Professional Documents

Culture Documents

CVEN 3502 - PART 3 - Wastewater Treatment

Uploaded by

zhunsheanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CVEN 3502 - PART 3 - Wastewater Treatment

Uploaded by

zhunsheanCopyright:

Available Formats

24/08/2014

Introduction to Membrane Processes

Part 3 Wastewater Applications

CHEN 6071: Water & Wastewater Engineering

School of Chemical Engineering

Part 3 Wastewater Treatment

The objective of these slides is to cover the following information:

1.

Features of membrane bioreactors: Process flow diagrams,

membrane properties and mechanical equipment

2

2.

R

Reaction

i E

Engineering

i

i concepts iin MBR Reactor

R

D

Design

i

3.

How membrane configuration impacts foot print and mixing

energy

Assessment: On-line quiz questions covering your knowledge of

1.

Design features of MBR versus conventional systems

Tutorial Problem

1.

Foot print calculation for MBR plant

2.

Aeration power calculation

24/08/2014

Eutrophication of receiving waters and transmission of

communicable disease as a result of wastewater discharge

Basic Objective of Wastewater Treatment

Before wastewater can be discharge to the environment it is necessary to

reduce the concentration of nutrients and pathogens so that the receiving

water (river or ocean) remains fishable

fishable & swimable.

swimable . Therefore, the

objectives of wastewater treatment are;

1. Remove nutrients that provide a food source for

bacteria which consume oxygen (kill fish) and promote

growth of macrophytes (plants) in receiving waters

[Fishable]

2. Disinfect to kill pathogens that cause ear, nose, throat

and intestinal disease in swimmers [Swimable]

How can these objectives be achieved using MBRs (what is different

between MBRs and conventional plants)?

24/08/2014

Wastewater Engineering Heuristics

Disinfection (Chlorine or UV light) is more effective after suspended solids

concentration and chlorine demand (nutrients) are reduced. Biological nutrient

removal is based on a reaction space where soluble nutrients are consumed by

microorganisms to form a biomass that can be removed prior to disinfection.

Reaction Engineering Parameters/Features

Attached growth systems

1.Hydraulic Residence Time (HRT) - (hours)

2. Solids Residence Time (SRT) (days)

3. Concentration of microorganisms

4. pH that favors growth of bacteria

5. Oxygen concentration & form

6 Oxygen transfer - (factor)

6.

7. Solid - liquid separation step

What is the key difference between

conventional process and an MBR?

Suspended media activated sludge

Requirements for Carbonaceous Material Removal

Suitable aeration system to maintain a DO in the mixed liquor

Facultative bacterial mass, principally heterotrophs, to utilise the

carbonaceous energy

Appropriate Solids Retention Time (SRT) and MLSS concentration

MLSS 3g/L to 4g/L for settleable sludge

5g/L to 12 g/L for MBR

SRT typically greater than 10 days depending on climate

Appropriately sized clarifier and RAS return system

Return Activated Sludge (RAS) increases HRT in smaller tanks

Returns nitrates formed by nitrification of ammonia

Solids retention time determined by rate of wasting of solids from tank

(WAS)

Determines the type of organisms that develop in the mixed liquor

24/08/2014

Removal of nitrogenous nutrients by nitrification & denitrification

Nitrification is the term used to describe the oxidation of free and saline ammonia to nitrite

and nitrate within the biological process - mediated through the autotrophic bacteria

Nitrosomonas and Nitrobacter,

Two stages:

NH4 ----> NO2 (Nitrosomonas)

NO2 ----> NO3 (Nitrobacter)

Nitrosomonas is slowest reacting of the two; uncommon to have significant presence of nitrite

in effluent as Nitrobacter usually rapidly converts it to nitrate.

Nitrification requires 4.6 mg O2/mg N oxidised, Factors that affect the efficacy of nitrification

include;

Solids Retention Time (SRT),

pH (alkalinity)

Toxins (heavy metals etc)

Dissolved Oxygen Concentration (Aeration & Alpha Factors)

Diurnal variation in N loading (how nitrogen varies depending on the time of day)

Nitrification Capacity

Influent TKN - two fractions; Organic N and Free and Saline NH3,

Enzymatic conversion of bulk of Organic N to NH3,

N in activated sludge-10 % of VSS in WAS, Always 2-3 mg/L TKN in effluent,

Ncapacity = TKNinf - (TKNeff + TKNsludge).

