Professional Documents

Culture Documents

029-QCP For Roads & Paving PDF

Uploaded by

Köksal PatanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

029-QCP For Roads & Paving PDF

Uploaded by

Köksal PatanCopyright:

Available Formats

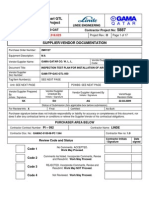

Pearl GTL

Project

Shell Project No: HP-3000-QAT

Project Document Number: T- 4.234.544

Purchase Order Number:

2MH127

Tag/Item Number(s):

N/A

Unit(s):

ASU

PCWBS:

LINDE ENGINEERING

Contractor Project No:

Project Rev.: A

Page 2 of 21

5887

QATAR SHELL GTL PROJECT (PEARL)

C2 AIR SEPARATION UNITS CONSTRUCTION

28.01.2008

Ready For Construction

SB

UA/MC

ZG

RFC

27.11.2007

Issued for Company Comments

IU

UA/IO

MC/ZG

ICC

25.11.2007

Issued for Review

IO

MC

ZG

IFR

25.11.2007

Issued for Internal Review

IO

MC

ZG

IIR

Date

Description

GAMA

Rev.

No.

Project

Rev

No.

Prepared Checked Approved

By

By

By

ORIGINATOR

Status

Document Title:

LINDE ENGINEERING AG

PROCEDURE FOR SURFACING, PAVING AND ROAD

WORKS

Document No.

Contractor

Gama Qatar Co. W. L. L.

LOC470

GAM

PRO

QAC

GTL

029

Org.

Code

Doc.

Type

Disc.

Code

Geogr.

Area

Seq.

No

Rev.

No

Project Document Number: T-4.234.544

Vendor Code

Rev No: A

Q A T A R

Doc. Title

GAM-PRO-QAC-GTL-029

QCP FOR SURFACING, PAVING AND ROAD WORKS

Date

28.01.2008 REV-D

CONTENTS

1.

SCOPE________________________________________________________________________5

2.

PURPOSE _____________________________________________________________________5

3.

HSSE _________________________________________________________________________5

4.

REFERENCES _________________________________________________________________5

5.

DEFINITIONS __________________________________________________________________6

6.

RESPONSIBILITIES ____________________________________________________________6

7.

6.1.

The Site Engineer/Supervisor______________________________________________________6

6.2.

QCE (Civil) _______________________________________________________________________6

6.3.

QCI (Civil)________________________________________________________________________6

PROCEDURE __________________________________________________________________7

7.1.

For Expansion Joints _____________________________________________________________8

7.2.

For Construction Joints___________________________________________________________8

7.3.

For Bituminous Shoulders ________________________________________________________9

8.

QUALITY ASSURANCE_________________________________________________________9

9.

ATTACHMENTS ______________________________________________________________10

T-4.234.544 Rev. A

Page 4 of 21

Q A T A R

Doc. Title

GAM-PRO-QAC-GTL-029

QCP FOR SURFACING, PAVING AND ROAD WORKS

Date

28.01.2008 REV-D

1. SCOPE

This surfacing, paving, and road works procedure defines the extent of inspection and testing to be

carried out related to road works activity.

2. PURPOSE

The purpose of this Quality Control Procedure is to detail all inspection and testing in order to verify that

road works conforms to project requirements. This procedure shall be read in conjunction with other

related procedures where road works activity is an integral part thereof.

3. HSSE

All works shall be in compliance with the State of Qatar laws and regulations, Ras Laffan Industrial City

and International standards, codes, Linde Engineering AG and QSGTL and/or its PMC requirements and

instructions.

In addition all employees and GAMA subcontractor employees on site will have through Linde

Engineering AG Site Safety Induction and GAMA Qatar Safety induction for site safety, health,

environmental and security prior to work activities. Other training courses will be attended as required by

Linde Engineering AG or QSGTL and/or its PMC as required.

At a minimum a Risk Assessment will have been prepared by the Risk Assessment Team (RAT) ranking

the hazards associated with project works and control measures to be taken to mitigate the hazards to an

acceptable level.

Each work scope or task will have a completed and approved Job Safety Analysis (JSA) identifying the

potential hazards and control measures that will be implemented to protect people and environment.

Supervisor as the basis of conducting his daily Pre-Task meeting and his weekly Tool Box Talk (TBT) will

use the JSA.

In addition to the above, employees conducting survey works will wear required PPE and highly visible

vest where traffic or other hazards may exist. For additional safety requirements for a particular or

specific task please refer to the JSA prepared for that task.

4. REFERENCES

T-4.234.067

T-4.234.564

T-4.234.073

T-4.234.075

DEP 34.13.20.31

T-4.231.953

T-4.234.544 Rev. A

:

:

:

:

:

:

MS for Survey

MS for Surfacing, paving and road works

MS for Dewatering

MS for concreting

Specification for Roads & Paving

Specification for joints and joint sealants

Page 5 of 21

Q A T A R

Doc. Title

GAM-PRO-QAC-GTL-029

QCP FOR SURFACING, PAVING AND ROAD WORKS

Date

28.01.2008 REV-D

5. DEFINITIONS

Company: QSGTL and / its PMC

Contractor: Linde Engineering AG

Sub Contractor: Gama Qatar Co. W.L.L

Contract: QSGTL Pearl Plant C2 ASU Construction Works

QCE: Quality Control Engineer

QCI: Quality Control Inspector

6. RESPONSIBILITIES

6.1.

THE SITE ENGINEER/SUPERVISOR

Ensure that the work is carried out in accordance with project specifications, drawings and

related QCPs and ITPs.

Ensure that proper execution and supervision for road levels, width, compacting of sub

base, gradient, super elevation, paving, temperature, aggregate mixing road finishing etc.

