Professional Documents

Culture Documents

Fmea

Uploaded by

chethan626Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fmea

Uploaded by

chethan626Copyright:

Available Formats

Case study

Preempting Problems

How Motorola

minimized risk

before changing

business-critical

applications

By Vic Nanda,

Motorola

n todays dynamic business environment, most companies face the

difficult challenge of quantifying and reducing risk due to planned

changes. This may include changes to a companys business processes,

IT applications or to the overall business environment.

Without the use of a formal method, the organizationwide impact of a

potential failure cant be quantified and simply becomes a subjective estimate (such as high, medium or low). If a formal risk assessment exercise is

conducted, only the localized impactor the immediate consequenceof

a failure is investigated, and there is no way to extrapolate the impact of a

failure to an entire company.

But there is a way to see the whole picture, and then act accordingly. An

organization can apply an approach that enhances design failure mode

effects analysis (DFMEA) to quantify and reduce its risk exposure in the

face of imminent change. Motorola did so with the help of the design,

measure, analyze, improve and control (DMAIC) method and, in the

process, averted significant setbacks during an IT application upgrade

and avoided spending more than a half-million dollars annually attributable to systems failures.

Project background

As part of a multimillion-dollar IT initiative, Motorola launched an ambitious project in 2006 to redesign and simplify the globally distributed

architecture for a business-critical application. The ultimate objective was

to improve operational efficiencies and cut costs by eliminating disparate

IT applications that offered similar functionality for Motorolas different

business units. Instead, one consolidated IT application would serve all

business units.

Due to this fundamental architectural change, there was potential for

post-implementation defects that would create downtime and put existing

business operations at risk. During the design phase of the project in late

2007, senior management decided the proposed architecture should be

examined thoroughly for potential failures. This entailed evaluating the

new architecture for design flaws that might jeopardize requirements for

high availability and reliability.

A Six Sigma project team (SSPT) was formed and included the following

participants: one Green Belt, one Black Belt (BB), one Master Black Belt,

one customer representative from the parent IT project that had spawned

the new project, and 15 subject matter experts from various functional

areas within the scope of the project.

A governance team for the project was also formed that was comprised of

two project sponsors, one project Champion, one representative from the

finance organization, the leader of the Six Sigma program in Motorola IT

six sigma forum magazine

february 2010

Preempting Problem s

Figure 1. Technical process flow

B2B Standard Order L2-L3

Using Dropship Phase 1

(Business Process)

System Architect

Thu Feb 07, 2008 12:33

(system)

Oracle_

ERP_

Orders

Ship Card

to provide

Promise

date

Oracle Sourcing

in OM to

provide

fulfillment details

Perform

Credit

Check

Yes

Manual

changes

applied on

Sales Order

SO changes required?

CTO Model?

Start

Perform

ATP

Check

Sales Order/

RMA/Mixed

Order Entered

Create New

Sales Order

Book

Sales

Order

Create Dropship

Purchase Order

Import

Requisition

Extract

Purchase

Order

Perform

Credit

Check

Update Sales

Order Status

Dropship

Purchase Order

Receipt

Import ASN

Receipt

for PO

Dropship

Sales Order

Shipped

Yes

3A4 Place Purchase Order

Configure/

Validate Model

Customer Order Credit Validation

Trifecta

Trifecta

3A8 Purchase Order Change

3B2 Advance Shipment Notification CMF

3A6 Distribute Order Status

Export Compliance Confirmation

3A4 Purchase Order Confirmation CMF

3B2 Advance Shipment Confirmation

3A8 Purchase Order Change Confirmation CMF

3A9 Purchase Order Cancellation Confirmation CMF

3A9 Purchase Order Cancellation Request CMF

(system)

Oracle_

ERP_ISC

Communicate

Sales Order

Status

Update Sales

Order Status

Extract

ASN

SO changes required?

Is Inventory available?

