Professional Documents

Culture Documents

Bulk Receiving Procedures

Uploaded by

emongclooney11Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bulk Receiving Procedures

Uploaded by

emongclooney11Copyright:

Available Formats

4/23/2014

BULK LPG Receiving Procedures

South Luzon LPG-Industrial

LPG Trade/Technical Services Group

February 21, 2014

Presentation Outline:

I. Delivery Truck Components

II. LPG Storage Tanks

Schematic Diagram

III. Fittings, LPG Storage Tanks

Filler Valve

Float Gauge/Roto Gauge

Pressure Gauge

Pressure Relief Valve

Liquid Transfer Valve

Multi Valve

IV. LPG Receiving

Pre Discharging Activities

While Discharging Activities

Post Discharging Activities

4/23/2014

TYPICAL APPURTENANCES OF AN LPG TANK TRUCK

PRESSURE RELIEF VALVE

TEMPERATURE GAUGE

SLIP TUBE

PRESSURE GAUGE

FIRE

EXTINGUISHER

EMERGENCY

SHUT-OFF

LIQUEFIED PETROLEUM GAS

FLAMMABLE

NO SMOKING WITHIN 50 FT

888888

PUMP

LPG METER

DISCHARGE VALVE

HYDRAULIC

OPERATOR

(w/ emergency

shutoff lever)

LOADING LINE VALVE

VAPOR LINE VALVE

POWER

TAKE OFF

(PTO)

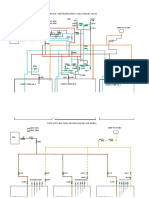

LPG Tank Truck to Receiving Tank Connection

MRV

LEVEL GAUGE

NOZZLE

FILLER

VALVE

PRESSURE RELIEF VALVE

VAPOR

RETURN

LINE

LPG PUMP

METER

EMERGENCY

SHUT-OFF

VALVE

SERVICE

VALVE

INTERNAL SAFETY

VALVE

TANK TRUCK

LIQUID LINE

RECEIVING LINE

VALVE

METER BY-PASS

VALVE

TANK AT CUSTOMER

DISCHARGE VALVE

4/23/2014

Float Gauge for LPG Bulk Storage Tank

LPG Liquid Truck Meter

4/23/2014

BULK RECEIVING PROCEDURES

PRE DISCHARGING ACTIVITIES

DELIVERY CREW parks the tank truck (T/T) at the designated

unloading area.

DELIVERY CREW ensures that the chock blocks are placed at

both side ends of the front wheel of the T/T.

Install grounding cable.

4/23/2014

DELIVERY CREW ensures that the FIRE EXTINGUISHER(FEX) is

properly positioned away from the T/T for accessibility (in case of

emergency).

DELIVERY CREW coordinates the delivery with the CUSTOMER or

authorized his representative.

Requests for certification from the Manager or his representative when

receiver is not in the list of authorized receiver.

CUSTOMER checks Delivery Note (DN)

from DELIVERY CREW and verifies the

following:

If the delivery address is correct.

If the identity of DELIVERY CREW

and T/T tally (with whats indicated

on the DN.

T/T dispatch time from Petron Bulk

Plant (for first delivery) or the time it

went out from previous customer

(for succeeding deliveries).

NOTE: CUSTOMER, from time to time, checks if the calibration certificate

of tank truck meter is updated (CC - 1 year validity only, renewed yearly

by T/T).

4/23/2014

CUSTOMER orients the DRIVER about the

emergency response plan (EXIT POINTS, FIRE

HYDRANTS, FIRE EXTINGUISHER, etc.) before

unloading the product

For some accounts, T/T to comply safety

checklist prior to unloading of product.

CUSTOMER checks VALVE BOX SEALS at:

1. Meter and valve compartment for the

first delivery point.

2. Liquid and vapor loading valves for the

succeeding delivery point if there is any.

NOTE: Seal number indicated in the

delivery document should tally with the

seal number installed in the T/T.

4/23/2014

TYPES OF SEALS

1. Tank truck meter

a. Meter head

b. Temperature

compensator

2. Tank truck

compartments

a. Meter box

b. Loading valve

box

CUSTOMER checks T/T METER SEALS.

