Professional Documents

Culture Documents

PO 210 EWEApresentation2014

Uploaded by

Anggita BayuCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PO 210 EWEApresentation2014

Uploaded by

Anggita BayuCopyright:

Available Formats

Aerodynamic Design Optimization of

Wind-lens Turbine

PO.ID

210

Nobuhito Oka, Masato Furukawa, Kazutoyo Yamada, Kenta Kawamitsu, Kota Kido and Akihiro Oka

Kyushu University, Japan

Abstracts

Table 1 shows the aerodynamic performances obtained

from the RANS simulations at the design operating

condition. The table shows that the output power

coefficient CW* in the optimal case is superior to that in

the other cases. That is also superior to the Betz limit.

As far as the authors know, the optimal design of the

present study is the only one which achieves a higher

output power coefficient than the Betz limit.

Initialdesign

designspecification

specification

Initial

design

specification

Initial

An optimum aerodynamic design method for the new

type of diffuser augmented wind turbine (DAWT) called

wind-lens turbine has been developed. The optimum

design method is based on a genetic algorithm (GA)

and a quasi-three-dimensional aerodynamic design

method. The quasi-three-dimensional aerodynamic

design consists of meridional viscous flow calculation

and two-dimensional blade element design.

Quasi three dimensional

aerodynamic design method

Decision of wind-lens meridional shape

& Blade loading distribution (r)

Meridional viscous Flow calculation

Coupling problem of the internal and external flow field

Axisymmetric viscous flow calculation on meridional plane

Blade force is introduced as body force

Table 1: Aerodynamic performances

Flow rate in wind-lens

Inlet flow distribution

Unit vector normal to

blade camber (nz , nr , n )

Relative flow angle

Aerodynamic performances of optimal and conventional

design cases are obtained from three-dimensional

Reynolds averaged Navier-Stokes (RANS) simulations.

The output power coefficient of the optimal case is

superior to the Betz limit. The numerical results show

that the aerodynamic performance of the wind-lens

turbine is affected by flow separations behind the windlens brim and inside the wind-lens.

Optimal

Conventional

Betz limit

Blade loading distribution

Two dimensional blade element design

No

Convergence

Two dimensional blade element theory on the

basis of the momentum theorem of ducted turbine

Designation of optional blade loading distribution

Three-Dimensional Flow Field

Evaluation & Selection

Crossover

No

A new type of DAWT called wind-lens turbine shown in

Figure 1 was developed in Kyushu University, Japan [1].

The distinctive feature of the wind-lens turbine is a brim

attached at the diffuser exit as shown in Figure 2. The

brim generates separation vortices behind it and the

diffuser creates meridional streamline curvature, so that

a low-pressure field is formed at the diffuser exit. The

low-pressure field draws the upstream wind into the

wind-lens and it generates non-uniform meridional flow

distributions at the rotor. This wind concentration on the

turbine rotor results in the significant enhancement of

the turbine output.

External flow field

Brim

Bell-mouth

Rotor

Wind-lens

Separation

vortex

Diffuser

Rotor

Inlet flow

distributions

Internal flow field

Convergence

Mutation

Yes

Optimized design

Figure 3: Flow chart of optimum aerodynamic design method

Design Specifications

Figure 4 shows the wind-lens shapes in the

conventional and optimal cases. In the optimal case, the

divergence angle of the near the diffuser exit is smaller,

the position of the wind-lens is located more backward

and the height of the wind-lens brim becomes lower

than that in the conventional case. Figure 5 shows the

blade loading distributions in the optimal and

conventional cases. Although a qualitative coincidence

of the blade loading distributions is observed between

the optimal and conventional designs, the blade loading

coefficients from mid-span section to tip section are

significantly different.

Hub

0.7

Figure 2: Schematic flow structure

A quasi-three-dimensional aerodynamic design method

has been developed for the wind-lens turbine, which

can take into account the non-uniform meridional flow

distributions [2]. The design method mainly consists of

two parts: meridional viscous flow calculation and twodimensional blade element design. The meridional

viscous flow calculation is introduced to obtain the nonuniform meridional flow distributions of the turbine rotor

inlet. Using the blade loading distribution and the

velocity distribution, the 3-D blade shape is designed by

the two dimensional blade element design method.

Taking into account the blade force, the meridional

viscous flow calculation is performed again. By

repeating the meridional viscous flow calculation and

the two dimensional blade element design, the blade

shape and the flow field are converged [2].

In the present study, a genetic algorithm (GA) has been

applied to the design method. The optimization objects

are the meridional shape of wind-lens and the blade

loading distribution. The same design specifications are

adopted except for the wind-lens shape and blade

loading distribution. A flow chart of the present optimum

design method is shown in Figure 3. The evaluation and

selection model is a Non-dominated Sorting Genetic

Algorithm II (NSGA-II) [3]. The crossover model is a

Real-coded Ensemble Crossover (REX) [4]. In the

optimization procedure, the aerodynamic performances

of each individual are obtained from the meridional

viscous flow calculation.