Extract

Sales

Order

Import

Sales

Order

Inventory

Available

Motorola

Pick

Release

Shipment against

Internal Sales Order

Ship

Confirm

Invoice Data

Manufacture

or buy

Buy

Export Compliance Verification

Export Compliance Verification

Maufacture/

Assemble

Buy from

Internal

Source

(system)

Vastera

Check

Compliance

Check

Compliance

Check

Compliance

Finance

Create

Customer

Invoice

Please note: This figure offers a high-level overview of a process flowchart structure. Focus on the specific activities is not necessary.

and the immediate supervisor of the BB on the SSPT.

The project team was chartered with the following

objectives:

1. Assess and quantify the risk to the entire company

as a result of potential failures in the proposed

new IT architecture.

2. Perform risk mitigation and provide improvement recommendations so the root causes that

pose the greatest risk to the company can be

addressed in an orderly fashion.

3. Estimate the reduction in risk, subject to implementation of recommended improvements.

Define phase

The team formulated the following statements:

Business case statementThe shift from a distributed IT architecture to a consolidated one was pro-

10

february 2010

W W W . AS Q . ORG

found and introduced significant risks that had to be

thoroughly understood and mitigated.

Opportunity statementProactive discovery of

design flaws could help uncover defects early in the

project and help minimize:

Cost of poor quality (COPQ) associated with

resolving design flaws later in the project (before

deployment)or worse, the much higher rework

cost if design flaws were discovered after deployment.

Cost of business impact as a result of IT downtime

to resolve defects found after deployment.

Goal statementThe project goal was to increase

the robustness of the new IT architecture by delivering measurable cost avoidance of at least $250,000

by identifying flaws in the proposed architecture by

March 14, 2008.

Project scopeThe scope identified the specific

Shipment Acknowledgement

P r e e m p t i n g P r o b l ems

In

this project, the

DFMEA

method served as a powerful tool for

quantifying and minimizing organizationwide risk.

architecture baseline to be analyzed, and listed seven

technical process flows to be evaluated to ensure their

flawless execution with the new architecture. The

scope also specified interfaces to other IT applications

that were in scope of the analysis.

Project planMilestone dates were set for the end

of each of the phases in the DMAIC lifecycle of the

project. A high-level project plan was supported by

a detailed plan that drilled down into each of the

project phases and listed start and end dates along

with responsibility for projects tasks.

The project due date was set by the SSPT and the

project sponsors.

Measure phase

This phase involved creating a measurement plan

that listed the performance measures to be used to

baseline current process performance and to calculate

project return on investment (ROI).

The performance measures were:

1. COPQinternal failure, or the total cost of IT

rework to resolve a process defect found before

go-live.

2. COPQexternal failure, or the total cost of IT

rework to resolve a process defect found after

go-live.

3. Business impact, or the impact in dollars to the

business due to a post-release defect.

Measurement data were collected from 57 large

IT projects to baseline process performance. Data

showed an average of 43 pre-release defects per projectwhich cost an average of $132.05 per defect to

resolveand an average of nine post-release defects

per project (defects reported after release of an IT

application to the business users).

The cost of rework for post-release defects was

$1,065.85, about eight times the cost of resolving prerelease defects. This is consistent with similar data

reported by IBM.1 Cost of an outage was based on a

2003 incident of a critical business application.

This phase ended with a formal milestone review

that involved the presentation of the phase results to

the project governance team.

Analyze phase

During this phase, the seven technical process flows

identified in the project were examined and modeled.

Process maps (abstractions of real processes) were prepared to depict the steps within the business-critical

application and its interfaces with other applications.

An example of a technical process flow is shown in

Figure 1. The four horizontal rectangles represent

four different business-critical applications involved in

this particular scenario, and the multiple dotted lines

from one rectangle to the next represent interface

messages between the applications.

After the technical flows were developed, the

DFMEA template (Table 1, p. 12) was populated with

header information for each process flow separated,

including names of activities (small boxes in Figure 1)

and interface messages (dotted lines in Figure 1). This

saved time during the DFMEA workshop because the

SSPT had templates ready for use.

With pre-work of the process maps completed, a

DFMEA workshop was scheduled and began with onehour training for the SSPT on the DFMEA Six Sigma

tool.

The team used the traditional 10-point scale for

scoring occurrence and detection. A five-point scale

was used for scoring severity because it aligned with

Motorolas five-point scale for scoring severity of

defects reported against IT software applications.

