Professional Documents

Culture Documents

005-Ms-Painting and Repair Works PDF

Uploaded by

Köksal PatanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

005-Ms-Painting and Repair Works PDF

Uploaded by

Köksal PatanCopyright:

Available Formats

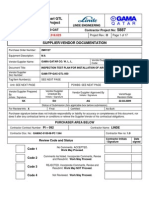

Pearl GTL

Project

Shell Project No: HP-3000-QAT

Project Document Number: T- 4.250.900

Purchase Order Number:

2MH127

Tag/Item Number(s):

N/A

Unit(s):

ASU

PCWBS:

LINDE ENGINEERING

Contractor Project No:

Project Rev.: B

Page 2 of 21

5887

QATAR SHELL GTL PROJECT (PEARL)

C2 AIR SEPARATION UNITS CONSTRUCTION

06.10.08

Ready For Constructions

SK

EO

AG

RFC

31.05.08

Ready For Constructions

FB

EO

AG

RFC

26.11.07

Issued for Company comments

BR

AU/MC

ZG

ICC

23.11.07

Issued for Review

BR

AU/MC

ZG

IFR

20.11.07

Issued for Internal Review

BR

AU/MC

ZG

IIR

Date

Description

GAMA

Rev.

No.

Project

Rev

No.

Prepared Checked Approved

By

By

By

ORIGINATOR

Status

Document Title:

LINDEGINEERING AG

METHOD STATEMENT FOR PAINTING AND REPAIR

WORKS(PIPING,EQUIPMENT&STEEL STRUCTURES)

Document No.

Contractor

Gama Qatar Co. W. L. L.

LOC470

GAM

MTS

MEC

GTL

005

Org.

Code

Doc.

Type

Disc.

Code

Geogr.

Area

Seq.

No

Rev.

No

Project Document Number: T-4.250.900

Vendor Code

Rev No: B

Q A T A R

Doc. Title

GAM-MTS-MEC-GTL-005

MS FOR PAINTING AND REPAIR

WORKS(PIPING,EQUIPMENTS&STEEL STRUCTURES)

Date

06.10.08 REV-E

TABLE OF CONTENTS

1.

SCOPE _____________________________________________________________________________ 5

2.

PURPOSE __________________________________________________________________________ 5

3.

HSSE ______________________________________________________________________________ 5

4.

REFERENCE _______________________________________________________________________ 5

5.

DEFINITIONS ______________________________________________________________________ 6

6.

RESPONSIBILITIES _________________________________________________________________ 6

6.1.

Structural Erection Superintendent ________________________________________________________ 6

6.2.

Painting Engineer _______________________________________________________________________ 6

6.3.

Painting Inspector_______________________________________________________________________ 6

7.

PERSONNEL SAFETY ________________________________________________________________ 7

8.

GENERAL __________________________________________________________________________ 7

9.

SURFACES PREPARATIONS__________________________________________________________ 7

10.

REPAIR OF DAMAGED GALVANISING&PAINTING: __________________________________ 8

11.

PAINTING APPLICATION __________________________________________________________ 9

11.1.

General _______________________________________________________________________________ 9

11.2.

Storage of materials ____________________________________________________________________ 10

11.3.

Surface condition ______________________________________________________________________ 10

11.4.

Ambient conditions _____________________________________________________________________ 10

11.5.

Equipment ____________________________________________________________________________ 10

11.6.

Application ___________________________________________________________________________ 10

12.

CALIBRATION ___________________________________________________________________ 11

13.

INSPECTION ____________________________________________________________________ 11

13.1.

Equipment ____________________________________________________________________________ 11

13.2.

Testing _______________________________________________________________________________ 11

14.

RECORDING _____________________________________________________________________ 11

15.

QUALITY ASSURANCE ____________________________________________________________ 12

16.

ATTACHMENTS __________________________________________________________________ 12

T-4.250.900 Rev. B

Page 4

of 21

Q A T A R

Doc. Title

GAM-MTS-MEC-GTL-005

MS FOR PAINTING AND REPAIR

WORKS(PIPING,EQUIPMENTS&STEEL STRUCTURES)

Date

06.10.08 REV-E

1. SCOPE

This Method Statements applies to the cleaning and Painting of Pipe spools and paints touch up

on hot-dip galvanized steel structures and equipments for C2 ASU Pearl GTL Project by GAMA

Qatar located inside the Ras Laffan Industrial City in Qatar.

2. PURPOSE

The main purpose of this Method Statements is to describe the minimum requirements and

responsibilities of activities associated with the painting and touch up to ensure that the activities

are carried out according to the project requirements.

3. HSSE

All works shall be in compliance with the State of Qatar laws and regulations, Ras Laffan Industrial

City and International standards, codes, LINDE ENGINEERING AG and QSGTL and/or its PMC

requirements and instructions.

In addition all employees and GAMA subcontractor employees on site will have through LINDE

ENGINEERING AG Site Safety Induction and GAMA Qatar Safety induction for site safety, health,

environmental and security prior to work activities. Other training courses will be attended as

required by LINDE ENGINEERING AG or QSGTL and/or its PMC as required.

At a minimum a Risk Assessment will have been prepared by the Risk Assessment Team (RAT)

ranking the hazards associated with project works and control measures to be taken to mitigate

the hazards to an acceptable level.

Each work scope or task will have a completed and approved Job Safety Analysis (JSA)

identifying the potential hazards and control measures that will be implemented to protect people

and environment. Supervisor as the basis of conducting his daily Pre-Task meeting and his

weekly Tool Box Talk (TBT) will use the JSA.

In addition to the above, employees conducting survey works will wear required PPE and highly

visible vest where traffic or other hazards may exist. For additional safety requirements for a

particular or specific task please refer to the JSA prepared for that

4. REFERENCE

SSPC-SP1

SSPC-SP2

SSPC-SP3

DEP 30.48.00.31 GEN

T-13.376.799

T-4.250.927

T-4.250.900 Rev. B

Solvent cleaning

Hand tool cleaning

Power tool cleaning

Painting and Coating of new Equipment

Painting and Coating of New Equipment (Amendments)

Material Handling, Storage and Preservation Procedure

Page 5

of 21

Q A T A R

Doc. Title

GAM-MTS-MEC-GTL-005

MS FOR PAINTING AND REPAIR

WORKS(PIPING,EQUIPMENTS&STEEL STRUCTURES)

Date

06.10.08 REV-E

T-4.250-915

T-4.250.919

T-4.250.916

Calibration Procedure

ITP for Painting and Coating

Procedure for Shop and Field Painting work at site

5. DEFINITIONS

Company: QSGTL/or its PMC

Contractor: LINDE ENGINEERING AG

Sub Contractor: GAMA QATAR

Contract: C2 ASU PEARL GTL Project

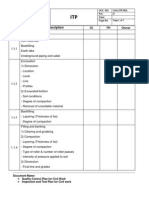

ITP: Inspection and Test Plan

QA/QC: Quality Assurance / Quality Control

TPI: Third Party Inspection

6. RESPONSIBILITIES

STRUCTURAL ERECTION SUPERINTENDENT

He is responsible to verify the availability of the materials, equipment and tools

Required for Touch up operation (brush and disks for cleaning, paint etc).