Spanwise distance

Optimum Aerodynamic Design Method

(Tip)

1

0.8

Radius r/D

Figure 1: Wind-lens turbine

0.6

0.5

Conventional

Figure 6 shows vortex cores and limiting streamlines on

the blade suction surface in the conventional and

optimal cases obtained by the RANS simulations.

Behaviors of separation vortices behind the brim of the

wind-lenses are significantly different between both

cases. In the conventional case, two large-scale

separation vortices are observed behind the brim.

However, only one large-scale separation vortex is

observed in the optimal case. Figure 7 shows

meridional streamlines and meridional velocity

distributions in tangentially-averaged flow fields

obtained by the RANS simulations. As mentioned above,

in the optimal case shown in Figure 7 (b), the

separation region behind the brim is much smaller than

the conventional case and there is no separation inside

the wind-lens. The suppression of the flow separation

behind the brim and inside the wind-lens in the optimal

case may be affected by the divergence angle in the

wind-lens, the brim height and the span-wise

distribution of the blade loading.

In order to achieve higher aerodynamic performance of

the wind-lens turbine, it is important that the design of

the rotor blade is performed coupled with the wind-lens.

These results indicate that the present aerodynamic

optimization for the wind-lens turbine design works well.

Separation

vortex

0.6

Separation

vortex

Conventional

Optimal

0.4

Flow

0.2

Flow

Wind-lens

Optimal

0.4

-0.1

(Hub) 0

0

0.1

Axial distance z/D

0.2

0.5

1.5

Local load coefficient (r)

Hn[-]CM

Rotation

1.0

0.413265

0.367347

Figure 4: Wind-lens shapes

Figure 5: Blade loading distributions

Aerodynamic Performance

The aerodynamic performances of the wind-lens turbine

are evaluated by the output power coefficient CW* and

the wind collection coefficient K. The output power

coefficient CW* is defined with the cross-sectional area

of the A* based on the outer diameter of wind-lens as

follows:

W

*

CW

(1)

V 3A* 2

where is the density of air, V is the free-stream wind

velocity and W is the wind turbine output power. The

theoretical limitation of the output power coefficient CW*

is CW* =0.593 according to the Betz limit. The wind

collection coefficient K is defined as the ratio of the

cross-sectional averaged velocity at the rotor inlet v1 to

the free-stream velocity V as follows:

v1

V

(2)

Wind-lens

Hn[-]CM

Rotation

1.0

0.413265

0.367347

0.321429

0.27551

0.229592

0.183673

0.137755

0.0918367

0.0459184

0

Trailing vortex

-1.0

K

1.01

1.07

0.66

Yes

3-D shape of wind lens turbine

& Aerodynamic performance

Introduction

CW*

0.604

0.474

0.593

Result of the calculation

3-D blade shape

(a) Conventional

0.321429

0.27551

0.229592

0.183673

0.137755

0.0918367

0.0459184

0

-1.0

Trailing vortex

(b) Optimal

Figure 6: Three-dimensional flow fields

Flow

Separation vortex

Rotor

vm/Utip

[-]

CM

0.413265

0.48

0.367347

0.321429

Flow separation

inside the wind-lens

(a) Conventional

Wind-lens

0.27551

0.229592

0.183673

0.137755

0.0918367

0.0459184

0

0.00

(b) Optimal

Figure 7 : Meridional streamlines and meridional velocity distributions

References

1. Ohya, Y., et al., Development of a shrouded wind turbine with a flanged

diffuser, Journal of Wind Engineering, Vol.96, pp.524-539., 2008

2. Oka, N., et al., Aerodynamic Design for Wind-Lens Turbine Using

Optimization Technique, Proceedings of the ASME 2013 FEDSM, Paper No.

FEDSM2013-16569., 2013

3. Deb, K., et al., A Fast and Elitist Multiobjective Genetic Algorithm : NSGA-II,

IEEE Trans. on evolutional computation, Vol. 6, No. 2, pp.182-197., 2002

4. Kobayashi, S., The frontiers of real-coded genetic algorithms, Journal of the

Japanese Society for Artificial Intelligence, Vol24, No.1, pp.147-162., 2009

EWEA 2014, Barcelona, Spain: Europes Premier Wind Energy Event

You might also like

- Jet Propulsion Cycles ExplainedDocument5 pagesJet Propulsion Cycles ExplainedAnggita BayuNo ratings yet

