Professional Documents

Culture Documents

Large Ar

Uploaded by

beefong7680Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Large Ar

Uploaded by

beefong7680Copyright:

Available Formats

Large Area GaN HEMT Power Devices for Power Electronic Applications: Switching

and Temperature Characteristics

Naiqian Zhang', Vivek Mehrotra', Sriram Chandrasekaran', Brendan Moran', Likun Shen', Umesh

Mishral, Edward Etzkorn' and David Clarke'

'Elecbical& Computer Engineering Dept.

University of Califomia Santa Barbara

Santa Barbara, CA 93 106

NZhang@rfmd com

lkshen@engineering.ucsb.edu

mishraaece.ucsb.edu

'Rockwell Scientific Company

1049 Camino Dos Rios

Thousand Oaks, CA 91360

vmehrotra@nusc.com

sriram@rwsc. com

Abstract - Large area AIGaNIGaN High Electron Mobility

Transistors (HEMT) for power electronic applications have

been fabricated. These power devices offer lower on-resistance

and higher switching speed than Sic devices due to higher

electron mobility and high channel charge density achieved by a

heterojunction. The GaN epi-layers were grown on semiinsulating 4H-Sic substrate by Metal Organic Chemical Vapor

Deposition (MOCVD) technique. The device structure was

grown on Sic substrates due to its high thermal conductivity.

The devices have been optimised with respect to electron

mobility, sheet concentration, voltage breakdown, on-resistance

and dispersion. Voltage breakdown of 13OOV was achieved on

small devices while breakdown in the range 600-900V was

achieved on packaged devices depending on the number of

devices that have been paralleled. The power device figure of

merit V j R / R , = 9.94~10' [V2.P'cni2], where VBR is the

breakdown voltage and %. is the on-resistance, is the highest

among any reported switching devices. Switching losses of large

area 600V 12.5A power devices were measured using resistive

and inductive loading. Switching times of< 30 ns were achieved

with an on-resistance of 0.4 C l (specific on-resistance = 1.7

&.em2).

The static and dynamic characteristics of GaN

HEMT devices were also measured as a function of temperature

up to 200OC. Finally, the temperature distributions in the active

device area were measured using Raman spectroscopy

(pyrospectroseopy). This technique can be used to measure

temperatures with a spatial resolution of 1-2 pm. Device

temperatures from both the active areas and Sic substrates

have been measured.

I. INTRODUCTION

High performance power electronic circuits are expected

to make a major impact on more-electric ships, submarines,

aircrafts, hybrid vehicles, nuclear-powered satellites, directed

energy weapons and spacecraft [1,2]. The primary benefits

are in terms of reduced weight and size, fuel savings, simple

thermal management and lower lifecycle costs. Si-based

power devices cannot meet the temperature, voltage,

switching speed, size and efficiency requirements to realize

these benefits. Wide bandgap semiconductors, particularly

S i c and GaN, are well suited to meet these requirements.

The wide bandgap results in very low intrinsic camer

concentration that provides negligible junction leakage

current up to 500C. This allows high temperature operation

0-7803-7754-0/03/$17.00 02003 IEEE

3Materials Department

University of California Santa Barbara

Santa Barbara, CA 93 106

moranbaengineering. ucsb.edu

edmaster@engineering. ucsb.edu

clarke@engineering.ucsb.edu

without excessive leakage or thermal runaway and reduces

cooling requirements. The high breakdown strength of S i c

and GaN results in thinner drift layers for a given blocking

voltage, as compared to silicon, thus reducing the specific onresistance and storage of minority carriers. Lastly, the high

inherent thermal conductivity of these materials (Sic) or the

substrates used for their growth (GaN on Sic) allows

efficient heat removal.

Rapid progress has been made towards the availability of

high-quality S i c substrates. This has resulted in the

development and commercialisation of SIC power devices.

On the other hand, tremendous progress has also been

achieved in GaN microwave power devices due to improved

material quality and process techniques. These advances can

now be exploited to develop GaN power switching devices

for power electronics.

AIGaN/GaN based High Electron Mobility Transistors

(HEMTs) offer lower on-resistance and higher switching

speed due to higher electron' mobility and high channel

charge density achieved by a heterojunction. Electron

mobility values of 1500-2000 cm2N.s have been achieved

compared to -400 cm2N.s in S i c [3]. Additionally, a twodimensional charge density of - 2 ~ 1 0 ' cni2

~ has also been

achieved in a HEMT structure. Other advantages of GaN

HEMT devices include lower parasitic capacitance and a

simple device fabrication (4 mask steps) [3]. In this paper,

we report on the switching and temperature characteristics of

large area 600V / 2.5A GaN HEMT power devices. The

GaN epi-layers were grown on semi-insulating S i c substrate

by Metal Organic Chemical Vapor Deposition (MOCVD)

technique. The device structure was grown on S i c substrates

due to its high thermal conductivity and the device layout was

optimized to achieve high blocking voltages. These high

performance devices lay the foundation for a high

temperature and high voltage front-end converter for

distributed power architecture in both commercial and

military applications.