PAINTING ENGINEER

He is responsible but not limited to as follows:

Ensuring that inspection and records are made in accordance to GAMA-QATAR

ITP and Contractor specification requirements.

Provide notification to Contractor 24 hours in advance before the inspections

indicated in the ITP, only for Witnessing (W) and Hold Point (H).

Keeping and filing all inspection reports/records and maintaining them as per DEP30.48.0031 and Contractor requirements.

PAINTING INSPECTOR

He is responsible but not limited to as follows:

Verify identification of paint and correct preservation.

Perform inspection on the surfaces before and after touch up according to

Procedure, Specification and GAMA-QATAR ITP requirements.

Notification to Contractor 24 hours before the touch up operation indicated in the

ITP.

Issue and sign the record and providing for Contractor inspector signature of record

as required.

T-4.250.900 Rev. B

Page 6

of 21

Q A T A R

Doc. Title

GAM-MTS-MEC-GTL-005

MS FOR PAINTING AND REPAIR

WORKS(PIPING,EQUIPMENTS&STEEL STRUCTURES)

Date

06.10.08 REV-E

Verify batch number, expire date, shelf life against Material Certificates and Material

Data Sheets

Ensure that the paint is not used after expiry date or shelf life

Ensure that climatic conditions are suitable for surface preparation and painting.

7. PERSONNEL SAFETY

All the necessary Personnel Safety equipment including goggles, masks and other protective

equipment recommended by Manufacturer shall be provided.

8. GENERAL

Damaged areas of hot dip galvanised surfaces of structural steelwork which has sustained

mechanical damage during either transportation or erection shall be repaired using an organic

zinc-rich coating containing not less than 90% zinc by weight in the dry film, as per the

DEP-30.48.00.31-painting & coating of New Equipment.

All damaged areas of hot dipped galvanised steelwork that is fabricated or modified by cutting;

welding etc. on site shall be repaired using a DEP-30.48.0031 painting & coating of New

Equipment.

The damaged area shall be re-cleaned as originally specified for that item and the full coating

system re-applied in accordance with the manufacturers application datas.

9. SURFACES PREPARATION

The surfaces shall be cleaned with following operations:

9.1) STRUCTURAL STEEL WORKS

a) For structural steelwork which has sustained mechanical damage during either

transportation or erection:

Solvent cleaning: from the surfaces shall be removed all foreign matter as oil, grease,

soil, salts or other contaminants by solvents, emulsions or other suitable method

The surface shall be cleaned by electric or air operated power wire brushes and or power

disc needle guns.

Surface preparation shall extend onto the undamaged galvanized coating for

approximately 25mm. After cleaning dry air shall be blown on the surfaces.

b) For Hot dip Galvanising touch up structural steelwork fabricated or modified by

Cutting, welding etc. on site:

Where galvanising is a standard, hot-dip galvanise in accordance with BS EN ISO 1461

or ASTM A123 as appropriate. Surfaces that require to be galvanised shall be prepared

by either organic solvent or alkaline cleaning followed by acid pickling or dry abrasive

T-4.250.900 Rev. B

Page 7

of 21

Q A T A R

Doc. Title

GAM-MTS-MEC-GTL-005

MS FOR PAINTING AND REPAIR

WORKS(PIPING,EQUIPMENTS&STEEL STRUCTURES)

Date

06.10.08 REV-E

blast cleaning and the requisite fluxing pre-treatment to dissolve and absorb any

remaining impurities on the metal surface after pickling. Steel surfaces shall then be zinc

coated (hot dip galvanised) for a zinc coating weight according to the steel thickness as

specified in Tables 1 and 2 of ASTM 123. The minimum coating weight for structural

shapes 6.4 mm thick or over shall be 710 g/m2, equivalent to a coating thickness of 100

microns.

Visible oil, grease or other surface contaminants shall be removed with a detergent

solution, clean fresh water used to rinse off the detergent solution and the damaged area

is allowed to dry.

All flux residues and weld spatter shall be removed from the weld areas.

9.2) FOR SURFACE PREPARATION (SHOP AND FIELD) ABOVE AND BELOW

GROUND

Visible oil, grease and soil shall be removed by solvent cleaning, area shall be washed in

clean fresh water and allowed to dry before conventional (air blast) cleaning, automatic

(wheel blast) or hand/power cleaning. GAMA Qatar Quality Department shall perform

surveillance to ensure cleaning is performed adequately, where applicable.

The surface shall be prepared prior to application of primer or paint by abrasive blasting

(paint shop application) or by hand tool/abrasive blasting (field application).The

method of surface preparation shall be recorded on form GAM-QCR-QAC-GTL-055.

Steel defects revealed during abrasive blasting (silvers, laminations, cracks, pitting etc.,)

shall be reported to the LINDE /SHELL/PMC for evaluation. Defects will be repaired as

directed by the LINDE /SHELL/PMC Representative.

Pipe ends and fitting ends shall be left uncoated for a distance of 50mm at shop

Field welds and damaged coating shall be made ready for painting application using

hand or power tools and then fully coated as applicable.

All blast cleaned surfaces shall be inspected for proper cleaning and anchor profile in

accordance with SSPC Specification and as per Project specification.

10. REPAIR OF DAMAGED GALVANISING AND PAINTING WORKS:

10.1 Damaged Galvanizing

Damaged hot dip galvanised coating shall be repaired as follows. Corrosion or other damage

shall be removed using light sweeps of an orbital sander. A 25mm band of sound galvanizing

around the damaged area shall be carefully feathered down to bare steel. Residual oil or

grease within the repair zone will be removed using a patent degreaser in accordance with

the manufacturers recommendations. On completion preparation surfaces shall be scrubbed

and rinsed with fresh water. When the areas to be repair coated are dry a zinc rich paint

(RESISTEX L722 or approved equal) shall be brush applied in accordance with the

manufacturers instructions to achieve the same thickness as that of the original galvanizing

(minimum 100 microns DFT). The repair coating shall be overlapped onto the feathered edge

of the existing galvanising

T-4.250.900 Rev. B

Page 8

of 21

Q A T A R

Doc. Title

GAM-MTS-MEC-GTL-005

MS FOR PAINTING AND REPAIR

WORKS(PIPING,EQUIPMENTS&STEEL STRUCTURES)

Date

06.10.08 REV-E

10.2 Damaged Painting for Piping

Any repair of damaged coating shall be cleaned by hand tools or power tools in

accordance with ISO 8501-1 grade st 3 and documented on form GAM-QCR-QAC-GTL056

Any repair areas shall be feathered into the undamaged coating a minimum of 50 mm.

