS 5156

SB Forging

LB Casting

Always Casting

Always Casting

Flush button piston valve &

Ram type piston valve

Casting & Fabricated

Glandless piston valve

SB Forging

LB Casting

SB Forging

LB Casting

Are used for very precise control

Page 6 of 8

Ball ( only few vendors)

4.12 Y type glob valve

5. Special parts

5.1 Strainer

Y type

T type

Basket

Conical

Plate

Y type

SB Forging

LB Casting

Used to remove foreign particle from

fluid

T type Wrought fitting

Basket Plate fabricated

Conical sheet fabricated

Plate sheet fabricated

5.2 Stem trap (condensate

removal)

Thermodynamic

Thermostatic

Inverted bucket

Ball float

Thermodynamic, Thermostatic, Inverted

bucket intermediate removal of

condensation

Thermodynamic Forging

Thermostatic Forging

Inverted bucket Casting

Ball float Casting

Ball float continuous removal of

condensation

Thermodynamic for piping loops

Thermostatic for precise control over

temp. Ex. Steam tracing

5.3 Flame arrestor

End of line

In of line

Detonation

5.4 Below

Inverted bucket & Ball float for heavy

condensate load

To protect the system from fire hazard

EN 12874

EJMA

Always Casting

Hydraulically formed

To take care of expansion & axial

Page 7 of 8

Single

Double

Universal

Universal tied

Hinged below

Gimble

Pressure balance

5.5 Sight glass

Flip

Flat

5.6 Hoses

Metallic

Rubber

5.7 Couplings

Flanged

Threaded

Quick coupling (Chicago

coupling)

Quick release

Cam locked

5.8 Rupture disk

Tension type

Reverse type

Flat type (nonmetallic)

5.9 Spray nozzle

Jet

Certain

Spray solid / hollow

deflection & lateral deflection

SB Forging

LB Casting

Hydraulically formed

To see process

Metallic for tank settlement or

loading / unloading

Rubber for utilities

Used along with utility hoses

Always Forging

ASME Sec.VIII

Sheet

Always Forging

To protect vessel & piping system from

over pressure or vacuum

For scrubbing, fire hazard, deuperheater

or inline mixing of aditives

Page 8 of 8

spiral

5.10 Sample cooler

5.11 Spray shower & eye

washer

Fabricated

Fabricated

To cool the sample

Emergency water requirement for

cleaning the body & eyes

You might also like

- General Piping and ValvesDocument184 pagesGeneral Piping and ValvesChiheb KaanicheNo ratings yet

- Flange FacingDocument6 pagesFlange FacingDurjoy ChakrabortyNo ratings yet

- API 600 Trim Number Chart API ValveDocument2 pagesAPI 600 Trim Number Chart API ValveCésar Oswaldo Aguilera OjedaNo ratings yet

- Standards in The Valve IndustryDocument2 pagesStandards in The Valve IndustryessnelsonNo ratings yet

- ASTM Grades in PipingDocument1 pageASTM Grades in PipingRajkumar ANo ratings yet

- Oil & Gas Piping Fundamentals Knowledge PlatformDocument153 pagesOil & Gas Piping Fundamentals Knowledge PlatformKalaiYarasanNo ratings yet

- Piping Specification SheetDocument63 pagesPiping Specification SheetNilesh Gohel100% (1)

- Piping Commodities: 1 PipeDocument4 pagesPiping Commodities: 1 PipeDhakshina KNo ratings yet

- ValveDocument9 pagesValveAdhie_ginthinkNo ratings yet

- PIPING PROCEDURESDocument9 pagesPIPING PROCEDURESippon_osotoNo ratings yet

- Piping 5.0 - Introduction to Piping EngineeringDocument32 pagesPiping 5.0 - Introduction to Piping EngineeringSteve WanNo ratings yet

- Hydrostatic Testing GuideDocument10 pagesHydrostatic Testing Guidepraveentien100% (1)

- Piping Group Time Charge Codes: Piping Sub-Group Operation Number & Name ( ) 250 251 252 253 PEL PME PDG PMCDocument39 pagesPiping Group Time Charge Codes: Piping Sub-Group Operation Number & Name ( ) 250 251 252 253 PEL PME PDG PMCTheVirus PapaNo ratings yet

- Piping Components GuideDocument110 pagesPiping Components Guidearianaseri100% (3)

- Piping SpecificationDocument3 pagesPiping SpecificationArun KumarNo ratings yet

- 07 ValvesDocument33 pages07 Valvesshiva_ssk17No ratings yet

- Pipe FittingsDocument40 pagesPipe FittingsLucky Jaswal100% (1)