11. DEVICE DESIGN

Fig. 1 shows the cross-section of the GaN HEMT device.

Room temperature hall measurements showed an electron

233

sheet concentration n, = 8 . 3 ~ 1 0 ~ and mobility = 1500

cm2N.s with no intentional doping in the whole material

system. Insulated-gate HEMT was utilized to achieve

breakdown voltages in excess of 600V [4] (Fig. 1). A Si02

layer under the gate was utilized to reduce gate leakage under

high drain hias, thus alleviating the leakage assisted impact

ionization in the AlGaN layer and increasing the breakdown

voltage. A breakdown voltage of 1300V with a specific onresistance of 1.7 n O c m 2 (active area 9 . 2 5 ~ 1 0 .cm2)

~ at a

gate bias of 2V was achieved in GaN HEMT with Lgd = 20

pm and W, = 500 pm. The threshold voltage was measured to

be -9 V. The breakdown voltage is by far the highest value

achieved on all devices based on GaN material, and the onresistance is lower than Sic switching devices reported in the

literature. The power device figure of merit V i R / R , =

leakage. Fig. 4 shows the I-V characteristics of the device

with a double gate dielectric scheme. It is clearly evident that

the dispersion is negligible.

9.94~10[V2.0-1cm-2],where Vsn is the breakdown voltage

and &, is the on-resistance, is the highest among any

reported switching devices.

0 . 9 ~L x = . o W

I -*

Fig. 2. I-V curves under DC (solid lines). and .nulsed (dotted lines)

conditions showing dispersion for an unoptimised device.

Ld=1.5-24pn

S

SO

I pn 760 Ton GaN

Semi-hrulsting SIC

85 nm AIN

Semi-insulating Sic

Fig. 3. Double-gate dielectric scheme to achieve low dispersion and gate

leakage.

Fig. I . Cross-section of the GaN HEMT power device

Dispersion of GaN power HEMTs was also measured

since it affects the switching speed.

Dispersion

characteristics were measured using gate lag measurements.

Fig. 2 shows a comparison of I-V curves obtained under DC

and Sops pulse conditions. It can be seen that the pulsed

current level is much lower than the DC level. The

discrepancy between DC and pulse measurement is referred

to as dispersion in microwave power electronics, which is

caused by slow response of traps in the material [3]. These

pulse measurements provide an indirect method to rapidly

probe the device switching speed. If the device is turned-on

at a speed faster than the pulse, the current carrying capability

is limited and is much lower than the DC current level. For

microwave applications, Si3N4surface passivation layer has

been used to solve the dispersion problem [3]. We have

utilized a double gate dielectric scheme to achieve the

advantages of both SiOz and Si3N4 as shown in Fig. 3. A thin

layer of Si3N4was first deposited on the device followed by a

SiOl layer deposited only under the gate. The device was

finished with a thick, planar SiJN4 passivation. The Si3Nd

layer substantially reduces dispersion to enable high

switching speed, while the Si02 layer reduces the gate

Fig. 4. I-V curves under DC (solid lines) and pulsed (dotted lines)

conditions showina

.nealiaible

.. disoersion for the double-eate

- dielectric

StNCNE.

The power device layout design was also optimized to

achieve high breakdown voltage. In microwave devices,

electric field crowding at the end of gate-fingers severely

limits the device voltage blocking capability. A circular

device deoign was used to distribute the electric field evenly

Voltage blocking

along the gate finger (Fig. 5).

measurements revealed a maximum breakdown voltage of

1050V for this design with an average voltage blocking

234

capability of 900V (Fig. 6). Large area devices were

fabricated using wire bonding to interconnect discrete smaller

power devices. Sixty-four small devices were bonded

together with a total gate length of 38.4 mm and with a

current capability >2.5A (Fig. 5). An on-resistance of 0.4Q

and a breakdown voltage of 600V were obtained for a

packaged device (Fig. 7). I-V curves of a large area device

are shown in Fig. 8.

111. SWITCHING MEASUREMENTS AND

TEMPERATURE EFFECTS

Switching characteristics of GaN HEMT devices were

measured using the inductive (Fig. 9) and resistive loads.

