Professional Documents

Culture Documents

Sigmarine 48

Uploaded by

aangCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sigmarine 48

Uploaded by

aangCopyright:

Available Formats

DATA

SIGMARINE 48

(SIGMARINE BTD)

3 pages

DESCRIPTION

September 2005

Revision of January 2003

general purpose gloss paint based on a modified alkyd resin

PRINCIPAL CHARACTERISTICS particularly suitable as a finish for boottop, topside, deck and

deckequipment

a quick drying, hard, tough, water- and weather resistant coating with

moderate gloss retention

can be applied over intact existing conventional systems, on Sigmarine

40 and on suitable primers, such as Sigma Vikote 14, Sigmarine 24 or

Sigmarine 21 depending on the location

good adhesion properties in wet and dry exposure conditions

this coating is particularly suitable for areas intermittently exposed to

water-immersion and atmospheric conditions

also available with non-skid material (supplied separately) for use on

deck surfaces

certificate for low flame spread: see sheet 1883

COLOURS AND GLOSS

white and various other colours (see also Marine shade card) - gloss

BASIC DATA AT 20C

(1 g/cm = 8.25 lb/US gal; 1 m/l = 40.7 ft/US gal)

Mass density

Volume solids

VOC (supplied)

1.2 g/cm

45 - 49 2% (colours) - 48 2% (white)

max. 345 g/kg (Directive 1999/13/EC, SED)

max. 402 g/l (approx. 3.4 lb/gal)

35 m per coat

Recommended dry film

thickness

Theoretical spreading rate

Touch dry after

Overcoating interval

Shelf life (cool and dry place)

Flash point

12.8-14.0 m/l (colours) - 13.7 m/l (white) for 35 m

1 hour at 20C, 3 hours at 5C

min. 16 hours at 20C, 24 hours at 5 - 10C

max. no limitations

at least 24 months

38C

RECOMMENDED

SUBSTRATE CONDITIONS

AND TEMPERATURES

previous coat; dry and free from any contamination

substrate temperature should be 3C above dew point

SYSTEM SPECIFICATION

systems for boottop and topside

systems for superstructure and deck fitting

Page 1/3

system sheet 3102

system sheet 3104

DATA

SIGMARINE 48

(SIGMARINE BTD)

September 2005

INSTRUCTIONS FOR USE

stir well before use

the temperature of the paint should preferably be above 15C, otherwise

extra thinner may be required to obtain application viscosity

too much solvent results in reduced sag resistance

adequate ventilation must be maintained during application and curing

(please refer to sheet 1433 and 1434)

AIRLESS SPRAY

Recommended thinner

Volume of thinner

Nozzle orifice

Nozzle pressure

Sigma thinner 20-05

0 - 2%, depending on required thickness and application conditions

approx. 0.48 mm (= 0.019 in)

8 - 12 MPa (= approx. 80 - 120 bar; 1140 - 1700 p.s.i.)

AIR SPRAY

Recommended thinner

Volume of thinner

Nozzle orifice

Nozzle pressure

Sigma thinner 20-05

10 - 15%, depending on required thickness and application conditions

2 - 3 mm

0.3 - 0.4 MPa (= approx. 3 - 4 bar, 43 - 57 p.s.i.)

BRUSH/ROLLER

Recommended thinner

Volume of thinner

Sigma thinner 20-05

0 - 2%

CLEANING SOLVENT

Sigma thinner 20-05

SAFETY PRECAUTIONS

for paint and recommended thinners see safety sheets 1430, 1431 and

relevant material safety data sheets

this is a solvent based paint and care should be taken to avoid inhalation of

spray mist or vapour as well as contact between the wet paint and exposed

skin or eyes

Worldwide availability

Whilst it is always the aim of Sigma Coatings to supply the same product on

a worldwide basis, slight modification of the product is sometimes

necessary to comply with local or national rules/circumstances.

Under these circumstances an alternative product data sheet is used.

REFERENCES

Explanation to product data sheets

Safety indications

Safety in confined spaces and health safety

Explosion hazard - toxic hazard

Safe working in confined spaces

Directives for ventilation practice

Page 2/3

see information sheet 1411

see information sheet 1430

see information sheet 1431

see information sheet 1433

see information sheet 1434

DATA

SIGMARINE 48

(SIGMARINE BTD)

September 2005

LIMITATION OF LIABILITY

The information in this data sheet is based upon laboratory tests we believe to be accurate and is intended for guidance

only. All recommendations or suggestions relating to the use of the products made by Sigma Coatings, whether in technical

documentation, or in response to a specific enquiry, or otherwise, are based on data which to the best of our knowledge

are reliable. The products and information are designed for users having the requisite knowledge and industrial skills and

it is the end-user's responsibility to determine the suitability of the product for its intended use.