- Butt Weld Stainless Steel FittingsDocument16 pagesButt Weld Stainless Steel Fittingsbayu susiloNo ratings yet

- Design & Construction of Piping SysDocument114 pagesDesign & Construction of Piping SysPedro Luis Choque MamaniNo ratings yet

- Approved List of Manufacturers: Line Pipes (Carbon/Alloy Steel)Document4 pagesApproved List of Manufacturers: Line Pipes (Carbon/Alloy Steel)Sourav Kumar GuptaNo ratings yet

- Material Selection and SpecificationDocument50 pagesMaterial Selection and SpecificationbashirNo ratings yet

- Piping ComponentDocument19 pagesPiping Componentreach_arindomNo ratings yet

- Piping Components Classification GuideDocument45 pagesPiping Components Classification Guideindika sunarkoNo ratings yet

- VMS PaliDocument61 pagesVMS Palichintan100% (2)

- Overview of Piping System Design for Process PlantsDocument110 pagesOverview of Piping System Design for Process PlantsEse Ichekor100% (4)

- SA-106 GR.BDocument2 pagesSA-106 GR.BTree TaweeNo ratings yet

- JIS Standard ValveDocument8 pagesJIS Standard ValveJong JavaNo ratings yet

- Barred TeesDocument1 pageBarred TeesAdvisNo ratings yet

- Valve MaterialTypeEquivalent PDFDocument3 pagesValve MaterialTypeEquivalent PDFInaamNo ratings yet

- Critical Line ListDocument20 pagesCritical Line ListCristhian Solano Bazalar100% (1)

- Spec Grade Number Symbol Number Symbol Asme (Astm) KS JISDocument50 pagesSpec Grade Number Symbol Number Symbol Asme (Astm) KS JISVinay TrivediNo ratings yet

- ANSI FlangeDocument10 pagesANSI FlangemechftpNo ratings yet

- Piping Design Reference InfoDocument254 pagesPiping Design Reference InfoDr. M. Praveen Sandeep100% (1)

- Piping SpecificationsDocument67 pagesPiping SpecificationsVedran Kosanovic100% (3)

- 300# RF Piping Dimensions ChartDocument148 pages300# RF Piping Dimensions Chartrerezhassan100% (1)

- Koc Standard FOR Colour Coding of Pipes and Fittings For Material Identification Doc No: Koc-Mp-026Document14 pagesKoc Standard FOR Colour Coding of Pipes and Fittings For Material Identification Doc No: Koc-Mp-026Praveen BabuNo ratings yet

- Super Duplex Stainless SteelDocument3 pagesSuper Duplex Stainless SteelNisa_nisheNo ratings yet

- Pipes PoolsDocument3 pagesPipes PoolsjorgemachigueNo ratings yet

- Double Disc Gate Valve: Pressure Seal BonnetDocument12 pagesDouble Disc Gate Valve: Pressure Seal BonnetMuhammadImaduddienSalamNo ratings yet

- Annexure To SOW 10 Standard Specification For Steam TracingDocument9 pagesAnnexure To SOW 10 Standard Specification For Steam TracingASHISH GORDENo ratings yet

- Piping Line List: Ventech Engineers, Inc. Pasadena, Texas, P.O.Box 4261Document3 pagesPiping Line List: Ventech Engineers, Inc. Pasadena, Texas, P.O.Box 4261samer8saifNo ratings yet

- Dim of Pipes Flanges and FittingsDocument10 pagesDim of Pipes Flanges and FittingsGeorge Manuel100% (1)

- Fittings TrainingDocument61 pagesFittings TrainingsbmmlaNo ratings yet

- Bolt DesignDocument1 pageBolt Designbala_ccc3353No ratings yet

- API602 Forged Steel Gate & Globe ValvesDocument4 pagesAPI602 Forged Steel Gate & Globe ValvesThomasFrenchNo ratings yet

- BS4504 16 DimensionsDocument2 pagesBS4504 16 DimensionsalfonscarlNo ratings yet

- Plant Piping Pressure Testing: (Exam For Inspectors Performing Test PKG & Sis Sheet Calculation Reviews)Document3 pagesPlant Piping Pressure Testing: (Exam For Inspectors Performing Test PKG & Sis Sheet Calculation Reviews)aslam.ambNo ratings yet

- Piping Codes and Standards - The Piping Engineering BlogDocument5 pagesPiping Codes and Standards - The Piping Engineering BlogSalman KhanNo ratings yet

- Duplex Material PDFDocument4 pagesDuplex Material PDFmengelito almonteNo ratings yet

- Mechanical BookDocument221 pagesMechanical BookPwan Khurana100% (1)

