Professional Documents

Culture Documents

Field Itp For Piping Work Samur Project Rev-5 (23 April 2013)

Uploaded by

Echik KiciOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Field Itp For Piping Work Samur Project Rev-5 (23 April 2013)

Uploaded by

Echik KiciCopyright:

Available Formats

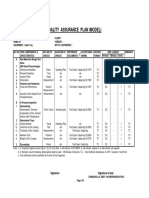

Form.

No

Inspection and Test Plan For Piping Work

MHI-APEX-REKIND

QA/QC

Project No.

Pages.:

ITP sheet No. 6419R A434-00001

Commodity

HC-T&C/2010/0008

QI - G-08

Identification

UNDER GROUND PIPING (1/4)

SUBCONTRACTOR

Activity

No,

1

2

Inspection/ Test Activity Item

Charateristic To Be

Verfied/Inspected/Tested

Methode of

Inspection

Material Receiving Inspection

Correct material and Appearance

CONTRACTOR

Frequency

Acceptance

Creteria/Reference Document

Verifing Document

Visual

Each Receiving

Specification and Code

QI - G.07b

Correct Identification

Review

Each Joint

Isometric Drawings

QI-L07

Date/ Sign

Date/ Sign

FIT-UP

a.

Identification of Joint

b.

Check cutting/fit-up

Correct Fit Up, Orientation, dimentional &Orientation,

record & mark on the piping Heat No, provision of

backing gas, root gap, angle, cleanliness, allignment,

weather condition, proper protection & correct as per

Isometric, tack wedling

Visual

Each Joint

Isometric Drawings , ASME B.31.3 ,

6419M A234-00100, WPS & Mill Cert.

QI-L07

c.

Tack Welding Check

Appearance & Location of tack weld

Visual

Each Joint

ASME Sec. IX & 6419M A234-00100

QI-L07

d.

Pad of Chathodic Protection Check

Visual & Dimensional

Visual

Each Joint

Isometric Drawings

QI-L07

Prepared by (Contractor)

Approved by (Contractor)

Rev.No:

Date:

4

Name: Edi Sunardi/QC Engineer

March-8-2013

Name: Amir GJ Tarigan/FQM

Certified Complete (Contractor-SM/CM) Date:

deleted

I:

RFI, mandatory inspection and repprt

W:

RFI, option inspection and as report

H:

R:

RFI, mandatory inspection and as report

No RFI, No inspection and review/sign re

S:

No RFI, monitoring works and no sig

Authorization (Contractor FQM)

Date:

Form. No

Inspection and Test Plan For Piping Work

MHI-APEX-REKIND

QA/QC

Project No.

ITP sheet No. 6419R A434-00001

Commodity

HC-T&C/2010/0008

QI - G-08

Pages.:

Identification

UNDER GROUND PIPING (2/4)

SUBCONTRACTOR

Activity

No,

Inspection/ Test Activity Item

Charateristic To Be

Verfied/Inspected/Tested

Methode of

Inspection

Frequency

Acceptance

Creteria/Reference Document

Verifing Document

CONTRACTOR

Date/ Sign

Date/ Sign

WELDING

a.

Consumable Control (including electrode control)

Correct Consumable (Storage & Baking).

Review

Random

Project Procedure/specification

b.

WPS & PQR Review and Approval

Welding Requirement (WPS/PQR Data)

Review

Each WPS/PQR

ASME Sec. IX & 6419M A234-00100

WPS/PQR

R/I*

R/W*

c.

Welders Performance Qualification Test and/or

Procedure Qualification Test

Performance & Qualification

Visual & Review

Each Welder

ASME Sec. IX & 6419M A234-00100

Welder Qualification Record/

Procedure Qualification Record

I/R

W/R

d.

Weld Inspection during & after

Profiles, defects, Interpass Temp, , No coarse ripple,

Undercut & reinforcement.

Visual

Each Joint

ASME B31.3 & 6419M A234-00100

QI-L07

Surface Condition (Clean & Dry)

Visual

Each Line

Vendor Specification

QI-N03

Primer Coat Condition & Application

Visual

Each Line

Vendor Specification

QI-N03

WRAPPING

a.

Surface Preparation

b.

Primer Coat

c.

Inner Tape Wrapping

Appearance Condition

Visual

Each Line

Vendor Specification

QI-N03

d.

Outer Tape Wrapping

Appearance Condition

Visual

Each Line

Vendor Specification

QI-N03

e.

Holiday Dtector Test

No Pinhole

Test

Each Line

No Pinhole

QI-N04

Strength

Test

Sample

Manufacture Specification / Data Sheet

Test Report

f.

Pull-Off / Peel Test (One time only as

prequalification at the beginning of wrapping

activities, not for production lines test)

as per

Manufacturer

Recommendation/Data-Sheet.

Prepared by (Contractor)

Approved by (Contractor)

Rev.No:

Date:

H: Hold, W: Witness, Ws: Spot W

4

Name: Edi Sunardi/QC Engineer

March-8-2013

Name: Amir GJ Tarigan/FQM

Certified Complete (Contractor-SM/CM) Date:

Authorization (Contractor FQM)

Date:

Certified Complete (Contractor-SM/CM) Date:

Form. No

Inspection and Test Plan For Piping Work

MHI-APEX-REKIND

QA/QC

Project No.

ITP sheet No. 6419R A434-00001

Commodity

HC-T&C/2010/0008

QI - G-08

Pages.:

Identification

UNDER GROUND PIPING (3/4)

SUBCONTRACTOR

Activity

No,

Inspection/ Test Activity Item

Charateristic To Be

Verfied/Inspected/Tested

Methode of

Inspection

Frequency

Acceptance

Creteria/Reference Document

Verifing Document

CONTRACTOR

Date/ Sign

Date/ Sign

NON DESTRUCTIVE EXAMINATION

A

RADIOGRAPHIC EXAMINATION

1.