Sigma Coatings has no control over either the quality or condition of the substrate, or the many factors affecting the use

and application of the product. Sigma Coatings does therefore not accept any liability arising from loss, injury or damage

resulting from such use or the contents of this data sheet (unless there are written agreements stating otherwise).

The data contained herein are liable to modification as a result of practical experience and continous product development.

This data sheet replaces and annuls all previous issues and it is therefore the user's responsibility to ensure that this sheet

is current prior to using the product.

The English text of this document shall prevail over any translation thereof.

DS

136828 white

Page 3/3

7238

7000002200

You might also like

- Sigmarine 28Document3 pagesSigmarine 28aangNo ratings yet

- Sigmafast 20: (Sigmasteel QD)Document3 pagesSigmafast 20: (Sigmasteel QD)akajsiNo ratings yet

- Sigma VikoteDocument3 pagesSigma VikoteimranNo ratings yet

- Sigmacap PriCoat 155 V2Document3 pagesSigmacap PriCoat 155 V2ajuhaseenNo ratings yet

- Sigmaweld 199 Technical Data SheetDocument4 pagesSigmaweld 199 Technical Data SheetMaria AndrewsNo ratings yet

- 7177 - Sigmaweld 199Document4 pages7177 - Sigmaweld 199eraswastaNo ratings yet

- 7117 - Sigmarine 28Document0 pages7117 - Sigmarine 28eraswastaNo ratings yet

- PDS 7435 09-2005 Sigma Phenguard 935 (English)Document4 pagesPDS 7435 09-2005 Sigma Phenguard 935 (English)KyNo ratings yet

- Sigmatherm Thermovit 600 (HR)Document2 pagesSigmatherm Thermovit 600 (HR)shibushineNo ratings yet

- 7240 - Sigmarine 49Document0 pages7240 - Sigmarine 49eraswastaNo ratings yet

- 7190 - Sigmarine 81Document0 pages7190 - Sigmarine 81eraswastaNo ratings yet

- Sigma Vikote 56Document3 pagesSigma Vikote 56Asela BollegalaNo ratings yet

- Sigmarine 24: Description Principal CharacteristicsDocument3 pagesSigmarine 24: Description Principal CharacteristicsJose Antonio GomezNo ratings yet

- 7686 Sigmacap Coaltar EPDocument3 pages7686 Sigmacap Coaltar EPDetoned StonedNo ratings yet

- 7102 - Sigma Vikote 63Document0 pages7102 - Sigma Vikote 63eraswastaNo ratings yet

- Sigmadur Gloss: Description PRINCIPAL CHARACTERISTICS - Unlimited RecoatableDocument4 pagesSigmadur Gloss: Description PRINCIPAL CHARACTERISTICS - Unlimited RecoatableKopnang AristideNo ratings yet

- Sigma PrimeDocument7 pagesSigma Primegstketut0% (1)

- Sigmadur 520 (English)Document4 pagesSigmadur 520 (English)KyNo ratings yet

- 7564 Sigmatherm 540Document2 pages7564 Sigmatherm 540Ibrahim MahranNo ratings yet

- Sigmacover 522Document4 pagesSigmacover 522Asela BollegalaNo ratings yet

- SigmaCover 280Document5 pagesSigmaCover 280ajuhaseenNo ratings yet

- 00 - 7565 SigmaTherm 350Document3 pages00 - 7565 SigmaTherm 350Elcio VilanculoNo ratings yet

- B22 7537 11-2006 Sigmadur 550Document4 pagesB22 7537 11-2006 Sigmadur 550Muhamad HassanNo ratings yet

- Sigmaguard 720Document4 pagesSigmaguard 720Danny DurhamNo ratings yet

- 7430 - Sigmacover 630Document0 pages7430 - Sigmacover 630eraswastaNo ratings yet

- Sigma Cover 510Document4 pagesSigma Cover 510supriadi90315100% (1)

- 00 - 7563 SigmaTherm 450Document2 pages00 - 7563 SigmaTherm 450Sherif YehiaNo ratings yet

- 7465 - Sigmacover 435Document0 pages7465 - Sigmacover 435eraswastaNo ratings yet

- en-US 7000Document4 pagesen-US 7000Jose Manuel Guizado SolisNo ratings yet

- Sigmacover 456: Description Principal CharacteristicsDocument5 pagesSigmacover 456: Description Principal Characteristicsmayukhguhanita2010No ratings yet