- Astm Nos For PipingDocument6 pagesAstm Nos For PipingJessica HerringNo ratings yet

- Documents Plc150Document7 pagesDocuments Plc150Anonymous cuOIjrLINo ratings yet

- 7a. Steel Pipeline FittingDocument37 pages7a. Steel Pipeline Fittingamaliabdulkader100% (1)

- Class 61502 Carbon Steel Piping Design LimitsDocument10 pagesClass 61502 Carbon Steel Piping Design LimitsbalajivangaruNo ratings yet

- process piping drafting_4장Document24 pagesprocess piping drafting_4장Ho KimNo ratings yet

- FlangesDocument5 pagesFlangesIhsan AhmedNo ratings yet

- Pipe Material and Welding Procedure SpecificationDocument39 pagesPipe Material and Welding Procedure Specificationmanojballa100% (1)

- Bellow Seal Valves: AN ISO 9001:2000 COMPANYDocument20 pagesBellow Seal Valves: AN ISO 9001:2000 COMPANYDeepak HishikarNo ratings yet

- MGH PTF CatalogDocument16 pagesMGH PTF CatalogWawanW36No ratings yet

- Tamil ebook by TAMIL NESAN from tamilebooks.netDocument284 pagesTamil ebook by TAMIL NESAN from tamilebooks.netKamalakannan AyyaduraiNo ratings yet

- Vessels Layout ConceptsDocument38 pagesVessels Layout ConceptsKamalakannan Ayyadurai100% (3)

- AWM Atkins 2017 FinalDocument4 pagesAWM Atkins 2017 FinalKamalakannan AyyaduraiNo ratings yet

- Kamalakannan Resume (01!08!2018)Document5 pagesKamalakannan Resume (01!08!2018)Kamalakannan AyyaduraiNo ratings yet

- 1922 Ve12 List of Supports R ADocument6 pages1922 Ve12 List of Supports R AKamalakannan AyyaduraiNo ratings yet

- GGJDocument5 pagesGGJKamalakannan AyyaduraiNo ratings yet

- Kamalakannan A Cover LetterDocument1 pageKamalakannan A Cover LetterKamalakannan AyyaduraiNo ratings yet

- Indman ApplicationDocument2 pagesIndman ApplicationFarzanaShaikNo ratings yet

- Piping Design Professional: Kamalakannan ADocument4 pagesPiping Design Professional: Kamalakannan AKamalakannan AyyaduraiNo ratings yet

- Gad Extraction ProcedureDocument16 pagesGad Extraction ProcedureKamalakannan AyyaduraiNo ratings yet

- A Guide to Generating PDMS Electronic SpecificationsDocument26 pagesA Guide to Generating PDMS Electronic SpecificationsAou UgohNo ratings yet

- PDMSKJBJDocument3 pagesPDMSKJBJKamalakannan AyyaduraiNo ratings yet

- CommandsDocument9 pagesCommandsKamalakannan AyyaduraiNo ratings yet

- GGJDocument5 pagesGGJKamalakannan AyyaduraiNo ratings yet

- ReadmeDocument16 pagesReadmeKamalakannan AyyaduraiNo ratings yet

- EM L 004 Piping Layout-Rev1mnDocument185 pagesEM L 004 Piping Layout-Rev1mnKamalakannan Ayyadurai100% (1)

- Air CoolerDocument6 pagesAir CoolerKamalakannan AyyaduraiNo ratings yet

- Enf Year Wise DataDocument6 pagesEnf Year Wise DataKamalakannan AyyaduraiNo ratings yet

- Flare SystemDocument13 pagesFlare SystemKamalakannan AyyaduraiNo ratings yet

- InstallDocument1 pageInstallKamalakannan AyyaduraiNo ratings yet

- Air CoolerDocument6 pagesAir CoolerKamalakannan AyyaduraiNo ratings yet

- Full List of Rejected ProductsDocument24 pagesFull List of Rejected ProductsThe Indian ExpressNo ratings yet

- Linkedin Corp. Interview Call LetterDocument3 pagesLinkedin Corp. Interview Call LetterKamalakannan AyyaduraiNo ratings yet

- Flare SystemDocument13 pagesFlare SystemKamalakannan AyyaduraiNo ratings yet

- Kamalakannan - Offer LetterDocument2 pagesKamalakannan - Offer LetterKamalakannan AyyaduraiNo ratings yet

- Kamalakannan ResumeDocument4 pagesKamalakannan ResumeKamalakannan AyyaduraiNo ratings yet

- Kamalakannan A Ver2Document4 pagesKamalakannan A Ver2Kamalakannan AyyaduraiNo ratings yet

