Professional Documents

Culture Documents

Rohi Product Cataloge

Uploaded by

finojCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rohi Product Cataloge

Uploaded by

finojCopyright:

Available Formats

ROHI International

Complete Fastener Solutions

Dear Customer

We take the opportunity to introduce our self to your esteemed organization, as the leading

suppliers of the fasteners based in Eastern Province - Jubail, Saudi Arabia.

Our establishment is supported by major In-Kingdom Saudi Arab manufacturers and

International manufacturers. Our trained & qualified sales people can answer your question and

queries with proper know-how & details for the product.

We are registered and approved vendors in Saudi Arabian Oil Company (Saudi Aramco), Royal

Commission and many other prestigious organizations.

Our vendor numbers:

Saudi Aramco

10039524

Royal Commission

12908

Saudi Chevron Philips

120412

In addition to this, we are providing satisfactory services to all major contractors/

sub-contractors, steel builders, off-shore oil & mining industries, chemical & petrochemical

industries, refineries, automotive industries and private sectors.

We are producing various items including anchor bolts, U bolts, pipe support, pipe clamp,

gratings, fabrication works etc. as per clients drawing and specifications.

We are attaching herewith, a list of specifications for your reference. This list is not exclusive as

we have mentioned the fast moving standards only.

Kindly forward us your inquiries of fasteners in any standard according to your job requirements.

We sincerely hope that you may find this introduction very useful for all your future fasteners

requirements.

If you require any further information about our company and products, please feel free to

contact us. Hoping to receive your valuable enquiries and looking forward to serve you in near

future.

ROHI International

Complete Fastener Solutions

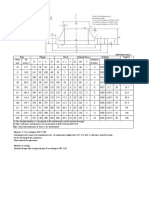

Heavy Hex Structural Bolts - ASTM A325M

Metric Series - Dimensions

Note:

1.

2.

3.

4.

5.

The Bolts will generally conform to ANSI B18.2.3.7M - Metric Heavy Hex Structural Bolts

Treads will conform to Class 6g of ANSI B1.13M

Material: High grade carbon/alloy steel

Heat Treatment: As per ASTM A325M and ASTM F568 Class 8.8

Thread Length LT:

LT1 for L 100

LT2 for L > 100

All dimensions are in millimeters

Nominal

Thread

Size

Pitch

M16

2.00

27.00

29.56

16.70

10.0

M20

2.50

34.00

37.29

20.84

M22

2.50

36.00

39.55

M24

3.00

41.00

M27

3.00

M30

3.50

Length of

Thread

LT1

LT2

Length

Range

L

0.6

31

38

50 - 200

12.5

0.8

36

43

50 - 200

22.84

14.0

0.8

38

45

70 - 200

45.20

24.84

15.0

1.0

41

48

70 - 200

46.00

50.85

27.84

17.0

1.2

44

51

80 - 200

50.00

55.37

30.84

18.7

1.2

49

56

100 - 200

W

Max.

C

Min.

B

Max.

H

Nom.

R

Min.

ROHI International

Complete Fastener Solutions

Heavy Hex Structural Bolts - ASTM A325M

Metric Series - Physical Properties, Tightening Torques

Physical Properties:

Physical Properties

Type 2

Nominal Thread Size

M16 to M36

Tensile Strength (min.)

2

(N/mm )

830

Proof Load Stress (min.)

2

(N/mm )

600

On GL = 2 Elongation % (min.)

12

Reduction of Area % (min.)

35

Hardness

C23 - C34

HR

Recommended Tightening Torques and Induced Loads:

Thread Size

&

Pitch

Stress Area

M16 - 2.00

157

233.0

72,800

M20 - 2.50

245

453.6

113,400

M22 - 2.50

303

616.0

140,000

M24 - 3.00

353

782.9

163,100

M27 - 3.00

459

1,145.3

212,100

M30 - 3.50

561

1,554.0

259,000

mm

Torque

Nm

Induced Load

N

Note:

The Tightening Torques are calculated to induce stress equal to approximately

70% of Yield Stress.

ROHI International

Complete Fastener Solutions

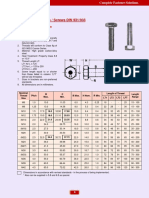

Hexagon Head Bolts / Screws DIN 931/933

Metric Series - Dimensions

Note:

1.

2.

3.

4.

5.

6.

7.

8.

The bolts and screws will generally

conform to ISO 4014, ISO 4017 and

DIN 931/933.

Threads will conform to Class 6g of

ISO 965/2 Coarse Series.

Material: High grade carbon/alloy

steel.

Heat Treatment: Property Class 8.8

or 10.9 *

Thread Length LT:

LT1 for L 125

LT2 for L > 125 to 200

LT3 for L > 200

Screw length equal to or shorter

than those listed in column LFT

will be fully threaded.

Sizes in brackets are non-preferred

standards.

All dimensions are in millimeters.

Nominal

Thread

Size

Pitch

M6

Length of Thread

W

Max.

C

Min.

B Max.

LT1

LT2

LT3

LFT

Length

Range

1.0

10.0

11.05

6.0

4.0

0.25

18

25

15 - 100

M8

1.25

13.0

14.38

8.0

5.3

0.4

22

28

30

15 - 100

M10

1.5

17.0

16.0

18.90

17.80

10.0

6.4

0.4

26

32

45

35

15 - 100

M12

1.75

19.0

18.0

21.10

20.03

12.0

7.5

0.6

30

36

49

40

20 - 150

(M14)

2.0

22.0

21.0

24.49

23.35

14.0

8.8

0.6

34

40

53

45

25 - 150

M16

2.0

24.0

26.75

16.0

10.0

0.6

38

44

57

50

25 - 200

(M18)

2.5

27.0

30.14

18.0

11.5

0.6

42

48

61

60

35 - 200

M20

2.5

30.0

33.53

20.0

12.5

0.8

46

52

65

60

35 - 200

(M22)

2.5

22.0

14.0

0.8

50

56

69

65

40 - 200

M24

3.0

36.0

39.98

24.0

15.0

0.8

54

60

73

75

40 - 200

(M27)

3.0

41.0

45.20

27.0

17.0

1.0

60

66

79

85

70 - 200

M30

3.5

46.0

50.85

30.0

18.7

1.0

66

72

85

85

75 - 300

(M33)

3.5

50.0

55.37

33.0

21.0

1.0

72

78

91

95

75 - 300

M36

4.0

55.0

60.79

36.0

22.5

1.0

78

84

97

100

80 - 300

M39

4.0

60.0

66.44

39.0

25.0

1.0

84

90

103

110

90 - 300

M42

4.5

65.0

72.02

42.0

26.0

1.2

90

96

109

120

90 - 300

32.0

34.0

35.72

37.72

H Nom.

R Min.

Dimensions in accordance with revised standards - in the process of being implemented.

* Also can be supplied in 5.8 and 6.8 as special.

ROHI International

Complete Fastener Solutions

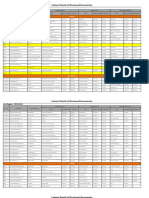

Hexagon Head Bolts / Screws DIN 931/933

Physical Properties:

PROPERTY CLASS

5.8

Diameter

6.8

All Diameters

Unit

N/mm

8.8

M16

All Diameters

N/mm

10.9

N/mm

>M16

N/mm

All Diameters

N/mm

Tensile Strength, (Min.)

520

600

800

830

1040

Yield Strength, 0.2% offset (Min.)

420

480

640

660

940

Proof Load Stress

380

440

580

600

830

Shear Strength, (Min.)

Hardness

Rockwell

300

360

480

498

624

B82 - B99.5

B89 - B99.5

C22 - C32

C23 - C34

C32 - C39

10

HR

Elongation % on GL= 5.65 A (Min)

A = Cross Sectional Area.