1. Meter head

2. Temperature compensator box provided with epoxy

NOTE: Checks for any sign of tampering.

4/23/2014

CUSTOMER checks T/T METER SEALS.

1. Meter head (temperature compensator unit is already builtin for digital T/T meters)

NOTE: Checks for any sign of tampering.

METER

TEMPERATURE

COMPENSATOR

1. Applied with

epoxy on the two

bolts and nuts to

seal off the

compensator

4/23/2014

TANK TRUCK CALIBRATION

CERTIFICATE

1. Issued by ITDI

2. Valid for 1 year.

CUSTOMER takes OPENING READING of the RECEIVING TANKS one tank

at the time if possible (to be witnessed by the DELIVERY CREW). The

opening reading should be agreed by both parties

Opening: 15% = ______liters

Approximate conversion per 1%

1,000 gals = 37 liters

2,500 gals = 118 liters

5,000 gals = 188 liters

10,000gals = 487 liters

CUSTOMER writes down the reading in the DN (attested by the

DELIVERY CREW).

NOTE: READ FLOAT GAUGE CAREFULLY TO AVOID ERRONEOUS CALCULATIONS.

4/23/2014

CUSTOMER ensures that

the

RECEIVING TANK has enough

ullage

(empty

space)

to

accommodate

the

delivery.

NOTE: ALL LPG TANKS MUST BE FILLEDUP TO 85% MAXIMUM LEVEL ONLY.

CUSTOMER witnesses the OPENING READING of the T/T METER

TOTALIZER.

NOTE: The reading should tally to what is indicated in the DN

Opening : 12113241

DELIVERY CREW inserts DN in the T/T meter register.

10

4/23/2014

CUSTOMER (autogasul) closes the SERVICE VALVE of the RECEIVING

TANK to prevent withdrawal of the product while the RECEIVING is

on-going.

NOTE: THIS IS IMPORTANT IN RECONCILIATION OF FLOAT GAUGE READING VIS--VIS T/T

REGISTER.

DELIVERY CREW connects the HOSE to the DISCHARGE VALVE of the

TANK TRUCK.

WRONG

NOTE: HOSE SHOULD BE PROPERLY LAID DOWN WITHOUT KINKS OR

WARPS TO ALLOW NORMAL FLOW OF LPG.

11

4/23/2014

DELIVERY CREW connects the HOSE NOZZLE to the FILLER VALVE

of the RECEIVING TANK and opens the NOZZLE VALVE.

NOTE: CUSTOMER ENSURES THAT THE IN-HOUSE FIRE EXTINGUISHERS ARE ALSO

ACCESSIBLE DURING THE ENTIRE PROCESS.

DELIVERY CREW conducts leak testing on all HOSE CONNECTIONS from

the TANK TRUCK to the RECEIVING TANK using SOAP AND WATER

SOLUTION prior to UNLOADING.

WRONG

NOTE: DO NOT START UNLOADING THE PRODUCT IF THERE IS ANY PRESENCE OF

LEAK (LEAK CAN ALSO BE DETECTED BY ITS ODORANT CALLED ETHYL MERCAPTAN) .

12

4/23/2014

BULK UNLOADING CHECKLIST

Before unloading

1. Tank truck parked at designated area

2. Chock blocks installed at the front wheel

3. Fire extinguisher (20 lbs) positioned at a safe distance from the

truck

4. Grounding cable connected

5. Seals properly checked

6. Tank truck totalizer opening reading reflected on the Delivery

Note

7. Opening reading of the receiving tank reflected on the Delivery

Note

8. Meter hose connected at the receiving tank

9. Emergency shut off valve and meter discharge valve opened

10. All connections leak tested

11. Receiving tank and hose nozzle valve opened

CUSTOMER gives GO signal to the

driver to start product discharging

DELIVERY CREW opens

DISCHARGE VALVES AND

APPURTENANCES near the tank

truck meter.

DELIVERY DRIVER operates the

PUMP to start unloading of the

product

NOTE: IF LEAK IS DETECTED, STOP THE OPERATION IMMEDIATELY AND REPAIR

LEAK BEFORE CONTINUINING BACK TO UNLOADING. ALERT THE FIRE BRIGADE

TEAM IN CASE OF SEVERE LEAK.

