Professional Documents

Culture Documents

Brosur WEST - LC Filter - F Series

Uploaded by

rudiawanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Brosur WEST - LC Filter - F Series

Uploaded by

rudiawanCopyright:

Available Formats

LC-F Pressurized Filter

Flow rates from 0.25 - 20 m3/hour

WEST LC-F Series Pressurized Filter are available as a standart

pre-engineered line of equipment or as a custom designed system with the

flexibility to meet a wide range of customer requirements.

Combining innovation,

technology, and low cost

Ranging in size from 8" to 36" in diameter and with flows

up to 20.0 m3/hour, LC-F Series Filters are a highly efficient means of removing

suspended solids, organic matters, hardness, and or mineral from water

depend on media filter to be used. Made from fiberglass with polyethylene liner

makes this products have a great reliability and durability from corrossion.

to present a qualified

manual/automatic

water filtration system

.

Configurations

Single system up to 20 m3/hour =

Duplex alternating up to 20 m3/hour =

Parallel alternating with n-1 x 20 m3/hour =

Available media

Filtration: Sand, Anthracite, Multimedia =

Adsorbsion: Activated Carbon =

Iron Removal: Birm, Ferrolite =

Softening: Lewatit S-80, Purolite C-100 =

Demineralizing: Lewatit S-100 and M-500, =

Purolite C-100 and A-400 =

Applications

=

=

=

=

=

Suspended Solid Removal

Organic/Color/Taste/Odor Reduction

Residual Chlorine Removal

Water Softening

Water Demineralizing

Standard Features

The LC-F Series Water Filter are designed for fully automatic or manual

backwash or regeneration for production of good quality water with the

following feature:

Corrosion Resistant Tanks made

from seamless polyethylene

reinforced with fiberglass.

Optional

Steam sanitizable manual =

Pressure transmitter 4-20 mA =

Mild steel or stainless steel skid =

Conductivity Measurement for demineralizer =

transmitter and/or alarm =

Filter Media Silica sand, activated

carbon, Ferrolite, High cation

exchange resin softener, Strong acid

cation and strong base anion resins

are standard, with other media

available as an option

Choice of Backwash/Regeneration

Backwash/Regeneration cycle may

be initiated manually or automatic

with controll valve or fully automatic

by PLC system .

Assembly Factory assembly and

skid mounting for quick installation

and minimum startup cost

Piping & Valve AW Class or

Schedule 80 PVC piping package

including true union ball valve

(manual) and air operated composite

plastic diaphragm valves is standard.

Air or electric actuated ball or

butterfly valves are available as an

option (auto )

Instruments Pressure indicators,

rotameters and an optional metering

valves supplied for accurate and safe

control of regeneration water and

chemical introduction

Internal distributors are corrosion

resistant, designed for optimum

efficiency and are fully supported

where required

For Further Information, Please Call :

You might also like

- Pedoman Pelaksanaan FTW A-009.pg0400.2019-S9 CompactDocument29 pagesPedoman Pelaksanaan FTW A-009.pg0400.2019-S9 CompactrudiawanNo ratings yet

- Ayam FrozenDocument1 pageAyam FrozenrudiawanNo ratings yet

- Laporan Harian "Konstruksi" Gresem Pipeline ProjectDocument10 pagesLaporan Harian "Konstruksi" Gresem Pipeline ProjectrudiawanNo ratings yet

- Quotation - PipeFittingValve (PT. Dinamika Selaras Engineering)Document6 pagesQuotation - PipeFittingValve (PT. Dinamika Selaras Engineering)rudiawanNo ratings yet

- Questionnaire To Calculate The Adequate Pulsation Dampener For Dosing PumpsDocument2 pagesQuestionnaire To Calculate The Adequate Pulsation Dampener For Dosing PumpsrudiawanNo ratings yet

- Turbine Meter Head Loss CurvesDocument2 pagesTurbine Meter Head Loss CurvesrudiawanNo ratings yet

- Lampiran G-1 - AMLDocument31 pagesLampiran G-1 - AMLrudiawanNo ratings yet

- Mercure Karawang Hotel: Pt. Bunyamin BrothersDocument1 pageMercure Karawang Hotel: Pt. Bunyamin BrothersrudiawanNo ratings yet

- Lift Plan: Sl. Points / Particulars UOM Qty./ Measurement/RemarksDocument2 pagesLift Plan: Sl. Points / Particulars UOM Qty./ Measurement/RemarksrudiawanNo ratings yet

- Sample Daily Hsqewqe ReportDocument15 pagesSample Daily Hsqewqe ReportrudiawanNo ratings yet

- DS Hydrant PilarDocument1 pageDS Hydrant PilarrudiawanNo ratings yet

- SquishyDocument1 pageSquishyrudiawanNo ratings yet

- MTO Pipa Steel Welded SpiralDocument4 pagesMTO Pipa Steel Welded SpiralrudiawanNo ratings yet

- Fire Hose Specification Sheet: Gresik, IndonesiaDocument1 pageFire Hose Specification Sheet: Gresik, IndonesiarudiawanNo ratings yet

- Activated Sludge ProcessDocument12 pagesActivated Sludge Processtvijayaraja100% (1)

- I. Direct Cost: Summary Rencana Anggaran Proyek (Rap) Trass and Limestone Handling System PROJECT - CITEUREUPDocument38 pagesI. Direct Cost: Summary Rencana Anggaran Proyek (Rap) Trass and Limestone Handling System PROJECT - CITEUREUPrudiawanNo ratings yet