Figs. 10 and 11 show the turn-on and turn-off characteristics

of a GaN HEMT device at a blocking voltage of >11OV and

drain current of -1.4A. The gate-to-source voltage was

switched fiom OV to -2OV. Turn-on and turn-off times less

than 3011s were measured under these conditions. From the

switching data, a turn-on loss of 0.612 pJ and a turn-off loss

of 0.834 pJ was calculated that corresponds to a total

switching loss of 1.45W at 1 MHz switching 6equency. The

conduction losses are about 0.68W corresponding to an onresistance of 0.4 Q. These devices have been measured up to

250V blocking voltage at a Switching current of -2.5A.

Fig. 5 . Circulardevice design for uniform electric field disuibution (left)

and paralleled GaN HEMTs with a total gate length of38.4mm with

current capability >2.5A (right)

UI1"F.U

0 . 1 II

COotrDl

DUT

S

Fig. 9. Schematic circuit used to measure the dynamic switching

characteristics ofGaN HEMT power devices (indicated as Device Under

Test- DLIT). The resistive loading cixuit is similar with a variable

resistor replacing the diode-inductor.

Fig. 6. I-V curves illustrating maximum voltage blocEing capability up

to 105OV and average voltage blocking of 900V.

nw

-TO

140

2.4

120

2.0

1.6

E

m

=P

B

Fig. 7. Packaged 600V l2.5A GaN HEMT device on Cu / Alios substrate

(left) with an on-resistance ofO.40. An exploded view ofthe device is

shown on the right

80

s

1.2

60

0.8

5

0

0.4

40

20

0.0

0.4

100 120

40

-40

-20

20

40

60

80

Time (ns)

Fig. IO. T u " characteristics afGaN HEMT device under resistive

load showing the drain-to-source voltage (Vds) and drain current (Id).

~.

6 S Io I2 i 4 I6 i n

Drain Voltage (V)

Fig. 8. I-V characteristics of a 600V / 2.SA GaN HEMT device.

o

The static and dynamic characteristics of GaN power

devices were also measured as a function of temperature up

to 200C. Fig. 12 shows the device I-V curves for different

gate voltages at 23OC and 200C. A larger gate voltage is

required for complete turn-off at 200"C, presumably due to

thermal activation of traps in GaN buffer. Voltage blocking

charactenstics of a single device are shown in Fig. 13 at 23C

235

Dynamic Characteristics at 23% and 200DC

and 200C. The dynamic characteristics of a single power

device in an array of 64 devices were measured as a function

of temperature using inductive loading measurements. Fig.

14 shows the turn-on and turn-off characteristics of a single

device under inductive load.

Effects of the resistive

contribution of the probes have been corrected in this

measurement. The switching losses at 2 0 0 T were measured

to be within 10% of the losses at 23C. These measurements

demonstrate the device switching capability up to 200C. A

scaled up packaged GaN HEMT device is therefore capable

of operation up to 200C with low switching and conduction

losses. However, further improvements in material growth

are necessary to achieve a low trap density at the surface and

in GaN buffer.

-Id 21%

...

-Id mvc

0.8

3

5

0.4

0.0

0.4

40

-20

20

40

60

80

100

IV. DEVICE RELIABILITY

2.0

1.2

(PI

Fig. 14. Dynamic charactenstics of a single GaN HEMT power device

room an m y of 64 devices under inductive load at 23% and 200C

demonstratingifs high temperahme capability.

2.4

1.6

Time

120

Device degradation was observed upon exposure to

ambient conditions within 4-6 weeks. The device showed

longer turn-on and turn-off times and the forward drop

increased rapidly. Fig. 15 shows this degradation, which is

probably due to poor device passivation. In addition to

improvements in materials growth to reduce trap density,

improved passivation materials are a critical need for

improving device reliability.

Time (nr)

Fig. 1 1 . Turn-off characteristics of GaN HEMT device under resistive

load showing the drain-to-source voltage (Vds) and drain current (Id).

1.6

0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0

12

do (v)

Fig. 12. Static I-V curves o f a single GaN HEMT device at 23C and

E

.......

200oc.

0.8

.:.

>

I......

0.4 0

.

.

.,oo

. .

. ~.

~

.

0.0

. . . . . . .

I 4.54

.

.

3

E

400

100

300

400

em

Time (SJ

Fig. 15. Tum-on characteristics of GaN HEMT device before (top) and

after degradation @onom) upon exposure to ambient for 4-6 weeks

l.Oe-5

5.0.-7

V. TEMPERATURE MEASUREMENTS

0.0

0

40

80

100

Vds 0

Fig. 13. Leakage current of large a m GaN HEMT power device at 23C

and 2 0 0 T at gate-to-source voltage of -2OV.