- SIgmaweld 199 - PDSDocument5 pagesSIgmaweld 199 - PDS이선엽No ratings yet

- PDS 7618 11-2005 Sigmaline 445Document4 pagesPDS 7618 11-2005 Sigmaline 445Anonymous 613HTXNo ratings yet

- 7285 - Sigma Ecofleet 238Document0 pages7285 - Sigma Ecofleet 238eraswastaNo ratings yet

- PDS 8316S 10-05-2004 Sigma Coltura Ep Flooring - Trowel Floor Composition (English) PDFDocument4 pagesPDS 8316S 10-05-2004 Sigma Coltura Ep Flooring - Trowel Floor Composition (English) PDFAnonymous jaEllxtL0aNo ratings yet

- Sigmafast 278Document4 pagesSigmafast 278MekhmanNo ratings yet

- Sigmacover 630 March 13Document6 pagesSigmacover 630 March 13leonciomavarezNo ratings yet

- 8215 - SigmatexDocument0 pages8215 - SigmatexeraswastaNo ratings yet

- SigmaAlphagen 230 PDFDocument3 pagesSigmaAlphagen 230 PDFCarlos VillacrizNo ratings yet

- Technical Data Sheet: DescriereDocument5 pagesTechnical Data Sheet: DescrieretamasraduNo ratings yet

- 7860 Sigmacap Filler 850Document3 pages7860 Sigmacap Filler 850Stephen Francis BothelloNo ratings yet

- Sou Ficha Técnica Soudaseal 235SFDocument2 pagesSou Ficha Técnica Soudaseal 235SFCarlos ChoqueNo ratings yet

- 7564-09-2005-Sigmatherm 540Document2 pages7564-09-2005-Sigmatherm 540Srikanth GantaNo ratings yet

- Sigmaguard CSF 575Document6 pagesSigmaguard CSF 575Erdi ErdoganNo ratings yet

- Sigmatherm 175: Description Principal CharacteristicsDocument3 pagesSigmatherm 175: Description Principal CharacteristicsJose Antonio GomezNo ratings yet

- 00 6825 PDFDocument5 pages00 6825 PDFibrahim_mohamed3361100% (1)

- Sigmazinc 109 HSDocument5 pagesSigmazinc 109 HSKrishna VachaNo ratings yet

- All DatasheetsDocument485 pagesAll Datasheetssflynn79No ratings yet

- 1411 - Explanation To Product Data SheetsDocument0 pages1411 - Explanation To Product Data SheetseraswastaNo ratings yet

- PDS - 7863 - Sigmacap Zinc Silicate IIDocument5 pagesPDS - 7863 - Sigmacap Zinc Silicate IIIbrahim MahranNo ratings yet

- Sigma Marine Coatings Manual - Part103Document2 pagesSigma Marine Coatings Manual - Part103Tommy2020No ratings yet

- SigmaPlane Ecol HS Antifouling PDFDocument3 pagesSigmaPlane Ecol HS Antifouling PDFCarlos VillacrizNo ratings yet

- Sigmadur 550Document4 pagesSigmadur 550gstketutNo ratings yet

- Sigma PC ManualDocument339 pagesSigma PC ManualSarisha Harrychund100% (2)

- E 9114 - Sika Unitherm 7854Document3 pagesE 9114 - Sika Unitherm 7854didapopescuNo ratings yet

- Sigmacover 410Document4 pagesSigmacover 410gstketutNo ratings yet

- Sika PDS - E - Sarnafil G 410 LDocument4 pagesSika PDS - E - Sarnafil G 410 Llwin_oo2435No ratings yet

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionFrom EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionNo ratings yet

- Portofolio Sertifikat - Fitri Maimunah PDFDocument8 pagesPortofolio Sertifikat - Fitri Maimunah PDFaang0% (1)

- Shipping Company SingapuraDocument2 pagesShipping Company SingapuraaangNo ratings yet

- Stowage FactorsDocument15 pagesStowage FactorsaangNo ratings yet

- Format Tely Sheet KM A22Document8 pagesFormat Tely Sheet KM A22aangNo ratings yet

- Macam Dan Jenis KapalDocument7 pagesMacam Dan Jenis KapalaangNo ratings yet

- Draft KedalamanDocument1 pageDraft KedalamanaangNo ratings yet

- Mdp36 The EndDocument42 pagesMdp36 The Endnanog36No ratings yet

- Business PlanDocument17 pagesBusiness PlanChester Cortez50% (2)

- DR K.M.NAIR - GEOSCIENTIST EXEMPLARDocument4 pagesDR K.M.NAIR - GEOSCIENTIST EXEMPLARDrThrivikramji KythNo ratings yet