Ensure that all company required carrying out inspection and/ or tests are informed as to

the program of the works and the inspection and testing requirement.

Ensure hat all preparations have been made as to the execution of the grouting activity.

6.2.

QCE (CIVIL)

Ensure that all other discipline have been inspected and approved for the Road works.

Review all relevant documentation and ensure that all activities related to Road works are

documented, inspected and approved by CONTRACTOR and COMPANY.

6.3.

QCI (CIVIL)

Ensure that he fully aware of the Road works activity programmed.

Ensure he attends inspection in a timely manner and records results the result of

inspection on appropriate forms.

Ensure that the Road works conform to the project requirements.

T-4.234.544 Rev. A

Page 6 of 21

Q A T A R

Doc. Title

GAM-PRO-QAC-GTL-029

QCP FOR SURFACING, PAVING AND ROAD WORKS

Date

28.01.2008 REV-D

7. PROCEDURE

The Site Engineer/Supervisor will raise Request for Inspection (RFI), as required and

initial / prepare the necessary documents related to the activity and submit to Quality

Department prior to work commenced.

To be using only approved materials and works will be done by company standard

specifications.

Ensure that the Surveying, Dewatering (If necessary), Concreting, Cross Drainage

systems and Formation works (cutting or filling) are executed as per the specification.

Company approval is required for all types of material used for paving, surfacing

and road works prior to commencement of activity.

Asphalting work or paving work shall not be carried until initial preparation have been

made and approved by CONTRACTOR and COMPANY.

The type and size of paving material shall be carefully checked and verified to ensure that

the correct type of material is used as required in the drawings and Project Specification.

Ensure that the surface preparation of existing ground (cutting or filling) shall be carefully

checked for rigidity of soil and water content before paving or bituminous shoulder

asphalting.

Ensure that the material used for bituminous work is free from oil, dust and foreign

materials, and strictly comply with the specification.

Ensure that the Compaction Test, Californian Bearing Ratio Test (CBR) are according to

ASTM Volume 04.03 , BS 1377 and BS5930

Be sure that during compaction of sub-base below the ground water level, if found any

differential settlement; provide the R.C.C. transition slabs at bottom level of paving area

as per DEP 34.13.20.31

.

Ensure that the construction of heavy and light duty roads shall be reinforced in

accordance with the standard drawing S.13.005, S.13.006, and S.13.007 as in DEP

34.13.20.31

Ensure that, road cross fall shall be maintain the slope of 1:20 as per DEP 34.13.20.31

Ensure that the thickness of flexible paving shall be maintained as 500mm. And also

maintain the rigid paving for heavy-duty roads & light duty roads are minimum 250mm and

150mm respectively as per DEP 34.13.20.31 & detailed drawing issued by the

COMPANY.

The maximum gradient maintained for patrol roads flexible paving shall not exceed 1 in

8.5.

T-4.234.544 Rev. A

Page 7 of 21

Q A T A R

Doc. Title

GAM-PRO-QAC-GTL-029

QCP FOR SURFACING, PAVING AND ROAD WORKS

Date

28.01.2008 REV-D

All the roads crossing are maintained the radius of curvature as per DEP 34.13.20.31

If applicable, make sure the minimum distance between the finished road surface and the

top of U/G pipe or other crossing shall maintain 0.50m as per drawings.

Cross barriers are installed as per the specification and DEP 34.13.20.31

7.1.

FOR EXPANSION JOINTS

The concrete surface shall be cleaned from loose dirt, paint, grease and it shall be dry

prior to applying the primer coat.

Expansion joints in roads and paving have to be maintaining the maximum distance not

exceeding 15m as per T.13.376.353- 3.5.

The Chamfered edge shall be maintained as minimum 20 mm at both joint sides.

The flexible joint filling material used shall be approved sponge rubber or prefabricated

polyethylene material like SIKA PE-Rundschnur.

Sika Primer- N3 shall be applied over the concrete surface in contact with the joint

sealant.

Sika Tank PK-25 shall be used as the final joint sealant. SIKA TANK PK-25 G can be

poured or SIKA TANK PK-25 ST can be placed with a mixing dispenser.

The material shall be pressed to the concrete surface by troweling with a scraper.

7.2.

FOR CONSTRUCTION JOINTS

The surface shall be free from standing water, dust, laitance, grease, curing compounds,

waxes and any other contaminants.

The surface shall be maintain as dry (may be dump).

Expansion joints in roads and paving have to be maintaining the maximum distance not

exceeding 7.50m as per T.13.376.353 - 3.5.

The joint width shall be maintained as 10mm to match with the sealing system

(T.4.231.953).

The timber crack inducer shall be fixed to the blinding layer to be kept in line with the cut

joint (T.4.231.953).

T-4.234.544 Rev. A

Page 8 of 21

Q A T A R

Doc. Title

GAM-PRO-QAC-GTL-029

QCP FOR SURFACING, PAVING AND ROAD WORKS

Date

28.01.2008 REV-D

SIKA TANK PK-25 shall be used as standard joint sealant (Hydrocarbon resistant) as per

T.4.231.953 and manufacturers instructions.

The mixed sealant shall be poured into the joints slowly for settlement and self levelling

until the joint is entirely filled as per T.4.231.953 and manufacturers instructions. The

excess sealant material shall be removed before it hardens.

After fabrication, the joint shall be protected from water at least 24 hours.

7.3.

FOR BITUMINOUS SHOULDERS

The Bituminous Asphalt shall be laid in shoulder areas beyond both side of the road

width as per the RFC drawing and as per T.13.376.495

The Tack Coat and Prime Coat materials are approved by the Contractor and company

only shall be used

The both sides of road (between road & shoulder ), the chamfered, standard size Curb

Stone shall be fixed above 100 mm blinding concrete as per the drawing and DEP

34.14.20.34 GEN

The level adjustment mortar for Curb Stone will be used as per DEP 34.14.20.34-Gen

The coating materials shall be sprayed with mechanical spray gun for even layer to all

surfaces.