Temperature distribution within a single power device

from the large area GaN device packaged on a ceramic

236

substrate (Fig. 16) was measured using Raman spectroscopy,

termed pyrospectroscopy [SI. This technique allows

temperature measurements from a spot size of 1-2 pm and is

being used to ascertain the spatial distribution of temperature

within the device for reliability prediction. Raman peak

shifts from both the active device areas and S i c substrate

were measured (Tdeviccand Tsubsmc). Temperatures were

derived from local peak shifts using a separate calibration

performed on GaN and SIC materials. Fig. 17 shows the

observed Raman peak shifts as a function of dissipated power

while Fig. 18 shows the derived temperatures within the

drain-to-gate region of a single power device. A temperature

of about 100C in the active area was measured at a

dissipated power of about 12W in a packaged device.

Fig. 16. Schematic of a large area GaN HEMT device used for high

resolution temperaare measurements.

GaN E2 Raman Peak Shins

G lZO.O

e 100.0

fP

80.0

60.0

f 40.0

20.0

0.0

5.0

10.0

15.0

Dissipated Power (w)

Fig. 18. Average device temperature in the drain-to-gate region ofa

single device derived from the GaN Raman peak shift (left). The location

of the collected specmm from the device is also shown (right).

VI. CONCLUSIONS

600V / 2 S A GaN HEMT devices for power electronic

applications have been demonstrated. AIGaN/GaN devices

with a sheet charge of 8 . 3 ~ 1 0 ~

mobility of 1500

cm2N.s, and a specific on-resistance of 1.7 d a n 2have

been fabricated. Switching times less than 30 ns were

achieved with an on-resistance of 0.4 0. The dynamic

characteristics were measured up to 2SOV. At blocking

voltages of IlOV, a turn-on loss of 0.612 pJ and a turn-off

loss of 0.834 pJ was measured that corresponds to a total

switching loss of 1.4SW at 1 MHz switching frequency. The

static and dynamic characteristics of GaN HEMT devices

were also measured as a function of temperature up to 20OoC

demonstrating their applicability for high temperature power

electronics.

High-resolution (1-2 pm) temperature

measurements were performed using Raman spectroscopy.

Finally, device reliability upon prolonged exposure to

ambient was investigated. Improvements in materials growth

to reduce trap density and improved passivation materials are

critical needs for improving device reliability.

567.2

ACKNOWLEDGMENT

0 566.8

0.0

This work was partially supported by the US Navy

Office of Naval Research (ONR) under contract # N00014993-0006, N00014-03-1-0386 and COMPACT MURI.

.?

5.0

10.0

15.0

Dissipated Power (W)

777.0

22 776.5

4HSiC Raman Peak Shifts

776.0

775.5

775.0

0.0

5.0

10.0

15.0

Dissipated Power (W)

Fig. 17. GaN E2 (top) and 4H-SiC (bottom) Raman peak shifts as a

function ofdissipated power from the active area of the device and

device substrate, respectively. The spatial variation of temperahue can

be derived from these peak shifts with a resolution of 1-2 pm.

REFERENCES

[ I ] R. T. Fingers and C. Scan Rubertus, Application of high temperature

magnetic materials, IEEE Trons. Magnelics. vol. 36, pp. 3373-75.2000

and references therein.

[2] V. Mehrotra, J. Sun and S . Chandrasekaran, Ultra compact d c d c

ConveRers for the digital age, I lndurhiol Electronics Sociery Con$

2002, vol. 4, pp. 3232-3237.

[3] N:Q. Zhang, Ph.D. dissertation, University of California Santa B d a r a

(2002); NQ

:

Bang et ai, Effects ofsurface traps on breakdown voltage

and switching speed of GaN power switching HEMTs, Electron

Deices Meerins, 2001, E D M Tech. Digest, pp. 25.5.1 -25.5.4.

[4] N:Q. Zhang, B. M o m , S . P. DenBaars, U. K. Mishra, X. W. Wang, and

T. P. Ma, Kilovolts AlGaNiGaN HEMTs as switching devices, Phys.

Slat. Sol. (a),vol. 188,pp. 213-7,2001.

[ 5 ] J. He, V. Mehrotra and M. C. Shaw, Ultra-high resolution temperature

measurement and thermal management of RF power devices using heat

pipes, Inll. Symp. On Power Semiconducror Devices ond ICs, ISPSD

Proc. 1999, pp. 145-148.