12

Recommended Tightening Torques and Induced Loads:

Nominal

Thread

Size

Stress

Area

5.8 *

6.8 *

8.8

10.9

Torque

Induced

Load

Torque

Induced

Load

Torque

Induced

Load

Torque

Induced

Load

Nm

Nm

Nm

Nm

M6

20.1

6.42

5,348

7.43

6,188

10.3

9,005

15.1

13,230

mm

M8

36.6

15.57

9,736

18.03

11,270

25.0

16,400

37.0

24,080

M10

58.0

30.85

15,428

35.70

17,850

50.0

26,360

74.0

38,700

M12

84.3

53.82

22,424

62.33

25,970

87.0

38,300

128.0

56,300

(M14)

115.0

85.65

30,590

99.18

35,420

139.0

52,300

205.0

76,800

M16

157.0

133.64

41,762

154.78

48,370

214.0

72,300

315.0

106,300

(M18)

192.0

183.86

51,072

212.94

59,150

304.0

91,200

435.0

129,900

M20

245.0

260.68

65,170

302.40

75,600

431.0

116,400

615.0

165,800

(M22)

303.0

354.63

80,598

409.64

93,100

586.0

144,000

835.0

205,100

M24

353.0

450.24

93,898

520.80

108,500

745.0

167,700

106.00

238,700

(M27)

459.0

657.72

122,094

763.56

141,400

109.00

218,100

155.00

310,400

M30

561.0

894.60

149,226

1037.40

172,900

148.00

266,600

210.50

379,400

(M33)

694.0

1219.68

184,604

1409.10

213,500

201.30

329,800

286.50

469,300

M36

817.0

1562.40

217,000

1809.36

251,300

258.60

388,200

368.00

552,500

(M39)

976.0

2025.66

259,700

2342.34

300,300

334.60

463,800

476.00

660,000

M42

1120.0

2502.53

297,920

2897.66

344,960

413.50

532,200

588.00

757,400

Note:

* Special

The Tightening Torques are calculated to induce approximate stresses as detailed below:

2

266 N/mm for Property Class 5.8

2

308 N/mm for Property Class 6.8

2

448 N/mm for Property Class 8.8, dia M16

2

462 N/mm for Property Class 8.8, dia M16

2

658 N/mm for Property Class 10.9

ROHI International

Complete Fastener Solutions

Hexagon Head Bolts / Screws - SAE J429

Inch Series, UNC/UNF - Dimensions

Note:

1.

2.

3.

4.

5.

6.

The bolts/screws will generally conform to SAE J429. (Bolts/Screws which will

also generally conform to American Standard ANSI B18.2.2.1)

Threads will conform to Class 2A of Unified threads(Coarse/Fine) of ANSI B1.1

Material: High grade carbon/alloy steel.

Heat Treatment: As per Grade 5 or 8 (Bolts/Screws made to Grades 5 and 8 as per SAE J429 will also

generally conform to requirements of BS 1768 Grade S and V respectively).

Thread Length LT:

LT1 for L 6

LT2 for L > 6

Screw Lengths equal to or shorter than those listed in column LFT will be fully threaded.

7. All dimensions are in inches.

T.P.I

Nominal

Thread

Size

UNC

1/4"

Length of Thread

UNF

W

Max.

C

Max.

B

Max.

H

Nom.

R

Min.

LT1

LT2

LFT

Length

Range

L

20

28

0.4375

0.505

0.2500

0.156

0.015

3/4

1/2 - 4

5/16"

18

24

0.5000

0.577

0.3125

0.203

0.015

7/8

1.1/8

1/2 - 4

3/8"

16

24

0.5625

0.650

0.3750

0.234

0.015

1.1/4

1/2 - 4

7/16"

14

20

0.6250

0.722

0.4375

0.281

0.015

1.1/8

1.3/8

3/4 - 4

1/2"

13

20

0.7500

0.866

0.500

0.313

0.015

1.1/4

1.1/2

1.1/2

3/4 - 8

5/8"

11

18

0.9375

1.083

0.6250

0.391

0.020

1.1/2

1.3/4

1.7/8

1-8

3/4"

10

16

1.1250

1.300

0.7500

0.469

0.020

1.3/4

2.1/8

1.1/2 - 8

7/8"

14

1.3125

1.515

0.8750

0.547

0.040

2.1/4

2.3/8

1.1/2 - 8

1"

12

1.5000

1.732

1.0000

0.609

0.060

2.1/4

2.1/2

2.5/8

1.1/2 - 8

ROHI International

Complete Fastener Solutions

Hexagon Head Bolts / Screws - SAE J429

Physical Properties:

Tensile Strength (Min.)

psi

N/mm

Proof Load Stress

psi

N/mm

Elongation % on GL=2" (Min.)

Rockwell Hardness HR

Reduction of Area % (Min.)

Grade 5

Grade 8

120000

150000

827

1034

85000

120000

586

827

14%

12%

C25 C34

C33 - C39

35%

35%

Recommended Tightening Torques and Induced Loads for UNC Threads:

Nominal

Thread

Size

UNC

Stress

Area

In

Grade 5

Grade 8

Torque

Induced Load

Torque

Induced Load

ft. lb

lbf

ft. lb

lbf

1/4"

0.0324

7.64

1930

11.06

2,794

5/16"

0.0532

15.68

3170

22.70

4,588

3/8"

0.0786

28.20

4750

40.83

6,875

7/16"

0.1078

45.13

6515

65.32

9,429

1/2"

0.1438

68.80

8691

99.58

12,578

5/8"

0.2290

135.23

14034

195.73

20,313

3/4"

0.3380

239.50

20715

316.67

29,982

7/8"

0.4670

386.08

28620

558.75

41,424

1"

0.6120

578.25

37507

836.92

51,287

Recommended Tightening Torques and Induced Loads for UNF Threads:

Nominal

Thread

Size

UNF

Stress

Area

In

Grade 5

Grade 8

Torque

Induced Load

Torque

Induced Load

ft. lb

lbf

ft. lb

lbf

1/4"

0.0368

8.68

2,192

12.57

3,174

5/16"

0.0587

17.31

3,498

25.05

5,062

3/8"

0.0886

31.79

5,354

46.01

7,749

7/16"

0.1196

50.15

7,240

72.58

10,478

1/2"

0.1612

77.13

9,742

113.19

14,298

5/8"

0.2580

152.36

15,812

220.50

22,884

3/4"

0.3750

265.75

22,982

384.58

33,262

7/8"

0.5130

424.08

31,440

613.83

45,503

1"

0.6670

630.17

40,878

912.08

59,163

Note: The Tightening Torques are calculated to induce stress equal to approximately 70% of

Yield Stress.

ROHI International

Complete Fastener Solutions

High Strength Friction Grip Bolts (10.9 Gr.)

Standard Specification

Material

Strength Grade

Threads

Surface Finish

: BS 4395 Part 2

Equivalent to DIN 6914, 6915

: Alloy Steel

: Class 10.9

: 6H of BS 3643 Part 1 & 2

: Black, Hot Dipped Galvanized

DIMENSIONS HSFG BOLT

Nominal

Size and

thread

diameter

Pitch of

thread

p

Diameter of

unthreaded

shank

d

Width across

flats

Width

across

corner

Diameter of

washer face

dt

Depth of

washer

face

c

Radius under

head

Transition

diameter

Thickness of

head

dn

(Coarse

Pitch

series)

Max.

Min.

Max.

Min.

Max

.

Min.

Max.

Min.

Max.

Max.

Min.

Min.

Max.

Min.