The shoulder width shall be maintain minimum as 1.5 m as per standard drawing

mentioned in DEP 34.13.20.31- Gen.

The surfacing and base of shoulder shall maintain as per drawing & DEP 34.13.20.31Gen.

8. QUALITY ASSURANCE

A Quality Assurance System shall be operated conforming to related standards. Controls and checks

shall be established and documented through relevant QCP, ITP and QCRs.

T-4.234.544 Rev. A

Page 9 of 21

Q A T A R

Doc. Title

GAM-PRO-QAC-GTL-029

QCP FOR SURFACING, PAVING AND ROAD WORKS

Date

28.01.2008 REV-D

9. ATTACHMENTS

GAM-QCR-QAC-GTL-001

GAM-QCR-QAC-GTL-005

GAM-QCR-QAC-GTL-006

GAM-QCR-QAC-GTL-007

GAM-QCR-QAC-GTL-009

GAM-QCR-QAC-GTL-017

GAM-QCR-QAC-GTL-020

GAM-QCR-QAC-GTL-052

GAM-QCR-QAC-GTL-054

T-4.234.544 Rev. A

: INITIAL EARTHWORK

: COMPACTION TEST REPORT

: INSPECTION CHECKLIST SURVEY REPORT

: INSPECTION CHECKLIST BACK FILLING

: POUR CARD

: FRESH CONCRETE TEST REPORT

: CONCRETE CUBE TEST.

: FINISHED BITUMINOUS SURFACE ELEVATION.

: BITUMINOUS ASPHALT SUB BASE LEVEL REPORT

Page 10 of 19

INSPECTION CHECKLIST

EARTHWORKS

CLEARING AND GRADING

FORM NO: GAM-QCR-QAC-GTL-001

Rev.0

Location Bldg/Area :

ITP: GAM-ITP-QAC-GTL-

Date :

Drawing Reference Nos :

1

2

3

4

5

6

7

8

9

10

11

12

13

Check work site, stock pile haul roads, disposal areas and any existing utilities clearly identified

Check that the Surveyor has established bench marks and confirmed elevations

Check work site and any existing utilities staked out (confirmed by surveyor or attach

surveyor's report)

Check provisions for de-watering (if appl.)

Check provisions for demolition of existing structures. (if appl.)

Check valid work permits obtained for all areas

Check site cleared of all unsuitable soil & rubbish

Check all unsuitable material hauled away to designated disposal area.

Check any retained soils are properly stock piled

Check retained soils appear acceptable and sampled as required

Check site properly graded to designated levels (confirmed by surveyor or attach surveyor's

report)

Check base soil appears acceptable & sampled as required

Check base scarified (if required)

N/A

YES

NO

N/A

YES

NO

N/A

YES

NO

N/A

YES

NO

N/A

YES

NO

N/A

YES

NO

N/A

YES

NO

N/A

YES

NO

N/A

YES

NO

N/A

YES

NO

N/A

YES

NO

N/A

YES

NO

N/A

YES

NO

Comments:

SIGN OFF AS ACCEPTED

GAMA QATAR

Name

Position

Signature

Date

0.

LINDE

PEARL GTL

PEARL GTL ASU PROJECT

LABORATORY COMPACTION TEST FORM

FORM NO: GAM-QCR-QAC-GTL-005

Initial Mass of Sample

ITP NO: GAM-ITP-QAC-GTL-

g

.Layers

Weight of Sample + Mould (g)

Test Method : ASTM D-1557

4.5 kg Hand Rammer

..Blows per Layer

Volume of Mould

Weight of Mould (g)

BULK DENSITY

Container NO.

Weight of Wet Sample + Container (g)

Weight of Dry Sample + Container (g)

Weight of Container (g)

Weight of Dry Sample (g)

Weight of Moisture (g)

MOISTURE CONTENT (%)

DRY DENSITY (%)

DRY DENSITY Mg / m3

MAXIMUM DRY DENSITY

Kg / m3

OPTIMUM MOISTURE CONTENT %

THE ABOVE DETERMINATION WERE PERFORMED IN ACCORDANCE WITH ASTM 1557

GAMA QATAR

LINDE

PEARL GTL

CHECKED BY :

LABORATORY

TECHNICIAN :

DATE :

INSPECTION CHECKLIST

SURVEYORS REPORT.

FORM NO:

GAM-QCR-QAC-GTL-006 ITP REF. NO: GAM-ITP-QAC-GTLRev. 0

REV. 0 DATE :

Location Bldg/Area:

No :

Briefly describe the intention of the Survey and purpose giving details of the utility/ excavation.

For Location give Marked up copy of Drawing:

Drawing Numbers

Calibration Cert No :

1. Confirm that surveying equipment is calibrated

2. Check that the drawings noted above are approved for use.

3. Check all existing utilities are clearly identified and staked out

4. Confirm that the proposed excavation is clearly staked/ Marked out.

5. Confirm depth of excavation.

N/A

YES

NO

N/A

YES

NO

N/A

YES

NO

N/A

YES

NO

Surveyors Comments plus any additional survey information.

SIGN OFF WILL CONFIRM RELEASE TO EXCAVATE.

GAMA QATAR

Name

Position

Signature

Date

0.