13

4/23/2014

DURING DISCHARGING ACTIVITIES

DELIVERY DRIVER upon start of

the PUMP, stays at the pump.

DELIVERY HELPER stays at the

meter.

While unloading is on going,

the DELIVERY CREW monitors

the presence of leaks at the T/T

AREA and the product to be

discharged based on desired

percent level

CUSTOMER monitors the RECEIVING TANK FARM area.

14

4/23/2014

During unloading, CUSTOMER monitors the

PRESSURE and FLOAT GAUGES of the RECEIVING

TANK while the DELIVERY CREW monitors the

pressure gauge and METER performance.

CUSTOMER signals the DELIVERY CREW upon

reaching

the

85%

MAXIMUM

level.

DELIVERY CREW shuts-off the PUMP & closes the DISCHARGE VALVE.

DELIVERY CREW closes the NOZZLE VALVE. Removes the HOSE and

covers the FILLER VALVE. Returns the HOSE and FIRE EXTINGUISHER

BACK

to

the

TANK

TRUCK

compartment.

NOTE:

-ALL LPG TANKS MUST BE FILLED-UP TO 85% MAXIMUM LEVEL ONLY.

-RECEIVING TANK PRESSURE SHOULD NOT EXCEED 150 PSI.

POST DISCHARGING ACTIVITIES

CUSTOMER takes the CLOSING READING of the RECEIVING TANK

(witnessed by the DELIVERY CREW). Set the product to settle for

about 15 20 mins before reading. Logs the READING on the DN.

The tank closing reading should be agreed by both parties.

DELIVERY CREW prints-out the METER REGISTER and pulls-out the

DN (witnessed by the CUSTOMER). Logs the FINAL READING of the

TOTALIZER (witnessed also by the CUSTOMER).

CUSTOMER and DELIVERY CREW computes the quantity of product

received based on the FLOAT GAUGE READINGS and the

CALIBRATION TABLE (see SAMPLE).

15

4/23/2014

CUSTOMER and DELIVERY CREW compute for the TOTAL QUANTITY

DELIVERED:

1) TOTALIZER:

Check if quantity PRINTED with the TOTALIZERS NET READING

(Closing Opening Readings). Signs net volume figures

2) FLOAT GAUGE:

Check if the NET QUANTITY (Closing Opening Reading) matches the

T/T TOTALIZER PRINT OUT. Signs net volume figures.

Should there be an alteration in any figures, customer should put his

initials on the erasures and alterations.

NOTE: IMMEDIATELY REPORT DISCREPANY beyond + 2% to 5% to Gasul

Operations, Technical Services or Area Sales Executive FOR APPROPRIATE

ACTION.

SAMPLE DELIVERY NOTE (DN)

Meter reading

1. Closing totalizer reading

2. Opening tolalizer reading

3. Net volume

Tank reading based on float gauge

1. Closing reading : 85%

2. Opening reading : 61%

3. Net volume: 24% or 24% x 188

liters (5,000 gals tank)

4. Compares meter and tank volume

16

4/23/2014

SAMPLE COMPUTATIONS: 5,000 gals tank

METER TOTALIZER

READINGS

CLOSING READING:

7910394

OPENING READING: (LESS)

7901474

TOTAL DELIVERY:

8,920 ltrs

VARIANCE:

TANK READINGS

TANK 1

TANK 2

85 %

85 %

15,980

15,980

61 %

61 %

11,468

11,468

4,512

4,512

9,024 ltrs

+ 104 Ltrs or 1.16 %

(METER REGISTER PRINT-OUT SHOULD TALLY TO THE TOTAL

DELIVERY BASED ON THE TOTALIZER)

