Professional Documents

Culture Documents

CIV500 Drainage

Uploaded by

Asad1001Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CIV500 Drainage

Uploaded by

Asad1001Copyright:

Available Formats

Civil and Structural Manual

500 Drainage

537 Component Design Considerations

This section describes some drainage components and tells how they are commonly

used. The standard drawings and forms are located in the Standard Drawings and

Forms section at the end of this manual.

Engineering Form 611

Engineering Form 611 (CIV-EF-611) shows how you can put the components

together to make some standard drainage system building blocks. It is intended to

give you some good starting arrangements; feel free to make changes or develop

other details to suit your needs.

CIV-EF-611 shows bell-and-spigot or plain end-and-hub connections, but similar

details can be easily envisioned for materials that require butt or other types of

joints. Check the actual dimensions of the fittings to be sure the pieces will fit in the

space available and will have adequate cover.

Note that the dimensions of cast iron bell-and-spigot fittings are different from the

dimensions of cast iron butt fittings.

Catch Basins and Drains

Catch basins and drains both serve the same purpose: to let liquid wastes enter the

underground drainage system quickly and safely.

Catch basins (Figure 500-11) contain a chamber where liquid is briefly retained to

aid in settling solids. The chamber is easily accessible for removing the accumulated material. Catch basins are normally built with the inlet opening flush with or

slightly below grade.

Fig. 500-11 Typical Catch Basin

Chevron Corporation

500-31

June 1997

500 Drainage

Civil and Structural Manual

Runoff from unpaved areas will contain suspended sediment that can clog small

catch basins, so be sure to use adequately sized basins. Experience is the best guide

for size selection.

A drain or drain hub is a simple inlet that has no retention capacity. If it protrudes

above grade, it is called a raised drain hub. If it is below grade, it is called a

recessed drain hub. Raised hubs can receive waste from vessels or pumps while

preventing surface fluids from entering. Details 3 and 4 on CIV-EF-611 show

recessed and raised drain hubs.

Sealed Drain Hubs and Catch Basins

Catch basins and drains can also provide a seal, (sometimes called a gas seal or

liquid seal) that prevents flammable or toxic gases in the downstream piping from

escaping to the atmosphere. Seals also keep heavier-than-air flammable or toxic

vapors from flowing into the system, and they prevent fire from traversing the

drainage system.

Since sealed drains will accumulate solids and are not easy to clean, do not use

them if the liquid will contain solids that might settle out. Instead, use sealed catch

basins with sufficient clearance between the bottom of seal and the bottom of basin

(Dimension E on Drawing GC-S78325).

Detail 8 on CIV-EF-611 shows a sealed drain. Drawing GC-S78325 shows a cast

iron, sealed catch basin. Fabricated steel, sealed catch basins are available (see

Drawing GD-S-99992). Adapters are available to connect the steel catch basin to

non-steel drain lines.

Manholes

Manholes provide access for inspection and cleaning (hydroblast or roto-rooter)

of drain lines, and they act as junction boxes for drains where fittings are not available or are more expensive. Manholes are also a good place to tie in future drain

lines.

If the standing water in sealed manholes is a groundwater pollution concern, then a

double wall manhole with leak monitoring between the walls might be required.

If the water table is high, ensure that the manhole weight exceeds the buoyant force

or anchor the manhole by extending its base beyond its walls.

If your manholes are in traffic areas, design them for wheel loads.

See CIV-EF-411 for typical manhole details.

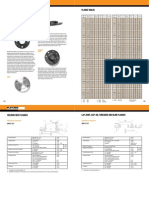

Manhole Covers

Manholes in systems carrying volatile flammable or toxic liquid should have vaportight covers to prevent the release of gases near ignition sources and people. See

Reference [21] for federal regulations governing emissions from manhole covers.

If samples will be taken from manholes frequently, consider using covers with

sample windows. The sample window shown in Figure 500-12 is not vapor tight.

June 1997

500-32

Chevron Corporation

Civil and Structural Manual

500 Drainage

Fig. 500-12 Manhole Cover Sample Window

Manhole Vents

You should provide vents to relieve pressure and prevent oxygen depletion in

manholes with vapor-tight covers.

Vents should end a safe distance (usually a minimum of 25 feet horizontally

and downwind if possible) from furnaces or permanent sources of ignition.

Vents should not terminate near walkways, platforms, or air intakes.

Vents within a 10-foot radius of walkways and equipment should end 18 inches

above the highest pipe or piece of equipment and 12 feet or more above walkways.

Vents in VOC or benzene service must be at least 3 feet in length and less than

4 inches in diameter. In addition, vents in benzene service must be controlled.

See Reference [21] for federal regulations on this topic.

Ways to Change Direction, Slope, and Size

At direction, slope, and size changes, you can use either manholes or fittings.

Manholes can be cheaper than large diameter fittings. Find out if local cleaning

contractors equipment can negotiate fittings.

If the pipe joint system is flexible enough to allow misalignment without leaking,

you can make small changes in slope and direction (a few degrees) by using

purposely misaligned joints. Joint manufacturers usually publish limits of flexibility. In areas where groundwater protection is very important, you probably

should not use this technique except as required for small field adjustments.