Risk priority number (RPN) = probability

(maximum = 10) x detection (maximum = 10)

x severity (maximum = 5).

RPNMaximum = 10 x 10 x 5 = 500.

RPNr = Reduced RPN after implementation of

corrective actions.

The SSPT deemed high-risk failures as those that

had an RPN > 80. This was also referred to as the

acceptance threshold.

The SSPT then decided to focus on uncovering

failure modes related to:

Planned modifications to the underlying

six sigma forum magazine

february 2010

11

Preempting Problem s

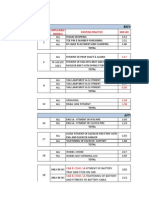

Table 1. DFMEA template

Failure mode effects analysis (FMEA)

Process/product: <Process name>

FMEA team: <List names of the people who contributed to this

FMEA>

Black Belt: <name>

Item

process steps

Key

process input

Potential

failure mode (In

what ways can the

key process go

wrong?)

Extract ASN

outbound

Customer order

credit validation

Extract SO

Shipment confirmation

Potential effects Severity of effect to Potential cause(s) Probability of

of failure

customer (1-5)

of failure (What

occurrence (1-10)

causes the key

input to go wrong?)

Motorola release pick

3A4, 3A8 or 3A9

Export

Motorola release pick

compliance

verification

Extract purchase Drop ship PO

order outbound

ASN = abstract syntax notation

DFMEA = design failure mode effects analysis

PO = purchase order

RPN = risk priority number

SO = sign off

commercial-off-the-shelf (COTS) business application. Failures in the COTS application due to

inherent defects were outside the scope of the

analysis because that was a risk users of the COTS

application were already exposed to, and those

defects were unrelated to the planned redesign

of the architecture.

Interface messages between the business-critical

application being redesigned and all other interfacing business applications.

The discovered failure modes were categorized as:

Application-related failures, including application crashes, version or patch-related problems,

application errors and configuration errors.

Data-related failures, including data validation

errors (data type and length), incomplete data

and data corruption.

In the case of IT applications, there are also failures

that can be attributed to infrastructure failures such as

network failure, memory leaks, database design errors

and capacity problems (CPU, memory or storage).

Due to the immensity of these types of infrastructure

12

february 2010

W W W . AS Q . ORG

failures, it was determined a separate DFMEA for

infrastructure-related failures was needed.

To save time, the team leveraged similarities across

the technical flows during the DFMEA analysis so

subsequent analysis could focus on unique differences

between the flows. In other words, if part of the technical flow between flows A and B was the same, then the

failure modes uncovered for that part during DFMEA

analysis of flow A would be applicable to flow B.

Finally, any additional miscellaneous failures identified were included in the DFMEA analysis for risk

assessment and possible handoff to others, such as the

infrastructure-related DFMEA analysis team.

Extending traditional DFMEA

As noted earlier, a significant challenge for the SSPT

was to devise an approach to extrapolate the results

of the traditional DFMEA to get a better sense of risk

exposure for all of Motorola. This entailed taking

a broader view of the RPN scoring in the DFMEA

exercise.

You might argue the severity scale can be used for

P r e e m p t i n g P r o b lems

this purpose. For example, a failure with a severe

impact that reaches across an organization could be

rated a 10 on the 10-point scale, but this approach

doesnt allow for a systematic way of computing organizationwide risk. For instance, an outbound variant (from enterprise resource planning [ERP] 7),

depending on the type of failure, could be encountered in up to three different variants of the process

(see Figure 2, p. 14).

Likewise, on the other side of the transaction,

depending on the type, a failure may be encountered

in up to six different ERPs. Or, a failure could be

encountered in up to two different process variants

inbound. Therefore, to get a true sense of organizationwide risk (referred to as enterprise RPN, or

eRPN), the individual RPN must be multiplied by

the number of process variants or ERPs, as the case

may be.

