Professional Documents

Culture Documents

Armado Y Desarmado Rollers Excavadoras

Uploaded by

gabicckCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Armado Y Desarmado Rollers Excavadoras

Uploaded by

gabicckCopyright:

Available Formats

RENR3963

Disassembly and Assembly Procedures

for Hydraulic Excavator Rollers

Disassembly

Reconditioning

1. Reference Material

Title

Form Number

Step

Procedure

Reference / Tool Required

Remove plug and stopper, then

drain the oil.

Drill with a .5 inch drill bit.

Remove retaining ring or pin.

Screwdriver or punch.

Remove the end collar.

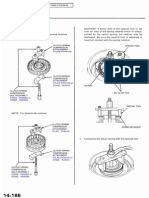

(See Illustration 1)

Use a hydraulic press.

Remove the o-ring from the shaft.

Rotate roller end for end and slide

the end collar and shaft out of the

roller assembly.

Remove o-rings from end collar.

Remove Duo-Cone seals from end

collars and roller assembly.

Inspect the set of Duo-Cone seals

side by side for reusability.

NOTE: Seals must be kept in

matching pairs if reused.

SEBF8511- proper reuse

information for Duo-Cone

seals.

Measure shaft to bearing clearance.

(See Illustration 2)

NOTE: If one or both bearings fail,

the feeler gauge test use bearing

removal adapter (FT2209 shaft

with FT2210, FT2211 or FT2212

driver) and press to remove both

bearings.

See Table 3 for shaft to

bearing clearance

specifications.

Critical

SEBF8511

Reusability and Assembly Recommendations for Duo-Cone Seals

SEBF8484

SEBF8364

NECG0604

SEBF8574

Tools and Specification Chart for Conventional Duo-Cone Seals

Assembly and Installation of Conventional Duo-Cone Seals

Tool Guide

SEBF8596

Guideline for Reusable Roller and Idler Components

Oil Fill Volume for Rollers

Shaft-to-Bearing

Clearance

2. Tooling Reference

Model Number

Seal Height Tooling

Shaft

3. Shaft/Bearing Clearance

Bearing

Roller

All Models

8T-0450

8T-0447 Calipers

Miscellaneous Tooling

Q

Remove end collar using a hydraulic

press.

Description

Measure shaft-to-bearing clearance.

Tooling Part Number

Plug Installation Tool

5P-7419

Stopper Installation Tool

5P-7392

Bearing Driver Group

1P-0520

Clearance (min/ max)

215B, 219, 219D, 225,

225B, 225D, 227, 229,

229D, 235, 235B, 235C,

231D

0.23 / 0.39 mm

(.00906 / .0154 in)

205, 205B, 211, 211B, 213,

213B, 215B, 215C, 215D,

235C, 235D, 245, 245B,

245D, 320, 320S, 320B,

322, 322B, 325, 325B,

330, 330B, 350, 375

0.25 / 0.48 mm

(.00984 / .0189 in)

231D, 307, 307B, 308B,

312, 312B, 315, 315B, 317,

318, 318B, 320, 320B

0.11 / 0.31 mm

(.00433 / .0122 in)

4. Seal Installers

Preparation for Assembly

Step

Procedure

10

Wash and remove all debris from

roller.

Clean components with alcohol and

dry with a lint free cloth.

11

12

Inspect seals for reusability.

13

Install o-rings in the end collar using

the o-ring compound.

Reference / Tool Required

Model Number

Critical

Use a lint free cloth.

Use 1U-6395 O-ring

compound.

14

Replace toric rings if reusing seals.

15

Dampen toric with proper lubricant.

Use 99% isopropyl alcohol or

approved assembly lubricant.

16

Install seals into end collars and

roller assemblies using the proper

installation tools.

(See Illustration 3)

See Table 2 for installation

tools.

Dry the Duo-Cone seals using

pressurized air at 30 psi for 1

minute.

Not necessary if 99%

isopropyl alcohol is used

Check assembled seal height in

end collars and assemblies at four

locations 90 degrees apart. The

difference in height must not

exceed 1.0 mm (0.039 in).

(See Illustration 4)

See Table 2 for proper seal

height tooling.

17

18

Assembly

Height

Carefully clean shaft without

degrading the seal ramp surface.