237

You might also like

- High Breakdown Voltage AlGaN-GaN HEMTs Achieved by Multiple Field PlatesDocument3 pagesHigh Breakdown Voltage AlGaN-GaN HEMTs Achieved by Multiple Field PlatesdaaanuNo ratings yet

- Test Data Reference Book (Secc 7 Rotating Machinery)Document41 pagesTest Data Reference Book (Secc 7 Rotating Machinery)J. Mauricio A. Bejarano100% (1)

- Khalil 2014Document9 pagesKhalil 2014Rikus OfAthasNo ratings yet

- Condition Monitoring of Discharged Zno Surge Arrester On Temperature Distribution Under Various Design ConditionsDocument4 pagesCondition Monitoring of Discharged Zno Surge Arrester On Temperature Distribution Under Various Design ConditionsLucho RufoNo ratings yet

- Robust Memristors Based On Layered Two-Dimensional MaterialsDocument31 pagesRobust Memristors Based On Layered Two-Dimensional Materialssritama royNo ratings yet

- k1 FCL DigSilentDocument8 pagesk1 FCL DigSilentksg9731No ratings yet

- Optimum Semiconductors For High-Power Electronics: Loss CausedDocument13 pagesOptimum Semiconductors For High-Power Electronics: Loss Causedvinay thakarNo ratings yet

- EMC AbstractDocument42 pagesEMC AbstractfountainsheadNo ratings yet

- Modeling and Characterization The Reverse Recovery of A High-Power Gaas Schottky DiodeDocument6 pagesModeling and Characterization The Reverse Recovery of A High-Power Gaas Schottky Diodeisma807No ratings yet

- PSpice LibraryguideOrCADDocument11 pagesPSpice LibraryguideOrCADluanleNo ratings yet

- AlGaN GaN OverviewDocument36 pagesAlGaN GaN OverviewyaakalaaNo ratings yet

- Tec 2015 2487513Document10 pagesTec 2015 2487513Amir NazirNo ratings yet

- A High-Efficiency 6.78-Mhz Full Active Rectifier With Adaptive Time Delay Control For Wireless Power TransmissionDocument10 pagesA High-Efficiency 6.78-Mhz Full Active Rectifier With Adaptive Time Delay Control For Wireless Power Transmissionfelix_007_villedaNo ratings yet

- Comparison of Finite-Element and IEC Methods For Cable Thermal Analysis Under Various Operating Environments (Kady2014)Document6 pagesComparison of Finite-Element and IEC Methods For Cable Thermal Analysis Under Various Operating Environments (Kady2014)daegerteNo ratings yet

- Design Practice For The Earthing System of The 400 KV Gas InsulaDocument5 pagesDesign Practice For The Earthing System of The 400 KV Gas Insulasorry2qazNo ratings yet

- Manualnew 2015 IV Sem MechDocument35 pagesManualnew 2015 IV Sem MechSahil jeswaniNo ratings yet

- Energies 12 03075 PDFDocument14 pagesEnergies 12 03075 PDFBat-ErdeneeeeeNo ratings yet

- CIRED 2 - MatheusDocument4 pagesCIRED 2 - MatheusEstácio Tavares Wanderley NetoNo ratings yet

- IGCT Technology Baseline and Future Opportunities: Peter Steimer, Oscar Apeldoorn, Eric Carroll, Andreas NagelDocument6 pagesIGCT Technology Baseline and Future Opportunities: Peter Steimer, Oscar Apeldoorn, Eric Carroll, Andreas NagelculwavesNo ratings yet

- D009 C3L A1 9493Document4 pagesD009 C3L A1 9493patrikosgnachNo ratings yet

- 2009 Xu J Et Al (APL) Reduction in Efficiency Droop in Polarization Matched GaInN GaInN LEDsDocument3 pages2009 Xu J Et Al (APL) Reduction in Efficiency Droop in Polarization Matched GaInN GaInN LEDsPawan KumarNo ratings yet

- Silicon PDFDocument7 pagesSilicon PDFDuvier Montoya ArbelaezNo ratings yet

- Parison FullDocument7 pagesParison FullTJPRC PublicationsNo ratings yet

- Introducing The 5.5kV-5kA HPT IGCTDocument6 pagesIntroducing The 5.5kV-5kA HPT IGCTislam benyettouNo ratings yet

- ArticleDocument2 pagesArticleTaíla RodriguesNo ratings yet

- Zulfaqar: Journal of Defence Science, Engineering & TechnologyDocument15 pagesZulfaqar: Journal of Defence Science, Engineering & TechnologyOlga OliveiraNo ratings yet