For instance, if a risk with an RPN of 500 is multiplied by one, it yields an eRPN of 500. On the other

hand, if a risk of a lower RPN of 200 is multiplied by

seven (assuming it would be encountered in all the

ERPs), it yields an eRPN of 1,400. In this example,

Action

taken

Risk priority

(reduced)

Recommended Responsibility and

action

target completion

date

Detection

RPN

Severity

Page: 1 of 1

Current controls that Probability

prevent either

of detection

the cause or

(1-10)

the failure mode

Occurrence

FMEA date: March 10-11, 2008

the risk that poses greater organizationwide risk is the

one with the lower RPN of 200. Without extrapolating

the risk to the entire company by using this concept

of eRPN, the team would have been misguided in

focusing on the failure with the RPN of 500.

eRPN = RPN x [ number of variants or

number of ERPs]

Maximum

= 500

Maximum

=3

Maximum

=7

3 variants (outbound)

2 variants (inbound)

7 ERPs

eRPNMaximum = 500 x 7 = 3,500.

eRPNr = Reduced eRPN after implementation of

corrective actions.

Computing eRPN is only part of the answer. Because

many failure modes might share common root causes,

those causes become relatively more important than

six sigma forum magazine

february 2010

13

Preempting Problem s

Figure 2. Computing enterprise-RPN (eRPN)

Three variants

Two variants

ERP 7

Outbound

Inbound

6 ERPs

Extract 1

Extract 2

Extract 3

Extract 4

Extract 5

Extract 6

One

Two

Three

Four

Five

Six

ERPs 1 6

RPN = risk priority number

ERP = enterprise resource planning

eRPN = enterprise RPN

others that might be responsible for one type of failure. Therefore, repetitive root causes must be carefully considered as they are likely to pose the most risk

to the organization.

By adding the eRPN of all failures that are attributed

to the same root cause, you can estimate the risk posed

by a specific root cause to the organization. This is

referred to as cumulative eRPN. That is, cumulative

eRPN is the sum of enterprise risk of all failures that

are attributed to the same or similar root cause.

Brainstorming causes

The first step is brainstorming the potential failures

at each step of the process. The SSPT examined each

process step and interface message and brainstormed

potential application and data-related failures. Each

potential failure was assessed for cause of failure.

Based on the team consensus on severity, probability

of occurrence and detection, the RPN score was computed for each failure.

During a one-week workshop, the SSPT uncovered 57 failure modes, including 27 high-risk failure

modes that exceeded the acceptance threshold and

had broad enterprise impact. Table 2 shows a partial

snapshot of the top-five high-risk failure modes, sorted

in descending order by eRPN. To allow for legibility,

certain columns have been suppressed.

The SSPT was interested in root causes with the

14

february 2010

W W W . AS Q . ORG

greatest cumulative eRPN. A partial snapshot of the

top-three root causes is shown in Table 3, p. 16. All

failures that were attributed to the same root cause

are listed in the first column while the associated root

cause is listed in the second column.

Figure 3, p. 17, shows the root causes organized

in descending order by cumulative eRPN. The different shadings in each histogram bar correspond

to the different failures attributed to the same root

cause.

For example, the first bar has six different failures

that result from this root cause. The heights of these

shaded portions in the first bar correspond to the

magnitude of organization-wide risk (eRPN) associated with each of those failures.

Improve phase

In this phase, the team brainstormed improvements

and corrective actions for this list of root causes. A

total of 15 improvement recommendations for the 13

root causes were made.

Figure 4, p. 18, shows the original risk profile and

the projected reduction in risk profile, subject to the

implementation of the improvement recommendations. This before-and-after representation of quantified risks served as a powerful way to present overall

risk exposure to senior management.

Recalculated RPNs show that 80% of the failure

P r e e m p t i n g P r o b l ems

Table 2. Top five high-risk failure modes

RPN

Enterprise RPN

(number of

affected flows x #

of affected ERPs

x RPN) - eRPN

Recommended action

Failure to provide

specified info per

customer in the ASN.

360

2160

Recommend that a

detailed request for ASN

data fields be specified.

24

144

No credit check

validation.

300

1800

Need SOA for credit

check. This may be

used for compliance

check as well.

10

60

120

840

30

210

30

210

Item process

steps

Potential effects

of failure (What is

the impact on key

output variables?)

Potential cause(s) of

failure (What causes

the key input to go

wrong?)

Extract ASN

outbound.