Part Number

4C-6206

1U-8849

9U-7537

312, 312 B, 320

1U-6145

307, 307B

123-3800

215B, 219, 219D, 225, 225B,

225D, 227, 229, 229D, 231D,

320B, 320S, 322, 322B,

325B

205, 205B, 211, 215B, 215C,

215D, 312, 312B, 315, 315B,

318B, 320, 320B, 325

1U-8842

235D, 245, 245B, 245D

1U-6443

227, 231D, 235, 235D, 245

215B, 225

Procedure

19

Lightly lubricate the bearings with

the same oil type used to fill the

roller.

Wipe the entire Duo-Cone seal ring

face in end collars and roller

assemblies.

(See Illustration 5)

20

21

Apply a light film of oil to the entire

Duo-Cone seal face.

(See Illustration 6)

22

Slide shaft and end collar into roller.

23

Install the o-ring onto the shaft.

24

Rotate the roller end for end and

place the other end collar on the

shaft and press into place.

25

26

Install Duo-Cone seals into end

collars and roller assemblies using

the proper installation tool. Use a

sudden, even, perpendicular force to

install the seals.

Check assembled seal height in the

retainer at 4 locations 90 degrees

apart.

Model Number

All Models

Reference / Tool Required

Critical

Seal Face

That Gets

Oiled

Use hoist if necessary.

307, 307B

3P-4603

7. Stopper Part Numbers

Tolerance (min/ max)

0.25 / 1.25 mm

(.009843 / .04921 in)

Model Usage

Part Number

205, 205B, 211, 211B, 213,

213B, 215B, 215C, 215D,

231D, 312, 312B, 315, 317,

318, 318B, 320, 320S, 320B,

322, 322B, 325, 325B, 330,

330B, 350, 375

5P-2247

Check the endplay.

See Table 6 for endplay

tolerances.

385, 375

185-5065

185-5102

176-8620

176-8621

152-4129

152-4134

1055 55 ml

SAE 30

8C-3698

745 35 ml

SAE 30

8C-3698

330

5Q-3206

179-1486

179-1491

460 25 ml

437 25 ml

SAE 30

8C-3698

330B

179-1486

183-2874

5Q-3203

179-4147

179-4148

437 25 ml

SAE 30

8C-3698

A= 285 15 ml

M= 350 15 ml

SAE 30

8C-3698

A= 285 15 ml

M= 350 15 ml

SAE 30

8C-3698

280 15 ml

350 15 ml

SAE 30

8C-3698

255 10 ml

SAE 30

8C-3698

255 10 ml

SAE 30

8C-3698

350

Duo Cone

Retainer Seal

Wipe the seal face using a lint free

cloth.

325

325B

Apply a thin layer of oil to the entire

seal ring face.

322, 322B

Press the bearing block into place.

8C-3698

312B, 312

5Q-3220

151-9747

127-3806

150 ml

SAE 30

8C-3698

70 5 ml

70 5 ml

145 15 ml

1600 50 ml

SAE 30

SAE 30

8C-3698

8C-3698

SAE 30

8C-3698

420 30 ml

SAE 30

8C-3698

340 25 ml

420 30 ml

450 15 ml

SAE 30

8C-3698

235C

Critical

Use a light oil to lubricate

the stopper.

20

20

30

40

10

See Table 2 for plug

installation tool.

31

Tap the end of the roller to check

for oil. If there is a dull thud, the

roller contains oil. If there is a

ringing noise, the roller is empty.

Use a small hammer.

40

Install the plug into the stopper to

the proper depth of 0 + 2 mm.

50

30

See Table 8 for oil fill

volumes.

170-5665

30

Add proper oil volume to the roller.

Purge

20

29

Pressure

Differential

Gauge

8T-0831

He

Cycleat

Reset

//

9W-5586

450 15 ml

SAE 30

8C-3698

231D, 229D,

227

225

8E-4576

340 25 ml

SAE 30

8C-3698

8E-4579

420 30 ml

SAE 30

225B, 225D

219, 219D

8E-4573

320 20 ml

SAE 30

8C-3698

8C-3698

215C, 215D,

213, 213B, 211,

211B, 205,

205B

8E-7494

350 20 ml

SAE 30

8C-3698

50

QQ

O

--M

-

235D

40

10

If using FT2724, do not allow

air to enter in a surge and do

not use pressure in excess of

138 kPa (20 psi), as this may

displace the toric ring.