To Remove 1 g NH4-N:

4.6 g Oxygen required,

0.15 g New Cells formed,

7.14 g Alkalinity (as CaCO3) destroyed,

0.08 g Inorganic Carbon consumed.

Requirements for Denitrification

NO3 ----> N2

Presence of nitrate (or nitrite) to act as final electron acceptor

Absence of dissolved oxygen

Facultative bacterial mass

Suitable energy source to act as electron donor

Anoxic Zone required in process.

24/08/2014

Key features of conventional secondary

wastewater treatment

Reactor Zones

Non Aerated*

Clarifier

Aerated

Return Activated Sludge (RAS)

Waste Activated

Sludge

*Anoxic (O2 available in nitrates, sulphates)

Anaerobic (no available O2)

MBR & Conventional Process

Conventional Process

Primary

Sedimentation

Tanks

Aeration

Basins (Biological

Reactor)

Final

Sedimentation

Tanks

Treated

Wastewater

WasteWater

Primary

y

Sedimentation

Tanks

Disinfection

Membrane

Bioreactor

MBR process

Disinfection

Conventional

process

MBR process

24/08/2014

Key difference between conventional and MBR

In a membrane bioreactors the secondary clarifier is replaced by a membrane

filtration unit that can be located in the bioreactor tank or a separate tank. The

objective is to produce a filterable sludge not a settleable sludge

Therefore MBR MLSS 8-12 g/L vs Conventional MLSS 3-4 g/L

Limitit on MLSS iin MBR d

Li

due tto effect

ff t off solids

lid on O2 transfer

t

f from

f

gas to

t liquid

li id

(alpha factor)

Fine bubble aeration is used to provide oxygen to the biomass, coarse bubble

aeration is used to control accumulation of biomass on the membrane

fine bubble aeration

coarse bubble

aeration

In an MBR suspended solids and particulate effluent quality are not

dependent on sludge settling (Example, Loudon Co Va, USA)

10.0

CA Title 22 reuse standard (unrestricted access) = 2.0 NTU

Turbidity (ntu)

1.0

Regional

g

effluent discharge

g policy

p

y = 0.5 NTU

EPA drinking water standard = 0.3 NTU

0.1

0.01

Average for MBR Effluent = 22 mNTU

0.001

Four-Month Operating Period

24/08/2014

Consequently, MBR systems are ideal for discharge into

recreational waters Cohasset MA, US

Cohasset, MA, USA Effluent Quality TSS < 1 mg/L

Turbidity < 1.0 NTU

Total coliform < 10 cfu/100 ml

However, the higher concentration of colloidal and small

particles in the WAS make sludge dewatering harder

MBRs are designed for higher MLSS which reduces volume (foot print)

of reactor. Elimination of clarifiers reduces footprint of plant

Comparative STP Land Area for similar

equivalent populations in UK

Swanage (28000 EP) - 0.7 ha

MLSS 12 g/L

Scale:

Glastonbury (30000 EP) - 4.5 ha

MLSS 3 g/L

Reference: G.Johnston, Aquatec-Maxcon, AWA MBR Workshop 20/11/2001

24/08/2014

Basic Configuration of the MBR

Metal Salt

(P removal)

P1

Anoxic Zone

Aerobic Zone

DO < 0.5 mg/L

N2

NO3

P2

DO > 1.0 mg/L

NH4+ NO3

Filtrate

RAS

TMP (+) = P1 - P2

Suction (pump)

Gravity

Flux =

TMP

(Rm + Rc)

Waste

Sludge

Typical loading rates (flux)

typically 10 25 l/m2/h depending on the manufacturer

Average Flux vs. Wastewater Quality

Flux (L/m

F

2/h)

70

50

30

10

Primary Unsettled Clarified

Tertiary

Secondary Secondary

Membrane A

Membrane B

Membrane C

16

24/08/2014

Operating Modes

Filtration Mode

Suction pump on for 8-13 minutes

Air

Ai blower

bl

on

Resting Mode

Suction pump off for 2 minutes

Air blower on

No backwashing required

Cleaning Mode

Performed when pressure increases by 0.2 bar

Approx. every 2 to 3 months

17

MBR Retrofit into Aerobic Basin

Filtrate Header

Backwash Tanks

& Pumps

Air scour line

Membranes

24/08/2014

Hollow fibre MBRs

0.04 & 0.2 m pores (e.g. Zenon/ GE,

Siemens/ Memcor, Koch)