LINDE

PEARL GTL

INSPECTION CHECKLIST

BACKFILL

UTILITIES / FOUNDATIONS

FORM NO: GAM-QCR-QAC-GTL007

Rev. 0

Location Bldg/Area:

ITP REF. NO: GAM-ITP-QAC-GTL-

REV. 0

DATE:

Drawing Reference Nos

ITEM DESCRIPTION

BACKFILL UTILITY

1

2

3

4

5

6

Confirm that Utility is completed tested and released for BACKFILL

Confirm that sand fill is completed

Confirm that fill is being laid in layers as required by the specification.

Confirm that compaction test have been performed and results recorded.

If the Utility requires tiles to be laid confirm that this has been done.

If warning tape is required confirm that it has been laid

N/A

YES

NO

N/A

YES

NO

N/A

YES

NO

N/A

YES

NO

N/A

YES

NO

N/A

YES

NO

N/A

YES

NO

N/A

YES

NO

N/A

YES

NO

N/A

YES

NO

N/A

YES

NO

BACKFILL FOUNDATIONS

7

8

9

10

11

Confirm that the foundation has been released for Coating and Backfill

Confirm that the foundation has been coated with liquid membrane as require by specification

Confirm that the foundation has been covered with hardboard and overlain with polyethylene.

Confirm that fill is being laid in layers as required by the specification.

Confirm that compaction test have been performed and results recorded.

COMMENTS :

SIGN OFF AS ACCEPTED

GAMA QATAR

Name

Position

Signature

Date

0.

LINDE

PEARL GTL

QSGTL PEARL PROJECT

C2 ASU Construction Works

FORM NO:

GAM-QCR-QAC-GTL-009

CONCRETE POUR CARD

Drawing and Rev.

No:

Complete Reference No. for Structure :

Date and Time Required

Date :

Class of Concrete

Delivery Intervals

Slump (mm)

No:

Quantity Required (m3)

Engineers

Inspection

ITEMS TO BE CHECKED

QC Status

BLINDING SATISFACTORY OR PREVIOUS CAST Q.C RELEASED

Coating of blind concrete

FORMWORK ERECTION SATISFACTORY :

DIMENSIONS / CLEANLINESS / OIL / SUPPORT TO BE CHECKED

REBAR INSTALLATION SATISFACTORY :

INSTALLED AS PER APPROVED DRAWING

EMBEDDED ITEM FIXING SATISFACTORY (ELECT. / MECH)

ANCHOR BOLTS (SEE SEPARATE SHEET)

PRE- POUR INSPECTION SATISFACTORY

THE ABOVE INDICATED ITEMS HAVE BEEN INSPECTED AND ARE READYY FOR Q.C VERIFACATION

Site Engineer

Or

Superintendent

Date:

Name:

Signature:

Time:

COMMENTS:

THE ABOVE LOCATION HAS BEEN INSPECTED PROR TO PLACEMENT OF CONCRETE AND THE WORK VERIFIED AS

CONFORMANT : ALL DISCREPANCY REPORTS HAVE BEEN TECHNICALLY FINALIZED : QC HOLD RELEASED

THE APPENDED SIGNATURE CONFIRMS THAT THE ABOVE RECORD OF INSPECTION / TEST HAS BEEN VERIFIED BY

THE FOLLOWING PERSON:

Civil QC

Inspector

Name:

Signature:

Date:

THE APPENDED SIGNATURE GIVES APPROVAL FOR THE PLACEMENT OF CONCRETE DETAILED ABOVE

LINDE

Name:

Signature:

COMPANY

Name:

Signature:

T-4.234.541 Rev. O

Date:

Date:

Page 1 of 2

QSGTL PEARL PROJECT

C2 ASU Construction Works

FORM NO:

GAM-QCR-QAC-GTL-009

CONCRETE POUR CARD

Date :

Type of Structure

Complete Reference No. for Structure :

Date and Time Required

Drawing and Rev. No:

Class of Concrete

Delivery Intervals

ITEMS TO BE CHECKED

Slump (mm)

Quantity Required (m3)

Engineers

Inspection

Q.C Status

CHECK THAT RELEASED FROM ELECTRICAL AND MECHANICAL SECTION (IF

REQUIRED)

CHECK THAT EARTHWORK COMPACTION TEST PASSED IN CASE OF

BACKFILLING / FOR ROCK SURFACE ONLY VISUAL INSPECTION - NO

COMPACTION TEST.

CHECK MINIMUM BLINDING THICKNESS AS PER DRAWING.

CHECKED FOR CLEANLINESS.

ALL SETTING OUT VERIFIED BY THE SURVEYOR INCLUDING DIMENSIONS,

LOCATION AND LEVEL.

THE ABOVE INDICATED ITEMS HAVE BEEN INSPECTED AND ARE READYY FOR Q.C VERIFACATION

Name:

Signature:

Date:

Site Engineer

Or

Superintendent

Time:

COMMENTS:

THE ABOVE LOCATION HAS BEEN INSPECTED PROR TO PLACEMENT OF CONCRETE AND THE WORK VERIFIED AS

CONFORMANT : ALL DISCREPANCY REPORTS HAVE BEEN TECHNICALLY FINALIZED : QC HOLD RELEASED

THE APPENDED SIGNATURE CONFIRMS THAT THE ABOVE RECORD OF INSPECTION / TEST HAS BEEN VERIFIED BY

THE FOLLOWING PERSON:

Civil QC

Inspector

Name:

Signature:

Date:

THE APPENDED SIGNATURE GIVES APPROVAL FOR THE PLACEMENT OF CONCRETE DETAILED ABOVE

Name:

Signature:

Date:

LINDE

Name:

Signature:

Date:

COMPANY

Type of Structure

T-4.234.541 Rev. O

Page 2 of 2

QSGTL PEARL PROJECT

C2 ASU Construction Works

Record No. :

FRESH CONCRETE TEST

REPORT

ITP No. :

Inspection Gr :

GAM-ITP-QAC-GTL-

Form No: GAM-QCR-QAC-GTL-017

No. :

SAMPLE NO.