30

10

127-3806

127-3807

8E-0830

8E-0831

8E-4579

124-8250

134-6636

8E-4576

8E-4579

9W-5586

30

50

40

Use the Test and Fill machine

(170-5664) to evaluate and fill the

joint. If this is not available,

perform the following test using the

FT2724. Introduce nitrogen into the

lubricant cavity to a pressure of 138

kPa (20 psi). Turn the ball valve to

a shut-off position. Next close the

pressure differential gauge. The

pressure is to be observed for 10

seconds. A pressure drop of 2.5

percent (3.5 kPa/0.5 psi) or less is

acceptable.

(See Illustration 8 or 9)

50

350 15 ml

SAE 30

235B, 235

Reference / Tool Required

CAT Part Number

225 10 ml

245D, 245B,

245

Test and Lubricate

Oil Weight

163-4143

307B, 307

Press the end collar into place.

5Q-3203

152-4125

163-4147

163-4145

152-4125

163-4147

163-4143

163-4144

163-4143

163-4144

163-4147

Oil Volume (ml)

318B, 317,

315, 315B

308B

Ball Valve

20

* If your model and roller group are not listed, consult SEBF8574.

110

10

28

1U-8843

Roller Group

Shaft

Use a hydraulic press.

Use a hydraulic press.

Lubricate the stopper. Install it

7 7 mm (.3 .3 in) below the

bottom of the shaft chamfer.

9W-2146

1U-8840

205, 205B, 211, 211B, 213,

213B, 215B, 215C, 215D,

219, 219D, 225, 225B,

225D, 227,229, 229D,

231D, 235, 235B, 235C,

235D, 245, 245B, 245D

Model Number

320B

27

6Y-0473

8. HE Oil Fill Volumes

Insert the retaining ring or if

necessary insert another pin.

(See Illustration 7)

Procedure

205, 205B, 211, 211B, 213,

213B, 215B, 215C, 215D,

231D, 312, 312B, 315,

315B, 317, 318, 318B, 320,

320S, 320B, 322, 322B,

325, 325B, 330, 330B, 350,

375

6. Endplay Tolerances

Part Number

Check assembled seal height in the

retainer at 4 locations 90 degrees

apart.

320

Step

Model Usage

1U-8841

Assembly

Step

5. Plug Part Numbers

375

350

330, 330B

220

Pressure Gauge

Use the Test and Fill Machine

(170-5664) to evaluate and fill the

joint.

10

Pressure test the roller using FT2724.

Introduce nitrogen into the lubricant

cavity to a pressure of 138 kPa

(20 psi). Turn the ball valve to a shutoff position. Next close the pressure

differential gauge. The pressure is to

be observed for 10 seconds. A

pressure drop of 2.5 percent

(3.5 kPa/ 0.5 psi) or less is acceptable.

RENR3963

Reconditioning

2002 Caterpillar Inc.

Printed in U.S.A. (6/02)

You might also like

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- SECTION 303-01B: Engine - 4.6L and 5.4L 2000 F-150 Workshop Manual AssemblyDocument35 pagesSECTION 303-01B: Engine - 4.6L and 5.4L 2000 F-150 Workshop Manual AssemblyHassan Vela VenegasNo ratings yet

- Eccentric Weight Housing Oil - Change: Operation and Maintenance ManualDocument3 pagesEccentric Weight Housing Oil - Change: Operation and Maintenance ManualLuis AugustoNo ratings yet

- Caterpillar Cat 120G MOTOR GRADER (Prefix 11W) Service Repair Manual (11W01019-01250)Document18 pagesCaterpillar Cat 120G MOTOR GRADER (Prefix 11W) Service Repair Manual (11W01019-01250)Arsel FirgiawanNo ratings yet

- TDY75 Oil-Cooling Electric DrumDocument12 pagesTDY75 Oil-Cooling Electric DrumAlexis Iván Pérez GuerreroNo ratings yet

- DD15 Detroit DieselDocument10 pagesDD15 Detroit Dieselstarsky100% (4)