M 12

M 16

M 20

1.75

2.0

2.5

12.70

16.70

20.84

11.30

15.30

19.16

22

27

32

21.16

26.16

31.00

25.4

31.2

35.9

23.70

29.30

35.03

22

27

32

19.91

24.91

29.75

0.4

0.4

0.4

1.00

1.00

1.20

0.6

0.6

0.8

14.7

18.7

23.24

8.45

10.45

13.90

7.55

9.55

12.10

M 22

M 24

M 27

2.5

3.0

3.0

22.84

24.84

27.84

21.16

23.16

26.16

36

41

46

35.00

40.00

45.00

41.6

47.3

53.1

39.55

45.20

50.85

36

41

46

33.75

38.75

43.75

0.4

0.5

0.5

1.20

1.20

1.50

0.8

0.8

1.0

25.24

27.24

30.84

14.90

15.90

17.90

13.10

14.10

16.10

M 30

M 36

3.5

4.0

30.84

37.00

29.16

35.00

50

60

49.00

58.80

57.7

69.3

55.37

66.44

50

60

47.75

57.75

0.5

0.5

1.50

1.50

1.0

1.0

33.84

40.00

22.05

24.05

17.95

21.95

ROHI International

Complete Fastener Solutions

High Strength Friction Grip Bolts (10.9 Gr.)

Standard Specification

Material

Strength Grade

Threads

Surface Finish

: BS 4395 Part 2

Equivalent to DIN 6914, 6915

: Alloy Steel

: Class 10.9

: 6H of BS 3643 Part 1 & 2

: Black, Hot Dipped Galvanized

DIMENSIONS HSGG NUT

Nominal size

and thread

diameter

Pitch thread

Width across flats

Width across corner

(Coarse pitch

series)

Max.

Min.

Max.

Min.

Max.

Min.

Max.

Max.

Min.

M 12

M 16

M 20

1.75

2.0

2.5

22

27

32

21.6

26.16

31.00

25.40

31.20

35.90

23.70

29.30

35.03

22

27

32

19.91

24.91

29.75

0.4

0.4

0.4

11.55

15.55

18.55

10.45

14.45

17.45

M 22

M 24

M 27

2.5

3.0

3.0

36

41

46

35.00

40.00

45.00

41.60

47.30

53.10

39.55

45.20

50.85

36

41

46

33.75

38.75

43.75

0.4

0.5

0.5

19.65

22.65

24.65

18.35

21.35

23.35

M 30

M 36

3.5

4.0

50

60

49.00

58.80

57.70

69.30

55.37

66.44

50

60

47.75

57.75

0.5

0.5

26.65

31.80

25.35

30.20

Diameter of

washer face

dt

Depth of

washer face

e

Thickness of nut

m

ROHI International

Complete Fastener Solutions

ASTM A193 Stud / ASTM A194 Nut

Standard Specification

Material

Strength Grade

Surface Finish

: Stud - ASTM A193 Gr B7, B7M, B8, B8M

Nut - ASTM A194 Gr 2H, 2HM, 8, 8M

: Alloy Steel / Stainless Steel 304/316

: Above Class 8.8

: Electro Galvanized, Hot Dipped Galvanized

PTFE Coated / Natural

MATERIAL SPECIFICATION OF HIGH PRESSURE TEMPERATURE BOLTING

Grade

Material

Min Tempering

Temperature

F (C)

Tensile

strength

(Min.)

Yield

strength

(Min.)

Elongation

% (Min.)

Reduction

% (Min.)

Brinell

Hardness

Recommended

Bolting

Temperature

Range

Min. C

Max. C

-100

400

-100

400

520

ASTM A193 Gr. B7

ASTM 4140,

4142,4145

1,100 (593 C)

125,000 psi

105,000 psi

16

50

ASTM A193 Gr. B7M

ASTM 4140,

4142,4145

1,150 (620 C)

100,000 psi

80,000 psi

18

50

ASTM A193 Gr. B16

Cr-MoVanadium

1,200 (650 C)

125,000 psi

105,000 psi

18

50

ASTM A193 Gr. B8

AISI 304

Carbide Solution

Treated

75,000 psi

30,000 psi

30

50

223 Max.

-250

575

ASTM A193 Gr. B8M

AISI 316

Carbide Solution

Treated

75,000 psi

30,000 psi

30

50

223 Max.

-250

600

235 Max.

DIMENSION FOR HEAVY HEXAGON NUTS ASTM A194 Gr 2H, 2HM, 8, 8M

B

Nom. Size

d x n in.

Basic

Min.

Max.

Min.

1/2 x 13

22.22

21.59

25.65

24.61

5/8 x 11

26.98

26.19

31.16

29.84

3/4 x 10

31.75

30.78

36.65

35.10

7/8 x 9

36.51

35.41

42.16

Basic

Max.

Min.

12.3

12.8

11.78

15.47

16.02

14.91

18.65

19.25

18.03

40.36

21.82

22.47

21.16

1x8

41.27

40.0

47.65

45.62

25.00

25.70

24.28

1 1/8 x 8

46.03

44.60

53.16

50.85

28.17

28.93

27.41

1 1/4 x 8

50.8

49.22

58.65

56.11

30.95

31.77

30.15

1 1/2 x 8

59.4

58.70

67.90

67.40

37.00

37.50

36.50

10

ROHI International

Complete Fastener Solutions

Stud Bolts ASTM A193

Inch Series. UNC/UN - Dimensions

Note:

1.

2.

3.

4.

5.

The stud bolts will generally conform to ASTM A193 Gr. B7

Threads will conform to Class 2A of Unified Coarse threads as per ANSI B1.1

Material: Medium Carbon Chromium Molybdenum Steel, CR-Mo Alloy Steel (Cr-Mo).

Heat treatment: As per Grade B7.

All dimensions are in inches.

Nominal

Thread

Size D

TPI

Length Range

L

Nominal

Thread

Size D

UNC

UN

1/2"

13

5/8"

TPI

UNC

UN

up to 230"

2 3/8"

up to 50"

11

up to 230"

2 1/2"

up to 60"

3/4"

10

up to 230"

2 5/8"

up to 60"

7/8"

up to 230"

2 3/4"

up to 60"

1"

up to 120"

2 7/8"

up to 60"

1 1/8"

up to 120"

3"

up to 48" *

1 1/4"

up to 120"

3 1/8"

up to 48" *

1 3/8"

up to 120"

3 1/4"

up to 48" *

1 1/2"

up to 120"

3 3/8"

up to 48" *

1 5/8"

up to 120"

3 1/2"

up to 48" *

1 3/4"

up to 120"

3 5/8"

up to 48" *

1 7/8"

up to 120"

3 3/4"

up to 48" *

2"

up to 120"

3 7/8"

up to 48" *

2 1/8"

up to 60"

4"

up to 48" *

2 1/4"

up to 60"

* Longer length than specified could be supplied against special order.

11

Length Range

ROHI International

Complete Fastener Solutions

Stud Bolts ASTM A193

Inch Series. UNC/UN - Physical Properties, Tightening Torques

Physical Properties:

Physical Properties

Diameter Range

Grade B7

Tensile Strength (min.)

2

Psi (N/mm )

2 1/2" and under

125,000 (860)

over 2 1/2" to 4"

115,000 (795)

2 1/2" and under

105,000 (720)

over 2 1/2" to 4"

95,000 (655)

Yield Strength (min.)

2

Psi (N/ mm )

2 1/2" and under

Elongation % on GL = 4D (min.)

16%

over 2 1/2" to 4"

2 1/2" and under

Reduction of Area % (min.)