ACCOMPLISHED DELIVERY NOTE

TOTALIZER

METER READING

1. Opening

2. Closing

Meter reading

print out

RECEIVING TANK

READING

1. Opening

2. Closing

Receiver Name

Printed and

signed

Note: All alterations

should be properly signed

17

4/23/2014

OTHER SAMPLE of ACCOMPLISHED DN

BULK UNLOADING CHECKLIST

After unloading

1. Pump switched off

2. Emergency shut off valve and meter discharge valve closed

3. Receiving tank and hose nozzle valve closed

4. Hoses disconnected

5. Grounding cable disconnected

6. Tank truck totalizer closing reading reflected on the Delivery

Note

7. Closing reading of the receiving tank reflected on the Delivery

Note

8. Comments/feedbacks/suggestions solicited from the receiver

9. Fire extinguisher (20 lbs) returned to the truck

10. Chock blocks removed

18

4/23/2014

T/T UNLOADING CHECKLIST:

1. The checklist should

be accomplished by

the delivery crew.

2. The receiver will verify

if the checklist was

accomplished.

3. Both parties shall sign

the document.

CUSTOMER opens the SERVICE VALVE to resume

OPERATION.

DELIVERY CREW solicits FEEDBACK, SUGGESTIONS OR

COMPLAINTS from the CUSTOMER.

CUSTOMER prints NAME and SIGNS the DN to acknowledge

he received the product in good quality and right quantity.

Arrange for release of the TANK TRUCK.

19

4/23/2014

3. Driver replaces FEX to the truck and removes

chock blocks.

4. Arrange for the release the delivery truck.

20

4/23/2014

Thank You.

21

You might also like

- Tank Truck Receiving PetronDocument36 pagesTank Truck Receiving PetronJf LarongNo ratings yet

- Gas Cylinder RulesDocument24 pagesGas Cylinder RulesAnuj SinhaNo ratings yet

- 1.1.1 LPG 1.1.2viscosity 1.1.3 Vapor Pressure 1.1.4 Specific Gravity 1.1.5 Flame Temperature 1.1.6 Flash Point 1.1.7 Odorization of LPG 1.1.8 Colour 1.1.9 ToxicityDocument6 pages1.1.1 LPG 1.1.2viscosity 1.1.3 Vapor Pressure 1.1.4 Specific Gravity 1.1.5 Flame Temperature 1.1.6 Flash Point 1.1.7 Odorization of LPG 1.1.8 Colour 1.1.9 ToxicityzeyadNo ratings yet

- The Red Book MY3Document47 pagesThe Red Book MY3Syed Arsalan AfsarNo ratings yet

- LPG Training BrochureDocument32 pagesLPG Training BrochureZoli BorbelyNo ratings yet

- LPG Tank Commissioning Training NotesDocument32 pagesLPG Tank Commissioning Training NotesKajubi Edris100% (1)

- Pec Table 9 Chapter 9Document46 pagesPec Table 9 Chapter 9Lester MuscaNo ratings yet

- LPG SpecificationDocument4 pagesLPG SpecificationAdeniyi Alese50% (2)

- Gas Networks - Technical OverviewDocument93 pagesGas Networks - Technical OverviewLamHotNo ratings yet

- LPG Safety Orientation 2015Document32 pagesLPG Safety Orientation 2015Mha RizNo ratings yet

- Gas Appliances Manufacturing Unit Rs. 13.72 Million Jun 2015Document23 pagesGas Appliances Manufacturing Unit Rs. 13.72 Million Jun 2015Rohs VantageNo ratings yet

- Difference Between Pressure Vessel and ColumnDocument1 pageDifference Between Pressure Vessel and ColumnDarshit GolwalaNo ratings yet

- Project Work Estimation: Mumbai Office: C-62/204, Sector-9, Shantinagar, Miraroad (East), Thane-401107, Maharashtra, IndiaDocument6 pagesProject Work Estimation: Mumbai Office: C-62/204, Sector-9, Shantinagar, Miraroad (East), Thane-401107, Maharashtra, IndiaAmul AmnajeNo ratings yet

- LPG Technical Cod enDocument83 pagesLPG Technical Cod enZecheru100% (1)

- Bulk Handle LPG SafelyDocument85 pagesBulk Handle LPG SafelyCHANDU100% (1)

- LPG Induction Course NewDocument28 pagesLPG Induction Course NewMha RizNo ratings yet