BATCH TIME

TIME of ARRIVAL

Laboratory :

Date :

DISCHARGE TIME

TIME of

DEPARTURE

CONCRETE

TIME TAKEN

TEMPERATURE (C)

SLUMP (mm)

CONCRETE

Remarks :

NUMBER OF CUBES

CAST

AIR

TOTAL

Full Name / Signature / Date

GAMA QATAR

T-4.234.541 Rev. O

MIX CODE

LINDE

QSGTL

CONCRETE

QUANTITY ( m3 )

LOCATION

QSGTL PEARL PROJECT

C2 ASU Construction Works

Record No. :

CONCRETE CUBE TEST

REPORT

ITP No. : GAM-ITP-QAC-GTL-

Form No: GAM-QCR-QAC-GTL-020

No. :

Cube

No.

Date:

Slump (mm)

7 - DAYS

LOAD

STRESS

7 - DAYS

LOAD

STRESS

7 - DAYS

LOAD

STRESS

7 - DAYS

MEAN

Inspection Gr :

Mix Type :

Laboratory :

Minimum Strength at 28 Days :

Date :

Week:

28 - DAYS

LOAD

STRESS

28 - DAYS

LOAD

Remarks :

STANDARD DEVIATIONS ARE THE PRECEEDING 40 RESULTS FOR 28 DAY AVERAGE

Full Name / Signature / Date

GAMA QATAR

T-4.234.541 Rev. O

LINDE

QSGTL

STRESS

28 - DAYS

LOAD

STRESS

28 - DAYS

MEAN

STANDART

DEVIATION

SITE CURING

28 DAYS

LOAD

STRESS

REMARKS

ASPHALT ROADS

REPORT NO:

Evaluation of finished surface

DATE:

Form No.: GAM-QCR-QAC-GTL-052

Road Description:_________________________________________________ Road Type:________________

Location :_________________________________________________________(attach sketch)

(grids, coordinates, stations)

Designated Road Base Material:___________________Drawing No.:________________ Rev.______________

EVALUATION OF ROAD SURFACE ELEVATIONS & TOLERANCES

Ref.

No.

Station & lane

Intended

Elev.

Actual

Elev.

Diff.

MM

Allow.

Tolerance

Surveyor

Signature

QC Status

Acc.

Def.

QC

Insp.

Signature

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

GAMA

LINDE

LINDE QC

QSGTL

Name

Position

Signature

Date

FORM NO -GAM-QCR-QAC-GTL-052

Page 1 of 2

Date.

ASPHALT ROADS

REPORT NO:

Evaluation of finished surface

DATE:

Form No.: GAM-QCR-QAC-GTL-052

Road Description:_________________________________________________ Road Type:________________

Location :_________________________________________________________(attach sketch)

(grids, coordinates, stations)

Designated Road Base Material:___________________Drawing No.:________________ Rev.______________

This section used for final inspection

ROAD MARKINGS & SIGNAGE

1 Confirm Road markings are as Drawings.

N/A YES

NO

2 Confirm all signs are in position as required by drawings.

N/A YES

NO

GAMA

LINDE

LINDE QC

QSGTL

Name

Position

Signature

Date

FORM NO -GAM-QCR-QAC-GTL-052

Page 2 of 2

ASPHALT ROADS

REPORT NO:

SUB-BASE

DATE:

Form No.: GAM-QCR-QAC-GTL-054

Road Description:_______________________________________ Road Type:________________

Location :_________________________________________________________(attach sketch)

(grids, coordinates, stations)

Designated Road Base Material:___________________Drawing No.:________________ Rev.

ITEM DESCRIPTION

QC

1

2

Station & lane

Intended

Actual

Diff.

Allow.

Surveyor

Elev.

Elev.

MM

Tolerance

Signature

QC Status

Acc.

Def.

Insp.

Date.

Signature

4

5

6

7

8

9

10

COMMENTS:

RELEASE FOR PRIME COAT

GAMA

Name

Position

Signature

Date

FORM NO: GAM-QCR-QAC-GTL-054

LINDE

LINDE QC

QSGTL

You might also like

- 009-Civil-Ms Concrete Works PDFDocument27 pages009-Civil-Ms Concrete Works PDFKöksal PatanNo ratings yet

- 010-MS For Grouting PDFDocument33 pages010-MS For Grouting PDFKöksal PatanNo ratings yet

- 004-Civil - MS Construction of Temporary Roads PDFDocument17 pages004-Civil - MS Construction of Temporary Roads PDFKöksal Patan100% (2)

- 005-CIVIL-MS Disposal of Excavated Materials PDFDocument15 pages005-CIVIL-MS Disposal of Excavated Materials PDFKöksal PatanNo ratings yet

- 027-PRO For MONITORING OF CONCRETE FOUNDATIONS PDFDocument9 pages027-PRO For MONITORING OF CONCRETE FOUNDATIONS PDFKöksal PatanNo ratings yet

- 004-MS For Erection of Equipment Platforms, Handrails, Gratings, Stairways PDFDocument9 pages004-MS For Erection of Equipment Platforms, Handrails, Gratings, Stairways PDFKöksal Patan100% (1)

- RT Mod MS 001Document10 pagesRT Mod MS 001Kelly BatesNo ratings yet

- GD Earth Works R2Document22 pagesGD Earth Works R2sivaprasad_2k11No ratings yet

- 022-PRO For FENCE & GATE PDFDocument14 pages022-PRO For FENCE & GATE PDFKöksal Patan100% (1)

- 008-CIVIL-MS Backfilling Works PDFDocument16 pages008-CIVIL-MS Backfilling Works PDFKöksal Patan100% (1)