RT Procedure Approval

Method ,Scope of Test

Review

At Once

NDE Procedure & ASME Sec. V

NDE Procedure

2.

Personnel Qualifications

Qualification as per requirement

Review

Each Personal

NDE Procedure & ASME Sec. V

Certificates

3.

Identification of Joints

Correct Joint & Visual

Review

Each Joints

Isometric Drawings

Third Party Form Sheet

4.

Perform Test & Evaluate of Result

Correct Test

Visual

Each Test

NDE Procedure & ASME Sec. V

Third Party Form Sheet

5.

Evaluate Of Results

Correct Evaluation of defects

Review

Each Test

ASME B31.3

Third Party Form Sheet

Method ,Scope of Test

Review

At Once

NDE Procedure & ASME Sec. V

NDE Procedure

Qualification as per requirement

Review

Each Personal

NDE Procedure & ASME Sec. V

Certificates

Correct Joint & Visual

Review

Each Joints

Isometric Drawings

Third Party Form Sheet

Correct Test

Visual

Each Test

NDE Procedure & ASME Sec. V

Third Party Form Sheet

Correct Evaluation of defects

Review

Each Test

ASME B31.3

Third Party Form Sheet

Ultrasonic, Dye Penetrant Examination &

Magnetic Particle Examination ( UT, DPE &

MPE )

(if Required)

1.

UT, DPE & MPE Procedure Approval

2.

Personnel Qualifications

3.

Identification of Joints

4.

Perform Test & Evaluate of Result

5.

Evaluate Of Results

Prepared by (Contractor)

Approved by (Contractor)

Rev.No:

Date:

H: Hold, W: Witness, Ws: Spot W

4

Name: Edi Sunardi/QC Engineer

March-8-2013

Name: Amir GJ Tarigan/FQM

Certified Complete (Contractor-SM/CM) Date:

Authorization (Contractor FQM)

Date:

Certified Complete (Contractor-SM/CM) Date:

Form. No

Inspection and Test Plan For Piping Work

MHI-APEX-REKIND

QA/QC

Project No.

ITP sheet No. 6419R A434-00001

Commodity

HC-T&C/2010/0008

QI - G-08

Pages.:

Identification

UNDER GROUND PIPING (4/4)

SUBCONTRACTOR

Activity

No,

Inspection/ Test Activity Item

CONTRACTOR

Charateristic To Be

Verfied/Inspected/Tested

Methode of

Inspection

Frequency

Acceptance

Creteria/Reference Document

Verifing Document

Correct Test Package

Review

Each Test Pack

Test Block Diagram

Test Package

Date/ Sign

Date/ Sign

HYDROSTATIC TEST

a.

Test Package Review and Released to Test

b.

Calibration of Gauges

Rangne,Calibration Status & condition

Review

Each Gauge

Valid Calibration

Certificate Calibration

c.

Perform pressure test

No Leakage ( Check Pressure, Temperature, Check for

any leak and Holding time), Calibration Certificate of

Gauges

Visual

Each Test Pack

ASME B31.3 & 6419M A234-00100

QI-L02

Condition of Trench and Bed, Check trench Size, bed

Size, No foreign Material, Correct Position and

Elevation.

Visual

Each Trench

AFC Drawings

Handover/Survey Report (put number

form)

Inspection Report completenes

Review

Correct Joint, (Refer to 2.& 3)

Visual

Each Joints

Isometric Drawings & 6419M A23400100

QI-L.07

INSTALLATION

a.

Trench & Bed condition Check

b.

Completeness check before lowering

b.

Field Fit up and Weld Joint

c.

NDE

Correct Joint & Defects

Review

Each Joints

NDE Procedure

NDE Report

d.

Field Joint Wrapping

Correct Joint (Refer to 4

Review

Each Joints

Isometric Drawings

Ws

Surface Condition (Clean & Dry)

Visual

Each Line

Vendor Specification

QI-N03

Ws

Application & Primer Coat Condition

Visual

Each Line

Vendor Specification

QI-N03

Ws

3. Inner Tape Wrapping

Appearance Condition

Visual

Each Line

Vendor Specification

QI-N03

Ws

4. Outer Tape Wrapping

Appearance Condition

Visual

Each Line

Vendor Specification

QI-N03

Ws

5. Holiday Detector Test

No Pinhole

Test

Each Line

No Pinhole

QI-N04

Backfill condition & Material Backfill.

Visual

Each Line

IFC Drawing

QI-C.0.06

1. Surface Preparation

2 .Primer Coat

e.

Backfilling

Prepared by (Contractor)

Approved by (Contractor)

Rev.No:

Date:

H: Hold, W: Witness, Ws: Spot W

March-8-2013

4

Name: Edi Sunardi/QC Engineer

Name: Amir GJ Tarigan/FQM

Certified Complete (Contractor-SM/CM) Date:

Authorization (Contractor FQM)

Form. No

Inspection and Test Plan For Piping Work

MHI-APEX-REKIND

QA/QC

Project No.

QI - G-08

Pages.:

ITP sheet No. 6419R A434-00001

Commodity

HC-T&C/2010/0008

Identification

ABOVE GROUND PIPING (1/9)

SUBCONTRACTOR

Activity

No,

1

Inspection/ Test Activity Item

Charateristic To Be

Verfied/Inspected/Tested

Methode of

Inspection

Material Receiving Inspection

Correct material and Appearance

Identification of Joint

b.

CONTRACTOR

Frequency

Acceptance

Creteria/Reference Document

Verifing Document

Visual

Each Receiving

Specification and Code

QI - G.07b

Correct Identification

Review

Each Joint

Isometric Drawings

QI-L07

Check cutting/fit-up.