- HEAT BALANCE OF COOLING WATER SYSTEM CALCULATION 冷却水系统热平衡计算书 REV 0Document4 pagesHEAT BALANCE OF COOLING WATER SYSTEM CALCULATION 冷却水系统热平衡计算书 REV 0rudiawanNo ratings yet

- Ijin Boring Penanaman Pipa GasDocument2 pagesIjin Boring Penanaman Pipa GasrudiawanNo ratings yet

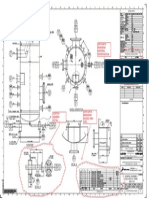

- Contoh Gambar VesselDocument1 pageContoh Gambar VesselrudiawanNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Biological and Physicochemical Indicators of Water Quality in Libreville and Its SurroundingsDocument7 pagesBiological and Physicochemical Indicators of Water Quality in Libreville and Its SurroundingsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Metabolism Exam 2 - GIFT - Spring 2016Document9 pagesMetabolism Exam 2 - GIFT - Spring 2016shafa_nathani100% (2)

- Rotary Positive Displacement Pumps, Commercial Ships Use: Standard Specification ForDocument8 pagesRotary Positive Displacement Pumps, Commercial Ships Use: Standard Specification ForCHRISTIAN ZAVALANo ratings yet

- MSDS BenzeneDocument3 pagesMSDS BenzeneUmair JavedNo ratings yet

- Lead PoisoningDocument3 pagesLead PoisoningSign UpNo ratings yet

- ENSC3007 Lab Write UpDocument9 pagesENSC3007 Lab Write UpammtstNo ratings yet

- Innoclean Plasma Bipolar General LeafletDocument2 pagesInnoclean Plasma Bipolar General Leafletwsc wspNo ratings yet

- Introduction To Metal EtchingDocument2 pagesIntroduction To Metal EtchingfoobiedotNo ratings yet

- Accc/Tw Prague (700) : Data SheetDocument1 pageAccc/Tw Prague (700) : Data SheetkmiqdNo ratings yet

- Ne335 Macro Lab1Document17 pagesNe335 Macro Lab1Moeen Khan RisaldarNo ratings yet

- EPRIDocument52 pagesEPRIDurga Prasad100% (2)

- FORMULATION AND EVALUATION OF GASTRO-RETENTIVE FLOATING TABLET OF QUETIAPINE FUMARATE Shanti Sagar, Srividya. L, B.K NanjawadeDocument14 pagesFORMULATION AND EVALUATION OF GASTRO-RETENTIVE FLOATING TABLET OF QUETIAPINE FUMARATE Shanti Sagar, Srividya. L, B.K NanjawadeiajpsNo ratings yet

- Year 10 Revision Paper QPDocument15 pagesYear 10 Revision Paper QPketamineNo ratings yet

- 832R12011 (Emerging Technologies For Wastewater Treatment - 2nd Ed.)Document188 pages832R12011 (Emerging Technologies For Wastewater Treatment - 2nd Ed.)Anonymous owMJ21JRzC100% (3)

- Geochemical Analysis of Iron Ore - SGSDocument2 pagesGeochemical Analysis of Iron Ore - SGSAnton De la ruaNo ratings yet

- Methodology For Petrophysical and Geomechanical Analysis of Shale Plays. Study Case: La Luna and Capacho Formations, Maracaibo Basin. Presentation of Paper SPE-185606-MSDocument24 pagesMethodology For Petrophysical and Geomechanical Analysis of Shale Plays. Study Case: La Luna and Capacho Formations, Maracaibo Basin. Presentation of Paper SPE-185606-MSCarlos LoboNo ratings yet

- Framo Operation ManualDocument16 pagesFramo Operation Manualcaptulcc100% (2)

- Nitoseal 130Document2 pagesNitoseal 130Venkata RaoNo ratings yet

- Spectracron 110 FD Alkyd Enamel PDFDocument2 pagesSpectracron 110 FD Alkyd Enamel PDFSatish Vishnubhotla0% (1)

- What Is Design Interpretation?Document15 pagesWhat Is Design Interpretation?dhirajNo ratings yet

- Nuclear Technology and EnergyDocument4 pagesNuclear Technology and EnergyJessica Anna LuchkaNo ratings yet

- Solar Stills For Desalination of Water in Rural Households: Amitava BhattacharyyaDocument10 pagesSolar Stills For Desalination of Water in Rural Households: Amitava BhattacharyyaTrimo Wahyu Bimantoro100% (1)

- Formation of PrecipitationDocument2 pagesFormation of PrecipitationArianne May Amosin50% (2)

- 4CH1 2C Que 20211120Document24 pages4CH1 2C Que 20211120Fazal AhmedNo ratings yet

- 0199152152Document138 pages0199152152Afzal UsmanNo ratings yet

- Continuous Winemaking Fermentation Using Quince-Immobilized Yeast at Room and Low TemperaturesDocument6 pagesContinuous Winemaking Fermentation Using Quince-Immobilized Yeast at Room and Low TemperaturesLoc VotuongNo ratings yet

- ứng dụng de novo trong điều trị SAR-CoV-2Document35 pagesứng dụng de novo trong điều trị SAR-CoV-2Beo NguyễnNo ratings yet

- Fish Processing HandoutDocument1 pageFish Processing HandoutGre ChieNo ratings yet

- Nanoformulation of Curcuma Longa Root Extract and Evaluation of Its Dissolution PotentialDocument9 pagesNanoformulation of Curcuma Longa Root Extract and Evaluation of Its Dissolution Potentialmuhammad adnan ayubNo ratings yet

- Naufal - Flare Technologies - PPTX (Tanpa Video)Document12 pagesNaufal - Flare Technologies - PPTX (Tanpa Video)Naufal AlhadyNo ratings yet