- 022-Itp For Fence & Gate PDFDocument5 pages022-Itp For Fence & Gate PDFKöksal Patan83% (6)

- 022 Itp For Fence Gate PDFDocument5 pages022 Itp For Fence Gate PDFJithesh.k.sNo ratings yet

- Method of Statment CONCRETEDocument7 pagesMethod of Statment CONCRETESyed AtherNo ratings yet

- 013-MS Utilization of Hilti DX 76 PDFDocument51 pages013-MS Utilization of Hilti DX 76 PDFKöksal PatanNo ratings yet

- Renovation Works at Al Forsan Sports ResortDocument7 pagesRenovation Works at Al Forsan Sports ResortAshimolowo BabatundeNo ratings yet

- 039-Itp For Embedded Plate PDFDocument7 pages039-Itp For Embedded Plate PDFKöksal PatanNo ratings yet

- Method Statement Excavation Civil WorksDocument9 pagesMethod Statement Excavation Civil WorksRanjith GabrielNo ratings yet

- Asphalt Concrete PavingDocument16 pagesAsphalt Concrete Pavingprobook450_ehsanNo ratings yet

- 31 32 13 Cement Stabilization PDFDocument7 pages31 32 13 Cement Stabilization PDFJUAN RULFONo ratings yet

- SKANDHANSHI INFRA PROJECTS EXCAVATION METHOD STATEMENTDocument6 pagesSKANDHANSHI INFRA PROJECTS EXCAVATION METHOD STATEMENTVinod MasaniNo ratings yet

- Method of Statement For Excavation, Trenching, Backfilling & Compaction WorkDocument9 pagesMethod of Statement For Excavation, Trenching, Backfilling & Compaction WorkAhmed Ibrahim100% (1)

- ITP Clearing and GrubbingDocument12 pagesITP Clearing and GrubbingAntonio Tomas Gonzalez LosaNo ratings yet

- Method Statement-Excavation Sipchem JubailDocument8 pagesMethod Statement-Excavation Sipchem JubailzanemtNo ratings yet

- 002-PDS-CON-010 Method Statement For Site Preparation WorksDocument15 pages002-PDS-CON-010 Method Statement For Site Preparation WorksMalik ZamanNo ratings yet

- ITP C 005 (Structural Concrete)Document4 pagesITP C 005 (Structural Concrete)segun ajibolaNo ratings yet

- ITP-00010 Pavement Road WorksDocument3 pagesITP-00010 Pavement Road WorksIsmail MydeenNo ratings yet

- EN131528-TCCSA-CS-M04-0003 (02) - Method Statement For Mass Concrete ConstructionDocument32 pagesEN131528-TCCSA-CS-M04-0003 (02) - Method Statement For Mass Concrete Construction章宇No ratings yet

- MS-001-Form Work, Reinforcement Steel & Concrete WorksDocument12 pagesMS-001-Form Work, Reinforcement Steel & Concrete WorksFrancis Phillip CapistranoNo ratings yet

- Inspection and Test Plan For Earthworks NSCR-PSC-N05-CRKDPT-PRO-QA-000000Document7 pagesInspection and Test Plan For Earthworks NSCR-PSC-N05-CRKDPT-PRO-QA-000000ResearcherNo ratings yet

- MS - Road and PavingDocument15 pagesMS - Road and PavingbukhoriNo ratings yet

- QA/QC Plan Ensures Project ComplianceDocument18 pagesQA/QC Plan Ensures Project ComplianceSen IMO67% (3)

- Earthwork Excavation-Method StatementDocument4 pagesEarthwork Excavation-Method StatementKhaled AbdelbakiNo ratings yet

- 30.99.97.1616 Rev. 1 - ITP For Civil WorksDocument26 pages30.99.97.1616 Rev. 1 - ITP For Civil Worksshajahan eNo ratings yet

- 021-Itp For Site Preparation and Earth Works PDFDocument6 pages021-Itp For Site Preparation and Earth Works PDFKöksal Patan100% (2)

- rev01-METHOD STATEMENT FOR INSTALLATION OF LINER TANK FOUNDATIONDocument7 pagesrev01-METHOD STATEMENT FOR INSTALLATION OF LINER TANK FOUNDATIONMahaboob PashaNo ratings yet

- Excavation and Backfill Inspection PlanDocument9 pagesExcavation and Backfill Inspection PlanShewale PravinNo ratings yet

- Site Quality Observation Report #3 Tabuk-J&PDocument15 pagesSite Quality Observation Report #3 Tabuk-J&PmasahinNo ratings yet

- Kas-Cc JC - BS2P2 - MS - Qa-010 - Box - Culvert - Casted - in Situ - Rev.0Document16 pagesKas-Cc JC - BS2P2 - MS - Qa-010 - Box - Culvert - Casted - in Situ - Rev.0Antonio Tomas Gonzalez LosaNo ratings yet

- Excavation Method StatementDocument6 pagesExcavation Method StatementWaleed SalihNo ratings yet

- T-242 - Method Statement For Excavation & BackfillDocument9 pagesT-242 - Method Statement For Excavation & Backfillsindalisindi100% (1)

- Traffic Signage Installation ITPDocument1 pageTraffic Signage Installation ITPmoytabura96No ratings yet

- Concrete Work: (Please Provide Detail of Repair Activities E.G)Document2 pagesConcrete Work: (Please Provide Detail of Repair Activities E.G)Eze NonsoNo ratings yet

- 028-Itp For Building Works PDFDocument10 pages028-Itp For Building Works PDFKöksal Patan100% (3)

- MS Traffic Signs Installations (Rev. 01)Document6 pagesMS Traffic Signs Installations (Rev. 01)moytabura96100% (1)