Correct Fit Up, Orientation, dimentional

&Orientation, record & mark on the piping Heat

No, provision of backing gas, pre-heat before tack

weld, root gap, angle, cleanliness, allignment,

weather condition, proper protection & correct as

per Isometric.

Visual

Each Joint

Isometric Drawings , ASME B.31.3 ,

6419M A234-00100, WPS & Mill

Cert.

QI-L07

Ws

c.

Tack Welding Check

Appearance & Location of tack weld

Visual

Each Joint

ASME Sec. IX & 6419M A23400100

QI-L07

Ws

d.

Weld Identification

Completed Weld

Visual

Each Joint

ASME B.31.3 , 6419M A23400100,

QI-L07

Ws

Date:

Date/ Sign

Date/ Sign

I

FIT-UP

a.

Prepared by (Contractor)

Approved by (Contractor)

Rev.No:

Date:

H: Hold, W: Witness, Ws: Spot W

Prepared by (Contractor)

Approved by (Contractor)

H: Hold, W: Witness, Ws: Spot W

4

Name: Edi Sunardi/QC Engineer

March-8-2013

Name: Amir GJ Tarigan/FQM

Certified Complete (Contractor-SM/CM)

Date:

Authorization (Contractor FQM)

Form. No

Inspection and Test Plan For Piping Work

MHI-APEX-REKIND

QA/QC

Project No.

QI - G-08

Pages.:

ITP sheet No. 6419R A434-00001

Commodity

HC-T&C/2010/0008

Identification

ABOVE GROUND PIPING (2/9)

SUBCONTRACTOR

Activity

No,

Inspection/ Test Activity Item

Date:

Charateristic To Be

Verfied/Inspected/Tested

Methode of

Inspection

Frequency

Acceptance

Creteria/Reference Document

Verifing Document

CONTRACTOR

Date/ Sign

Date/ Sign

WELDING

a.

Consumable Control (including electrode

control)

Correct Consumable (Storage & Baking).

Review

Random

Project Procedure/specification

Ws

b.

WPS & PQR Review and Approval

Welding Requirement (WPS/PQR Data)

Review

Each WPS/PQR

ASME Sec. IX & 6419M A23400100

WPS/PQR

c.

Welders Performance Qualification Test

and/or Procedure Qualification Test

Performance & Qualification

Visual & Review

Each Welder

ASME Sec. IX & 6419M A23400100

Welder Qualification Record/

Procedure Qualification Record

d.

Preheat ( if specified)- Torch or Heating

Element

Correct temperature

Visual & Review

as specified

ASME B31.3 & 6419M A234-00100

e.

Weld Inspection during & after

Profiles, defects, Interpass Temp, Post Heat, No

coarse ripple, Undercut & reinforcement.

Visual

Each Joint

ASME B31.3 & 6419M A23400100, WPS

QI-L07

d.

Visual Inspection

Visual

Each Joint

ASME B31.3 & 6419M A234-00100

QI-L07

Weld profile

Prepared by (Contractor)

Approved by (Contractor)

Rev.No:

Date:

H: Hold, W: Witness, Ws: Spot W

4

Name: Edi Sunardi/QC Engineer

March-8-2013

Name: Amir GJ Tarigan/FQM

Certified Complete (Contractor-SM/CM) Date:

QA/QC

Project No.

Inspection/ Test Activity Item

QI - G-08

Pages.:

ITP sheet No. 6419R A434-00001

Commodity

HC-T&C/2010/0008

Identification

ABOVE GROUND PIPING (3/9)

Charateristic To Be

Verfied/Inspected/Tested

Methode of

Inspection

SUBCONTRACTOR

Frequency

Acceptance

Creteria/Reference Document

Verifing Document

CONTRACTOR

Date/ Sign

Date/ Sign

POSITIVE MATERIAL IDENTIFICATION

(PMI) TEST PROCEDURE AT SITE Dwg

No.

(6419R A43000003)

Date:

Form. No

Inspection and Test Plan For Piping Work

MHI-APEX-REKIND

Activity

No,

Authorization (Contractor FQM)

a.

PMI Test Procedure Approval

Method ,Scope of Test

Review

as specified

PMI Test Procedure at Site

(Dwg No.

6419R A430-00003)

PMI Test Procedure

b.

Identification of Weld Joints/Material

Correct Joint & Visual

Review

as specified

PMI Test Procedure at Site

(Dwg No.

6419R A430-00003)

QI-AV.01

c.

Perform Test & Evaluate result

Correct Test

Test

Each Test

PMI Test Procedure at Site

(Dwg No.

6419R A430-00003)

QI-AV.01

d.

Evaluate Of Results

Correct Evaluation of material

Review

Each Test

PMI Test Procedure at Site

(Dwg No.

6419R A430-00003)

QI-AV.01

Prepared by (Contractor)

Approved by (Contractor)

Rev.No:

Date:

H: Hold, W: Witness, Ws: Spot W

4

Name: Edi Sunardi/QC Engineer

March-8-2013

Name: Amir GJ Tarigan/FQM

Certified Complete (Contractor-SM/CM) Date:

Authorization (Contractor FQM)

Form. No

Inspection and Test Plan For Piping Work

MHI-APEX-REKIND

QA/QC

Project No.

QI - G-08

Pages.:

ITP sheet No. 6419R A434-00001

Commodity

HC-T&C/2010/0008

Identification

ABOVE GROUND PIPING (4/9)

SUBCONTRACTOR

Activity

No,

Inspection/ Test Activity Item

Charateristic To Be

Verfied/Inspected/Tested

Methode of

Inspection

Correct pipe support , location / type / size

/material

Visual

Condition of Cleanless

Visual

Alignment And Squareness, Plumb/Level/Slope

Visual

Frequency

Acceptance

Creteria/Reference Document

Verifing Document

Each Line

Isometric Drawings

QI-L.01

Each Line

Project Specification

CONTRACTOR

Date/ Sign

Date/ Sign

INSTALLATION

a.