Dedicated filtrate pump

TMP 30 - 70 kPa (vacuum)

Varying degrees of oxidant resistance

Liquid backwash

Continuous or Intermittent aeration

(course bubble for fouling control)

19

Hollow Fiber (HF) MBR North Head STP NSW

Anoxic zone

Aerobic zones

Membrane

filtration zone

De-aeration zone

10

24/08/2014

Flat sheet MBRs

0.4 m pores (e.g. Kubota) or 0.08 m pores (e.g. Toray)

Gravity driven process

Continuous aeration to prevent solids accumulation Train or Unit

TMP 20 - 50 kPa

No short term backwash

Single Sheet

Cassette

21

Flat Sheet Membrane Victor Harbour SA

Bioselector

(anoxic/anaerobic)

Swing aeration zones

Aerobic zone

Membrane filtration zone

11

24/08/2014

Compare the turbulence in the different zones of the donut

reactor MBR at Horseshoe Bay, Qld

Inner ring anoxic zone (no turbulence)

Outer ring aerobic zone

(fine bubble aeration)

Membrane zone (coarse bubble aeration)

23

Horseshoe Bay MBR design considered carry over

of oxygen from membrane zone

2-Stage concept,

MLE - like

Raw

influent

DO ~ 6 mg/L

Nearly saturated

Highly aerated MBR tank

1st Anoxic

4-Stage concept,

Bardenpho - like

Raw

influent

Future MBR

cassettes

Diffusers for peak

aeration

S-recycle 10 Q

2nd Anoxic

A-recycle 6 Q

MBR /

Aerobic

Aerobic

Permeate

DO ~ 1.5

mg/L

S-recycle 3 Q

DO ~ 6

mg/L

Permeate

1st Aerobic

MBR / Aerobic

12

24/08/2014

Aeration

1.

Air flow requirements for membrane scouring/ fouling

control given by membrane suppliers:

No. & type of diffuser (usually coarse bubble)

Timing (continuous or intermittent)

Airflow & tank depth

2.

Blower size (kW), controls etc.

Oxygen transfer efficiency & rate: (S)OTE & (S)OTR

BNR process air requirements

Compare required SOTR (from modelling) with that supplied

for membrane scouring

g ((see above))

Consider need for additional aerobic zone(s) & take into

account recycled oxygen from MBR tanks

Remember alpha factor ! ( OTR/SOTR as MLSS)

Recalculate blower requirements from airflow, tank depth

etc.

How does membrane configuration impact foot print

(Reactor volume) & energy consumption in MBRs?

Tank requirements for flat sheet and hollow fibre

membranes of membranes differ due to packing density

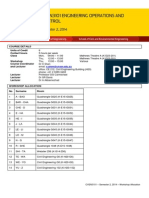

Comparison

p

of two possible

p

membrane types

yp for Horseshoe Bay

y WRP

Membrane type

No. of membrane cassettes

No. of membranes per cassette or membrane modules per cassette

Area per membrane cassette, m2

Total membrane area, m2

Flat sheet

6

400

320

1920

Hollow fibre

2

36

1138

2275

MBR tanks, operating total volume, m3

280

60

Ave. flow rate, m3/d

Peak flow rate, m3/d

Flux rate, ave. L/m2.h

Flux rate

rate, peak L/m2.h

L/m2 h

700

2100

15.2

45 6

45.6

700

2100

12.6

37 8

37.8

Note:

Similarity in flux

MBR tank volume * required operating MLSS = Minimum

Mandatory aerobic mass fraction for process!

13

24/08/2014

Airflow/ blower power requirement are influence by water

head above diffuser, air flow rate and operating mode

(continuous or intermittent)

Comparison of two possible membrane types for Horseshoe Bay WRP

Membrane type

Membrane cleaning airflow peak, Nm3/h

Aeration credits, kg/h AOR

No. of blowers, installed for cleaning

No. of blowers, duty for cleaning

Blower delivery pressure, kPa

Air cleaning blower motor installed power, kW per blower

Air cleaning blower motor expected peak power draw, kW

Air cleaning blower motor expected ave. power draw, kW

Expected power consumption for membrane cleaning, kWh/d

Air cleaning operating mode

Flat sheet

1008

15.96

3

2

50

18.5

15.4

12.9

Hollow fibre

1520

TBA

2

1

35

18.5

TBA

10.9

619

262

Continuous

Intermittent

Operational Problems in MBRs

Accumulation of solids in fibre

bundles

Short

Sh t circuiting

i iti iin membrane

b

tank (uneven flow loading)