- Compressor WabcoDocument6 pagesCompressor Wabcoruben_cruz_34No ratings yet

- Greddy SBD ManualDocument22 pagesGreddy SBD ManualKenneth ChanNo ratings yet

- Pistons and Connecting Rods - InstallDocument3 pagesPistons and Connecting Rods - Installsergio blandon lNo ratings yet

- 5P-2378 Master PinDocument5 pages5P-2378 Master PinAlbertoNo ratings yet

- Cummin KTA50-G3 Main Bearing Installation ManualDocument15 pagesCummin KTA50-G3 Main Bearing Installation ManualRey Anthony Pole100% (2)

- MS210 MS230 MS250 Service ManualDocument74 pagesMS210 MS230 MS250 Service ManualTabata Natalia75% (4)

- SRBF8091 ролики 3500Document20 pagesSRBF8091 ролики 3500mohamed hamedNo ratings yet

- Pistons and Connecting Rods - AssembleDocument6 pagesPistons and Connecting Rods - AssemblealonsoNo ratings yet

- 1995 - 1998 Acura 2.5TL 3.2TL Service Manual - Part3Document200 pages1995 - 1998 Acura 2.5TL 3.2TL Service Manual - Part3CandieApple100% (1)

- 78 Dt400e DT250E ManualDocument18 pages78 Dt400e DT250E Manualdisgustipate0% (1)

- 8218 спецификация головки 3116 -с7Document19 pages8218 спецификация головки 3116 -с7Евгений АбрамовNo ratings yet

- Montagem e Desmontagem Da Camisa 3306Document3 pagesMontagem e Desmontagem Da Camisa 3306Lucas ApostoloNo ratings yet

- Caterpillar Cat 235 EXCAVATOR (Prefix 62X) Service Repair Manual (62X00001-00288)Document23 pagesCaterpillar Cat 235 EXCAVATOR (Prefix 62X) Service Repair Manual (62X00001-00288)rpoy9396615No ratings yet

- Valve Lash G3408Document9 pagesValve Lash G3408Djebali MouradNo ratings yet

- 18SP607 - Series 60 Egr Ddec V Fuel Pump, Combination Pressure Regulator / Check Valve, and N3 Injector O-Ring and Washer KitDocument7 pages18SP607 - Series 60 Egr Ddec V Fuel Pump, Combination Pressure Regulator / Check Valve, and N3 Injector O-Ring and Washer KitaraceliluciojimenezNo ratings yet

- 3S AWD Trans Service ManualDocument103 pages3S AWD Trans Service ManualMatt BushnellNo ratings yet

- คู่มือบำรุงรักษา root blowerDocument17 pagesคู่มือบำรุงรักษา root blowervarayutjNo ratings yet

- BMW E60 Engine Seals NotebookDocument24 pagesBMW E60 Engine Seals NotebookPeter McCracken100% (6)

- Service Manual Transmission FWD Mitsubishi ManualDocument276 pagesService Manual Transmission FWD Mitsubishi ManualJose Chong Loo Gonzalez100% (2)

- G3406 Connecting Rod BearingsDocument4 pagesG3406 Connecting Rod BearingsnobodymagdesignNo ratings yet

- Pistons and Connecting Rods - Install: Desmontagem e MontagemDocument3 pagesPistons and Connecting Rods - Install: Desmontagem e MontagemJefferson SilvaNo ratings yet

- SM47013 PDFDocument8 pagesSM47013 PDFHENKO7659No ratings yet

- Lubrication Specifications Universal JointsDocument6 pagesLubrication Specifications Universal Jointsmohammed barghothiNo ratings yet

- Helical Gearbox InstallationDocument8 pagesHelical Gearbox InstallationKUNALJAYNo ratings yet

- Volvo D6D Shop ArmedDocument45 pagesVolvo D6D Shop ArmedBASILIO JARA HUERTA100% (4)

- Caterpillar Cat 235D EXCAVATOR (Prefix 8TJ) Service Repair Manual (8TJ00001 and Up)Document23 pagesCaterpillar Cat 235D EXCAVATOR (Prefix 8TJ) Service Repair Manual (8TJ00001 and Up)rpoy9396615No ratings yet