- LPG Cylinder Filling CenterDocument7 pagesLPG Cylinder Filling CenterDayo Idowu100% (1)

- L P G Part 1-Safety-LPG Short Course-5-05-Rev1Document18 pagesL P G Part 1-Safety-LPG Short Course-5-05-Rev1liveconnectionz282No ratings yet

- Design of LNG Plant Facilities.: N.Bandyopadhyay - Consulting EngineerDocument6 pagesDesign of LNG Plant Facilities.: N.Bandyopadhyay - Consulting EngineerHoàng KakaNo ratings yet

- LPG QuestionnaireDocument6 pagesLPG QuestionnaireSushama SinghNo ratings yet

- Decommissioning 12710Document14 pagesDecommissioning 12710xjaf01No ratings yet

- OGRA LPG Rules 2001Document17 pagesOGRA LPG Rules 2001محمد نعمان بٹNo ratings yet

- Lpgbottlingplant 12494506726011 Phpapp03Document15 pagesLpgbottlingplant 12494506726011 Phpapp03mdashrafalamNo ratings yet

- Minimum Maximum LPG Energy Content (Btu/f)Document5 pagesMinimum Maximum LPG Energy Content (Btu/f)Mirza Aatir SalmanNo ratings yet

- OLPG S1-01 - OESA LPG Depots and Filling PlantsDocument38 pagesOLPG S1-01 - OESA LPG Depots and Filling PlantsGogne Rodolph100% (1)

- Cargo Piping SystemDocument4 pagesCargo Piping Systemdinar rosandy100% (1)

- Characteristics of LPGasDocument8 pagesCharacteristics of LPGasAnkita KulshreshthaNo ratings yet

- LPG T4S-Original Reg-15.02.2019Document179 pagesLPG T4S-Original Reg-15.02.2019Abdul Kareem0% (1)

- LPG RulesDocument12 pagesLPG RulesAhmed KhanNo ratings yet

- L-545 Servicemans ManualDocument56 pagesL-545 Servicemans ManualingenerproNo ratings yet

- Check List For LPG/LNG LicenseDocument8 pagesCheck List For LPG/LNG LicenseChachi TerijanNo ratings yet

- Procedure For Transfer of Bunkers To Vessel - ISO 13739Document50 pagesProcedure For Transfer of Bunkers To Vessel - ISO 13739asep supriyadi100% (1)

- LPGStatutory RequirementsDocument4 pagesLPGStatutory RequirementsalwacsNo ratings yet

- Loadtec Brochure 6-16Document17 pagesLoadtec Brochure 6-16Phattapoom Roopngam100% (1)

- Gas Installation PDFDocument31 pagesGas Installation PDFNelson VargasNo ratings yet

- Piping Diagram DrawingDocument40 pagesPiping Diagram DrawingFrengky Edward Pakpahan100% (1)

- Nitrogen Handling PurgingDocument9 pagesNitrogen Handling PurgingJeet Singh100% (1)

- Gas-Freeing Purging Process EquipmentDocument2 pagesGas-Freeing Purging Process Equipmentrenjithv_4100% (1)

- Crude Oil WashingDocument2 pagesCrude Oil WashingMin Soe100% (1)

- Cloud and Pour PointDocument2 pagesCloud and Pour PointJennifer Galloway0% (2)

- Guide To New Autogas Markets 2021Document60 pagesGuide To New Autogas Markets 2021BET AMBROSENo ratings yet

- CV Parul WordDocument5 pagesCV Parul Wordkkrish_nits867182No ratings yet

- Power Point Chapter7.16 (Incinerator)Document13 pagesPower Point Chapter7.16 (Incinerator)Toma AdrianaNo ratings yet

- Petroleum Storage Tank FireDocument5 pagesPetroleum Storage Tank FireSadish Nair100% (1)

- LPG InspcDocument2 pagesLPG InspcMaha JanNo ratings yet

- Guidelines For VOC Management Plan - Final - 2010Document31 pagesGuidelines For VOC Management Plan - Final - 2010Cari RiveraNo ratings yet

- LPG Properties Bharat PetroleumDocument19 pagesLPG Properties Bharat PetroleumSharon LambertNo ratings yet