Repair shall be performed prior to the subsequent coat.

Any damage or repair shall be performed prior to the next coat application. Coating of

weld joints shall be in accordance with original paint application as specified in Project

specification.

For item such as equipment already painted by a supplier, GAMA Qatar shall use the

same paint or an equivalent and compatible paint approved by the supplier.

Repair of damaged surfaces of zinc silicate primer shall be performed as detailed in the

Project specification.

Any holidays, defects and unacceptable work shall be repaired in accordance with

manufacturer's recommendations. Holidays should be generally ground to bare metal

feathering the adjacent sound coating back a minimum of 25mm.

11. PAINTING APPLICATION

GENERAL

After preparation of the substrate surface, any grit, dust etc.Shall be removed and the

layer of primer applied before any corrosion or recontamination occurs, normally within

four hours after blasting. As per DEP 30.48.00.31-painting & coating of new equipment.

Prepared surfaces shall be dry, free of rust, mill scale, dust, oil, grease or other visible

contamination.

When the thicknesses are too thin, additional layers of the same product shall be

applied according with the manufacturer instructions to reach the thickness required.

As a general rule, the painting shall be applied by means of brush or roller as

recommended by Manufacturer.

Two pack components shall be mixed as per Manufacturers recommendation.

Mixed paint shall not be used beyond their pot life.

T-4.250.900 Rev. B

Page 9

of 21

Q A T A R

Doc. Title

GAM-MTS-MEC-GTL-005

MS FOR PAINTING AND REPAIR

WORKS(PIPING,EQUIPMENTS&STEEL STRUCTURES)

Date

06.10.08 REV-E

STORAGE OF MATERIALS

All painting materials shall be furnished by the painting manufacturer in original

unopened containers bearing the label and instructions of the painting manufacturer

(as batch number, construction date, safety precautions etc.).

Painting materials shall be stored according to safety regulations and

Manufacturers recommendation.

Paint shall not be mixed or stored in contaminated containers.

SURFACE CONDITION

Surface shall be cleaned, dry and free from dust during application of painting.

No painting shall be applied with the surface temperature is less than 3 C (5 F) above

the dew point or the ambient air temperature is less than 5 C and the relative humidity

of the air measured in the vicinity of surface to be painted is greater than 85% or when

the air temperature is > 40 C, these values can be modified if other wise

recommended by painting manufacturer.

AMBIENT CONDITIONS

Painting shall not be applied during exposure to inclement weather conditions (e.g.

high winds, rain or airborne dust).

EQUIPMENT

For touch-up or repairs to the localised damaged areas, weld or other irregular

surfaces, provided that the manufacturer considers the painting material suitable for

brush or roller shall be used for small areas in accordance with the Manufactures

recommendations.

Spray equipment shall be in compliance with the painting manufacturer's instructions

(e.g. nozzle tips, spray angle, pressure etc.).

APPLICATION

The paints shall be applied uniformly on the entire surface.

All defective work or work not conforming to specification shall be repaired according to

this procedure.

Repairs shall be carried out as per DEP 30.48.00.31 and its amendment T-13.376.799

T-4.250.900 Rev. B

Page 10

of 21

Q A T A R

Doc. Title

GAM-MTS-MEC-GTL-005

MS FOR PAINTING AND REPAIR

WORKS(PIPING,EQUIPMENTS&STEEL STRUCTURES)

Date

06.10.08 REV-E

12. CALIBRATION

All inspection, measuring and test equipment shall be calibrated in accordance

With Gama-Qatar Equipment and instrument calibration procedure T-4.250-915

13. INSPECTION

The entire surface preparation and application works shall be subject to inspection, according

to this Method statements and applicable ITPs.

EQUIPMENT

Electro magnetic D.F.T. gauge (Elcometer or equivalent);

Steel surface thermometer;

Wind, Temperature and Humidity meter (Kestrel 3000 or equivalent)

TESTING

Visual Inspection

Painting film should be inspected visually after application in order to verify that the

whole surface is free of defects as: blister, forces, flaking mechanical damage, sags

Repair of painting

Defective or damaged paintings shall be removed by hand tools or power tool until a

surface is cleaned and the new layer of paint can apply.

14. RECORDING

After painting operation, Gama-Qatar painting inspector shall prepare and sign off the GAMQCR-QAC-GTL-055 Painting Report & GAM-QCR-QAC-GTL-056 Touch up Report

(Procedure for Painting - GAM-PRO-QAC-GTL-032)

T-4.250.900 Rev. B

Page 11

of 21

Q A T A R

Doc. Title

GAM-MTS-MEC-GTL-005

MS FOR PAINTING AND REPAIR

WORKS(PIPING,EQUIPMENTS&STEEL STRUCTURES)

Date

06.10.08 REV-E

15. QUALITY ASSURANCE

A Quality Assurance System shall be operated conforming to related standards. Controls

and checks shall be established and documented through relevant QCP-T-4.250.916,

ITP-T-4.250.919 and QCRs.

16. ATTACHMENTS

JSA

T-4.250.900 Rev. B

Page 12

of 21

Q A T A R

JOB SAFETY ANALYSIS FORM

NEW

REVISED

JSA Number:

Job being analysed: Painting & repair touch up (Galvanizing)

Department/Section doing JSA:

HSSE & Construction

Normal Approvals:

Name

JSA by:

Page No:

JSA Members:

Job Performers:

Signature

Date

Job Supervisor:

Additional Approvals (Determined by Job Supervisor in correlation with LINDE HSSE Manager).

Name

Signature

Discipline Superindent(LINDE)

HSSE Representative(LINDE)

OTHERS(List Below):

Date

General job requirements / Common

Personnal Protective Equipment.

1. The following Personal Protective

Equipment shall be worn during galvanizing

activities: Approved chemical resistant

coveralls, safety glasses, safety helmet,

safety shoes and gloves.

2.Permit To Work.

Approval required for hazardous work detailed in the LINDE work permit procedure.

Changing conditions and emergency procedures

Stop work. Switch of equipment.Supervisor directs personnel to nearest and safest muster point considering wind direction. Supervisor counts all employees. Missing

employees are reported to LINDE HSSE Dept. When all clear is given check with LINDE HSSE before returning to work.