- A Wide Band Gap Devices Based Switched Capacitor Circuits For Photovoltaic ApplicationsDocument10 pagesA Wide Band Gap Devices Based Switched Capacitor Circuits For Photovoltaic ApplicationsMIKS DARKNo ratings yet

- Diseño de BushingsDocument6 pagesDiseño de BushingsIWueNo ratings yet

- Electromagnetic Interference Issues of Power Electronics Systems With Wide Band Gap Semiconductor DevicesDocument6 pagesElectromagnetic Interference Issues of Power Electronics Systems With Wide Band Gap Semiconductor DevicesDinesh KumarNo ratings yet

- Reliability Issues GaN HEMTDocument4 pagesReliability Issues GaN HEMTSva KolisiNo ratings yet

- Improved Design and Evaluation of Electrical Earthing Systems For Maryland 13233 KV Transmission StationDocument9 pagesImproved Design and Evaluation of Electrical Earthing Systems For Maryland 13233 KV Transmission StationInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- X - The Series Connection of IGBT's With Active Voltage SharingDocument8 pagesX - The Series Connection of IGBT's With Active Voltage SharingOsman T.No ratings yet

- High Performance Gan Pin Rectifiers Grown On Free-Standing Gan SubstratesDocument2 pagesHigh Performance Gan Pin Rectifiers Grown On Free-Standing Gan Substratesbeefong7680No ratings yet

- Topic: Islanding DetectionDocument11 pagesTopic: Islanding DetectionRatik MittalNo ratings yet

- CSE - 22 Assessment of The Dielectric Type Test Currently Applied On Mass Impregnated Non Draining HVDC CablesDocument18 pagesCSE - 22 Assessment of The Dielectric Type Test Currently Applied On Mass Impregnated Non Draining HVDC CablesMirasNo ratings yet

- VRC Power Line Ice Management De-Icing System Smart Grid (English)Document26 pagesVRC Power Line Ice Management De-Icing System Smart Grid (English)PolarStar100% (1)

- Design of Low Inductance Switching Power Cell For GaN HEMT Based InverterDocument11 pagesDesign of Low Inductance Switching Power Cell For GaN HEMT Based InverterArmandinho CaveroNo ratings yet

- A 400-nW 19.5-fJ/Conversion-Step 8-ENOB 80-kS/s SAR ADC in 0.18-M CmosDocument5 pagesA 400-nW 19.5-fJ/Conversion-Step 8-ENOB 80-kS/s SAR ADC in 0.18-M CmosSuraj Kumar PrustyNo ratings yet

- Sizing of Power Cables For Circuit Breaker Controlled FeedersDocument25 pagesSizing of Power Cables For Circuit Breaker Controlled Feedersakash_ing7683100% (1)

- Power Device-Analytical Model-RajanDocument6 pagesPower Device-Analytical Model-RajanMD.Minhazul Islam ShazedNo ratings yet

- 2010 IRPS Tutorial Program: Mark Porter, MedtronicsDocument6 pages2010 IRPS Tutorial Program: Mark Porter, MedtronicsYash SharmaNo ratings yet

- HVE PresentationDocument41 pagesHVE PresentationJaswant RathoreNo ratings yet

- RC 160 PaperDocument7 pagesRC 160 PaperSatyabrata MahapatraNo ratings yet

- Wide Band-Gap SemiconductorsDocument28 pagesWide Band-Gap SemiconductorsclionpoorNo ratings yet

- 00707781Document6 pages00707781sandeepbabu28No ratings yet

- Firelli Submarine ProposalDocument23 pagesFirelli Submarine ProposalAct PornlapusNo ratings yet

- A Practical Approach of Reducing Dielectric Losses and Calculation of An Existing 33KV HV-UG Power Cable of A Distribution NetworkDocument17 pagesA Practical Approach of Reducing Dielectric Losses and Calculation of An Existing 33KV HV-UG Power Cable of A Distribution NetworkudayakumartNo ratings yet

- Evaluation of The Transient Overvoltage Stresses On 132 KV Power Transmission NetworkDocument8 pagesEvaluation of The Transient Overvoltage Stresses On 132 KV Power Transmission NetworkIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalNo ratings yet

- 10 Watt High Efficiency GaAs MMIC Power Amplifier For Space ApplicationsDocument4 pages10 Watt High Efficiency GaAs MMIC Power Amplifier For Space Applicationsln zNo ratings yet

- Wide Band-Gap SemiconductorDocument3 pagesWide Band-Gap SemiconductorAnonymous xzi9LiTNo ratings yet

- Nanometer MOSFETDocument12 pagesNanometer MOSFETSibi ManojNo ratings yet

- Practical Control of Switching Overvoltages by Switch-Sync Controller PDFDocument6 pagesPractical Control of Switching Overvoltages by Switch-Sync Controller PDFkaushikray06No ratings yet