50%

over 2 1/2" to 4"

Tightening Torques:

Nominal

Thread Size

UNC

8 UN

Stress

Area

in

GRADE B7

Torque

Induced Load

ft - lb

lbf

Nominal

Thread Size

UNC

Stress

Area

8 UN

in

GRADE B7

Torque

Induced Load

ft - lb

lbf

1/2"

0.142

86.98

10,437

2 3/8"

3.987

11,599.70

293,045

5/8"

0.226

173.03

16,611

2 1/2"

4.440

13,597.50

326,340

3/4"

0.334

306.86

24,549

2 5/8"

4.921

14,317.06

327,247

7/8"

0.462

495.21

33,957

2 3/4"

5.430

16,550.19

361,095

1"

0.606

742.35

44,541

2 7/8"

5.953

18,969.00

395,875

1 1/8"

0.790

1,088.72

58,065

3"

6.510

21,645.75

432,915

1 1/4"

1.000

1,531.25

73,500

3 1/8"

7.084

24,535.73

471,086

1 3/8"

1.233

2,076.82

90,625

3 1/4"

7.690

27,700.02

511,385

1 1/2"

1.492

2,741.55

109,662

3 3/8"

8.312

31,092.08

552,748

1 5/8"

1.780

3,543.31

130,830

3 1/2"

8.960

34,757.33

595,840

1 3/4"

2.080

4,459.00

152,880

3 5/8"

9.639

38,726.72

640,994

1 7/8"

2.410

5,535.47

177,135

3 3/4"

10.340

42,975.63

687,610

2"

2.770

6,786.50

203,595

3 7/8"

11.064

47,517.58

735,756

2 1/8"

3.152

8,205.05

231,672

4"

11.810

52,357.67

785,365

2 1/4"

3.560

9,812.25

261,660

Note:

The Tightening Torques are calculated to induce stress equal to approximately 70% of Yield Stress.

12

ROHI International

Complete Fastener Solutions

Heavy Hexagon Nuts ASTM A563M

Metric Series - Dimensions, Physical Properties

Note:

1.

2.

3.

4.

5.

6.

7.

The nuts will generally conform to ANSI B18.2.4.6M - Metric

Heavy Hexagonal Nuts.

Threads will conform to Class 6H of ANSI B1.13M for Coarse

Series.

Material & Heat Treatment.

To achieve mechanical properties of Property Class 8S or 10S of

ASTM A563M.

Nuts of Property Class 8S are used with bolts of ASTM A325M

Type 1 and 2 (non-coated). Nuts of Property Class 10S are used

with bolts of ASTM A325M - Type 1 and 2 (Zinc-coated) (In

general, nuts of a higher property class can replace nuts of a

lower property class in a joint).

In Bolt/Nut assembly, tightening should be done by rotation of nut.

Sizes in brackets are non-preferred standards.

All dimensions are in millimeters.

Dimensions:

Thread Size

Pitch

W Max.

C Max.

H Nom.

M12

1.75

21.00

24.25

12.10

(M14)

2.00

24.00

27.71

13.95

M16

2.00

27.00

31.18

16.75

M20

2.50

34.00

39.26

20.05

(M22)

2.50

36.00

41.57

22.95

M24

3.00

41.00

47.34

23.55

(M27)

3.00

46.00

53.12

26.95

M30

3.50

50.00

57.74

29.90

Physical Properties:

Property

Class

For use with Bolts of

type and finish

8S

ASTM A325M

Type 1 and 2

(non-coated)

10S

ASTM A325M

Type 1 and 2

(zinc-coated)

Proof Load Stress

2

N/mm

Rockwell

Hardness

HR

1,075

B89 - C38

1,245

(Normal Tapping)

1,165

(Oversize Tapping)

13

C26 - C38

ROHI International

Complete Fastener Solutions

Heavy Hexagon Nuts ASTM A194

Note:

1.

2.

3.

4.

5.

The nuts will generally conform to ANSI/ASME B18.2.2

Heavy Hex Nuts.

Threads will conform to Class 2B of ANSI B1.1

Material and Heat Treatment:

To achieve mechanical properties of Grade 2H and

4 which conform the requirements of ASTM A194.

In Bolt/Nut assembly, tightening should be done by

rotation of nut. Torque values as recommended in

tables for bolts.

All dimensions are in inches.

Dimensions:

TPI

UNC / UN

Thread Size

1/2"

9/16"

5/8"

3/4"

7/8"

1"

1 1/8"

1 1/4"

1 3/8"

W Max.

C Max.

H Nom.

8

8

8

0.875"

0.938"

1.062"

1.250"

1.438"

1.625"

1.812"

2.000"

2.188"

1.010"

1.083"

1.227"

1.443"

1.660"

1.876"

2.093"

2.309"

2.526"

0.484"

0.547"

0.609"

0.734"

0.859"

0.984"

1.109"

1.219"

1.344"

8

8

8

8

8

8

8

8

8

8

8

2.375"

2.562"

2.750"

2.938"

3.125"

3.500"

3.875"

4.250"

4.625"

5.000"

5.375"

2.742"

2.959"

3.175"

3.392"

3.608"

4.041"

4.474"

4.907"

5.340"

5.774"

6.207"

1.469"

1.594"

1.719"

1.844"

1.969"

2.203"

2.453"

2.703"

2.953"

3.188"

3.438"

13

12

11

10

9

8

1 1/2"

1 5/8"

1 3/4"

1 7/8"

2"

2 1/4"

2 1/2"

2 3/4"

3"

3 1/4"

3 1/2"

Physical Properties:

Grade

For use with

Bolts/Stud Bolts

of Grade

Proof Load Stress

psi

175,000

over 1 1/2"

ASTM A325 T-1

ASTM A193 B7

ASTM A307 B

All Sizes

ASTM A320 L7

175,000

Size

up to 1 1/2" incl.

2H

14

Rockwell Hardness

HR

C24 - C38

B95 - C38

C24 - C38

ROHI International

Complete Fastener Solutions

Hexagon Nuts DIN 934

Metric Series - Dimensions, Physical Properties

Note:

1.

The nuts will generally conform to ISO 4032, DIN 934, also DIN 555.

2.

Threads will conform to Class 6H of ISO 965/2 for Coarse Series.

3.

Material & Heat Treatment:

To achieve mechanical properties of Property Class 8 or 10.

4.

Nuts of Property Class 8 are used with bolts of Property Class 8.8.

Nuts of Property Class 10 are used with bolts of Property Class 10.9.

(In general, nuts of a higher property class can replace nuts of a

lower property class in a joint).

5.

In Bolt/Nut assembly, tightening should be done by rotation of nut.

6.

Sizes in brackets are non-preferred standards.

7.

All dimensions are in millimeters.

Dimensions:

Nominal

Thread Size

Pitch

W Max.

C Min.

H Max.

M6

1.0

10.0

11.05

5.00

M8

1.25

M10

1.5

17.0

13.0

16.0

18.90

14.38

17.77

6.50

8.00

M12

1.75

19.0

18.0

21.10

20.03

10.00

(M14)

2.0

22.0

21.0

24.49

23.35

11.00

M16

2.0

24.0

26.75

13.00

(M18)

2.5

27.0

29.56

15.00

M20

2.5

30.0

32.95

16.00

(M22)

2.5

M24

3.0

36.0

39.55

19.00

(M27)

3.0

41.0

45.20

22.00

34.0

32.0

37.29

35.03

18.00

M30

3.5

46.0

50.85

24.00

(M33)

3.5

50.0

55.37

26.00

M36

4.0

55.0

60.79

29.00

(M39)

4.0

60.0

66.44

31.00

M42

4.5

65.0

71.30

34.00

Dimensions in accordance with revised standards in the process of being

implemented.

Physical Properties:

Property Class 5

Nut Size

Proof

Load

Stress

Over

To

N/mm2

M4

M7

580

M7

M10

590

M10

M16

610

M16

M42

630

For use with

Bolts of

Property Class

Property Class 6

Hardness HR

Proof

Load

Stress

Min.

N/mm2

Max.

Hardness HR

Min.

N/mm2

Max.

670

B71

C30

680

B79

C30

4.6, 5.6, 5.8

C30

720

870

Hardness HR

Hardness HR

Min.

N/mm2

Min.

Max.

C26

C36

Max.