LINDE EMERGENCY TELEPHONE NO.

HSSE MANAGER:

HOT LINE :

Note: 1) If any of the tasks involves biological, physical or chemical hazards, then The LINDE Industrial Hygienist must also approve the work.

2)Use additional sheets as necessary.

3)Details on safety (PPE,Hazard etc) and environmental requirements can be found in LINDE and Shell Safety and Environment Procedures.

JOB SAFETY ANALYSIS / RISK ASSESSMENT

Q

Q A

A T

T A

A R

R

SCOPE : Painting & Repair Touchup

Initial Risk

ITEM

ACTIVITY

HAZARD / POTENTIAL

CONSEQUENCES

Cleaning &

1.1

Degreasing the pipe

surface.

P C

RANK

Skin irritation

1.1.1

1.2

Residual Risk

RISK

Vapor inhalation.

1.1.2

1.2.1

1.2.2

1.2.3

1.2.4

1.3

Eye injury.

1.3.1

2

1.4

Slip, trip fall same level.

1.4.1

2

CURRENT

CONTROLS

When using cleaning up chemicals,

1.1.1.1

chemical resistant PPE such as face

shield, face mask, helmet, aprons,

coverall, gloves and boots shall be

worn to protect against contact and

exposure.

Ensure a copy of MSDS for hazardous

substances, in a readily

understandable form, shall kept at the

job site at all times for workers

reference and use.

Approved respirators shall be worn to 1.2.1.1

prevent inhalation of chemical vapors,

where necessary.

Ventilate the area and/or use exhaust

at the area.

Ensure not to breathe the vapors while

applying cleaning solvent in the

surface.

Ensure a copy of MSDS for hazardous

substances, in a readily

understandable form, shall kept at the

job site at all times for workers

reference and use.

When using cleaning up chemicals,

chemical resistant PPE such as face

shield, face mask, helmet, aprons,

clothing, gloves and boots shall be

worn to protect against contact and

exposure.

Supervisor/foremen shall be

responsible for ensuring that after the

work of the day their areas are

cleaned up and kept tidy.

ADDITIONAL

CONTROLS

P C

Prior to entry of any chemical

substances into the site

MSDS shall be produced to

the LINDE HSSE Manager for

approval.

MSDS copies to be attached. 1

Prior to entry of any chemical

substances into the site

MSDS shall be produced to

the LINDE HSSE Manager for

1

approval.

JOB SAFETY ANALYSIS / RISK ASSESSMENT

Q

Q A

A T

T A

A R

R

SCOPE : Painting & Repair Touchup

Initial Risk

ITEM

ACTIVITY

Blasting Works.

HAZARD / POTENTIAL

CONSEQUENCES

2.1

P C

RANK

Unqualified personnel.

2.1.1

2

2.2

Residual Risk

RISK

Improper used of

equipment.

2.1.2

2.2.1

2

2.2.2

2.3

Electric shock.

2.3.1

2

2.3.2

2.3.3

CURRENT

CONTROLS

Only trained and experienced

personnel shall be assigned for

blasting operations.

The blast cleaning team shall include

at least one person responsible for the

operation and supply of the cleaning

material to the lance operators.

The cleaning team shall check daily

2.2.1.1

before starting work and whenever the

equipment is moved to ensure that

grounding and bonding of the

equipment and hoses are not worn or

faulty.

Air compressors and airlines shall be

inspected or tested before the

commencement of work, and

observed by a watchman during

The required precautions shall be

2.3.1.1

specified against electrostatic

discharges and shall include

grounding of metal casing and frame

of the compressor and all other metal

equipment in the area.

The lance must be fitted with a dead

man switch that, when released by the

operator, shuts-off the blast.

Grounding shall be provided for all

electrical equipment.Grounding cables

shall have their continuity and

conductivity checked by a competent

electrician.

ADDITIONAL

CONTROLS

The lance must be fitted with

a dead man switch that, when

released by the operator,

shuts-off the blast.

P C

A grounding wire with screw

clamp and grounding stake of

minimum 1 m. length, if

1

necessary, shall be provided

at the compressor and a

bonding wire connection to

the work piece shall be

provided at the cleaning lance.

JOB SAFETY ANALYSIS / RISK ASSESSMENT

Q

Q A

A T

T A

A R

R

SCOPE : Painting & Repair Touchup

Initial Risk

ITEM

ACTIVITY

HAZARD / POTENTIAL

CONSEQUENCES

2.4

P C

Residual Risk

RISK

RANK

Eye injury due to fine

grade grit blasting.

2.4.1

6

2.4.2

2.5

Fire Hazard

2.5.1

2

8

2.5.2

Chemical cleaning

and rinsing in clean

water.

3.1

Skin irritation to affected

open body parts.

3.1.1

3.1.2

CURRENT

CONTROLS

Workers shall wear safety helmets,

2.4.1.1

overalls with hoods, gloves, safety

boots, goggles, hearing protection and

respiratory protective equipment.

Overalls should be taped at the

ankles, cuffs and collars.

Ensure all necessary precautions shall 2.5.1.1

be taken for the absence of flammable

atmosphere including the air intake of

the air compressor.

Maintained at least one fully charged 9

kg multipurpose dry powder fire

extinguisher in the workplace,(within

15m).

When using cleaning up chemicals,

3.1.1.1

chemical resistant PPE such as face

shield, face mask, helmet, aprons,

approved coverall, gloves and boots

shall be worn to protect against

contact and exposure.

Ensure a copy of MSDS for hazardous

substances, in a readily

understandable form, shall kept at the

job site at all times for workers

reference and use.

ADDITIONAL

CONTROLS

P C

The air supplied blasting

helmets shall be provided with

air, at rate of not less than

1

0.17 cubic meter per minute.

Prior to entry of any chemical

substances into the site

MSDS shall be produced to

the LINDE HSSE Manager for

approval.

MSDS copies to be attached. 1

Obtained Hot Work Permit.

JOB SAFETY ANALYSIS / RISK ASSESSMENT

SCOPE : Painting & Repair Touchup

Q

Q A

A T

T A

A R

R

Initial Risk

ITEM

ACTIVITY

HAZARD / POTENTIAL

CONSEQUENCES

3.2

P C

Residual Risk

RISK

RANK

Chemical hazards.

3.2.1

2

3.2.2

3.2.3

3.3

Eye injury.

3.3.1

2

Dipping in a flux

solution.

4.1

Dropped hazard.