- Comparison of Measured Transient Overvoltages in The Collection Grid of Nysted Offshore Wind Farm With EMT SimulationsDocument8 pagesComparison of Measured Transient Overvoltages in The Collection Grid of Nysted Offshore Wind Farm With EMT SimulationsalimaghamiNo ratings yet

- Simulation Research On Single Event Burnout Performances of p-GaN Gate HEMTs With 2DEG AlxGa1-xN ChanneDocument8 pagesSimulation Research On Single Event Burnout Performances of p-GaN Gate HEMTs With 2DEG AlxGa1-xN ChanneMaddi PravallikaNo ratings yet

- Of in EGAT 500 Transinission System: An Analysis Switching Overvoltages KVDocument5 pagesOf in EGAT 500 Transinission System: An Analysis Switching Overvoltages KVKarina LozadaNo ratings yet

- Curved In-Plane Electromechanical Relay For Low Power Logic ApplicationsDocument9 pagesCurved In-Plane Electromechanical Relay For Low Power Logic Applicationsyingying.li346No ratings yet

- 32 Paper 60Document5 pages32 Paper 60shankul.saurabhNo ratings yet

- ExtraDocument6 pagesExtraRaja SekarNo ratings yet

- Ar 21212 IableDocument5 pagesAr 21212 Iablebeefong7680No ratings yet

- 343435454Document5 pages343435454beefong7680No ratings yet

- ExperimentalDocument6 pagesExperimentalbeefong7680No ratings yet

- 34343434Document4 pages34343434beefong7680No ratings yet

- Study and Fabrication of PIN Photodiode by Using ZnSePSSi StructureDocument5 pagesStudy and Fabrication of PIN Photodiode by Using ZnSePSSi Structurebeefong7680No ratings yet

- ComparisonDocument3 pagesComparisonbeefong7680No ratings yet

- DoubleDocument8 pagesDoublebeefong7680No ratings yet

- Gaas Schottky Diodes For Mixing Applications Beyond I Tliz: Second International Symposium On Space Terahertz TechnologyDocument17 pagesGaas Schottky Diodes For Mixing Applications Beyond I Tliz: Second International Symposium On Space Terahertz Technologybeefong7680No ratings yet

- 05121341556421243434Document7 pages05121341556421243434beefong7680No ratings yet

- 0213234543234233623233Document7 pages0213234543234233623233beefong7680No ratings yet

- 062323233324435534566924Document7 pages062323233324435534566924beefong7680No ratings yet

- 0161313147783131359Document6 pages0161313147783131359beefong7680No ratings yet

- High Performance Gan Pin Rectifiers Grown On Free-Standing Gan SubstratesDocument2 pagesHigh Performance Gan Pin Rectifiers Grown On Free-Standing Gan Substratesbeefong7680No ratings yet

- Bus-Powered M Series Multifunction DAQ For USB - 16-Bit, Up To 400 KS/S, Up To 32 Analog Inputs, IsolationDocument18 pagesBus-Powered M Series Multifunction DAQ For USB - 16-Bit, Up To 400 KS/S, Up To 32 Analog Inputs, Isolationbeefong7680No ratings yet

- Power Electronics - Homework #1 (Due Date:10/8) : Q - . 5V DC DDocument2 pagesPower Electronics - Homework #1 (Due Date:10/8) : Q - . 5V DC Dbeefong7680No ratings yet

- Magnetic Field Determination For Different Block Permanent Magnet SystemsDocument14 pagesMagnetic Field Determination For Different Block Permanent Magnet Systemsbeefong7680No ratings yet

- Location and Orientation About The Capsule (Without Outer Magnetic Field)Document6 pagesLocation and Orientation About The Capsule (Without Outer Magnetic Field)beefong7680No ratings yet

- Arduino 程式碼Document6 pagesArduino 程式碼beefong7680No ratings yet

- Bus-Powered M Series Multifunction DAQ For USB - 16-Bit, Up To 400 KS/S, Up To 32 Analog Inputs, IsolationDocument18 pagesBus-Powered M Series Multifunction DAQ For USB - 16-Bit, Up To 400 KS/S, Up To 32 Analog Inputs, Isolationbeefong7680No ratings yet

- Quantum MechanicsDocument15 pagesQuantum Mechanicsbeefong7680100% (1)

- Einstein, Albert - Relativity - The Special and General Theory (163s) (T) PDFDocument163 pagesEinstein, Albert - Relativity - The Special and General Theory (163s) (T) PDFbeefong7680No ratings yet