- Kamalakannan ResumeDocument4 pagesKamalakannan ResumeKamalakannan AyyaduraiNo ratings yet

- Cytogenectics Reading ListDocument2 pagesCytogenectics Reading ListHassan GillNo ratings yet

- Polifur 1K Synthetic Top Coat MSDS Rev 2 ENDocument14 pagesPolifur 1K Synthetic Top Coat MSDS Rev 2 ENvictorzy06No ratings yet

- The Leaders of The NationDocument3 pagesThe Leaders of The NationMark Dave RodriguezNo ratings yet

- NCERT Solutions For Class 12 Flamingo English Lost SpringDocument20 pagesNCERT Solutions For Class 12 Flamingo English Lost SpringHarsh solutions100% (1)

- Chapter 1-The Indian Contract Act, 1872, Unit 1-Nature of ContractsDocument10 pagesChapter 1-The Indian Contract Act, 1872, Unit 1-Nature of ContractsALANKRIT TRIPATHINo ratings yet

- ClarifierDocument2 pagesClarifierchagar_harshNo ratings yet

- Telecomm SwitchingDocument49 pagesTelecomm SwitchingTalha KhalidNo ratings yet

- Camp ApplianceDocument1 pageCamp ApplianceflyzalNo ratings yet

- ICS Technical College Prospectus 2024 Edition 1Document36 pagesICS Technical College Prospectus 2024 Edition 1samuel287kalumeNo ratings yet

- Liquid Air Energy Storage Systems A - 2021 - Renewable and Sustainable EnergyDocument12 pagesLiquid Air Energy Storage Systems A - 2021 - Renewable and Sustainable EnergyJosePPMolinaNo ratings yet

- NotesTransl 108 (1985) Larsen, Who Is This GenerationDocument20 pagesNotesTransl 108 (1985) Larsen, Who Is This GenerationluzuNo ratings yet

- RCC Lintel and Slab PlanDocument3 pagesRCC Lintel and Slab PlanSaurabh Parmar 28No ratings yet

- IELTS Writing Task 2/ IELTS EssayDocument2 pagesIELTS Writing Task 2/ IELTS EssayOlya HerasiyNo ratings yet

- Macbeth Introduction0Document40 pagesMacbeth Introduction0MohammedelamineNo ratings yet

- Sankalp Sanjeevani NEET: PhysicsDocument11 pagesSankalp Sanjeevani NEET: PhysicsKey RavenNo ratings yet

- MechanismDocument17 pagesMechanismm_er100No ratings yet

- Year 2 - Push and Pull FPDDocument18 pagesYear 2 - Push and Pull FPDRebecca LNo ratings yet

- School readiness assessmentDocument10 pagesSchool readiness assessmentJave Gene De AquinoNo ratings yet

- Learn R For Applied StatisticsDocument457 pagesLearn R For Applied StatisticsyasortyNo ratings yet

- Cambridge IGCSE: 0450/11 Business StudiesDocument12 pagesCambridge IGCSE: 0450/11 Business StudiesGodfreyFrankMwakalingaNo ratings yet

- (Salim Ross) PUA 524 - Introduction To Law and The Legal System (Mid Term)Document4 pages(Salim Ross) PUA 524 - Introduction To Law and The Legal System (Mid Term)Salim RossNo ratings yet

- BH Tif03Document21 pagesBH Tif03Andres R. OlguinNo ratings yet

- Hci01 HumanComputerInteraction OverviewDocument140 pagesHci01 HumanComputerInteraction OverviewAlexSpiridonNo ratings yet

- 2000 T.R. Higgins Award Paper - A Practical Look at Frame Analysis, Stability and Leaning ColumnsDocument15 pages2000 T.R. Higgins Award Paper - A Practical Look at Frame Analysis, Stability and Leaning ColumnsSamuel PintoNo ratings yet

- IT Technician CVDocument3 pagesIT Technician CVRavi KumarNo ratings yet

- Lessons Learned - Risk Management Issues in Genetic Counseling (2007)Document151 pagesLessons Learned - Risk Management Issues in Genetic Counseling (2007)AditiNo ratings yet

- Master of Advanced Nursing Practice degreeDocument2 pagesMaster of Advanced Nursing Practice degreeAgusfian Trima PutraNo ratings yet

- NVH PDFDocument3 pagesNVH PDFSubhendu BarisalNo ratings yet

- Food 8 - Part 2Document7 pagesFood 8 - Part 2Mónica MaiaNo ratings yet

- On MCH and Maternal Health in BangladeshDocument46 pagesOn MCH and Maternal Health in BangladeshTanni ChowdhuryNo ratings yet