4.1.1

4.1.2

2

6

4.1.3

4.1.4

4.1.5

CURRENT

CONTROLS

Approved respirators shall be worn to

prevent inhalation of chemical vapors,

where necessary.

Ensure not to breathe the vapors while

applying chemical cleaning solvent in

the surface.

Ensure a copy of MSDS for hazardous

substances, in a readily

understandable form, shall kept at the

job site at all times for workers

reference and use.

When using cleaning up chemicals,

chemical resistant PPE such as face

shield, face mask, helmet, aprons,

clothing, gloves and boots shall be

worn to protect against contact and

exposure.

Ensure chain sling are properly

attached to pipe before dipping into

tank.

Supervisor shall ensure that sequence

of activities to be carried out for the

work as per Work Method Statement.

3.2.1.1

3.3.1.1

4.1.1.1

4.1.1.2

ADDITIONAL

CONTROLS

P C

Prior to entry of any chemical

substances into the site

MSDS shall be produced to

1

the LINDE HSSE Manager for

approval.

Provision of Eye Wash station

in the area.

JSAs should be implemented

during daily TSTI.

Ensure to check presence of

chain deformation, cracked or

cut links.

Post warning sign in the work area.

Before using a chain sling personnel

should be familiar with the proper sling

hitches and their corresponding

working load limits.

Before lifting , check each branch of

the chain is free from twists, knots or

kinks which cause stresses that may

result in failure of the chain.

JOB SAFETY ANALYSIS / RISK ASSESSMENT

Q

Q A

A T

T A

A R

R

SCOPE : Painting & Repair Touchup

Initial Risk

ITEM

ACTIVITY

HAZARD / POTENTIAL

CONSEQUENCES

4.2

Drying.

5.1

Flux solution splash

(Eye injury).

P C

Residual Risk

RISK

RANK

4.2.1

2

Sub standard drying

oven.

4.2.2

4.2.3

5.1.1

5.1.2

5.1.3

5.2

Immerse in molten

zinc.

Burn injury due to hot

surface.

6.1

Improper set up of

equipment.

6.2

Unqualified personnel.

5.2.1

CURRENT

CONTROLS

Approved PPE including face shield by 4.2.1.1

employees working is close proximity

of pre-treatment section.

Competent personnel.

MSDS communicated.

Drying oven shall be inspected and

approved by Third party and LINDE

prior to use.

Ensure to have a valid certificates

checks.

Ensure to have Third party inspection.

Ensure not to touch any hot parts of

5.2.1.1

the pipe surface s and equipment

while its being under drying process.

5.2.2 Ensure employee carrying out pipe

drying operations will practice safe

work procedures.

5.2.3 Ensure there are enough a good

safeguarding system to eliminate the

possibility of the employee placing

parts of their bodies near hazardous

hot pit.

5.2.4 Ensure to cool it down before touching

the work piece.

6.1.1 Equipment operators shall be

6.1.1.1

competent in the SAFE use and

operation of their equipment.

6.1.2 Daily routine checks on equipments.

6.1.3 Third party inspection every month to

check chemical purity.

6.2.1 Only trained and competent personnel

shall be assigned for galvanizing and

monitoring the process.

ADDITIONAL

CONTROLS

The area shall be isolated by

proper covers, in order to

control the solution splash.

P C

Supervisor/foreman shall

ensure that TSTI is properly

executed at the work front and

hazards discussed.

Inspected & properly colour

coded & approved by LINDE.

JOB SAFETY ANALYSIS / RISK ASSESSMENT

SCOPE : Painting & Repair Touchup

Q

Q A

A T

T A

A R

R

Initial Risk

ITEM

ACTIVITY

HAZARD / POTENTIAL

CONSEQUENCES

6.3

P C

Residual Risk

RISK

RANK

6.3.1

Personnal injury due to

unaware of the process.

2

6.3.2

6.4

Dropped hazard.

6.4.1

10

6.4.2

6.4.3

6.4.4

6.4.5

Surface cleaning

after galvanizng.

7.1

Improper use of tools.

7.1.1

7.1.2

CURRENT

CONTROLS

When monitoring of the process,

chemical resistant PPE such as face

shield, face mask, helmet, aprons,

clothing, gloves and boots shall be

worn to protect against contact and

exposure.

Personnel shall ensure that sequence

of activities to be carried out for the

work as per Work Method Statement.

Ensure chain sling are properly

attached to pipe before dipping into

tank.

Supervisor shall ensure that sequence

of activities to be carried out for the

work as per Work Method Statement.

Post warning sign in the work area.

Before using a chain sling personnel

should be familiar with the proper sling

hitches and their corresponding

working load limits.

Before lifting , check each branch of

the chain is free from twists, knots or

kinks which cause stresses that may

result in failure of the chain.

Operate tools according to

manufacturers instruction.

Perform maintenance on tools

regularly.

6.3.1.1

6.4.1.1

6.4.1.2

6.4.1.3

ADDITIONAL

CONTROLS

Supervisor/foreman shall

ensure that the TSTI is

properly executed at the work

front and hazards discussed.

JSAs should be implemented

during daily TSTI

Ensure to check presence of

chain deformation, cracked or

cut links.

Ensure to immerse the pipe

gradually slow on a

galvanizing kettle.

Ensure all tools shall be

inspected and color coded by

LINDE.

P C

JOB SAFETY ANALYSIS / RISK ASSESSMENT

SCOPE : Painting & Repair Touchup

Q

Q A

A T

T A

A R

R

Initial Risk

ITEM

ACTIVITY

On site repair and

touch (regalvanizedany bare

spot).

HAZARD / POTENTIAL

CONSEQUENCES

8.1

P C

Residual Risk

RISK

RANK

Breathing problem due

to toxic atmosphere.

8.1.1

8.1.2

2

6

8.1.3

8.1.4

8.2

Poor housekeeping.

8.2.1

8.2.2

3

8.2.3

8.2.4

8.2.5

8.3

Paint liquid splash. ( Eye

injury).

8.3.1

2

6

8.3.2

8.3.3

CURRENT

CONTROLS

Warning signs shall be placed in the

area to alert the employees in the

vicinity concerning the painting activity.

Respirators shall be worn to prevent

inhalation of chemical vapors, where

necessary.

Provisions for mechanical ventillation.

Respirators shall be worn to prevent

inhalation of chemical vapors, where

necessary.

Ensure hazardous materials is

properly identified with signs for

different types of chemical.

Ensure that area is properly

barricaded and secured during

operation.

Hoses shall be laid straight as

8.1.1.1

8.1.1.2

8.2.1.1

8.2.1.2

possible from spray pump up to the

coating point.

Disposal of emptied paint cans shall

be properly disposed according to

waste segregation plan and MSDS.