- An Energy Saving Guide For Plastic Injection Molding MachinesDocument16 pagesAn Energy Saving Guide For Plastic Injection Molding MachinesStefania LadinoNo ratings yet

- The Problem of Units and The Circumstance For POMPDocument33 pagesThe Problem of Units and The Circumstance For POMPamarendra123No ratings yet

- Biodegradable Plastic Bag Manufacturing Industry-800655 PDFDocument68 pagesBiodegradable Plastic Bag Manufacturing Industry-800655 PDFAryanNo ratings yet

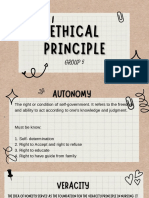

- Group 5 - Ethical PrinciplesDocument11 pagesGroup 5 - Ethical Principlesvirgo paigeNo ratings yet

- Form - Pelaporan B3Document16 pagesForm - Pelaporan B3sukma nugraNo ratings yet

- Emerging Re-Emerging Infectious Disease 2022Document57 pagesEmerging Re-Emerging Infectious Disease 2022marioNo ratings yet

- Safety AuditDocument9 pagesSafety AuditRobena Nagum BagasNo ratings yet

- Chap 6 - Karen HorneyDocument95 pagesChap 6 - Karen HorneyDiana San JuanNo ratings yet

- Remote Control Unit Manual BookDocument21 pagesRemote Control Unit Manual BookIgor Ungur100% (1)

- 8 Categories of Lipids: FunctionsDocument3 pages8 Categories of Lipids: FunctionsCaryl Alvarado SilangNo ratings yet

- Schindler 3100: Cost-Effective MRL Traction Elevator For Two-And Three-Story BuildingsDocument20 pagesSchindler 3100: Cost-Effective MRL Traction Elevator For Two-And Three-Story BuildingsHakim BgNo ratings yet

- User Manual: 3603807 CONTACT US - 09501447202,8070690001Document1 pageUser Manual: 3603807 CONTACT US - 09501447202,8070690001Arokiaraj RajNo ratings yet

- MAOH600 Ropu 48 Presentation Script and ReferencesDocument10 pagesMAOH600 Ropu 48 Presentation Script and ReferencesFano AsiataNo ratings yet

- Catalogue CV. Traka Abadi UniversalDocument15 pagesCatalogue CV. Traka Abadi UniversalHackers StevenNo ratings yet

- Assignment On Inservice Education Sub: Community Health NursingDocument17 pagesAssignment On Inservice Education Sub: Community Health NursingPrity DeviNo ratings yet

- Aakanksha ProjectDocument32 pagesAakanksha ProjectAakash murarkaNo ratings yet

- DR Hoon Park III - Indigenous Microorganism (IMO)Document33 pagesDR Hoon Park III - Indigenous Microorganism (IMO)neofrieda79100% (1)

- My Public Self My Hidden Self My Blind Spots My Unknown SelfDocument2 pagesMy Public Self My Hidden Self My Blind Spots My Unknown SelfMaria Hosanna PalorNo ratings yet

- E-Kabin - O Series - Monoblock Enclosure - ENGDocument12 pagesE-Kabin - O Series - Monoblock Enclosure - ENGCatalina CocoşNo ratings yet

- Sebaran Populasi Dan Klasifikasi Resistensi Eleusine Indica Terhadap Glifosat Pada Perkebunan Kelapa Sawit Di Kabupaten Deli SerdangDocument7 pagesSebaran Populasi Dan Klasifikasi Resistensi Eleusine Indica Terhadap Glifosat Pada Perkebunan Kelapa Sawit Di Kabupaten Deli SerdangRiyo RiyoNo ratings yet

- EF4e Beg Quicktest 05Document3 pagesEF4e Beg Quicktest 05terrenoruralcamboriuNo ratings yet

- Figure 1: Basic Design of Fluidized-Bed ReactorDocument3 pagesFigure 1: Basic Design of Fluidized-Bed ReactorElany Whishaw0% (1)

- UgpeDocument3 pagesUgpeOlety Subrahmanya SastryNo ratings yet

- Intentions and Results ASFA and Incarcerated ParentsDocument10 pagesIntentions and Results ASFA and Incarcerated Parentsaflee123No ratings yet

- Boeco BM-800 - User ManualDocument21 pagesBoeco BM-800 - User ManualJuan Carlos CrespoNo ratings yet

- IB Final ShellDocument25 pagesIB Final ShellsnehakopadeNo ratings yet

- ECC83/12AX7: Quick Reference DataDocument4 pagesECC83/12AX7: Quick Reference DataLuisNo ratings yet