Pipe support

b.

Pipe Spool internal cleaning prior to

installation

c.

Pipes / Spools Installation

d.

Alignment And Squareness

Correct installation

e.

Plumb / Level / Slope

f.

Gaskets / Valves (included Control

Valve,Check Valve & Safety Valve)

g.

Strainers / Support / Hangers (clearance &

set-up on cold and hot condition)

h.

NDE

d.

Bolt tightening

i.

Fina Punchlist

Date:

Each Line

Isometric Drawings

QI-L.01

Visual

Each Line

Isometric Drawings

QI-L.01

Correct installation

Visual

Each Line

Isometric Drawings

QI-L.01

Correct installation

Visual

Each Line

Isometric Drawings

QI-L.01

Each Line

Isometric Drawings

QI-L.01

Each Line

NDT Procedure

NDE Report

Correct installation

Visual

Completeness of NDE

Test

conform to torque value

Test

- Line Check before hydrotest

- Pipe support welded direct to Pipe

Prepared by (Contractor)

Completeness of Installation, Correct material

spec, Orientation as per dwg, gasket, nut & bolt

matl, Tighten, pipe support any change in pipe

routing record.

Visual & Review

Each Line

Isometric Drawing, P & ID

QI-L.01

Completeness of Installation, Correct material

spec,

Visual, DPE & Review

Each Support

Isometric Drawing, P & ID

Third Party Form Sheet

Approved by (Contractor)

Rev.No:

Date:

H: Hold, W: Witness, Ws: Spot W

4

Name: Edi Sunardi/QC Engineer

March-8-2013

Name: Amir GJ Tarigan/FQM

Certified Complete (Contractor-SM/CM) Date:

MHI-APEX-REKIND

QA/QC

Activity

No,

Inspection/ Test Activity Item

NON DESTRUCTIVE EXAMINATION

RADIOGRAPHIC EXAMINATION

QI - G-08

Pages.:

ITP sheet No. 6419R A434-00001

Commodity

HC-T&C/2010/0008

Date:

Form. No

Inspection and Test Plan For Piping Work

Project No.

Authorization (Contractor FQM)

Identification

ABOVE GROUND PIPING (5/9)

Charateristic To Be

Verfied/Inspected/Tested

Methode of

Inspection

SUBCONTRACTOR

Frequency

Acceptance

Creteria/Reference Document

Verifing Document

CONTRACTOR

Date/ Sign

Date/ Sign

approval procedure, qualification personnel, .

1.

UT

Method ,Scope of Test

Review

At Once

NDE Procedure & ASME Sec. V

NDE Procedure

2.

PT

Qualification as per requirement

Review

Each Personal

NDE Procedure & ASME Sec. V

Certificates

3.

MPI

Correct Joint & Visual

Review

Each Joints

Isometric Drawings

Third Party Form Sheet

Ws

4.

Perform Test

Correct Test

Visual

Each Test

NDE Procedure & ASME Sec. V

Third Party Form Sheet

5.

Evaluate Of Results

Correct Evaluation of defects

Review

Each Test

ASME B31.3

Third Party Form Sheet

Prepared by (Contractor)

Approved by (Contractor)

Rev.No:

Date:

H: Hold, W: Witness, Ws: Spot W

4

Name: Edi Sunardi/QC Engineer

March-8-2013

Name: Amir GJ Tarigan/FQM

Certified Complete (Contractor-SM/CM) Date:

QA/QC

Project No.

Inspection/ Test Activity Item

Ultrasonic, Dye Penetrant Examination &

Magnetic Particle Examination ( UT, DPE &

MPE )

(if Required)

1.

UT, DPE & MPE Procedure Approval

2.

Personnel Qualifications

3.

Identification of Joints

4.

Perform Test

5.

Evaluate Of Results

QI - G-08

Pages.:

ITP sheet No. 6419R A434-00001

Commodity

HC-T&C/2010/0008

Date:

Form. No

Inspection and Test Plan For Piping Work

MHI-APEX-REKIND

Activity

No,

Authorization (Contractor FQM)

Identification

ABOVE GROUND PIPING (6/9)

SUBCONTRACTOR

CONTRACTOR

Charateristic To Be

Verfied/Inspected/Tested

Methode of

Inspection

Frequency

Acceptance

Creteria/Reference Document

Verifing Document

Method ,Scope of Test

Review

At Once

NDE Procedure & ASME Sec. V

NDE Procedure

Qualification as per requirement

Review

Each Personal

NDE Procedure & ASME Sec. V

Certificates

Correct Joint & Visual

Review

Each Joints

Isometric Drawings

Third Party Form Sheet

Ws

Correct Test

Visual

Each Test

NDE Procedure & ASME Sec. V

Third Party Form Sheet

Correct Evaluation of defects

Review

Each Test

ASME B31.3

Third Party Form Sheet

Date/ Sign

Date/ Sign

Prepared by (Contractor)

Approved by (Contractor)

Rev.No:

Date:

Name: Edi Sunardi/QC Engineer

H: Hold, W: Witness, Ws: Spot W

March-8-2013

Name: Amir GJ Tarigan/FQM

Certified Complete (Contractor-SM/CM) Date:

MHI-APEX-REKIND

Authorization (Contractor FQM)

Form. No

Inspection and Test Plan For Piping Work

QA/QC

Project No.

QI - G-08

Pages.:

ITP sheet No. 6419R A434-00001

Commodity

HC-T&C/2010/0008

Identification

ABOVE GROUND PIPING (7/9)

SUBCONTRACTOR

Activity

No,

Inspection/ Test Activity Item

Charateristic To Be

Verfied/Inspected/Tested

Methode of

Inspection

Frequency

Acceptance

Creteria/Reference Document

Verifing Document

CONTRACTOR

Date/ Sign

Date/ Sign

POSTWELD HEAT TREATMENT (PWHT),

if required

Date:

a.