Avoid spilling/polluting any materials

into the environment.

Approved PPE including face shield by 8.3.1.1

employees working is close proximity

of spray painting.

ADDITIONAL

CONTROLS

P C

Prior to entry of any chemical

substances into the site

MSDS shall be produced to

the LINDE HSSE Manager for

approval.

1

Ensure a copy of MSDS for

hazardous substances, in a

readily understandable form,

shall kept at the job site at all

times for workers reference

and

use. and access to be

Walkway

clear.

Paint materials should stored

only in protected and

designated area.

The area shall be isolated by

proper covers, in order to

control the spread of particles

Competent personnel.

MSDS communicated.

JOB SAFETY ANALYSIS / RISK ASSESSMENT

Q

Q A

A T

T A

A R

R

SCOPE : Painting & Repair Touchup

Initial Risk

ITEM

ACTIVITY

HAZARD / POTENTIAL

CONSEQUENCES

8.4

P C

RANK

Skin irritation to affected

open body parts.

8.4.1

2

8.5

Residual Risk

RISK

Improper handling,

storing & disposal of

materials.

8.4.2

8.5.1

8.5.2

8.5.3

CURRENT

CONTROLS

Ensure employee wear the approved 8.4.1.1

coverall & safety gloves.

Ensure a copy of MSDS for hazardous

substances, in a readily

understandable form, shall kept at the

job site at all times for workers

reference and use.

Ensure all container shall be labeled

8.5.1.1

with the chemical name, ingredients,

warning pictograms and precautions

for storage and handling.

8.5.1.2

Flammable liquid shall be safely stored

in proper containers.

The storage shall be equipped with

appropriate warning signs and locked

to avoid unathorized entry.

ADDITIONAL

CONTROLS

P C

Prior to entry of any chemical

substances into the site

MSDS shall be produced to

the LINDE HSSE Manager for 1

approval.

The name of the responsible

person shall be posted at the

storage.

Proper disposal as per

LINDE/GAMA/MSDS

procedure.

You might also like

- 035-Procedure Structural Steel Repair Works at Site PDFDocument14 pages035-Procedure Structural Steel Repair Works at Site PDFKöksal Patan100% (1)

- 005-CIVIL-MS Disposal of Excavated Materials PDFDocument15 pages005-CIVIL-MS Disposal of Excavated Materials PDFKöksal PatanNo ratings yet

- Blasting and Painting ProcedureDocument9 pagesBlasting and Painting Procedureisukuru67% (12)

- Procedure for holiday testingDocument2 pagesProcedure for holiday testingSaptarshi MandalNo ratings yet

- Petroleum Development Oman Gathering Station - On Plot (No. 47), Ghaba North Pdo Contract No .Document10 pagesPetroleum Development Oman Gathering Station - On Plot (No. 47), Ghaba North Pdo Contract No .Burning TrainNo ratings yet

- Corrosion Protection Services GuideDocument37 pagesCorrosion Protection Services GuideTASNEEM100% (2)

- Internal Painting Works ITPDocument2 pagesInternal Painting Works ITPPrasanna Kumar100% (1)

- INSPECTION AND TEST PLAN FOR PIPE RACK AND PIPING PAINTING WORKSDocument2 pagesINSPECTION AND TEST PLAN FOR PIPE RACK AND PIPING PAINTING WORKSRanjan KumarNo ratings yet

- 032-Itp For Painting and Coating PDFDocument19 pages032-Itp For Painting and Coating PDFKöksal Patan80% (20)

- Coating CardDocument15 pagesCoating CardAnton Thomas PunzalanNo ratings yet

- Method of Painting WorksDocument43 pagesMethod of Painting WorksIkram Syed50% (2)

- Method Statement Installation Os Static Equipment and InternalsDocument24 pagesMethod Statement Installation Os Static Equipment and InternalsAjin SNo ratings yet

- Blasting & Painting Report for Project NOV OCS/BPR/1115/001Document2 pagesBlasting & Painting Report for Project NOV OCS/BPR/1115/001vinothNo ratings yet

- Application Guide Penguard MidcoatDocument6 pagesApplication Guide Penguard Midcoatadeoye_okunoyeNo ratings yet

- Blasting & Painting ProcedureDocument10 pagesBlasting & Painting ProcedurepraksahNo ratings yet

- ITP For Painting WorksDocument27 pagesITP For Painting Workssree50% (2)

- Method Statement For Blasting and Painting of Process EquipmentDocument11 pagesMethod Statement For Blasting and Painting of Process EquipmentNnamdi Amadi100% (3)

- Coating Procedure - General Rev.03Document35 pagesCoating Procedure - General Rev.03moytabura96100% (2)

- ITP Blasting Painting.Document2 pagesITP Blasting Painting.mohd as shahiddin jafri100% (4)

- Inar Profiles Pvt. LTD., Kotturu, Industrial Area, Visakhapatnam, Andhrapradesh, IndiaDocument14 pagesInar Profiles Pvt. LTD., Kotturu, Industrial Area, Visakhapatnam, Andhrapradesh, IndiaSreedhar Patnaik.MNo ratings yet

- Painting ProcedureDocument8 pagesPainting ProcedureSunday Paul50% (2)

- Method Statement For Painting of ValvesDocument4 pagesMethod Statement For Painting of ValvesRashid Kayum100% (1)

- GASOLINE STORAGE TANK INSPECTION AND TEST PLANDocument1 pageGASOLINE STORAGE TANK INSPECTION AND TEST PLANAmer Y KNo ratings yet

- Jotun Resist 86Document5 pagesJotun Resist 86Ansar AliNo ratings yet

- Itp Concrete CoatingDocument4 pagesItp Concrete Coatingkaml100% (1)

- Joint Coating Application & Pipe Coating Procedure-009-RappDocument8 pagesJoint Coating Application & Pipe Coating Procedure-009-Rappgst ajahNo ratings yet

- Painting Procedure NG SystemsDocument6 pagesPainting Procedure NG SystemsTanveer Rajput EngrNo ratings yet

- Field Joint CoatingDocument7 pagesField Joint CoatingTeodor EzaruNo ratings yet

- Repair Touch-Up Paint ProcedureDocument10 pagesRepair Touch-Up Paint ProcedureLiyakathalikhan Shahjahan100% (1)

- Surfacepreparation StandardDocument11 pagesSurfacepreparation StandardAri SupramonoNo ratings yet

- Procedure For Painting of TanksDocument18 pagesProcedure For Painting of TanksJijesh Arayarath100% (3)

- BGAS-CSWIP Site Coatings Inspector TrainingDocument3 pagesBGAS-CSWIP Site Coatings Inspector Trainingdang21720140% (2)