- Bulk LPG TT - Safety in Design & OperationDocument35 pagesBulk LPG TT - Safety in Design & OperationNilambar Bariha100% (1)

- LPG - Calculation Guide: Liquid PhaseDocument1 pageLPG - Calculation Guide: Liquid PhaseChhom100% (1)

- LPG Marketing and Distribution Business Rs. 48.52 Million Dec-2020Document21 pagesLPG Marketing and Distribution Business Rs. 48.52 Million Dec-2020Ayan NoorNo ratings yet

- Specification For Auto LPG Dispensing StationDocument5 pagesSpecification For Auto LPG Dispensing StationShyBokxNo ratings yet

- SOP-017-Testing of Specific Gravity of CondensateDocument9 pagesSOP-017-Testing of Specific Gravity of CondensateAmnaKamranNo ratings yet

- Recommended International Code of Practice For The Storage and Transport of Edible Fats and Oils in BulkDocument12 pagesRecommended International Code of Practice For The Storage and Transport of Edible Fats and Oils in BulkMohamad YusofNo ratings yet

- Check List 84 - BALLASTING, DeballastingDocument1 pageCheck List 84 - BALLASTING, Deballastingprakash7kNo ratings yet

- Fuel Piping Leak Test ReportDocument1 pageFuel Piping Leak Test ReportRoshan ShanmughanNo ratings yet

- LPG Refilling PlantDocument13 pagesLPG Refilling PlantASKOKONo ratings yet

- 4.6 - LP - Gas - Meter - Calibration - TestingDocument5 pages4.6 - LP - Gas - Meter - Calibration - Testingابوالحروف العربي ابوالحروفNo ratings yet

- Ship/Shore Safety Check List: Company Forms and Check ListsDocument3 pagesShip/Shore Safety Check List: Company Forms and Check ListsopytnymoryakNo ratings yet

- Discharging Operations 3Document14 pagesDischarging Operations 3Subir BairagiNo ratings yet

- Bobtail Eqp CETP B3 CursoDocument16 pagesBobtail Eqp CETP B3 CursoAntonio ArveloNo ratings yet

- Electronic Expansion ValveDocument5 pagesElectronic Expansion Valveemongclooney11No ratings yet

- Comparison Between Direct On Line, Star DeltaDocument6 pagesComparison Between Direct On Line, Star DeltaReza Kandhy WindakaNo ratings yet

- Unit 33Document13 pagesUnit 33rajpre1213No ratings yet

- Eco V (HRV)Document8 pagesEco V (HRV)Jake ClooneyNo ratings yet

- 6-SEW CoolingTowers WEBDocument10 pages6-SEW CoolingTowers WEBvagemNo ratings yet

- 3 Wire Motor Start StopDocument5 pages3 Wire Motor Start StopAndy DukesNo ratings yet

- Gas MetersDocument5 pagesGas Metersemongclooney11No ratings yet

- Bladder Type Expansion Tank Sizing & Operating Instructions: WPA and WFA SeriesDocument2 pagesBladder Type Expansion Tank Sizing & Operating Instructions: WPA and WFA Seriesemongclooney11No ratings yet

- Bermad IrrigationDocument48 pagesBermad Irrigationemongclooney11No ratings yet

- Pressure VesselDocument2 pagesPressure VesselSheikh Faiz RockerNo ratings yet

- Taco Air SeparatorDocument12 pagesTaco Air Separatoremongclooney11No ratings yet

- Engineering Design Guideline Pump Rev3Document14 pagesEngineering Design Guideline Pump Rev3hclsvw67% (3)

- Standards Publication: (Special Applications - Non-Sour Service)Document30 pagesStandards Publication: (Special Applications - Non-Sour Service)p.abdulameen1234No ratings yet

- FMRC 1612 Polyvinyl Chloride (PVC) Pipe and Fittings For Underground Fire Protection Service PDFDocument30 pagesFMRC 1612 Polyvinyl Chloride (PVC) Pipe and Fittings For Underground Fire Protection Service PDFdyıldırım_4No ratings yet