- C Molo TM003 eDocument8 pagesC Molo TM003 ejcclaNo ratings yet

- C107C1 - CAT TH580B Chain Shackles - Dist PDFDocument15 pagesC107C1 - CAT TH580B Chain Shackles - Dist PDFBart JohnNo ratings yet

- Ace3 0620.06 GB PDFDocument12 pagesAce3 0620.06 GB PDFduhgrandoNo ratings yet

- Tiras de Desgaste RielDocument6 pagesTiras de Desgaste RielCristobal Gutierrez CarrascoNo ratings yet

- Rs125 Race: De-Restrict An Aprilia Rs 125 2006 Euro 3Document9 pagesRs125 Race: De-Restrict An Aprilia Rs 125 2006 Euro 3Administrator100% (9)

- Caterpillar Cat 235 EXCAVATOR (Prefix 64R) Service Repair Manual (64R01258 and Up)Document25 pagesCaterpillar Cat 235 EXCAVATOR (Prefix 64R) Service Repair Manual (64R01258 and Up)rpoy9396615No ratings yet

- E Mopi TS005 eDocument8 pagesE Mopi TS005 emikestifflerNo ratings yet

- SEBF8229-спецификация головок 3176, С10,С12, 3196Document18 pagesSEBF8229-спецификация головок 3176, С10,С12, 3196Евгений АбрамовNo ratings yet

- Caterpillar Cat 235 EXCAVATOR (Prefix 62X) Service Repair Manual (62X00289 and Up)Document24 pagesCaterpillar Cat 235 EXCAVATOR (Prefix 62X) Service Repair Manual (62X00289 and Up)rpoy9396615No ratings yet

- Piaggio X9 500 Service Station Manual (2002-EnGLISH-70 Pages)Document69 pagesPiaggio X9 500 Service Station Manual (2002-EnGLISH-70 Pages)Alessandro MigliettaNo ratings yet

- 18SP635Document8 pages18SP635giovanni ampueroNo ratings yet

- S300Document4 pagesS300Inkanata SacNo ratings yet

- Transmision 02G StandarDocument141 pagesTransmision 02G Standargayt333100% (3)

- Piaggio X9 500 Service Station Manual (2002-EnGLISH-70 Pages)Document69 pagesPiaggio X9 500 Service Station Manual (2002-EnGLISH-70 Pages)Enis MurgicNo ratings yet

- Warning: Mudguards (Kit P/N 715 001 208)Document5 pagesWarning: Mudguards (Kit P/N 715 001 208)bapal1986No ratings yet

- Unit Injector - Install: Disassembly and AssemblyDocument5 pagesUnit Injector - Install: Disassembly and AssemblyJoze 23No ratings yet

- ZT 6000 VSDocument14 pagesZT 6000 VSdesign_artNo ratings yet

- Install Cylinder HeadDocument6 pagesInstall Cylinder Headrahmat sanusiNo ratings yet

- SUMITOMO R450LC-7 EXCAVATOR Service Repair Manual PDFDocument18 pagesSUMITOMO R450LC-7 EXCAVATOR Service Repair Manual PDFsekfsekmddde100% (4)

- Two Cycle Carburetor and the Back Alley MechanicFrom EverandTwo Cycle Carburetor and the Back Alley MechanicRating: 4.5 out of 5 stars4.5/5 (2)

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- VW Transporter T4 (Petrol and Diesel - 1990-1995) Workshop Manual: Owners Edition (Owners' Workshop Manuals)From EverandVW Transporter T4 (Petrol and Diesel - 1990-1995) Workshop Manual: Owners Edition (Owners' Workshop Manuals)No ratings yet

- VW Transporter T4 Workshop Manual Diesel 2000-2004From EverandVW Transporter T4 Workshop Manual Diesel 2000-2004Rating: 5 out of 5 stars5/5 (5)

- Beatriz Milhazes Interview: There Is Nothing Simple About What I'm Doing'Document2 pagesBeatriz Milhazes Interview: There Is Nothing Simple About What I'm Doing'C_RigbyNo ratings yet

- Bond Purchase Contract (Executed Copy)Document15 pagesBond Purchase Contract (Executed Copy)argo alfathNo ratings yet