- QCP-05 Penalty System For WelderDocument9 pagesQCP-05 Penalty System For Weldernaseema1No ratings yet

- Itp PaintingDocument14 pagesItp PaintingNamta George100% (4)

- ItpDocument7 pagesItpJose Sherin100% (1)

- NORSOK Coating System No. 1 Carbon Steel 120CDocument5 pagesNORSOK Coating System No. 1 Carbon Steel 120CSam Jose100% (1)

- MS - Dolly Test ProcedureDocument4 pagesMS - Dolly Test ProcedureRahul Moottolikandy100% (1)

- Inspection and Test Plan - Cold Insulation Application & MaterialsDocument1 pageInspection and Test Plan - Cold Insulation Application & MaterialsDineshNo ratings yet

- Painting Inspection ReportDocument1 pagePainting Inspection Reportsandipthummar1743100% (3)

- External Pipe Wrapping - Inspection and Test Plan: Description of LocationDocument2 pagesExternal Pipe Wrapping - Inspection and Test Plan: Description of LocationDavidNo ratings yet

- CAT Group Painting Works QA ProcedureDocument7 pagesCAT Group Painting Works QA ProcedurekbldamNo ratings yet

- Specification Checklist For Steel and Concrete Coating PDFDocument5 pagesSpecification Checklist For Steel and Concrete Coating PDFGenaro BandaNo ratings yet

- WD946-EZ300-00009 Procedure For Painting Rev 0Document21 pagesWD946-EZ300-00009 Procedure For Painting Rev 0Manuel BurdilesNo ratings yet

- Method Statement - Chemical CleaningDocument12 pagesMethod Statement - Chemical Cleaningdadz mingiNo ratings yet

- Abrasive Blasting Safe Work PDFDocument2 pagesAbrasive Blasting Safe Work PDFamirthraj74100% (1)

- 2648 - Aco 9 2001 661 t7 4 0 Method Statement For Asphalt Road WorksDocument13 pages2648 - Aco 9 2001 661 t7 4 0 Method Statement For Asphalt Road WorksmohsinNo ratings yet

- Blasting and Painting Procedure PDFDocument9 pagesBlasting and Painting Procedure PDFharry50% (2)

- AYC CHECKLIST PAINTING Rev.01Document3 pagesAYC CHECKLIST PAINTING Rev.01moytabura96No ratings yet

- Quality Tool Box Meeting - FormatDocument2 pagesQuality Tool Box Meeting - FormatRam100% (2)

- Itp For InsulationDocument14 pagesItp For InsulationHytham El-NoubyNo ratings yet

- Contractor IOT Infrastructure & Energy Services LTDDocument38 pagesContractor IOT Infrastructure & Energy Services LTDNaveen KurupNo ratings yet

- Method Statement For Surface Preparation PaintingDocument9 pagesMethod Statement For Surface Preparation Paintingjamil100% (3)

- MIP17-MS-2012 Method Statement For Fabrication and Installation of PipingDocument23 pagesMIP17-MS-2012 Method Statement For Fabrication and Installation of PipingAmeerHamzaWarraichNo ratings yet

- Method Statement For Coating Repair of Air Handling Units (Ahu)Document6 pagesMethod Statement For Coating Repair of Air Handling Units (Ahu)moytabura96100% (1)

- Method Statement For Installation Anchor BoltsDocument7 pagesMethod Statement For Installation Anchor BoltsSyed AtherNo ratings yet

- Daily Paint ReportDocument2 pagesDaily Paint Reportcarey stewart100% (3)

- Surface Preparation & Painting Inspection ProcedureDocument21 pagesSurface Preparation & Painting Inspection ProcedureTrịnh Minh Khoa100% (2)

- 032-Procedure For Shop and Field Painting Work On Site PDFDocument26 pages032-Procedure For Shop and Field Painting Work On Site PDFKöksal Patan100% (1)

- 004-MS For Erection of Equipment Platforms, Handrails, Gratings, Stairways PDFDocument9 pages004-MS For Erection of Equipment Platforms, Handrails, Gratings, Stairways PDFKöksal Patan100% (1)

- 004-Civil - MS Construction of Temporary Roads PDFDocument17 pages004-Civil - MS Construction of Temporary Roads PDFKöksal Patan100% (2)

- 017-CIVIL-MS For Installation of Fence & Gate PDFDocument18 pages017-CIVIL-MS For Installation of Fence & Gate PDFKöksal Patan100% (6)

- 015-Method Statement For Painting Works (Building) PDFDocument21 pages015-Method Statement For Painting Works (Building) PDFKöksal Patan86% (21)

- 016-CIVIL - MS Anchor Bolt Installation PDFDocument14 pages016-CIVIL - MS Anchor Bolt Installation PDFKöksal Patan71% (7)

- 013-MS Utilization of Hilti DX 76 PDFDocument51 pages013-MS Utilization of Hilti DX 76 PDFKöksal PatanNo ratings yet

- 014-MS For Bolt Tightening (Piping& Equipments) PDFDocument23 pages014-MS For Bolt Tightening (Piping& Equipments) PDFKöksal PatanNo ratings yet

- 015-MS For Night Works PDFDocument16 pages015-MS For Night Works PDFKöksal Patan80% (5)

- 014-MS For General Scaffolding PDFDocument33 pages014-MS For General Scaffolding PDFKöksal Patan100% (2)

- 050-Itp For Installation of Air Intake Filter PDFDocument17 pages050-Itp For Installation of Air Intake Filter PDFKöksal PatanNo ratings yet

- 010-MS For Welding and Hot Works For General Activities at TSF Area PDFDocument17 pages010-MS For Welding and Hot Works For General Activities at TSF Area PDFKöksal PatanNo ratings yet

- 012-Civil - MS Ag and Ug Coating of Concrete Surfaces PDFDocument18 pages012-Civil - MS Ag and Ug Coating of Concrete Surfaces PDFKöksal PatanNo ratings yet

- 013-MS For Mass Concrete Works PDFDocument26 pages013-MS For Mass Concrete Works PDFKöksal Patan100% (1)

- 047-Itp For Oxygen Lines Fabrication and Installation PDFDocument28 pages047-Itp For Oxygen Lines Fabrication and Installation PDFKöksal PatanNo ratings yet

- 049-Itp For Lighting and Small Power (Building) PDFDocument15 pages049-Itp For Lighting and Small Power (Building) PDFKöksal Patan100% (1)

- 012-MS For Wall Cladding, Roof Cladding & Life Line Installation PDFDocument16 pages012-MS For Wall Cladding, Roof Cladding & Life Line Installation PDFKöksal Patan91% (11)