- Method Statement For Installation Anchor BoltsDocument7 pagesMethod Statement For Installation Anchor BoltsSyed AtherNo ratings yet

- Mobilization Plan PDFDocument26 pagesMobilization Plan PDFManuel GutierrezNo ratings yet

- 025-ITP For Sewer & Drainage PDFDocument6 pages025-ITP For Sewer & Drainage PDFKöksal PatanNo ratings yet

- Civil Quality Control Plan EarthworksDocument3 pagesCivil Quality Control Plan Earthworksroekyat hendrawanNo ratings yet

- Project: Mars Factory Extension Project at Jafza: Consultant Client ContractorDocument9 pagesProject: Mars Factory Extension Project at Jafza: Consultant Client ContractorAzhar Shaikh100% (1)

- 3009 - Method Statement For Administration Building Construction PDFDocument38 pages3009 - Method Statement For Administration Building Construction PDFNjilou LagaticNo ratings yet

- ITP For RC RC Slab, Beams WorkDocument3 pagesITP For RC RC Slab, Beams WorkMohammed Ghareib NasrNo ratings yet

- ItpDocument7 pagesItpJose Sherin100% (1)

- 01-ABC Subcontract Plan.-Rev.01Document6 pages01-ABC Subcontract Plan.-Rev.01Shahid BhattiNo ratings yet

- Method Statement For Chamber Construction of TSE Line Ev ManagerDocument20 pagesMethod Statement For Chamber Construction of TSE Line Ev ManagerBleep News100% (1)

- Method Statement For The, Gulf Eagle Project: Installation, Commissioning & Load Testing of CraneDocument14 pagesMethod Statement For The, Gulf Eagle Project: Installation, Commissioning & Load Testing of CraneFAYIZNo ratings yet

- Block Work Masonry MethodologyDocument4 pagesBlock Work Masonry MethodologyEyutt HghghNo ratings yet

- Construction Method StatementDocument18 pagesConstruction Method StatementAziz RahmanNo ratings yet

- Client:: Inspection & Test Plan For Excavation WorksDocument3 pagesClient:: Inspection & Test Plan For Excavation WorksAnonymous PxHPgLNo ratings yet

- METHOD STATEMENT DRAINAGE CONSTRUCTIONDocument9 pagesMETHOD STATEMENT DRAINAGE CONSTRUCTIONAishah AliasNo ratings yet

- 017-CIVIL-MS For Installation of Fence & Gate PDFDocument18 pages017-CIVIL-MS For Installation of Fence & Gate PDFKöksal Patan100% (6)

- 015-Method Statement For Painting Works (Building) PDFDocument21 pages015-Method Statement For Painting Works (Building) PDFKöksal Patan86% (21)

- 016-CIVIL - MS Anchor Bolt Installation PDFDocument14 pages016-CIVIL - MS Anchor Bolt Installation PDFKöksal Patan71% (7)

- 013-MS Utilization of Hilti DX 76 PDFDocument51 pages013-MS Utilization of Hilti DX 76 PDFKöksal PatanNo ratings yet

- 014-MS For Bolt Tightening (Piping& Equipments) PDFDocument23 pages014-MS For Bolt Tightening (Piping& Equipments) PDFKöksal PatanNo ratings yet

- 015-MS For Night Works PDFDocument16 pages015-MS For Night Works PDFKöksal Patan80% (5)

- 014-MS For General Scaffolding PDFDocument33 pages014-MS For General Scaffolding PDFKöksal Patan100% (2)

- 050-Itp For Installation of Air Intake Filter PDFDocument17 pages050-Itp For Installation of Air Intake Filter PDFKöksal PatanNo ratings yet

- 010-MS For Welding and Hot Works For General Activities at TSF Area PDFDocument17 pages010-MS For Welding and Hot Works For General Activities at TSF Area PDFKöksal PatanNo ratings yet

- 012-Civil - MS Ag and Ug Coating of Concrete Surfaces PDFDocument18 pages012-Civil - MS Ag and Ug Coating of Concrete Surfaces PDFKöksal PatanNo ratings yet

- 013-MS For Mass Concrete Works PDFDocument26 pages013-MS For Mass Concrete Works PDFKöksal Patan100% (1)

- 047-Itp For Oxygen Lines Fabrication and Installation PDFDocument28 pages047-Itp For Oxygen Lines Fabrication and Installation PDFKöksal PatanNo ratings yet

- 049-Itp For Lighting and Small Power (Building) PDFDocument15 pages049-Itp For Lighting and Small Power (Building) PDFKöksal Patan100% (1)

- 012-MS For Wall Cladding, Roof Cladding & Life Line Installation PDFDocument16 pages012-MS For Wall Cladding, Roof Cladding & Life Line Installation PDFKöksal Patan91% (11)

- 048-Itp For Installation of Hvac Unit PDFDocument8 pages048-Itp For Installation of Hvac Unit PDFKöksal Patan100% (4)

- 009-Method Statement - Main Erection Sequence For Acc PDFDocument68 pages009-Method Statement - Main Erection Sequence For Acc PDFKöksal Patan100% (6)

- 011-Method Statement For Repair of Concrete Works PDFDocument25 pages011-Method Statement For Repair of Concrete Works PDFKöksal Patan91% (33)

- 046-ITP For INSTALLATION OF MAC-BAC-ST MACHINERY UNIT PDFDocument18 pages046-ITP For INSTALLATION OF MAC-BAC-ST MACHINERY UNIT PDFKöksal PatanNo ratings yet

- 008-MS For Prefabrication of CS, TT & CN Pipe Spools PDFDocument23 pages008-MS For Prefabrication of CS, TT & CN Pipe Spools PDFKöksal PatanNo ratings yet