- Fluids ImDocument2 pagesFluids ImAnggita BayuNo ratings yet

- Microturbine Market PilavachiDocument12 pagesMicroturbine Market PilavachiAnggita Bayu100% (1)

- STG sg2Document162 pagesSTG sg2Radwa EL-MahdyNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Grupo Presion Del MotorDocument12 pagesGrupo Presion Del MotorGenaro GutierrezNo ratings yet

- Air Treatment SolutionsDocument7 pagesAir Treatment SolutionsPrince NeroNo ratings yet

- Experimental Study On Bump-Foil Gas Bearing With Different Diametric Clearance ConfigurationsDocument7 pagesExperimental Study On Bump-Foil Gas Bearing With Different Diametric Clearance ConfigurationswataruNo ratings yet

- NPTEL Fluid Mechanics Video CourseDocument1 pageNPTEL Fluid Mechanics Video CourseshubhamNo ratings yet

- CHE 304 Optional Homework Due Toluene HyDocument9 pagesCHE 304 Optional Homework Due Toluene Hyqurat ul ainNo ratings yet

- Gas Turbines SiemensDocument60 pagesGas Turbines SiemensCenk Yağız ÖzçelikNo ratings yet

- HAZIDDocument19 pagesHAZIDRogelio Lazo ArjonaNo ratings yet

- Vapour Absorption Refrigeration Systems ExplainedDocument15 pagesVapour Absorption Refrigeration Systems ExplainedSatheesh ChandranNo ratings yet

- Gas Turbine Power Plant: By: Ms. Monika DeshwalDocument19 pagesGas Turbine Power Plant: By: Ms. Monika DeshwalKeshantSharma100% (1)

- Blown Air Gas Burners Technical Specifications and DimensionsDocument36 pagesBlown Air Gas Burners Technical Specifications and Dimensionsomar djmsNo ratings yet

- Gas Chromatography Natural Gas Analysis StandardDocument15 pagesGas Chromatography Natural Gas Analysis Standardsevero9767% (3)

- As 2430-1 Classification of Hazardous AreasDocument18 pagesAs 2430-1 Classification of Hazardous AreasCheehoong YapNo ratings yet

- (3-2-2) NPTEL - Properties of Cryogenic FluidsDocument42 pages(3-2-2) NPTEL - Properties of Cryogenic FluidsAnonymous VDnLHNG7QQNo ratings yet

- ATPL Nhom4 BDHKDocument114 pagesATPL Nhom4 BDHKVăn Thành NguyễnNo ratings yet

- MPE112s - Sheet - 03 - Ideal GasDocument1 pageMPE112s - Sheet - 03 - Ideal Gasb5fc94cdd3100% (1)

- Rankine Cycle PDFDocument41 pagesRankine Cycle PDFAlmeghalawy83% (12)

- Refinery Safety Hazards and Best PracticesDocument32 pagesRefinery Safety Hazards and Best PracticesAbdulsalamNo ratings yet

- Compressor Valve Reference DataDocument3 pagesCompressor Valve Reference DataHusnu KusumaNo ratings yet

- S/N Item Description Qty Box No. 1Document9 pagesS/N Item Description Qty Box No. 1Nguyễn Kim HùngNo ratings yet

- Derivation of Fluid Flow Equations Review of Basic StepsDocument9 pagesDerivation of Fluid Flow Equations Review of Basic StepsAaron LisandrioNo ratings yet

- Refigeration KBu Sept 20Document85 pagesRefigeration KBu Sept 20ManeeshNo ratings yet

- Abdul Basit - Instrument TechnicianDocument3 pagesAbdul Basit - Instrument Technician586301No ratings yet

- Practica de Lugeon Cap. VDocument7 pagesPractica de Lugeon Cap. VKarl MejíaNo ratings yet

- MPD IntroDocument59 pagesMPD IntroeRU100% (1)

- Temporal Stability of Inviscid Incompressible Flows: SabhileshDocument34 pagesTemporal Stability of Inviscid Incompressible Flows: SabhileshSabhilesh SinghNo ratings yet

- Approximate Solution of Navier Stokes EquationDocument58 pagesApproximate Solution of Navier Stokes EquationsineNo ratings yet

- Basic Needs of Humans, Animals and PlantsDocument11 pagesBasic Needs of Humans, Animals and PlantsJane Baligod RapadasNo ratings yet

- Lab Report FluidDocument14 pagesLab Report FluidFaris DanialNo ratings yet

- Copt ManualDocument79 pagesCopt ManualPradeep Shukla94% (17)

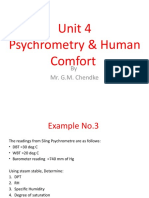

- Unit 4.5 Psychrometry Example No.3Document19 pagesUnit 4.5 Psychrometry Example No.3Vivek GondkarNo ratings yet