1040

B92

C30

880

B85

C30

4.6, 5.6, 5.8, 6.8

15

920

Property Class 10

Proof

Load

Stress

855

700

B76

Property Class 8

Proof

Load

Stress

1040

1050

B97

C36

4.6, 5.6, 5.8, 6.8 and 8.8

1060

8.8 and 10.9

ROHI International

Complete Fastener Solutions

Hexagon Nuts SAE J995

Note:

1.

2.

3.

4.

The nuts will generally conform to ANSI/ASME B18.2.2.

Threads will conform to Class 2B of ANSI B1.1

Material & Heat Treatment:

To achieve mechanical properties of Grade 5 or 8 of SAE J995

which conform the requirements of ASTM A563 Grade B or D.

SAE J995 Gr. 2 also conform the requirements of ASTM A563

Grade A.

In Bolt/Nut assembly, tightening should be done by rotation of

nut. Torque values as recommended in tables for bolts.

All dimensions are in inches.

Dimensions:

TPI

Nominal

Thread Size

UNC

UNF

1/4"

20

5/16"

W Max.

C Max.

H Max.

28

0.4380

0.505

0.219

18

24

0.5000

0.577

0.266

3/8"

16

24

0.5620

0.650

0.328

7/16"

14

20

0.6880

0.794

0.375

1/2"

13

20

0.7500

0.866

0.4375

9/16"

12

18

0.8750

1.010

0.484

5/8"

11

18

0.9380

1.083

0.547

3/4"

10

16

1.1250

1.300

0.641

7/8"

14

1.3120

1.515

0.750

1"

12

1.5000

1.732

0.859

Physical Properties:

Grade

Size

For use with Bolts

of Grade

Proof Load Stress

psi

Rockwell Hardness

HR

1/4" - 1 1/2"

SAE Gr. 2

ASTM A307 A,C

90,000

C32 (max)

1/4" - 1

SAE Gr. 5

120,000

C32 (max)

SAE Gr. 8

150,000

1/4" - 5/8"

8

C24 - C32

3/4" - 1"

C26 - C34

16

ROHI International

Complete Fastener Solutions

Hardened Plain Washers

Standard Specification

Material

Type

Hardness

Surface Finish

:

:

:

:

:

ASTM F436

Medium Carbon Steel

Type 1

HRC 38 to 45

Black, Electro Galvanized,

Hot Dipped Galvanized

Unit : mm

Nom. Size

of Bolt

12

13

23

3.0

16

17

30

3.0

20

21

47

4.0

22

23

38

4.0

24

25

44

4.0

27

28

55

4.5

30

31

59

4.5

33

34

64

5.0

36

37

68

5.0

High Strength Plain Washers For Friction Grip Joints

Material

Strength Grade

:

:

:

:

Hardness

Surface Finish

Medium Carbon Steel

F35

HRC 38 to 45

Black, Electro Galvanized,

Hot Dipped Galvanized

Unit : mm

Nom

Size

of

Bolt

d*

D*

t*

C or R

Basic

Max.

Basic

Min.

Basic

Min.

Max.

12

13

13.27

24

23.48

3.3

2.7

16

17

17.27

30

29.48

4.3

3.7

20

21

21.33

37

36.38

4.3

3.7

22

23

23.33

39

38.38

4.3

3.7

24

25

25.33

44

43.38

4.3

3.7

27

28

28.52

50

49.00

5.6

4.4

30

31

31.62

56

54.80

5.6

4.4

36

37

37.62

66

64.80

6.6

5.4

* Values as per DIN 6916

17

Approx.

1.5

2.0

2.4

2.5

3.0

ROHI International

Complete Fastener Solutions

Direct Tension Indicators (DTIs)

Direct Tension Indicators (DTIs) are simple and extremely accurate devices for ensuring that

bolts have been installed above the specified minimum tension value. Used properly they

positively ensure the correct amount of clamping force. Readers who have installed highstrength bolts using torque/tension values will notice that this manual does not relate torque to

tension. Torque, or twisting force, is not a reliable measure of bolt tension. DTIs measure

tension regardless of applied torque.

A DTI is a hardened, washer-shaped device with protrusions, bumps: pressed out on one face,

manufactured according to the provisions of ASTM F959. The fact that it resembles a washer is

incidental. It is, in fact, a precision made mechanical load cell, a device for tensioning which is

covered by an ASTM Standard.

When a DTI is installed on a bolt with the bumps placed against the underside of the bolt head

there are noticeable gaps between the bumps. As the nut is turned and the bolt tensioned, the

bumps flatten. When the bumps are flattened so that the gaps have been reduced to the

required dimension, the bolt has been properly tensioned and required clamping force is

present. A DTI does not make it more difficult to tension a bolt, it merely shows that the bolt has

been properly tensioned.

Direct Tension Indicators are supplied either plain finish, that is without a coating,

mechanically galvanized to ASTM B695 Class 50, or produced from weathering steel for use

with Type 3 high-strength bolts. Other coatings may be available upon inquiry.

18

ROHI International

Complete Fastener Solutions

Hexagon Nuts SAE J995

PITCH

THICKNESS

COARSE

FINE

10

12

14

16

18

20

22

24

27

30

33

36

42

0.5

0.7

0.8

1.25

1.5

1.75

2.5

2.5

2.5

3.5

3.5

4.5

1

1.25

1.5

1.25

1.5

1.5

1.5

1.5

1.5

1.5

2

2.5

5

8

ANY OTHER SIZE CAN BE SUPPLIED

10

12

14

16

20

25

30

35

40

45

50

55

60

LENGTH

65

70

75

80

85

90

95

100

110

120

130

140

150

160

170

180

190

200

220

250

300

19

ROHI International

Complete Fastener Solutions

Inch Sizes

PITCH

THICKNESS

UNC

UNF

3/16

1/4

5/16

3/8

7/16

1/2

9/16

5/8

3/4

7/8

24

20

18

16

14

13

12

12

11

10

32

28

24

24

20

20

18

18

16

1 1/8

1 1/4

1 1/2

14

12

14

12

12

1/2

ANY OTHER SIZE CAN BE SUPPLIED

5/8

3/4

7/8

1

1 1/4

1 1/2

1 3/4

2

2 1/4

2 1/2

LENGTH

2 3/4

3

3 1/4

3 1/2

3 3/4

4

4 1/2

5

5 1/2

6

6 1/2

7

8

9

10

11

12

Inch Equivalents

INCH

METRIC

INCH

METRIC

INCH

METRIC

INCH

METRIC

1/32

0.7937

9/32

7.1437

17/32

13.4937

25/32

19.8437

1/16

1.5875

5/16

7.9375

9/16

14.2875

13/16

20.6375

3/32

2.3812

11/32

8.7312

19/32

15.0812

27/32

21.4312

1/8

3.1750

3/8

9.5250

5/8

15.8750

7/8

22.2250

5/32

3.9687

13/32

10.3187

21/32

16.0687

29/32

23.0187

3/16

4.7625

7/16

11.1125

11/16

17.4625

15/16

23.8125

7/32

5.5562

15/32

11.9062

23/32

18.2562

31/32

24.6062

1/4

6.3500

1/2

12.7000

3/4

19.0500

25.4000

20

ROHI International

Complete Fastener Solutions

DIN Standards

21

ROHI International

Complete Fastener Solutions

DIN Standards

22

ROHI International

Complete Fastener Solutions

All Kinds of Screws

Grade Markings

GR.2

GR.5

GR.8

4.6

8.8

10.9

INCH

METRIC

23

12.9

ROHI International

Complete Fastener Solutions

Technical Data

CONVERSION CHARTS:

Rockwell

C

Scale

Brinell

Hardness

Number

60

59

Approx Tensile

Strength

Rockwell

C Scale

MPa

KSI

654

634

2320

2260

336

328

34

33

58

57

615

595

2200

2140

319

310

56

55

577

560

2080

2010

54

53

543

524

52

51

Rockwell

B Scale

Brinell

Hardness

Number

Approx Tensile

Strength

MPa

KSI

318

309

1030

1010

150

147

32

31

301

294

980

960

142

139

301

292

30

29

285

279

940

910

136

132

1950

1890

283

274

28

27

272

265

890

870

129

126

512

500

1830

1770

265

257

26

25

259

253

850

830

123

120

50

49

488

476

1720

1660

249

241

24

23

247

241

810

790

118

115

48

47

464

453

1610

1550

233

225

22

21

100

99

235

230

770

760

112

110

46

45

442

430

1510

1460

219

212

20

(19)

98

225

220

740

720

107

104

44

43

419

408

1420

1380

206

200

(18)

(17)

97

215

210

710

700

103

102

42

41

398

387

1340

1300

194

188

(16)

(15)

96

206

201

690

680

100

99

40

39

377

367

1250

1210

181

176

(14)

(13)

95

94

197

193

670

660

97

96

38

37

357

347

1170

1140

170

165

(12)

(11)

93

190

186

640

630

93

91

36

35

337

327

1100

1070

160

155

(10)

(8)

92

90

183

179

620

600

90

87

Values in ( ) are - beyond the normal range and are given for information only

24

ROHI International

Complete Fastener Solutions

Technical Data

SI UNITS & CONVERSION FOR CHARACTERISTICS OF MECHANICAL FASTENERS:

Conversion

Property

Unit

Symbol

Approximate Equivalent

From

To

Multiply By

Length

metre

centimetre

millimetre

m

cm

mm

inch

inch

foot

mm

cm

mm

25.4

2.54

304.8

25mm = 1 in.

300mm = 1 ft.

1m = 39.37 in.

Mass

kilogram

gram

tonne megagram)

kg

g

t

ounce

pound

ton (2240 lb)

g

kg

kg

28.35

0.4536

984.2

28g= 1 oz.

1kg = 2.2 lb.= 35 oz

1t = 2206lbs

Density

kilogram per cub.

metre

kg/m

pounds per cu.

ft.

kg/mm

16.02

16 kg/m = 1 lb/ft

Temperature

deg. celsius

deg. Fahr.

( F - 32) x 5/9

C = 32 F 100 C=212 F

square metre

square millimetre

sq. inch.

sq. ft.

mm

2

m

Area

645.2

0.0929

645 mm = 1 in

2

2

1 m = 11ft

16387

0.02832

0.7645

16400mm = 1 in

3

3

1 m = 35 ft

3

3

1 m = 103 yd

m

2

mm

Volume

cubic metre

cubic centimetre

cubic millimetre

m

3

cm

3

mm

cu. in.

cu. ft.

cu. yd.

mm

3

m

3

m

Force

newton

kilonewton

meganewton

N

kN

MN

ounce (Force)

pound (Force)

Kip

N

kN

MN

0.278

0.00445

0.00445

1 N = 3.60 ozf

4.4 N = 1 lbt

1 kN = 225 lbt

Stress

megapascal

2

newton/mm

MPa

2

N/mm

pound/in (psi-)

2

kip/in (ksi)

MPa

MPa

0.0069

6.895

1 Mpa = 145 psi

7 Mpa = 1 ksi

N-m

inch - ounce

inch - pound

foot - pound

N-m

N-m

N-m

0.00706

0.113

1.356

1 N-m = 140 in oz

1 N-m = 9 in lb

1 N-m = 0.75 ft.lbs

14 Nm = 1 ft lb

Torque

newton - metre

Note: 1 MPa = 1 N/mm

1 KSI = 1.000 lb/in

1N = 0.1019 kgf

25

ROHI International

Complete Fastener Solutions

Bent Bolts (Metric System)

``

26

ROHI International

Complete Fastener Solutions

Anchor Bolts (Metric Series)

27

ROHI International

Complete Fastener Solutions

Anchor Bolts (Metric Series)

DIMENSIONS mm

ANCHOR

THREAD

DIAMETER

CUTTING LENGTH mm

G

Type

SQUARE

PLATE

SP

SQ

JE

CUT

LENGTH

CUT

LENGTH

CUT

LENGTH

CUT

LENGTH

12

40

16

40

45

100

50

29

10

75

330

330

355

381

355

455

410

530

16

50

19

40

55

100

65

35

12

90

400

400

355

388

355

455

420

595

20

60

22

50

70

150

50

75

39

12

90

480

480

405

443

405

485

485

695

355

565

22

70

25

50

75

150

55

80

48

16

100

570

570

460

506

460

545

545

790

415

660

24

85

28

55

90

200

65

90

55

20

100

700

700

510

560

510

610

610

890

475

735

27

75

100

200

75

560

619

560

675

673

990

535

935

30

100

36

75

115

200

85

110

64

20

125

820

820

610

674

610

735

735

1035

596

945

33

90

125

200

90

660

800

800

1125

655

1040

36

115

42

90

125

200

95

115

76

25

150

1010

1010

710

865

865

1290

715

1130

39

100

145

200

110

760

925

925

1360

770

1225

42

130

49

115

150

255

120

130

85

25

175

1120

1120

815

990

990

1475

830

1315

48

150

56

125

180

255

125

915

1120

1120

1675

956

1510

56

170

63

140

200

255

145

1015

1270

1245

1870

1070

1695

64

190

70

160

200

255

160

1120

1375

1370

2070

1190

1910

Note: Material

Nuts

: ASTM A36/JIS G3123/SS41 or ANSI 1018 as available (where the required size is not available we use next size and

thread area will be machined down) to the required thread diameter.

: DIN 555 Class 5 or better (as available)

Surface Finish : Natural or Hot Dip Galv. (ASTM A153)

28

ROHI International

Complete Fastener Solutions

Anchor Bolts (Inch Series)

Table 1 : ASTM A307, Grade A Bolt Sizes- Inch Series

Bolt Properties

Size

Type 1

Stress

Area

Type

Lt

TPI

Max.

Proj.

(note c)

da

hef

min.

12da

(in)

(in)

Type 1S

Length

(L)

Edge

Dist

Proj.+hef

4da100

+da/2

6da

SL+150

Spacing

hef min.

Length

(L)

Edge

Dist

Spacing

Proj.+hef (note d)

(note e)

SD

SL

Sleeve

(in2)

(mm)

(mm)

(in)

(mm)

(mm)

(mm)

(in)

(mm)

(mm)

(mm)

(mm)

1/2

Hex

1.50

13

0.142

107

152

10

108

76

275

15

127

114

50

125

5/8

Hex

1.75

11

0.226

115

191

12

110

95

325

17 1/2

127

129

50

175

3/4

Hex

2.00

10

0.334

123

229

14

111

114

325

17 1/2

127

145

50

175

7/8

Hex

2.25

0.462

131

267

15 1/2

113

133

325

18

127

161

50

175

Hex

2.50

0.606

139

305

17 1/2

114

152

400

21

139

202

75

250

1-1/8

Hex

2.75

0.763

146

343

19 1/2

116

171

421

22 1/2

139

218

75

250

1-1/4

Hex

3.00

0.969

154

381

21

127

191

441

23 1/2

149

234

75

250

1-3/8

Hex

3.25

1.155

162

419

23

140

210

460

24 1/2

160

250

75

250

1-1/2

Hex

3.50

1.405

170

457

24 1/2

152

229

604

30 1/2

183

291

100

375

1-3/4

Heavy Hex

4.00

1.899

186

533

28 1/2

178

267

642

32 1/2

206

322

100

375

Heavy Hex

4.50

4.5

2.498

202

610

32

203

305

755

37 1/2

228

354

100

450

2-1/4

Heavy Hex

5.00

4.5

3.248

218

686

35 1/2

229

343

793

40

250

386

100

450

2-1/2

Heavy Hex

5.50

3.999

234

762

39

254

381

981

48

297

468

150

600

2-3/4

Heavy Hex

6.00

4.934

250

838

43

279

419

1019

50

319

499

150

600

Heavy Hex

6.50

5.967

266

914

46 1/2

305

457

1057

52

342

531

150

600

29

ROHI International

Complete Fastener Solutions

Anchor Bolts (Inch Series)

Table 2 : ASTM A36, ASTM F1554 Grade 36 Anchor Rods - Inch Series

Bolt Properties

Size

da

TPI

Type 2S

L1

T1

da+13

2da

12da

4da100+da/2

6da

SL+150

(note b)

(note c)

SD

SL

(in )

(mm)

(mm)

(mm)

(mm)

(mm)

(mm)

(mm)

(mm)

(mm)

(mm)

Stress

Area

2

(in)

Type 2

hef

min.