Fines from unhappy

customers.

Customer order

credit validation.

Revenue impact

(shipped to

customer with bad

credit or exceeding

available credit).

Master data

synchronization

between two

ERPs for BOM.

Wrong product built.

Data not synched.

Lack of identification

ERP configuration

of common elements

differencesERP

Failed processes

of key dataERPs

application/

(bottomline impact).

perform functions

process setup.

differently.

Need common

nomenclature

data governance.

Failed processes.

Failure

Effect

Lack of identification

of common elements

of key dataERPs

perfom functions

differently.

245

1715

225

1575

225

Cause(s)

1575

Original

enterprise

risk

This is a GEMS-specific

issue (business-specific).

This will create requests

for Motorola PDM.

Decode program should

be capable of dealing

with BOM changes (refer

to DropShip for details).

Identify common

elements of key data

(data quality control);

OM will be the system of

record for the common

elements.

Identify common

elements of key data

(data quality control);

OM will be the system of

record for the common

elements.

Recommendation

Reduced enterprise risk

(after corrective action)

ASN = abstract syntax notation GEMS = Motorola department

BOM = bill of material

PDM = product data management

ERP = enterprise resource planning RPN = risk priority number

eRPN = enterprise RPN SOA = service-oriented architecture

eRPNr = enterprise RPN reduced OM = order management

modes could be further lowered below the acceptance threshold if the associated corrective actions

were implemented. Only one of the 27 failure modes,

with an RPN of 120, remained above the acceptance

threshold of 80 even after implementation of all corrective actions.

Next, each recommendation was examined for

implementation impact to the IT project using the

following criteria:

1. No negative financial impact (budget).

2. No schedule impact.

RPNr eRPNr

3. No impact to business processes.

If the above criteria were met, the recommendation was categorized as low implementation risk.

If one of these criteria was not met, the recommendation was considered high implementation

risk and required further impact assessment prior

to implementation.

Finally, the results of the analysis, along with the

assessment of implementation risk associated with

each of the recommendations, were presented to

senior management.

six sigma forum magazine

february 2010

15

Preempting Problem s

Table 3. Top three high-risk failure modes

Potential cause(s)

of failure (What

causes the key input

to go wrong?)

Recommended action

Responsibility

and target

completion date

Implementation

risk (low/high)

Cumulative

eRPN for the

root cause

Extract SO, extract

ASNoutbound,

export compliance

Errors in decode

verification, 3A6

mechanism for

distribute order

manufacturing BOM.

status, any

interaction message.

Create pre-processor logic for

taking sales BOM and generating

manufacturing BOM. Over long

term, need general restructuring

of BOMs to reflect a standard

BOM configuration process.

Data purged

Data purged

4110

ERP configuration

differencesERP

application/process

setup, need common

nomenclature data

governance.

Lack of identification

of common elements

of key dataERPs

perfom functions

differently.

Identify common elements of

key data (data quality control);

OM will send one set of common

elements.

Data purged

Data purged

3150

3A9 PO cancellation

request CMF, 3A9

PO cancellation

confirmation CMF,

3A8 PO change

confirmation CMF,

3A8 PO change,

extract PO

outbound.

Change request

too late in the

manufacturing

process, POSO

discrepancy, order

status info from ISC

to OM not available,

sequencing of the

changes, timings of

the cancellations.

Need order status synch (3A6)

near real-timebetween ISC and

OMPO and SO.

Design needs to incorporate this

status control point.

Additional actions:

Need a process for handling

SC-initiated change requests.

BAM will also help detect

changes.

Need workflow control for L2 PO

change before commit.

Data purged

Data purged

2593

Item process steps

Cause(s)

Recommendations

BOM = bill of material ISC = Motorola department

ASN = abstract syntax notation OM = order management

CMF = common message format

PO = purchase order

ERP = enterprise resource planning SC = source

eRPN = enterprise risk priority number SO = sign off

Control phase

As the implementation of the corrective actions was

spread over several months and phases of the parent

IT project, this Six Sigma project concluded with the

handoff of all corrective actions to the program manager of the parent IT project, along with assignment

of primary ownership and due date for each corrective

action.