- Emtech Lecture 1Document2 pagesEmtech Lecture 1Shayra VillacortaNo ratings yet

- 10th STD Science Lesson Plan LDocument31 pages10th STD Science Lesson Plan Lyotoheg662No ratings yet

- Valuation of SharesDocument10 pagesValuation of SharesAmira JNo ratings yet

- Arvind Medicare v. Neeru MehraDocument21 pagesArvind Medicare v. Neeru MehraSparsh GoelNo ratings yet

- Second Division G.R. No. 212860, March 14, 2018 Republic of The Philippines, Petitioner, V. Florie Grace M. Cote, Respondent. Decision REYES, JR., J.Document6 pagesSecond Division G.R. No. 212860, March 14, 2018 Republic of The Philippines, Petitioner, V. Florie Grace M. Cote, Respondent. Decision REYES, JR., J.cnfhdxNo ratings yet

- Employee Productivity and Organizational Performance Evidence From Pharmaceutical Firms in NigeriaDocument9 pagesEmployee Productivity and Organizational Performance Evidence From Pharmaceutical Firms in NigeriaEditor IJTSRDNo ratings yet

- Sample Script For GraduationDocument15 pagesSample Script For GraduationRowena Lalongisip De Leon100% (3)

- Medical AbbreDocument5 pagesMedical AbbreFloida Rose KatterNo ratings yet

- Limited Liability Companies Act Chapter 151 of The Revised Laws of Saint Vincent and The Grenadines, 2009Document63 pagesLimited Liability Companies Act Chapter 151 of The Revised Laws of Saint Vincent and The Grenadines, 2009Logan's LtdNo ratings yet

- IO FormativeDocument3 pagesIO Formativenb6tckkscvNo ratings yet

- Disaster Management Action Plan: Office of The CMO District-Champawat UttarakhandDocument13 pagesDisaster Management Action Plan: Office of The CMO District-Champawat Uttarakhandpurunjay joshiNo ratings yet

- Introduction of TECHNIP PDFDocument123 pagesIntroduction of TECHNIP PDFdigeca100% (1)

- Duty and Power To Address Corruption PDFDocument26 pagesDuty and Power To Address Corruption PDFLau Dreyfus ArbuluNo ratings yet

- Letter of IntentDocument1 pageLetter of IntentReigneth VillenaNo ratings yet

- IAC-2012 Abstract Submission GuidelinesDocument4 pagesIAC-2012 Abstract Submission GuidelinesAngel ChicchonNo ratings yet

- Inalcik Za OdrinDocument11 pagesInalcik Za OdrinIvan StojanovNo ratings yet

- Enlightened Despotism PPT For 2 Hour DelayDocument19 pagesEnlightened Despotism PPT For 2 Hour Delayapi-245769776No ratings yet

- Knowledge For You (Knowledge4u.org) Magazine Volume 1 Issue 1Document4 pagesKnowledge For You (Knowledge4u.org) Magazine Volume 1 Issue 1Brîndușa PetruțescuNo ratings yet

- National Accounts Transportation Logistics in Chicago IL Resume David BriggsDocument2 pagesNational Accounts Transportation Logistics in Chicago IL Resume David BriggsDavidBriggsNo ratings yet

- Lesson3 Thehumanasanembodiedspirit 180717110754Document24 pagesLesson3 Thehumanasanembodiedspirit 180717110754Noriel Del RosarioNo ratings yet

- Construction and WeightDocument79 pagesConstruction and Weightusman nawazNo ratings yet

- SuchikaDocument2 pagesSuchikaGauravNo ratings yet

- Qw-482 Welding Procedure SpecificationDocument2 pagesQw-482 Welding Procedure SpecificationAmanSharmaNo ratings yet

- On JioDocument10 pagesOn JioSimranNo ratings yet

- Macbeth Lesson PlanDocument2 pagesMacbeth Lesson Planrymahoney10No ratings yet

- Gynecology Part 1Document12 pagesGynecology Part 1Subramaniam Sundaram100% (3)

- Speech SynthesisDocument8 pagesSpeech Synthesispatelsam1111No ratings yet

- Glycemic Index MontignacDocument4 pagesGlycemic Index MontignacCristina HanuschiNo ratings yet