PWHT Procedure Approval

Method ,Scope of Test

Review

At Once

ASME B31.3

PWHT Procedure

b.

Joints Identification

Correct Joint & Visual

Visual

Each Joint &

Whenever Applicable

ASME B31.3

PWHT Report/Chart

Ws

c.

Perform Test

Correct Test

Visual

Each Joint &

Whenever Applicable

ASME B31.3

PWHT Report/Chart

d.

Evaluation of Result

Correct result

Review

Each Joint &

Whenever Applicable

ASME B31.3

PWHT Report/Chart

e.

NDE after PWHT (if applicable)

Correct Test

Review

Each Joint &

Whenever Applicable

ASME B31.3

Third Party Form Sheet

8. NDE Post PWHT - stand

alone

Approved by (Contractor)

Prepared by (Contractor)

Rev.No:

Date:

Name: Edi Sunardi/QC Engineer

H: Hold, W: Witness, Ws: Spot W

March-8-2013

Name: Amir GJ Tarigan/FQM

Certified Complete (Contractor-SM/CM) Date:

Authorization (Contractor FQM)

Form. No

Inspection and Test Plan For Piping Work

MHI-APEX-REKIND

QA/QC

Project No.

QI - G-08

Pages.:

ITP sheet No. 6419R A434-00001

Commodity

HC-T&C/2010/0008

Identification

ABOVE GROUND PIPING (8/9)

SUBCONTRACTOR

Activity

No,

Inspection/ Test Activity Item

Charateristic To Be

Verfied/Inspected/Tested

Methode of

Inspection

Frequency

Acceptance

Creteria/Reference Document

Verifing Document

CONTRACTOR

Date/ Sign

Date/ Sign

HARDNESS TEST (HT) , if required

Date:

a.

HT Procedure Approval

Method ,Scope of Test

Review

At Once

ASME B31.3

PWHT Procedure

b.

Joints Identification

Correct Joint & Visual

Visual

Each Joint &

Whenever Applicable

ASME B31.3

QI-L04

Ws

c.

Perform Test

Correct Test

Visual

Each Joint &

Whenever Applicable

ASME B31.3

QI-L04

d.

Evaluate Test Results

Prepared by (Contractor)

Correct result

Review

Each Joint &

Whenever Applicable

Approved by (Contractor)

ASME B31.3

Rev.No:

QI-L04

Date:

H: Hold, W: Witness, Ws: Spot W

4

Name: Edi Sunardi/QC Engineer

March-8-2013

Name: Amir GJ Tarigan/FQM

Certified Complete (Contractor-SM/CM) Date:

MHI-APEX-REKIND

Authorization (Contractor FQM)

Form. No

Inspection and Test Plan For Piping Work

QA/QC

Project No.

QI - G-08

Pages.:

ITP sheet No. 6419R A434-00001

Commodity

HC-T&C/2010/0008

Identification

ABOVE GROUND PIPING (9/9)

SUBCONTRACTOR

Activity

No,

Inspection/ Test Activity Item

Charateristic To Be

Verfied/Inspected/Tested

Methode of

Inspection

Method ,Scope of Test

Valid Calibration, Range, Condition

CONTRACTOR

Frequency

Acceptance

Creteria/Reference Document

Verifing Document

Review

Each Test Pack

Test Block Diagram

Test Package

Review

Each Gauge

Valid Calibration

Calibration certificates

Date/ Sign

Date/ Sign

PRESSURE TEST

a.

Test Package Review and released to Test

b.

Calibration of Gauges

Da

c.

Hold and Check for Leaks

Correct hold pressure and leakage, check

Pressure, Temp, Holding time & check for any

leak.

Visual

Each Test Pack

ASME B31.3 & 6419M A234-00100

QI-L02

FLUSHING / BLOWING

10

a.

Procedure Review

Method ,Scope of Work

Review

At Once

ASME B31.3

Steam Blow Out/Oil

Flushing/Clean Up Procedure

b.

Flushing / Blowing

Correct Line System & be carreful the isolation

of equipment or instrument, may damage during

flushing/blowing

Visual

Each Line

Flushing/Blowing Procedure

Precommissioning Report

c.

Cleanliness Check

Condition of Cleanliness

Visual

Each Line

Flushing/Blowing Procedure

Precommissioning Report

Completeness Correct Installation

Visual

Each Line

Isometric Drawings

QI-L05

REINSTATEMENT PIPE WORK

11

a.

Install Permanent Gaskets & Instruments,

completeness of installation of all piping

accessories and Bolt tightness.

Prepared by (Contractor)

Approved by (Contractor)

Rev.No:

Rev.No:

4

Name: Edi Sunardi/QC Engineer

H: Hold, W: Witness, Ws: Spot W

March-8-2013

Name: Amir GJ Tarigan/FQM

Certified Complete (Contractor-SM/CM)

Date: Authorization (Contractor FQM)

rm. No

Rev. No:

Date

- G-08

05-March-13

ges.:

SAMUR PROJECT

CONTRACTOR

OWNER

Date/ Sign

Date/ Sign

W

tion and repprt

nd as report

ion and as report

nd review/sign report

orks and no sign report

Date:

Remarks

rm. No

Rev. No:

Date

- G-08

ges.:

05-March-13

SAMUR PROJECT

CONTRACTOR

OWNER

Date/ Sign

Remarks

Date/ Sign

R/W*

* If new PQR to witness the

test

W/R

S

W

W

ess, Ws: Spot Witness, R: Review, I: Inspection

Date:

rm. No

Rev. No:

- G-08

ges.:

Date

05-March-13

SAMUR PROJECT

CONTRACTOR

OWNER

Date/ Sign

Remarks

Date/ Sign

A

R

S

R

R

ess, Ws: Spot Witness, R: Review, I: Inspection

Date:

rm. No

Rev. No:

Date

- G-08

ges.:

05-March-13

SAMUR PROJECT

CONTRACTOR

OWNER

Date/ Sign

Date/ Sign

W

R

R

Ws

Ws

Ws

Ws

Ws

Ws

Remarks

tness, Ws: Spot Witness, R: Review, I: Inspection

Date:

rm. No

Rev. No:

Date

- G-08

ges.:

05-March-13

SAMUR PROJECT

CONTRACTOR

OWNER

Date/ Sign

Remarks

Date/ Sign

W

Ws

Ws

Ws

ess, Ws: Spot Witness, R: Review, I: Inspection

ess, Ws: Spot Witness, R: Review, I: Inspection

Date:

rm. No

Rev. No:

- G-08

ges.:

Date

05-March-13

SAMUR PROJECT

CONTRACTOR

OWNER

Date/ Sign

Date/ Sign

Ws

Remarks

ess, Ws: Spot Witness, R: Review, I: Inspection

Date:

rm. No

Rev. No:

Date

- G-08

ges.:

05-March-13

SAMUR PROJECT

CONTRACTOR

OWNER

Date/ Sign

Date/ Sign

Ws

Remarks

ess, Ws: Spot Witness, R: Review, I: Inspection

Date:

rm. No

Rev. No:

- G-08

Date

05-March-13

ges.:

SAMUR PROJECT

CONTRACTOR

OWNER

Date/ Sign

Date/ Sign

Ws

Ws

Ws

Ws

Ws

Ws

Ws

Ws

S

Remarks

Ws

Ws

ess, Ws: Spot Witness, R: Review, I: Inspection

Date:

rm. No

Rev. No:

Date

- G-08

05-March-13

ges.:

SAMUR PROJECT

CONTRACTOR

OWNER

Date/ Sign

Date/ Sign

R

R

R

R

R

Remarks

ess, Ws: Spot Witness, R: Review, I: Inspection

Date:

rm. No

Rev. No:

Date

- G-08

05-March-13

ges.:

SAMUR PROJECT

CONTRACTOR

OWNER

Date/ Sign

Date/ Sign

R

R

Ws

Ws

Remarks

ess, Ws: Spot Witness, R: Review, I: Inspection

Date:

rm. No

Rev. No:

Date

- G-08

ges.:

05-March-13

SAMUR PROJECT

CONTRACTOR

OWNER

Date/ Sign

Date/ Sign

R

Ws

Ws

Remarks

Ws

ess, Ws: Spot Witness, R: Review, I: Inspection

Date:

rm. No

Rev. No:

Date

- G-08

ges.:

05-March-13

SAMUR PROJECT

CONTRACTOR

OWNER

Date/ Sign

Date/ Sign

Ws

Remarks

tness, Ws: Spot Witness, R: Review, I: Inspection

FQM)

Date:

rm. No

Rev. No:

Date

- G-08

ges.:

05-March-13

SAMUR PROJECT

CONTRACTOR

OWNER

Date/ Sign

Date/ Sign

R

R

Remarks

Ws

Ws

s, Ws: Spot Witness, R: Review, I: Inspection

or FQM)

Date:

You might also like

- ITP For Piping SystemsDocument6 pagesITP For Piping SystemsP SHANKAR BABU100% (16)

- Method Statement For Project Signages Rev 0 AfcDocument16 pagesMethod Statement For Project Signages Rev 0 AfcEchik Kici0% (1)

- Inspection Test PlanDocument3 pagesInspection Test PlanMohd Shafuaaz Kassim100% (2)

- ITP For Piping WorksDocument3 pagesITP For Piping WorksOrlando1949100% (3)

- Welding Consumable and Storage ProcedureDocument10 pagesWelding Consumable and Storage Procedurehasan_676489616100% (1)

- Inspection and Test Plan For Structural Steel Erection: ITP NO: 7979-ITP-ME-019 Rev.2Document8 pagesInspection and Test Plan For Structural Steel Erection: ITP NO: 7979-ITP-ME-019 Rev.2Santosh Kumar Bogela100% (12)

- ITP Installation of Boiler - R1Document14 pagesITP Installation of Boiler - R1crys100% (4)

- Inspection Test Plan - Piping FabricationDocument5 pagesInspection Test Plan - Piping Fabricationhassan_ndt80% (5)

- 15 ITP Installation of Static EquipmentDocument4 pages15 ITP Installation of Static Equipmenta.hasan670No ratings yet

- 100 Welding Consumable Control ProcedureDocument10 pages100 Welding Consumable Control ProcedureAhmed Elsayed100% (3)

- Weld Map & NDE Extent of Pressure VesselDocument32 pagesWeld Map & NDE Extent of Pressure VesselMahesh Kumar100% (2)

- Installation Static Equipment ITPDocument3 pagesInstallation Static Equipment ITPAwais Tariq90% (10)

- Itp For InsulationDocument14 pagesItp For InsulationHytham El-NoubyNo ratings yet

- Itp For Aboveground Piping Metallic (Fabrication, Erection, Installation and Pressure Testing)Document24 pagesItp For Aboveground Piping Metallic (Fabrication, Erection, Installation and Pressure Testing)Rakhesh Rajeevan100% (3)

- Welding Consumables Handling Procedure.Document5 pagesWelding Consumables Handling Procedure.Mohammed Kamal78% (23)

- ITP - PipingDocument7 pagesITP - PipingRiaz Rasool100% (2)

- Tank Erection Itp & Org ChartDocument34 pagesTank Erection Itp & Org Charthasan_676489616100% (2)