Benefit realization

This project resulted in a 77% reduction in overall

risk to Motorola.2 Further, the risk of potential failure

for 26 of the 27 identified high-risk failure modes was

reduced to well below the acceptance threshold.

Based on historical data on the number of defects,

defect containment effectiveness and cost of rework

16

february 2010

W W W . AS Q . ORG

for 57 large Motorola IT projects, the SSPT determined that identification of the 27 high-risk defects

resulted in direct annual cost avoidance of $2,905 and

$5,329 in pre-release rework and post-release COPQ,

respectively.

By taking into consideration the business impact of

post-release defects and extrapolating historical data

from a similar outage affecting a much smaller portion of the business in 2003, the SSPT concluded that

similar outages in the future would have an annual

business impact of at least $560,000, depending on

the types of system failures encountered.

This includes items such as impact to cash-conversion cycle, cost of expedited freight, manual rework

of defective orders by business employees (non-IT

personnel), contract penalties, loss of business and

loss of export privileges. Therefore, minimum projected annualized cost avoidance was $568,234 or

P r e e m p t i n g P r o blems

Figure 3. Root causes that pose greatest risk to the enterprise

Cumulative eRPN for common root causes

4,000

Cumulative eRPN

3,000

2,000

1,000

0

Root cause 1

group

Root cause

group

1

2

3

4

5

6

7

8

9

10

11

12

13

10 11 12

13

Failure modes

Identify good error messaging process and standard

escalation process

Invoice data

3C1 return product

3A4 place purchase order

Extract purchase orderinbound

Additional step: item cost synch

Disconnect in transfer priceOM PO has a different

transfer price than the ISC SO

Master data synchronization between two ERPs for BOM

Customer order credit validation

3A8 purchase order change

3A8 purchase order change confirmation CMF

3A9 purchase order cancellation confirmation CMF

3A9 purchase order cancellation request CMF

Extract purchase orderoutbound

Need common nomenclature data governance

ERP configuration differencesERP

application/process setup

Any interaction message 2

Any interaction message 1

3A6 distribute order status

Export compliance verification

Extract ASNoutbound

Extract SO

Root cause descriptions

Errors in decode mechanism for manufacturing BOM.

Lack of identification of common elements of key data.

Change request too late in the manufacturing process, PO-SO

discrepancy, order status information from ISC to OS not

available, sequencing of the changes, timing of the cancellations.

No credit check validation.

Failure to provide specified info per customer in the ASN.

Data not synchronized.

Current process only takes the order header and lines, and does

not take in adjustments.

Item cost not the same in both ERPs in the same entity.

Change management processing.

Change or cancellation rejection from ISC.

Data errorinvalid or incomplete.

Inability to create commercial invoice holds up shipment.

Insufficient error handling.

Note: Errors in decode mechanism for

manufacturing BOM pose the greatest

risk to the enterprise.

ASN = abstract syntax notation

BOM = bill of material

CMF = common message format

ERP = enterprise resource planning

eRPN = Enterprise risk priority number

ISC = Motorola department

OM = order management

PO = purchase order

SO = sign off

six sigma forum magazine

february 2010

17

more, depending on the types of system failures encountered.

The estimated project cost was $77,280.

Thus, this project yielded an ROI of 6.35 times

the investment in the first year alone.

Figure 4. Reduction in enterprise risk

Limitations

eRPNr (after), eRPN (before)

Preempting Problem s

Before and after corrective actions to potential failure modes

eRPN

eRPNr

2000

1500

Failure modes that show smallest

The results of this project are directly appliimprovement, unless strategic

cable to a situation in which a company wants

recommendations are implemented.

to quantify and reduce business risks due to

1000

process or technology changes. Even though

the change was technology-related in this proj500

ect, the underlying Six Sigma tool of FMEA

can be used to uncover potential failure modes

for a process (also called process FMEA, or

0

PFMEA) or during product design (DFMEA).