Edge Dist

Spacing

hef

min.

Edge

Dist

Spacing

Sleeve

1/2

13

0.142

26

25

152

108

76

275

127

114

50

125

5/8

11

0.226

29

32

191

110

95

325

127

129

50

175

3/4

10

0.334

32

38

229

111

114

325

127

145

50

175

7/8

0.462

35

44

267

113

133

325

127

161

50

175

0.606

38

51

305

114

152

400

139

202

75

250

1-1/8

0.763

42

57

343

116

171

421

139

218

75

250

1-1/4

0.969

45

64

381

127

191

441

149

234

75

250

1-3/8

1.155

48

70

419

140

210

460

160

250

75

250

1-1/2

1.405

51

76

457

152

229

604

183

291

100

375

1-3/4

1.899

57

89

533

178

267

642

206

322

100

375

4.5

2.498

64

102

610

203

305

755

228

354

100

450

2-1/4

4.5

3.248

70

114

686

229

343

793

250

386

100

450

2-1/2

4.0

3.999

77

127

762

254

381

981

297

468

150

600

2-3/4

4.0

4.934

83

140

838

279

419

1019

319

499

150

600

4.0

5.967

89

152

914

305

457

1057

342

531

150

600

30

ROHI International

Complete Fastener Solutions

Anchor Bolts (Metric Series)

Table 2M - ASTM A36 Anchor Rods - Metric

Bolt Properties

Nominal Dia

(da) &

Thread Pitch

Stress

Area

2

Type 2

Type 2S

L1

T1

hef

min.

da+13

2da

12da

4da100+da/2

6da

SL+150

(note b)

(note c)

SD

SL

Edge Dist

Spacing

hef

min.

Edge

Dist

Spacing

Sleeve

(mm)

(mm )

(mm)

(mm)

(mm)

(mm)

(mm)

(mm)

(mm)

(mm)

(mm)

(mm)

M12 x 1.75

84.3

25

24

144

106

72

275

125

110

50

125

M16 x 2

157

29

32

192

108

96

275

125

130

50

125

M20 x 2.5

245

33

40

240

110

120

325

125

150

50

175

M24 x 3

353

37

48

288

112

144

400

138

195

75

250

M27 x 3

459

40

54

324

114

162

400

138

210

75

250

M30 x 3.5

561

43

60

360

120

180

400

143

225

75

250

M36 x 4

817

49

72

432

144

216

525

176

280

100

375

M42 x 4.5

1120

55

84

504

168

252

525

197

310

100

375

M48 x 5

1470

61

96

576

192

288

600

218

340

100

450

M56 x 5.5

2030

69

112

672

224

336

672

246

380

100

450

M64 x 6

2680

77

128

768

256

384

768

299

470

150

600

M72 x 6

3460

85

144

864

288

432

864

327

510

150

600

31

ROHI International

Complete Fastener Solutions

Anchor Bolts (Metric Series)

Table 3M - ASTM A193M Anchor Rods - Metric

Bolt Properties

Nominal Dia

(da) &

Thread Pitch

Stress

Area

2

Type 3

Type 3S

L1

T1

hef

min.

Edge Dist

Spacing

hef

min.

Edge

Dist

Spacing

2da+13

3da

12da

6da100+da/2

6da

SL+150

(note b)

(note c)

SD

SL

Sleeve

(mm)

(mm )

(mm)

(mm)

(mm)

(mm)

(mm)

(mm)

(mm)

(mm)

(mm)

(mm)

M12 x 1.75

84.3

37

36

144

106

72

275

125

110

50

125

M16 x 2

157

45

48

192

108

96

275

125

130

50

125

M20 x 2.5

245

53

60

240

120

120

325

135

150

50

175

M24 x 3

353

61

72

288

144

144

400

140

195

75

250

M27 x 3

459

67

81

324

162

162

400

186

210

75

250

M30 x 3.5

561

73

90

360

180

180

400

203

225

75

250

M36 x 4

817

85

108

432

216

216

525

248

280

100

375

M42 x 4.5

1120

97

126

504

252

252

525

281

310

100

375

M48 x 5

1470

109

144

576

288

288

600

314

340

100

450

M56 x 5.5

2030

125

168

672

336

336

672

358

380

100

450

M64 x 6

2680

141

192

768

384

384

768

427

470

150

600

M72 x 6

3460

157

216

864

432

432

864

471

510

150

600

32

ROHI International

Complete Fastener Solutions

Anchor Bolt Sleeve

Technical Data:

See Table 1 for material test data. Each Sleeve is approximately twice the bolt diameter with a depth of 8 bolt

diameters, minimum Tests by a state Department of Transportation laboratory indicates that the Wilson Anchor Bolt

Sleeve provided greater pullout strength than the regular grout pocket. The grout pocket was formed in a concrete

mass and the sleeve of the same size was cast into the mass. After curing the concrete, #5 reinforcing bars were set

in each pocket, using expanding grout. When cured, both bars were given a tensile load. The standard pocket failed

when the bar with the grout attached pulled out. The Wilson Anchor Bolt Sleeve retained the grout and failure

occurred around the bar. The sleeve remained intact. When used as a sleeve for anchor bolts the product is in an

in-place form and not considered a structural member. Due to its configuration 180 psi is the maximum compressive

loading.

Table 1: Material and Testing Data

Plastic

High Density Polyethylene

Density, gms/cc

ASTM D 1505 - 68

.956

ASTM D 1525 - 70

256 oF / 124 oC

Brittleness Temperature F

ASTM D 746 -70

-180 oF / -118 oC

Torch Application

Slow Burn

Compression Test

180 psi/12.7 kg/sq. cm.

Vicat Softening Point F

o

Table 2: Grout Volume Required

Bolt

Size

1/2"

Bolt

Size

2" x.5"

Shells

Per Carton

100

Cubic Inches of

Grout Per Shell/Carton

15.95

1595

Bags of Grout

Per Carton

1.06

3/4"

2" x.5"

100

15.16

1516

1.11

5/8"

2" x.7"

100

21.41

2141

1.42

3/4"

2" x.7"

100

20.50

2050

1.36

7/8"

2" x.7"

100

19.52

1952

1.30

1"

3" x.10"

50

65.80

3290

2.19

1-1/4"

3" x.10"

50

61.40

3070

2.04

1-1/2"

4" x.15"

20

167.60

3352

2.23

1-3/4"

4" x.15"

20

158.00

3160

2.11

2"

4" x.18"

20

176.76

3525

2.35

2-1/4"

4" x.18"

20

161.82

3236

2.15

2-1/2"

6" x.24"

10

575.28

5753

3.82

3"

6" x.24"

10

523.44

5235

3.48

NOTE: Grout Estimate based on .87 cu. ft. yield per 100 lb. of non-corrosive grout.