- 048-Itp For Installation of Hvac Unit PDFDocument8 pages048-Itp For Installation of Hvac Unit PDFKöksal Patan100% (4)

- 009-Method Statement - Main Erection Sequence For Acc PDFDocument68 pages009-Method Statement - Main Erection Sequence For Acc PDFKöksal Patan100% (6)

- 011-Method Statement For Repair of Concrete Works PDFDocument25 pages011-Method Statement For Repair of Concrete Works PDFKöksal Patan91% (33)

- 046-ITP For INSTALLATION OF MAC-BAC-ST MACHINERY UNIT PDFDocument18 pages046-ITP For INSTALLATION OF MAC-BAC-ST MACHINERY UNIT PDFKöksal PatanNo ratings yet

- 008-MS For Prefabrication of CS, TT & CN Pipe Spools PDFDocument23 pages008-MS For Prefabrication of CS, TT & CN Pipe Spools PDFKöksal PatanNo ratings yet

- 010-MS For Grouting PDFDocument33 pages010-MS For Grouting PDFKöksal PatanNo ratings yet

- 045-ITP For MASONRY & PLASTERING WORKS (Buildings) PDFDocument10 pages045-ITP For MASONRY & PLASTERING WORKS (Buildings) PDFKöksal Patan83% (12)

- 008-CIVIL-MS Backfilling Works PDFDocument16 pages008-CIVIL-MS Backfilling Works PDFKöksal Patan100% (1)

- 009-Civil-Ms Concrete Works PDFDocument27 pages009-Civil-Ms Concrete Works PDFKöksal PatanNo ratings yet

- 044-ITP For Installation of Gypsum Board (Buildings) PDFDocument10 pages044-ITP For Installation of Gypsum Board (Buildings) PDFKöksal Patan100% (3)

- 043-ITP FOR Water Proofing (Buildings) PDFDocument13 pages043-ITP FOR Water Proofing (Buildings) PDFKöksal Patan100% (3)

- 041 - ITP For Painting (Building) PDFDocument12 pages041 - ITP For Painting (Building) PDFKöksal Patan78% (9)

- 040-ITP For Repair of Steam Distribution Manifold PDFDocument11 pages040-ITP For Repair of Steam Distribution Manifold PDFKöksal PatanNo ratings yet

- 038-Itp For Coldboxes PDFDocument25 pages038-Itp For Coldboxes PDFKöksal PatanNo ratings yet

- 039-Itp For Embedded Plate PDFDocument7 pages039-Itp For Embedded Plate PDFKöksal PatanNo ratings yet

- 007-MS For Structural Steel Assembly Warehouse, Workshops PDFDocument25 pages007-MS For Structural Steel Assembly Warehouse, Workshops PDFKöksal PatanNo ratings yet

- 18m RTTDocument31 pages18m RTTanon_477481779No ratings yet

- Western Arts Tradition ARTS 1Document31 pagesWestern Arts Tradition ARTS 1Krystine Joy Mandanas VillelaNo ratings yet

- MomaDocument123 pagesMomaAngelica GonzalezNo ratings yet

- Tubular Pole Supply PricesDocument4 pagesTubular Pole Supply PricesSridhar Reddy GandraNo ratings yet

- Types of FabricsDocument32 pagesTypes of Fabricstextile028No ratings yet

- Victaulic DimensionsDocument2 pagesVictaulic DimensionsSH1961No ratings yet

- Technical Data BookletDocument53 pagesTechnical Data Booklettracy8763No ratings yet

- 1b. Speaking Part 1 Sep Dec 2018Document8 pages1b. Speaking Part 1 Sep Dec 2018Huy NguyenNo ratings yet

- Vista Paint Acoustic KoteDocument1 pageVista Paint Acoustic Kotedep_vinNo ratings yet

- B+G+2 Boq - (367-625)Document116 pagesB+G+2 Boq - (367-625)Amy Fitzpatrick100% (3)

- Crayola Colored Pencil ChartDocument1 pageCrayola Colored Pencil ChartBridget Guildner100% (1)

- C1 - 1 2011 June HermineDocument13 pagesC1 - 1 2011 June HermineHai AnhNo ratings yet

- Art Study IndiaDocument10 pagesArt Study IndiarominachemearriagaNo ratings yet

- Designs of SheratonDocument143 pagesDesigns of SheratonAlexander Amann100% (2)

- Carbothane 133 FLV PDSDocument2 pagesCarbothane 133 FLV PDSHomer SilvaNo ratings yet

- PALLAVA ART AND ARCHITECTUREDocument5 pagesPALLAVA ART AND ARCHITECTUREchinmayeedeepakNo ratings yet

- 350 - Guide To Making An RPGDocument9 pages350 - Guide To Making An RPGsuperbala16No ratings yet

- PorcelainDocument15 pagesPorcelainEneaGjonajNo ratings yet

- ADM - CPAR Q1 MELC 3 16pDocument16 pagesADM - CPAR Q1 MELC 3 16pDionel T. Galagar LptNo ratings yet

- Arts Throughout HistoryDocument8 pagesArts Throughout Historyapi-264373083100% (4)

- Bill No: 02 SUBSTRUCTURE Note: Please note that the works to the Water Well have been EXCLUDED due to lack of necessary details. EXCAVATION & EARTH WORKSDocument36 pagesBill No: 02 SUBSTRUCTURE Note: Please note that the works to the Water Well have been EXCLUDED due to lack of necessary details. EXCAVATION & EARTH WORKSmaheshqs19100% (1)

- Class XI Holiday Homework Assignments for All SubjectsDocument7 pagesClass XI Holiday Homework Assignments for All SubjectsAdhish ChatterjeeNo ratings yet

- Mural Art LessonDocument9 pagesMural Art Lessonalbrickcj castilloNo ratings yet

- Civil Service Reviewer With Question and AnswerDocument88 pagesCivil Service Reviewer With Question and AnswerEduard Anthony Ajero100% (4)

- Dip Viscosity Cups, Zahn TypeDocument2 pagesDip Viscosity Cups, Zahn Typedaniela0% (1)

- Bio - Okwui EnwezorDocument2 pagesBio - Okwui EnwezorJan HoppeNo ratings yet

- Matching Lists of ItemsDocument2 pagesMatching Lists of ItemsJonathan Fajardo Cusack100% (6)

- PDF Architectural MagazinesDocument4 pagesPDF Architectural MagazinesdevrishabhNo ratings yet

- FS Ss-S-200eDocument23 pagesFS Ss-S-200eGiorgos LympertasNo ratings yet

- PigmentsDocument6 pagesPigmentsrashed141_tx100% (1)