Access for Cleaning, Inspection, and Repair

Manholes provide better access than cleanouts for inspection and repair, but

cleanouts are just as good for cleaning. Cleanouts are usually cheaper than

manholes unless the cleanouts are built from large diameter fittings. Talk with local

Chevron Corporation

500-33

June 1997

Civil and Structural Manual

500 Drainage

20. Akan, A. Osman Kinematic-Wave Method for Peak Runoff Estimates, American Society of Civil Engineers, Journal of Transportation Engineering, Vol.

111, No. 4, July, 1985.

Summary: A technical paper that gives several very practical formulas for overland flow time (for use with the Rational Formula.) The paper gives formulas

for plain, flat slopes; flat slopes intercepted by gutters; converging slopes; and

others.

21. 40 Code of Federal Regulations Part 60 and 61.

Standards of Performance for New Stationary Sources Subpart QQQ, Volatile

Organic Compounds Emissions from Petroleum Refinery Wastewater Systems

(40 CFR 60.692-2), requires all process drains to have water seals and all

junction boxes to be covered. Junction boxes may have a vent pipe, but it must

be at least three feet long, and less than four inches in diameter.

The National Emission Standard for Hazardous Air Pollutants Subpart FF,

National Emission Standard for Benzene Waste Operations (40 CFR 61.346)

applies to facilities at which the total annual benzene quantity from facility

waste is more than 10 megagrams per year or aqueous waste streams are

treated to a total of 6 megagrams per year of benzene. Process drains subject to

this standard must have water seals, and manholes must have covers that allow

emissions less than 500 ppm above background levels. Junction boxes must be

covered and may have a vent pipe, but it must be at least three feet long, less

than four inches in diameter, and emissions from the vent pipe must be

controlled.

22. Coatings Manual.

23. Corrosion Prevention Manual.

24. Safety In Designs Manual. (SID)

25. Airport Drainage Advisory Circular No. 150/5320-5B. United States Department of Transportation Federal Aviation Administration, July 1970.

Summary: This circular provides guidance for the design and maintenance of

airport drainage systems. It includes nomographs for flow in open channels

and an equation for calculating overland flow time for use with the Rational

Formula.

26. NOAA Technical Memorandum NWS Hydro-35, 5 to 60 Minute Precipitation

Frequency for the Eastern and Central United States, 1977.

Summary: Gives intensity-duration-frequency information for use with the

Rational Formula. Gives rainfall-frequency values for durations of 5, 15, and

60 minutes at return periods of 2 and 100 years for 37 states from North

Dakota to Texas and eastward. Equations are given to derive 10- and 30-minute

values for return periods between 2 and 100 years.

27. NOAA Atlas 2, Precipitation-Frequency Atlas of the Western United States,

Volumes I - XI, 1973.

Chevron Corporation

500-105

June 1997

You might also like

- D 25Document7 pagesD 25isaacalvareztejanoNo ratings yet

- Spirax 1Document7 pagesSpirax 1Asad1001No ratings yet

- Design of Skirt Support: S 18,000 Stress Value E" 0.60 For Butt Joint of SA-285-CplateDocument1 pageDesign of Skirt Support: S 18,000 Stress Value E" 0.60 For Butt Joint of SA-285-CplateAsad1001No ratings yet

- Article of Metal BehaviourDocument15 pagesArticle of Metal BehaviourAsad1001No ratings yet

- PLENTY Side Entry MixersDocument26 pagesPLENTY Side Entry MixersDainycious KibiwottNo ratings yet

- Plane Sections Remain Plane. Y: CompressionDocument5 pagesPlane Sections Remain Plane. Y: CompressionakanyilmazNo ratings yet

- General Information OilseparatorDocument8 pagesGeneral Information OilseparatorAsad1001No ratings yet

- Nfpa Codes PDFDocument9 pagesNfpa Codes PDFarman_moralaNo ratings yet

- Design of Skirt Support: S 18,000 Stress Value E" 0.60 For Butt Joint of SA-285-CplateDocument1 pageDesign of Skirt Support: S 18,000 Stress Value E" 0.60 For Butt Joint of SA-285-CplateAsad1001No ratings yet

- Std11 Maths EM 1Document271 pagesStd11 Maths EM 1Hariprasad ManoharanNo ratings yet

- Anhydrous Ammonia Fittings and Ancillary EquipmentDocument2 pagesAnhydrous Ammonia Fittings and Ancillary Equipmentthanga1981No ratings yet

- Gas Liquid Separation TechnologyDocument24 pagesGas Liquid Separation TechnologyAsad1001No ratings yet

- Gasket StandardsDocument40 pagesGasket StandardsSiva Raman Murugesan100% (1)

- Friction Factors For Pipe Flow - Moody - 1944Document14 pagesFriction Factors For Pipe Flow - Moody - 1944badecote100% (1)