Excessive power consumption

on blowers to achieve

adequate bubble induced

shear

Problems de-watering sludge

d tto accumulation

due

l ti off fifine

colloids (normally carry over in

clarifier on conventional plants)

14

24/08/2014

Energy & power: MBRs tend to be energy/ power intensive

Mainly due to high air flow requirements (large blowers) for

membrane scouring

Trend

T dh

has b

been iimproving

i ((e.g. iintermittent

t

itt t aeration)

ti )

Lower efficiency of aeration due to high MLSS and

high viscosity (the factor question)

Trade-off capital costs vs. operating costs

Smaller, more compact reactors vs. long term power

requirements to get higher effluent quality (effectively

ultrafiltration)

Power consumption

MBR vs. Conventional BNR plants

Typical average power consumption

Data based on typical domestic sewage:

Biodegradable COD ~ 415 mg/L (raw) ; ~265 mg/L (primary treated, settled)

Type of plant

kWh/kgCOD

(biodegradabale)

kWh/m3

MBR-BNR (extended aeration type,

without primary sedimentation)

3.5

1.46

BNR (extended aeration type,

type with diffused

air)

17

1.7

0 70

0.70

BNR (extended aeration type, with mech.

Surface aerators)

1.6

0.67

BNR (With primary sedimentation,

Anaerobic Digestion, with diffused air)

1.4

0.38

Source: Ken Hartley (2007) Personal comm.

15

24/08/2014

Conclusions Membranes vs traditional treatment

Traditional Technology

Membrane Filtration

Filtrate quality sensitive to

Feed water changes

Flow changes

Chemically assisted separation

common

Low additional cost for spare

capacity

Stable treated water quality

Copes with:

Sudden flow changes

Sudden, short term feed

condition changes

Performance = fn (Contaminant)

Chemicals used for:

Filter cake conditioning (some

applications/vendors

Chemical Cleaning

Higher additional cost for spare

capacity

16

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Generic Organic Aquaponics Business Plan 102111Document17 pagesGeneric Organic Aquaponics Business Plan 102111illanizaharudinNo ratings yet

- 01 - Physical Properties of SoilDocument3 pages01 - Physical Properties of SoilHomer Batalao0% (2)

- Material Safety Data SheetDocument5 pagesMaterial Safety Data SheetFustos CornelNo ratings yet

- Bund Wall Inspection ChecklistDocument4 pagesBund Wall Inspection ChecklistMoses Muchakaviri67% (3)

- Tunnel PresentationDocument68 pagesTunnel PresentationCatalin Boroianu100% (2)

- C W Rystalline Aterproofing: (An 9001: 2015, 14001: 2015 & 18001: 2007 Certified Company) ISO ISO OhsasDocument8 pagesC W Rystalline Aterproofing: (An 9001: 2015, 14001: 2015 & 18001: 2007 Certified Company) ISO ISO OhsasgangadevimgmNo ratings yet

- Spray Dryer ExperimentDocument17 pagesSpray Dryer Experimentthurgah100% (1)

- Length Change of Hydraulic-Cement Mortars Exposed To A Sulfate SolutionDocument8 pagesLength Change of Hydraulic-Cement Mortars Exposed To A Sulfate SolutionzhunsheanNo ratings yet

- SAACKE Burner SKV (G) Technical-Group Pdf-En PDFDocument3 pagesSAACKE Burner SKV (G) Technical-Group Pdf-En PDFsmall yu100% (1)

- Presentation GuidelinesDocument1 pagePresentation GuidelineszhunsheanNo ratings yet

- Basics of X-Ray Powder DiffractionDocument97 pagesBasics of X-Ray Powder DiffractionGeorgia ManikaNo ratings yet

- William HunnicuttDocument139 pagesWilliam HunnicuttzhunsheanNo ratings yet

- Potential Expansion of Portland-Cement Mortars Exposed To SulfateDocument3 pagesPotential Expansion of Portland-Cement Mortars Exposed To SulfatezhunsheanNo ratings yet