- Q.c-me-UQ-09 (Weld Identification and Weld Traceability Procedure) Re WriteDocument5 pagesQ.c-me-UQ-09 (Weld Identification and Weld Traceability Procedure) Re WriteAws Mohamed100% (1)

- Master Drawing List For GE - All Ge DrawingsDocument7 pagesMaster Drawing List For GE - All Ge DrawingsSulaiman JafferyNo ratings yet

- Design of 610 mm MS Pumping MainDocument6 pagesDesign of 610 mm MS Pumping MainMathiTwadCNo ratings yet

- General Question Related To Coiled Tubing UnitDocument4 pagesGeneral Question Related To Coiled Tubing UnitBOy GeologErNo ratings yet

- Turbine Maintenance BookDocument223 pagesTurbine Maintenance Bookbarrunsiswo100% (9)

- WPS - Smaw - 2Document6 pagesWPS - Smaw - 2Harkesh RajputNo ratings yet

- 038-Pro Welding Consumable Control Procedure PDFDocument20 pages038-Pro Welding Consumable Control Procedure PDFKöksal Patan100% (7)

- B2020-TDC-VF-009 Vessel Fabrication R0Document5 pagesB2020-TDC-VF-009 Vessel Fabrication R0Ramalingam PrabhakaranNo ratings yet

- 10) Itp - Tank Fabrication PDFDocument6 pages10) Itp - Tank Fabrication PDFAndy Chong100% (5)

- ITP For Fabrication & Erection of TanksDocument20 pagesITP For Fabrication & Erection of TanksosersNo ratings yet

- Piping Release Report (Spool For Paint)Document2 pagesPiping Release Report (Spool For Paint)Siddiqui Abdul Khaliq100% (1)

- Welding Consumable Control Procedure 1Document9 pagesWelding Consumable Control Procedure 1eklavyak076757100% (4)

- Itp - Tanks - 01Document10 pagesItp - Tanks - 01ravigurajapuNo ratings yet

- Pressure Vessel Dimension Inspection PDFDocument17 pagesPressure Vessel Dimension Inspection PDFEqubal KhanNo ratings yet

- 005-WPS For Carbon Steel (1.6-4.6MM) PDFDocument7 pages005-WPS For Carbon Steel (1.6-4.6MM) PDFKöksal Patan0% (1)

- ITP SampleDocument2 pagesITP Sampleeiman_zerep50% (2)

- Itp PipingDocument4 pagesItp PipingkennethNo ratings yet

- Fabrication Division QMDDocument11 pagesFabrication Division QMDRakesh RanjanNo ratings yet

- Repair and Modification ITPDocument8 pagesRepair and Modification ITPShewale PravinNo ratings yet

- 013-WPS FOR SS321 (1.5 - 26.6 MM) PDFDocument26 pages013-WPS FOR SS321 (1.5 - 26.6 MM) PDFKöksal PatanNo ratings yet

- Saudi Aramco Welding Consumables ChecklistDocument5 pagesSaudi Aramco Welding Consumables ChecklistAnsuman KalidasNo ratings yet

- Inter Office Memo: Sr. No. Material Specification Test Piece Size Welding ProcessDocument1 pageInter Office Memo: Sr. No. Material Specification Test Piece Size Welding Processg_sanchetiNo ratings yet

- Weld Map & TracebilityDocument2 pagesWeld Map & TracebilityvinothNo ratings yet

- DRP001-OUF-STA-MTS-L-000-030-O1 - WMS Pickling and Passivation PDFDocument36 pagesDRP001-OUF-STA-MTS-L-000-030-O1 - WMS Pickling and Passivation PDFrodman823No ratings yet

- WPS Steps of MakingDocument51 pagesWPS Steps of MakingSaut Maruli Tua Samosir100% (1)

- Electrode Handling Procedure - Simple - SMAWDocument7 pagesElectrode Handling Procedure - Simple - SMAWGalih Suksmono Adi0% (1)

- Field Welding Inspection Checklist: Wisconsin Department of TransportationDocument1 pageField Welding Inspection Checklist: Wisconsin Department of Transportationandreafaith biatingoNo ratings yet

- QW-483 BlankDocument2 pagesQW-483 BlankCraftyBob100% (1)

- Daily Welding Progress ReportDocument1 pageDaily Welding Progress ReportManoj KumarNo ratings yet

- 033-Itp For Piping Installation Ag and Ug PDFDocument13 pages033-Itp For Piping Installation Ag and Ug PDFKöksal Patan75% (4)

- Engineering Standards Manual ISD 341-2: Chapter 13, Welding & Joining Volume 2, Welding Fabrication ProcedureDocument7 pagesEngineering Standards Manual ISD 341-2: Chapter 13, Welding & Joining Volume 2, Welding Fabrication Proceduremabrouk2013No ratings yet

- Inspection Test Plan For FabricationDocument4 pagesInspection Test Plan For FabricationAshwani Dogra100% (9)

- Sample # 1Document3 pagesSample # 1Clarence Ferro100% (1)

- Multiple PQR QualificationDocument4 pagesMultiple PQR QualificationKarthikeyan ShanmugavelNo ratings yet

- Offshore Marinetech PVT - LTD: Electrode Baking RegisterDocument3 pagesOffshore Marinetech PVT - LTD: Electrode Baking RegisterPrathamesh OmtechNo ratings yet

- Inspection and Test Plan For Steel StrucDocument6 pagesInspection and Test Plan For Steel Strucwawan gunawan100% (1)

- Algeria Oman Fertilizer Project Inspection and Test PlanDocument22 pagesAlgeria Oman Fertilizer Project Inspection and Test Planmister pogi100% (3)

- Itp Non AsmeDocument7 pagesItp Non AsmeAkhilesh Kumar100% (1)