As with any approach, there are potential

1

4

7

10

13

16

19

22

25

limitations. It is widely acknowledged that an

Potential failure modes (27) above cut-off RPN

FMEA cannot uncover complex failure modes

(for example, a sequence of smaller failures

Note: This figure is not intended to show a trend. It is sorted by

that may have a compounding effect). The

decreasing order of eRPN. Original enterprise risk (red) can be

SSPT did not consider failure modes that were

significantly reduced (green) if recommendations are implemented.

associated with failures in the standard COTS

RPN = risk priority number

application because these were not a conseeRPN = enterprise risk priority number

quence of migrating to a new IT architecture.

Finally, the scoring of failure scenarios in

a FMEA analysis is always a subjective exercise, and final RPN scores are based on group

consensus. Also, in this case, the DFMEA analysis was

BIBLIOGRAPHY

challenging due to a lack of historical data regarding

Arkusinski, Andy, Failure Modes and Effects Analysis During Design of

potential failures. This was because the new architecComputer Software, presentation, 24th Digital Avionics Systems Conferture had not been previously implemented in other

ence, Oct. 30, 2005.

companies or within Motorola.

Haapanen, Pentti and Atte Helmunen, Failure Mode and Effects Analysis

Despite these limitations, the DFMEA method

of Software-Based Automation Systems, STUK (Finlands radiation and

nuclear safety authority), August 2002, p. 37.

served as a powerful tool for quantifying and minimizing organizationwide risk. Results of the analysis met

Vijayaraghavan, G.V., A Taxonomy of E-commerce Risks and Failures, masters degree thesis, Florida Institute of Technology, May 2003.

management expectations regarding quantification

of risk at the organizational level, and the approach

EDITORS NOTE AND ACKNOWLEDGEMENTS

described in this project can be readily adopted by

other companies that face similar challenges in assessThis article is based on an excerpt of Nandas Six Sigma Software Process &

ing organization-level risk exposure in the face of

Quality Improvement: Success Stories from Motorola, IBM, Xerox and Other Leading

Companies, McGraw Hill, 2010. The author thanks Motorola for its permisplanned changes in their business.

sion to include information contained in this article.

REFERENCE AND NOTE

1. Humphrey Watts, A Discipline for Software Engineering, Addison Wesley,

1995.

2. The balance of 23% should not be misunderstood as residual risk of any

one failure to Motorola. Instead, it is the cumulative effect of all 27 highrisk failures together. In other words, it is more appropriate to consider

each high-risk failure separately because the high-risk failures were not

related, and thus were unlikely to be encountered simultaneously.

18

february 2010

W W W . AS Q . ORG

What do you think of this article? Please share

your comments and thoughts with the editor by e-mailing

godfrey@asq.org.

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Name: - Date: - Q.1 Match The Body PartsDocument5 pagesName: - Date: - Q.1 Match The Body Partschethan626No ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Option Selling WorkshopDocument10 pagesOption Selling Workshopchethan626No ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- 21-05-2020online Learning - Circular 1 PDFDocument8 pages21-05-2020online Learning - Circular 1 PDFchethan626No ratings yet

- National Guard Black Belt Training: Unclassified / FouoDocument22 pagesNational Guard Black Belt Training: Unclassified / Fouochethan626No ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Factorial Analysis of Employee Satisfaction On Annual Performance Appraisal Practice at Tata Motors LTDDocument6 pagesFactorial Analysis of Employee Satisfaction On Annual Performance Appraisal Practice at Tata Motors LTDchethan626No ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Strike Call OI Put OI Cumulative Call Cumulative Put Total ValueDocument13 pagesStrike Call OI Put OI Cumulative Call Cumulative Put Total Valuechethan626No ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Mechanical EngineerDocument67 pagesMechanical EngineersameerNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Identification Work Cycle: Discomfort SurveyDocument1 pageIdentification Work Cycle: Discomfort Surveychethan626No ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Before Inversion: STN Applicable Models Existing Practice Min WCDocument4 pagesBefore Inversion: STN Applicable Models Existing Practice Min WCchethan626No ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Six SigmaDocument18 pagesSix Sigmachethan626No ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Job Aid: Process Performance Metric FormulasDocument3 pagesJob Aid: Process Performance Metric Formulaschethan626No ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Sine Wave Inverter SchematicsDocument7 pagesSine Wave Inverter Schematicshpoerbaya100% (1)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Signotec PDF Signing Adobe Plugin enDocument17 pagesSignotec PDF Signing Adobe Plugin enAlexander MoralesNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- MasterDocument65 pagesMasterJenniferP.Barroso0% (1)