- CVEN 4402 - Workshop - Week 7Document50 pagesCVEN 4402 - Workshop - Week 7zhunsheanNo ratings yet

- CVEN 3502 - PART 4 - Non-Traditional Water SourcesDocument17 pagesCVEN 3502 - PART 4 - Non-Traditional Water SourceszhunsheanNo ratings yet

- Groundwater Education Investment Fund Project Borehole Infrastructure ReportDocument3 pagesGroundwater Education Investment Fund Project Borehole Infrastructure ReportzhunsheanNo ratings yet

- 2014 S2 CVEN3101 Workshop AllocationDocument1 page2014 S2 CVEN3101 Workshop AllocationzhunsheanNo ratings yet

- Groundwater Education Investment Fund Project Borehole Infrastructure ReportDocument3 pagesGroundwater Education Investment Fund Project Borehole Infrastructure ReportzhunsheanNo ratings yet

- Stifness MethododDocument23 pagesStifness MethododzhunsheanNo ratings yet

- PAPER 2222 With Mark AnswersDocument16 pagesPAPER 2222 With Mark AnswersAbhijeet GholapNo ratings yet

- Busan George Fixed Link Canal Basics of TunnelDocument31 pagesBusan George Fixed Link Canal Basics of TunnelbhargavipulivarthiNo ratings yet

- Section - 15985 Temperature Control Specifiers GuideDocument6 pagesSection - 15985 Temperature Control Specifiers GuideAntonio LebrunNo ratings yet

- Method and Practice of Community Water PurificationDocument51 pagesMethod and Practice of Community Water PurificationUsman Ahmad TijjaniNo ratings yet

- Homeowners Guide To Stormwater BMP Maintenance: What You Need To Know To Take Care of Your PropertyDocument24 pagesHomeowners Guide To Stormwater BMP Maintenance: What You Need To Know To Take Care of Your PropertyClaire KidwellNo ratings yet

- OvergrazingDocument6 pagesOvergrazingNoah AusejoNo ratings yet

- Pwps Mobilepac BrochureDocument6 pagesPwps Mobilepac BrochureMarcos Huata100% (1)

- Thin Layer ChromatographyDocument2 pagesThin Layer ChromatographyMigena CanajNo ratings yet

- 2 Company Profile SPP Pumps - Oil & Gas - BrochureDocument10 pages2 Company Profile SPP Pumps - Oil & Gas - Brochurelemuel bacsaNo ratings yet

- List Capel SPK2 1075Document5 pagesList Capel SPK2 1075singki bernando junitra singki bernando junitraNo ratings yet

- Negi 2018Document20 pagesNegi 2018alireza shamsNo ratings yet

- Teknik Menjawab Sains UPSRDocument25 pagesTeknik Menjawab Sains UPSRhilmi72No ratings yet

- Hydraulic GradientDocument1 pageHydraulic GradientPika ThoidingjamNo ratings yet

- 2051 - IPWW - CCN XAY DA B - Operation Cost Service Form - OP1 - TTDocument11 pages2051 - IPWW - CCN XAY DA B - Operation Cost Service Form - OP1 - TT呂仲書No ratings yet

- 1st Appraisal Presentation 2Document17 pages1st Appraisal Presentation 2Talha Jamil MalikNo ratings yet

- Test 11Document5 pagesTest 11amitNo ratings yet

- Soil Moisture Distribution Under Drip Irrigation and - 2016 - Agricultural WaterDocument10 pagesSoil Moisture Distribution Under Drip Irrigation and - 2016 - Agricultural WaterJ M Jimenez TNo ratings yet

- Hatch Cover and Ballast TankDocument2 pagesHatch Cover and Ballast TankJan ChengayNo ratings yet

- Environmental, Health, and Safety Guidelines For Pesticide Manufacturing, Formulation, and PackagingDocument17 pagesEnvironmental, Health, and Safety Guidelines For Pesticide Manufacturing, Formulation, and Packagingmaddukuri jagadeesh babuNo ratings yet

- Ifs ElbowDocument105 pagesIfs ElbowHeru YuliantoNo ratings yet

- Bay of BengalDocument4 pagesBay of Bengalnk4j3tk34j5No ratings yet

- Combined PH WorksheetsDocument9 pagesCombined PH WorksheetsNeen NaazNo ratings yet