- The Sugars of Honey-A ReviewDocument14 pagesThe Sugars of Honey-A ReviewsedianpoNo ratings yet

- Giới Thiệu Tế Bào HọcDocument6 pagesGiới Thiệu Tế Bào HọcNguyễn Phúc DuyNo ratings yet

- PolymersDocument9 pagesPolymersChhavi SharmaNo ratings yet

- Item BarangDocument5 pagesItem BarangRinaldhi JimmyNo ratings yet

- Applicant Profile: A. Position For Which You Are ApplyingDocument3 pagesApplicant Profile: A. Position For Which You Are ApplyingViệt Đặng XuânNo ratings yet

- Effect of Varying Mixing & Compaction Temperature On Marshall Properties of Bituminous Concrete MixDocument44 pagesEffect of Varying Mixing & Compaction Temperature On Marshall Properties of Bituminous Concrete Mixshiva5059100% (1)

- Phase Diagram 2Document6 pagesPhase Diagram 2Mohd AzhamNo ratings yet

- 12 Mathematics Linear Programming Test 02Document3 pages12 Mathematics Linear Programming Test 02abiNo ratings yet

- Acrylic Sheet Fabrication GuideDocument44 pagesAcrylic Sheet Fabrication GuideBa BagymkyzyNo ratings yet

- How To Revive Cultures - Atcc GuideDocument3 pagesHow To Revive Cultures - Atcc GuidesyriusNo ratings yet

- MSS - Manual Bernoulli FilterDocument3 pagesMSS - Manual Bernoulli FilterFLTR PURPLE E.No ratings yet

- Graphite Powder 500GDocument7 pagesGraphite Powder 500Gakbar macheteNo ratings yet

- Fittings DK LOK Pipe Fitting BrochureDocument11 pagesFittings DK LOK Pipe Fitting BrochureHafiz KamalNo ratings yet

- 1.1 Introduction To Physical Chemistry QuestionsDocument2 pages1.1 Introduction To Physical Chemistry QuestionsWrl RossNo ratings yet

- DLL Week 1 G 9 Science 22-23 Q2Document25 pagesDLL Week 1 G 9 Science 22-23 Q2Lady MayugaNo ratings yet

- Safety Data Sheet: 1. IdentificationDocument10 pagesSafety Data Sheet: 1. Identificationkrishnadas kotaNo ratings yet

- Biofertilizer Technology ManualDocument39 pagesBiofertilizer Technology ManualneharockNo ratings yet

- Adhemax Neutralizer CR Ds v3Document8 pagesAdhemax Neutralizer CR Ds v3José Emilio Román de AndaNo ratings yet

- Column Chromatography in Chemistry Is A Method Used To Purify Individual Chemical Compounds From Mixtures of CompoundsDocument12 pagesColumn Chromatography in Chemistry Is A Method Used To Purify Individual Chemical Compounds From Mixtures of CompoundsHuzaini IsmailNo ratings yet

- Bingo de Los Elementos Tabla Periodica PDFDocument18 pagesBingo de Los Elementos Tabla Periodica PDFAfi NarvaezNo ratings yet

- SABUN Dan DETERGENDocument34 pagesSABUN Dan DETERGENIsna NurhidayatiNo ratings yet

- Chemical Industry Pakistan 2030 PDFDocument151 pagesChemical Industry Pakistan 2030 PDFhatim75% (8)

- Work Instruction: Liquid Limit DeterminationDocument4 pagesWork Instruction: Liquid Limit DeterminationCris LegaspiNo ratings yet

- Development of Stainless Steel Sheets For Cylinder Head GasketDocument7 pagesDevelopment of Stainless Steel Sheets For Cylinder Head Gasketstefan.vince536No ratings yet

- The Innate Immune ResponseDocument38 pagesThe Innate Immune ResponseJosue LopezNo ratings yet

- Predicting Reservoir System AAPG 1999Document156 pagesPredicting Reservoir System AAPG 1999anjumbukhari100% (1)

- Immunological Techniques IDocument28 pagesImmunological Techniques Imartinian_4everNo ratings yet

- Pxydiagram ThermoDocument23 pagesPxydiagram Thermoapi-285386989No ratings yet