- INSPECTION AND TEST PLAN (ITP) FOR TEST TANK PDM T-1001 A Rev B PDFDocument7 pagesINSPECTION AND TEST PLAN (ITP) FOR TEST TANK PDM T-1001 A Rev B PDFgst ajah100% (4)

- Quality Assurance Plan for Structural FabricationDocument1 pageQuality Assurance Plan for Structural FabricationproxywarNo ratings yet

- Model Qap Cable TrayDocument2 pagesModel Qap Cable Trayveerendra100% (3)

- ITP Format For New PVDocument8 pagesITP Format For New PVDavid LambertNo ratings yet

- Fabrication Process Inspection PlanDocument48 pagesFabrication Process Inspection Planmohd as shahiddin jafriNo ratings yet

- IRT For CP SystemDocument3 pagesIRT For CP SystemAnonymous i3lI9MNo ratings yet

- Itp For SSDP Project Rev CDocument9 pagesItp For SSDP Project Rev CRachel FloresNo ratings yet

- Section 2 QAP, Cable TrayDocument3 pagesSection 2 QAP, Cable TrayveerendraNo ratings yet

- Hardness Test ProcedureDocument5 pagesHardness Test Proceduremanojballa100% (1)

- Column Condenser ITP inspection planDocument2 pagesColumn Condenser ITP inspection planAshish DhokNo ratings yet

- RFI Summary For 1BDocument54 pagesRFI Summary For 1BEchik Kici100% (2)

- Trail Mix G35aDocument1 pageTrail Mix G35aEchik KiciNo ratings yet

- Punch List 20181124Document145 pagesPunch List 20181124Echik Kici0% (1)

- Form Attchment - RFI PICTURE-2Document2 pagesForm Attchment - RFI PICTURE-2Echik Kici100% (1)

- Field ITP Civil Rev-8after Lump-Sump.Document17 pagesField ITP Civil Rev-8after Lump-Sump.Echik Kici100% (3)

- AQA GCSE Chemistry Combined U7 Organic Chemistry Knowledge OrganiserDocument2 pagesAQA GCSE Chemistry Combined U7 Organic Chemistry Knowledge OrganiserDEVANDRAN A/L MOHAN MoeNo ratings yet

- IFR 101 ManualDocument28 pagesIFR 101 ManualsunhuynhNo ratings yet

- Aci 318R 08Document1 pageAci 318R 08Sayed Diab AlsayedNo ratings yet

- Different Approaches in Modeling of RC Shear Wall: A ReviewDocument15 pagesDifferent Approaches in Modeling of RC Shear Wall: A Reviewrahimmulla100% (2)

- High Efficiency Compressed Air Filtration & Water SeparationDocument8 pagesHigh Efficiency Compressed Air Filtration & Water SeparationMelvic BinosNo ratings yet

- Dickella Premakumara Final Best Practices PDFDocument36 pagesDickella Premakumara Final Best Practices PDFjune dela cernaNo ratings yet

- YK60A Digital Inverter Battery Charger ManualDocument35 pagesYK60A Digital Inverter Battery Charger ManualS M NaveedNo ratings yet

- Harduaganj Thermal Power Plant by Geetesh SharmaDocument66 pagesHarduaganj Thermal Power Plant by Geetesh Sharmageeteshaccurate100% (1)

- Corrosion of Chrome PlatingDocument37 pagesCorrosion of Chrome PlatingdavideNo ratings yet

- Cane Ite PDFDocument4 pagesCane Ite PDFJim HaigNo ratings yet

- Steel ConstructionDocument46 pagesSteel ConstructionKhadeeja AslamNo ratings yet

- Powder Metallurgy LabDocument8 pagesPowder Metallurgy Labשירי חדדNo ratings yet

- Replacement of bucket elevator projectDocument3 pagesReplacement of bucket elevator projectChoo Weng HoeNo ratings yet

- Almex Light Weight BrochureDocument16 pagesAlmex Light Weight BrochureGijoNo ratings yet

- King Saud University Mass Transfer ExamDocument7 pagesKing Saud University Mass Transfer ExamAnnisa RahmaditaNo ratings yet

- Technical Object First Draft & Peer Reviews (1) .EditedDocument5 pagesTechnical Object First Draft & Peer Reviews (1) .EditedJohn MainaNo ratings yet

- Plastic AnalysisDocument23 pagesPlastic AnalysisPraveen Kumar R100% (1)

- I. Statement of The ProblemDocument5 pagesI. Statement of The ProblemFloredelNo ratings yet

- An Accelerator Free Peroxide Vulcanization TechniqueDocument17 pagesAn Accelerator Free Peroxide Vulcanization TechniqueClinton ThomsonNo ratings yet

- Bager Mini JCB 1cxDocument24 pagesBager Mini JCB 1cxZoricaNo ratings yet

- ExhibitorsDocument6 pagesExhibitorsamanprajapati488No ratings yet

- ProductSpec HS2.4S HS3.75S HSZ2.4S HSZ3.75S HSD2.55S1Document1 pageProductSpec HS2.4S HS3.75S HSZ2.4S HSZ3.75S HSD2.55S1Araujo Felipe AndrésNo ratings yet

- MICRO-M-3: Microelectronic Operation and Unit TroubleshootingDocument32 pagesMICRO-M-3: Microelectronic Operation and Unit TroubleshootinghanamanNo ratings yet

- KSB Influence of Pumps On Energy ConsumptionDocument14 pagesKSB Influence of Pumps On Energy Consumption@sssNo ratings yet

- Brochure Husker RollsDocument2 pagesBrochure Husker RollsEmerson OliveiraNo ratings yet

- TM 5-811-6 Generator and Electrical Facilities DesignDocument26 pagesTM 5-811-6 Generator and Electrical Facilities DesignrockclaudiuNo ratings yet