- Base Ring AnalysisDocument9 pagesBase Ring Analysisasirul_meNo ratings yet

- GasketsDocument1 pageGasketsAsad1001No ratings yet

- Complex NumberDocument44 pagesComplex NumberAsad100167% (3)

- Flange TableDocument12 pagesFlange Table235meenuNo ratings yet

- Tube To Tubesheet ConnectionDocument19 pagesTube To Tubesheet ConnectionbalajiNo ratings yet

- Integration Formulas: 1. Common IntegralsDocument5 pagesIntegration Formulas: 1. Common IntegralssiegherrNo ratings yet

- Pentair PSV Engineering HandbookDocument233 pagesPentair PSV Engineering HandbookAsad1001No ratings yet

- Gas Liquid Separation TechnologyDocument24 pagesGas Liquid Separation TechnologyAsad1001No ratings yet

- Iron-Carbon Phase DiagramDocument1 pageIron-Carbon Phase DiagramAsad1001No ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Wafer-God and the Bloody History of the VaticanDocument58 pagesThe Wafer-God and the Bloody History of the VaticanMin Hotep Tzaddik BeyNo ratings yet

- Fda PDFDocument2 pagesFda PDFVictorNo ratings yet

- Khaton Prayer BookDocument47 pagesKhaton Prayer BookKarma TsheringNo ratings yet

- Crash Cart - General Checklist For Medical Supplies On Crash CartsDocument3 pagesCrash Cart - General Checklist For Medical Supplies On Crash CartsYassen ManiriNo ratings yet

- Lec 10 - MQueues and Shared Memory PDFDocument57 pagesLec 10 - MQueues and Shared Memory PDFUchiha ItachiNo ratings yet

- OLA CAB MARKET ANALYSIS AND TRENDSDocument55 pagesOLA CAB MARKET ANALYSIS AND TRENDSnitin gadkariNo ratings yet

- Docking 1Document12 pagesDocking 1Naveen Virendra SinghNo ratings yet

- MKT-case StudyDocument7 pagesMKT-case StudyJoe Thampi KuruppumadhomNo ratings yet

- E PortfolioDocument76 pagesE PortfolioMAGALLON ANDREWNo ratings yet

- MSC Euribia - 2023-06-01Document2 pagesMSC Euribia - 2023-06-01蔡國懷No ratings yet

- Daughters of The Storm by Kim Wilkins - Chapter SamplerDocument32 pagesDaughters of The Storm by Kim Wilkins - Chapter SamplerHarlequinAustraliaNo ratings yet

- Class 9th Chemistry Unit#4 Structure of MoleculesDocument8 pagesClass 9th Chemistry Unit#4 Structure of MoleculesIrfanullahNo ratings yet

- HP 5973 Quick ReferenceDocument28 pagesHP 5973 Quick ReferenceDavid ruizNo ratings yet

- 4 - Complex IntegralsDocument89 pages4 - Complex IntegralsryuzackyNo ratings yet

- Write 10 Lines On My Favourite Subject EnglishDocument1 pageWrite 10 Lines On My Favourite Subject EnglishIrene ThebestNo ratings yet

- Ireland in Pre Celtic TimesDocument398 pagesIreland in Pre Celtic TimesGrant MacDonald100% (5)

- Power Bi ProjectsDocument15 pagesPower Bi ProjectssandeshNo ratings yet

- Castel - From Dangerousness To RiskDocument10 pagesCastel - From Dangerousness To Riskregmatar100% (2)

- Mechanical Questions & AnswersDocument161 pagesMechanical Questions & AnswersTobaNo ratings yet

- SQL 1: Basic Statements: Yufei TaoDocument24 pagesSQL 1: Basic Statements: Yufei TaoHui Ka HoNo ratings yet

- The Life and Works of Jose RizalDocument20 pagesThe Life and Works of Jose RizalBemtot Blanquig100% (1)

- Homo Sapiens ActivityDocument8 pagesHomo Sapiens ActivityJhon Leamarch BaliguatNo ratings yet

- RestrukturisasiDocument17 pagesRestrukturisasimuhammad hayel wallaNo ratings yet

- Assignment 3 Part 3 PDFDocument6 pagesAssignment 3 Part 3 PDFStudent555No ratings yet

- Ch. 7 - Audit Reports CA Study NotesDocument3 pagesCh. 7 - Audit Reports CA Study NotesUnpredictable TalentNo ratings yet

- T23 Field Weld Guidelines Rev 01Document4 pagesT23 Field Weld Guidelines Rev 01tek_surinderNo ratings yet

- Understanding Culture, Society and PoliticsDocument62 pagesUnderstanding Culture, Society and PoliticsTeds TV89% (84)

- PowerhouseDocument10 pagesPowerhouseRanjan DhungelNo ratings yet

- Brochure - Truemax Concrete Pump Truck Mounted TP25M4Document16 pagesBrochure - Truemax Concrete Pump Truck Mounted TP25M4RizkiRamadhanNo ratings yet

- Hotel and Restaurant at Blue Nile FallsDocument26 pagesHotel and Restaurant at Blue Nile Fallsbig johnNo ratings yet