- Super-Mini-Series Z482 Z602 D722 D902Document12 pagesSuper-Mini-Series Z482 Z602 D722 D902Anonymous 9xvU1F100% (1)

- Blended Activity 2 Tubio Dexter James G. BEED General Content MWF 2 5 PMDocument8 pagesBlended Activity 2 Tubio Dexter James G. BEED General Content MWF 2 5 PMDexter TubioNo ratings yet

- Ms6001b Operation DescriptionDocument53 pagesMs6001b Operation Descriptionprasad503486% (7)

- C2K Contents Manual BDocument71 pagesC2K Contents Manual BtimonNo ratings yet

- Pdra 23082022Document2 pagesPdra 23082022Ajmal SeemabNo ratings yet

- QRG Lube FilterDocument132 pagesQRG Lube FilterJose AlbertoNo ratings yet

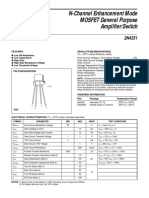

- EMOSFET Nchannel 2N4351Document1 pageEMOSFET Nchannel 2N4351Pradina Kiky WasibagnoNo ratings yet

- Inorgchem - D-Block Elements: PropertiesDocument8 pagesInorgchem - D-Block Elements: PropertiesHasantha PereraNo ratings yet

- Conduc T: Market Interaction of FirmsDocument10 pagesConduc T: Market Interaction of FirmsChin Yee LooNo ratings yet

- Katalogas enDocument20 pagesKatalogas enEman AdelNo ratings yet

- Design of Grounding and Lightning Protection SystemDocument26 pagesDesign of Grounding and Lightning Protection SystemTarun Chugh100% (1)

- Pratt & Whitney PW1921G Geared Turbo Fan Engine Possible ResonanceDocument10 pagesPratt & Whitney PW1921G Geared Turbo Fan Engine Possible ResonancenickNo ratings yet

- Aes - Mcqs - Unit - 1 To 5Document9 pagesAes - Mcqs - Unit - 1 To 5KumarJinneNo ratings yet

- 200 E 2 Floating Head Heat Exchanger MaintenanceDocument16 pages200 E 2 Floating Head Heat Exchanger Maintenancesubha50% (2)

- SB Ibl P CBL Submersible Power CableDocument23 pagesSB Ibl P CBL Submersible Power CableMuhammad ShahrukhNo ratings yet

- VW Oil SpecDocument18 pagesVW Oil Specjpsum161100% (2)

- Review of Related Studies (Solar Panel) : Charger - BODY FULL PDFDocument2 pagesReview of Related Studies (Solar Panel) : Charger - BODY FULL PDFMatti NoNo ratings yet

- 2016-10 TEK Index Masonry DesignDocument6 pages2016-10 TEK Index Masonry Designsuesspj11No ratings yet

- Unit 4 Pump: Suction, Delivery, Static and Accelerating HeadDocument11 pagesUnit 4 Pump: Suction, Delivery, Static and Accelerating HeadSurya PalNo ratings yet

- PDS - GulfSea Synth Compressor Oil 46 68Document2 pagesPDS - GulfSea Synth Compressor Oil 46 68Md.Obydur RahmanNo ratings yet

- XLProCalcul User Manual EngDocument80 pagesXLProCalcul User Manual EngJhonathan ST100% (2)

- Reading Material ATEX ProcessDocument14 pagesReading Material ATEX ProcessABHISHEK DOLLENo ratings yet

- FINAL TEST 1 K 2Document4 pagesFINAL TEST 1 K 2Nguyen Cuong100% (1)

- 2800 Series: 2806C-E16TAG2Document2 pages2800 Series: 2806C-E16TAG2Tony LiNo ratings yet

- WEG CFW700 Quick Parameter Reference PDFDocument76 pagesWEG CFW700 Quick Parameter Reference PDFEdson Luiz ValandroNo ratings yet

- Tune Up Spark Plug GappingDocument26 pagesTune Up Spark Plug GappingSelazinap LptNo ratings yet

- Internal Combustion Engine Heat Release Calculation Using Single Zone and CFD 3D Numerical ModelsDocument12 pagesInternal Combustion Engine Heat Release Calculation Using Single Zone and CFD 3D Numerical ModelsPinsteritNo ratings yet

- Meter L&TDocument12 pagesMeter L&TnenusakNo ratings yet

- Model Answer Summer 2016Document22 pagesModel Answer Summer 2016DiyaNegi0% (1)

- 1.7 Financial ManagementDocument26 pages1.7 Financial ManagementEngr Mohammed UsmaniaNo ratings yet