Composition and Materials:

The Wilson Anchor Bolt Sleeve is manufactured of high impact plastic. It is non-rusting, non-conductive and

lightweight. Single unit construction provides for reduction in installation labor because no welding, threading or

cleaning is required. The configuration is such that the grout and concrete "lock" it in place, providing greater pullout

strength than with straight pipes.

33

ROHI International

Complete Fastener Solutions

U Bolts

Fabricated as per Clients Drawing in Carbon Steel

(Natural / EG / HDG Finish) and in Stainless Steel 304/316

U BOLT (GRIPPED)

Nom

Pipe

Size

Pipe

O/D

Max

Load

Kg

15

21.3

28

25

37

220

20

26.9

10

33

25

40

220

25

33.7

10

40

25

43

220

32

42.4

10

53

10

35

49

545

40

48.3

16

60

10

35

56

545

50

60.3

16

71

10

35

60

545

65

76.1

20

89

12

40

78

1000

80

88.9

20

102

12

40

85

1000

90

101.6

20

116

12

40

90

1000

100

114.3

20

128

12

40

97

1000

125

139.7

20

152

12

40

110

1000

150

168.3

20

182

12

40

125

1000

200

219.1

20

236

16

40

154

1635

225

244.5

20

266

20

50

173

3405

250

273.0

22

294

20

50

185

3405

300

323.9

22

346

20

50

210

3405

350

355.6

24

378

20

55

230

3405

400

406.4

24

429

20

55

255

3405

450

451

24

483

24

55

280

4450

500

508

24

534

24

60

305

4450

550

559

24

585

24

60

335

4450

600

610

24

636

24

60

360

4450

Material - Carbon Steel.

Complete with 2 nuts

34

ROHI International

Complete Fastener Solutions

U Bolts

Fabricated as per Clients Drawing in Carbon Steel

(Natural / EG / HDG Finish) and in Stainless Steel 304/316

U BOLT (NON GRIPPED)

Nom

Pipe

Size

Pipe

O/D

Max

Load

Kg

15

21.3

10

30

60

65

220

20

26.9

10

35

60

68

220

25

33.7

10

42

65

70

220

32

42.4

10

54

10

65

74

545

40

48.3

16

62

10

65

78

545

50

60.3

16

74

10

65

84

545

65

76.1

20

90

12

80

92

1000

80

88.9

20

106

12

80

100

1000

90

101.6

20

116

12

80

109

1000

100

114.3

20

128

12

80

114

1000

125

139.7

20

155

12

80

129

1000

150

168.3

20

189

16

100

154

1635

200

219.1

20

238

16

100

176

1635

225

244.5

20

268

20

110

187

3405

250

273.0

22

296

20

110

213

3405

300

323.9

22

348

20

110

246

3405

350

355.6

24

380

20

110

260

3405

400

406.4

24

431

20

110

285

3405

450

457.0

24

484

24

120

320

4450

500

508.0

24

536

24

120

345

4450

550

559.0

24

586

24

120

373

4450

600

610.0

24

638

24

120

400

4450

Material - Carbon Steel.

Complete with 4 nuts

35

ROHI International

Complete Fastener Solutions

Pipe Clip

Carbon Steel (Galvanized / Coated Finish)

and in Stainless Steel 304/316

(Moderate Loads)

Nom

Pipe

Size

Pipe

O/D

Steel

Size F

15

21.3

92

32

12

M12

30 x 6

107

47

20

26.9

95

38

12

M12

30 x 6

110

53

25

33.7

97

44

12

M12

30 x 6

112

59

32

42.4

102

49

12

M12

30 x 6

117

64

40

48.3

102

46

25

M12

30 x 6

124

68

50

60.3

127

54

25

M12

30 x 6

149

76

65

76.1

140

67

25

M12

45 x 8

162

89

80

88.9

152

76

25

M12

45 x 8

175

99

90

101.6

159

82

25

M12

45 x 8

181

104

100

114.3

165

100

25

M16

50 x 10

194

129

125

139.7

178

114

25

M16

50 x 10

206

150

168.3

216

135

38

M20

65 x 10

175

193.7

230

150

38

M20

200

219.1

241

163

38

225

244.5

265

180

38

(Heavy Loads)

Pipe

O/D

142

Nom

Pipe

Size

254

173

150

168.3

229

143

44

M30

65 x 10

268

188

175

193.7

241

158

44

M20

65 x 10

279

201

200

219.1

254

172

M20

65 x 12

303

218

225

244.5

305

273.0

305

Steel

Size F

100 x 12

279

193

M30

110 x 12

291

208

44

M30

110 x 12

305

220

198

51

M36

100 x 20

356

258

214

51

M36

100 x 20

356

265

250

273.0

279

192

38

M20

65 x 12

317

230

250

300

323.9

305

220

38

M20

65 x 12

343

258

300

323.9

330

240

51

M36

100 x 20

381

291

350

355.6

330

243

51

M24

80 x 15

378

291

350

355.6

356

262

57

M42

110 x 20

413

319

406.4

381

292

57

M42

110 x 25

438

349

400

406.4

356

273

51

M24

80 x 15

403

320

400

450

457.2

381

300

51

M24

80 x 15

429

348

450

457.0

406

317

57

M42

110 x 25

464

375

500

508.0

406

329

51

M24

80 x 20

457

380

500

508.0

457

353

57

M42

130 x 25

521

417

550

558.0

432

365

51

M24

100 x 20

489

422

550

558.8

483

393

57

M42

150 x 30

559

469

610.0

508

418

57

M42

150 x 30

584

494

600

610.0

457

390

51

M24

100 x 20

514

447

600

650

660.4

559

431

51

M30

130 x 25

622

494

650

660.4

581

443

57

M42

150 x 30

657

519

700

711.2

585

457

51

M30

130 x 25

648

520

700

711.2

610

472

57

M42

150 x 30

686

548

750

762.0

610

482

51

M30

130 x 25

673

545

750

762.0

635

497

57

M42

150 x 30

711

573

812.8

661

525

57

M42

150 x 30

734

601

914.4

711

575

57

M42

150 x 30

787

631

800

812.8

647

508

51

M30

130 x 25

710

571

800

900

914.4

699

560

51

M30

130 x 25

762

623

900

36

ROHI International

Complete Fastener Solutions

Pipe Clamps

Carbon Steel (Galvanized / Coated Finish) and

in Stainless Steel 304/316

EXTENDED PIPE CLAMP

OFFSET PIPE CLAMP

Nom

Pipe

Size

Pipe

O/D

Steel

Size F

Nom

Pipe

Size

Pipe

O/D

Steel

Size F

20

26.9

115

M10

25 x 6

20

26.9

185

M10

65

12

25 x 6

25

33.7

125

M10

30 x 6

25

33.7

190

M10

65

12

30 x 6

32

42.4

130

M10

30 x 6

32

42.4

200

M10

70

12

30 x 6

40

48.3

135

M10

30 x 6

40

48.3

210

M10

75

12

30 x 6

50

60.3

158

M12

40 x 6

50

60.3

230

M12

80

14

40 x 6

65

76.1

190

M12

40 x 6

65

76.1

265

M12

85

14

40 x 6

80

88.9

206

M12

40 x 6

80

88.9

280

M12

95

14

40 x 6

90

101.6

219

M12

40 x 6

90

101.6

295

M12

100

14

40 x 6

100

114.3

241

M12

40 x 6

100

114.3

315

M12

105

14

40 x 6

125

139.7

273

M12

40 x 6

125

139.7

350

M12

120

14

40 x 6

150

168.3

330

M16

50 x 10

150

168.3

420

M16

135

18

50 x 10

200

219.1

380

M16

50 x 10

200

219.1

475

M16

160

18

50 x 10

Material - Carbon Steel

Material - Carbon Steel

Standard length supplied 300 mm

Longer legs supplied by request.

Standard clearance 50 mm from back of pipe to