- HTML Question PaperDocument14 pagesHTML Question PaperNarendran88% (41)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Brochure Thermoformer Range enDocument52 pagesBrochure Thermoformer Range enJawad LOUHADINo ratings yet

- Job Order Company SecretaryDocument3 pagesJob Order Company SecretaryMae Francesca Isabel GarciaNo ratings yet

- Alternate Mode KatalogDocument148 pagesAlternate Mode Katalogbeto bonfimNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Emona DATEx User Manual V1Document52 pagesEmona DATEx User Manual V1Jesus VinasNo ratings yet

- CatalogDocument66 pagesCataloggmconNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- PhotutilsDocument401 pagesPhotutilsBurak BaşoğluNo ratings yet

- MB Gusset DesignDocument172 pagesMB Gusset DesignRamakrishnan Sakthivel100% (1)

- 20Document83 pages20altaminNo ratings yet

- PDF Transport Phenomena Bird Solutions Manual PDFDocument2 pagesPDF Transport Phenomena Bird Solutions Manual PDFHamza Faheem0% (3)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Piper PA-46-350P Malibu Mirage N186CB 11-16Document30 pagesPiper PA-46-350P Malibu Mirage N186CB 11-16Antonio Cesar de Sa LeitaoNo ratings yet

- Indigo ManualDocument232 pagesIndigo Manualjasopanev100% (2)

- Vezbi Za Natprevar 1Document9 pagesVezbi Za Natprevar 1Zorica ArnaudovaNo ratings yet

- PlainSight BTCDocument11 pagesPlainSight BTCMidnight Hacker100% (1)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Case Studies MaintenanceDocument7 pagesCase Studies MaintenancemarinflorentinaoanaNo ratings yet

- Mutual Aid Pact Internally Provided Backup Empty Shell Recovery Operations Center ConsiderationsDocument2 pagesMutual Aid Pact Internally Provided Backup Empty Shell Recovery Operations Center ConsiderationsRedNo ratings yet

- PLC-Driver (V5) Siemens LOGO! - Ethernet TCP-IP - Programming InterfaceDocument7 pagesPLC-Driver (V5) Siemens LOGO! - Ethernet TCP-IP - Programming InterfaceAdelmoKarigNo ratings yet

- CASE Tools Tutorial CASE Tools Tutorial CASE Tools Tutorial CASE Tools TutorialDocument52 pagesCASE Tools Tutorial CASE Tools Tutorial CASE Tools Tutorial CASE Tools TutorialAleeza BukhariNo ratings yet

- MBA Project Report of ICFAI Distance Learning ProgramsDocument4 pagesMBA Project Report of ICFAI Distance Learning ProgramsPrakashB144No ratings yet

- Last Clean ExceptionDocument4 pagesLast Clean ExceptionHavanna G.No ratings yet

- Fortinet Product Matrix September 2013Document4 pagesFortinet Product Matrix September 2013Tuấn LêNo ratings yet

- Sheet 7 FPDocument7 pagesSheet 7 FPyehyaNo ratings yet

- HSM USB Serial Driver Release Notes PDFDocument32 pagesHSM USB Serial Driver Release Notes PDFVeimar CelisNo ratings yet

- Chapter 4 - Iot SecurityDocument28 pagesChapter 4 - Iot SecurityBirunthaa SashaNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Wind Speed Modelling Using Inverse Weibull Distrubition - A Case Study For B - Lec - K, Turkey (#299493) - 285602Document5 pagesWind Speed Modelling Using Inverse Weibull Distrubition - A Case Study For B - Lec - K, Turkey (#299493) - 285602CherinetNo ratings yet

- Hiring Process Analytics Project 4 On StatisticsDocument6 pagesHiring Process Analytics Project 4 On StatisticsNiraj Ingole100% (1)

- Murata MA40 SERIESDocument2 pagesMurata MA40 SERIESMiltonAlvaradoPonceNo ratings yet