- 045-ITP For MASONRY & PLASTERING WORKS (Buildings) PDFDocument10 pages045-ITP For MASONRY & PLASTERING WORKS (Buildings) PDFKöksal Patan83% (12)

- 008-CIVIL-MS Backfilling Works PDFDocument16 pages008-CIVIL-MS Backfilling Works PDFKöksal Patan100% (1)

- 044-ITP For Installation of Gypsum Board (Buildings) PDFDocument10 pages044-ITP For Installation of Gypsum Board (Buildings) PDFKöksal Patan100% (3)

- 043-ITP FOR Water Proofing (Buildings) PDFDocument13 pages043-ITP FOR Water Proofing (Buildings) PDFKöksal Patan100% (3)

- 041 - ITP For Painting (Building) PDFDocument12 pages041 - ITP For Painting (Building) PDFKöksal Patan78% (9)

- 040-ITP For Repair of Steam Distribution Manifold PDFDocument11 pages040-ITP For Repair of Steam Distribution Manifold PDFKöksal PatanNo ratings yet

- 038-Itp For Coldboxes PDFDocument25 pages038-Itp For Coldboxes PDFKöksal PatanNo ratings yet

- 039-Itp For Embedded Plate PDFDocument7 pages039-Itp For Embedded Plate PDFKöksal PatanNo ratings yet

- 007-MS For Structural Steel Assembly Warehouse, Workshops PDFDocument25 pages007-MS For Structural Steel Assembly Warehouse, Workshops PDFKöksal PatanNo ratings yet

- Sika Igasol - 17: High Build, Bituminous Emulsion CoatingDocument3 pagesSika Igasol - 17: High Build, Bituminous Emulsion CoatingAhmed AbdallahNo ratings yet

- As 1160-1996Document18 pagesAs 1160-1996Alexandru LetNo ratings yet

- MIX DESIGN DBM Well SpunDocument30 pagesMIX DESIGN DBM Well SpunTarun100% (2)

- COE Tender for NMT Infrastructure ConstructionDocument43 pagesCOE Tender for NMT Infrastructure ConstructionerkiyhunNo ratings yet

- BAUTEST Accreditation AnnexDocument28 pagesBAUTEST Accreditation AnnexrcNo ratings yet

- A Mini Project On Design of Flexible PavementDocument94 pagesA Mini Project On Design of Flexible Pavementsohail irfanNo ratings yet

- Case Study - Strategic Management - ChevronDocument66 pagesCase Study - Strategic Management - ChevronThanos PitatzisNo ratings yet

- Roof Inspection ChecklistDocument4 pagesRoof Inspection Checklistpanjemadjo100% (1)

- Astm D-113 PDFDocument3 pagesAstm D-113 PDFjulianovmNo ratings yet

- 32 00 00 Exterior Improvements: 32 01 16 Flexible Paving RehabilitationDocument9 pages32 00 00 Exterior Improvements: 32 01 16 Flexible Paving RehabilitationAnonymous Wj1DqbENo ratings yet

- FCE345 Highway MaterialsDocument43 pagesFCE345 Highway Materialsjava nameNo ratings yet

- BitucellDocument2 pagesBitucellDillesh ReddyNo ratings yet

- Mastic-Mix DesignDocument10 pagesMastic-Mix DesignVaasu KotyadaNo ratings yet

- Prep o Ion of Cutback BitumenDocument18 pagesPrep o Ion of Cutback BitumenRupesh KumarNo ratings yet

- Determining The Permanent Shear Strain and Stiffness of Asphalt Mixtures Using The Superpave Shear Tester (SST)Document12 pagesDetermining The Permanent Shear Strain and Stiffness of Asphalt Mixtures Using The Superpave Shear Tester (SST)РостNo ratings yet

- Management: Annual Report 009Document17 pagesManagement: Annual Report 009ChrisYapNo ratings yet

- Aashto T 269-111 - Astm D 3203-05Document4 pagesAashto T 269-111 - Astm D 3203-05iipmnpti iipmNo ratings yet

- Typical LiquidsDocument94 pagesTypical LiquidsChevronelleNo ratings yet

- Brochure PDFDocument2 pagesBrochure PDFzzzs9554No ratings yet

- TankingDocument14 pagesTankingSameer JagadeNo ratings yet

- Maintenance of National Road No. 3 in CambodiaDocument20 pagesMaintenance of National Road No. 3 in Cambodiaroldski90% (10)

- SHRP A 407Document184 pagesSHRP A 407adji234No ratings yet

- SSR W.E.F. 01.09.2017Document41 pagesSSR W.E.F. 01.09.2017Mayank AwasthiNo ratings yet

- Determining Demulsibility of Emulsified Asphalt: Standard Test Method ForDocument2 pagesDetermining Demulsibility of Emulsified Asphalt: Standard Test Method ForROBERTO MIRANDANo ratings yet

- Laboratory Manual On Advanced Pavement Engg - IISc Bangalore - CiSTUPDocument54 pagesLaboratory Manual On Advanced Pavement Engg - IISc Bangalore - CiSTUPSantosh KumarNo ratings yet

- BS 743 1970 - Materials For Damp-Proof Courses PDFDocument13 pagesBS 743 1970 - Materials For Damp-Proof Courses PDFhenryNo ratings yet

- A Major ProjectDocument16 pagesA Major ProjectRajuNo ratings yet

- Military Camp Daily Construction ProgressDocument44 pagesMilitary Camp Daily Construction ProgressRyan TagaNo ratings yet

- Nitoproof 30 IndonesiaDocument3 pagesNitoproof 30 IndonesiahenzaiNo ratings yet

- Keyword 4: Keyword: Strength of The Mixture of AsphaltDocument2 pagesKeyword 4: Keyword: Strength of The Mixture of AsphaltJohn Michael GeneralNo ratings yet