Professional Documents

Culture Documents

Observation: Modes P3 Sensor P3 Theoretical Output Led 1 Led2

Uploaded by

Vishnu SureshOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Observation: Modes P3 Sensor P3 Theoretical Output Led 1 Led2

Uploaded by

Vishnu SureshCopyright:

Available Formats

Observation

1. System sweeps through the code every 20ms.Thus various sensor values are acquisitted

and checked for accuracy every 20ms thereby satisfying the demand for high precision

and instant error detection and correction.

2. Following table gives an description of how different modes are handled by the system.

Modes

P3 sensor

Output

LED 1

LED2

No error

P3

theoretical

No error

P3 sensor

No output

No output

No error

Error

P3 sensor

No output

Blink

Error

No error

Blink

No output

Error

Error

P3

Theoretical

Next lane

Blink

Blink

When both P3 sensor value and P3 theoretical value are in error, control is shifted to the

next lane.

3. (About power on self-test).

(See if this is required)

Brief explanation of our project:

As already said, our model is an observer based design with a predictive unit developed on an

empirical model.

Our system performances consists of

acquisition of data (Data being turbine pressure, NLR(speed),inlet pressure(taken as

constant at atmospheric pressure)

Conversion of data (Conversion to voltage in the range of 0-3.3v etc)

Fault detection

Isolation

Error correction using interpolation

Interrupt service routine

1. Acquisition of data:

For our project we need the values of turbine pressure and airplane speed measured in

NLR. We input that data to DECU which is LPC2148 ARM microcontroller. We also need

the value of inlet pressure. However, we conveniently assume it as constant as

atmospheric pressure value. We need these values at every sample period(i.e. every

20ms)

2. Conversion of data:

To input turbine pressure and NLR to our DECU we need to represent them in the form

of voltage in the range of 0 to 3.3V.

3. Fault Detection:

When there is an error in the input parameters i.e. Turbine pressure or NLR .our model

immediately detects the fault

4. Fault Isolation:

Fault isolation is the practice of designing systems such that when there is fault, the

negative consequences are limited in scope. Limiting the scope of problems reduces the

potential for damage and makes systems easier to maintain.

We acquire P3 and NLR values every 20 ms and when there is a fault it is detected

immediately. These make Fault isolation possible

5. Fault correction:

Based on the the datasheet which gives the relation between P3/P1 ratio and NLR,

Weve developed an interpolated expression for P3 which acts as predictive model. So

whenever a fault is detected, P3 can thus be indirectly measured.

6. Interrupt service routine:

Our controller is lpc2148 ARM, We have developed an interrupt service routine which

sweeps through the instruction set every 20ms checking for P3,inspecting possible

errors etc. It also performs power on self-check, ADC self-check etc.

You might also like

- Applications of 8051 Microcontrollers Temperature Measurement and ControllingDocument5 pagesApplications of 8051 Microcontrollers Temperature Measurement and ControllingsachinshymNo ratings yet

- Mechatronics NotesDocument131 pagesMechatronics NotesNagarajNo ratings yet

- RPM IndicatorDocument39 pagesRPM IndicatorAnkur PatelNo ratings yet

- Effective Multi-Tap Transformer Measurement Using A Scanner and The 4263B LCR MeterDocument9 pagesEffective Multi-Tap Transformer Measurement Using A Scanner and The 4263B LCR MetertomichelNo ratings yet

- Mechatronics:: Unit I Mechatronics, Sensors and ActuatorsDocument31 pagesMechatronics:: Unit I Mechatronics, Sensors and ActuatorsChandra HasanNo ratings yet

- Total Circuit Internal Working ExplanationDocument11 pagesTotal Circuit Internal Working ExplanationRajkumar NmlNo ratings yet

- Barometric Pressure Measurement Using Semiconductor Pressure SensorsDocument12 pagesBarometric Pressure Measurement Using Semiconductor Pressure Sensorssoldadorx01No ratings yet

- Barometer Mpx2100apDocument10 pagesBarometer Mpx2100apVurdalack666No ratings yet

- How Can I Make Loop Check For Pressure Transmitter and Temperature TransmitterDocument11 pagesHow Can I Make Loop Check For Pressure Transmitter and Temperature Transmittersushant_jhawer100% (1)

- IV Drip Rate Monitoring DeviceDocument5 pagesIV Drip Rate Monitoring DeviceLevi MoreiraNo ratings yet

- AP PTC 2012 19 Teratam EnuDocument7 pagesAP PTC 2012 19 Teratam EnubcqbaoNo ratings yet

- Chapter 2 Discrete Data Control SystemsDocument78 pagesChapter 2 Discrete Data Control SystemsAmruth ThelkarNo ratings yet

- Introduction to Digital Control SystemsDocument70 pagesIntroduction to Digital Control SystemsAmruth Thelkar67% (3)

- Iot Based Transformer Monitoring System.Document82 pagesIot Based Transformer Monitoring System.ra patNo ratings yet

- Es1107 Assignment-01Document6 pagesEs1107 Assignment-01K. BHANU PRAKASH REDDYNo ratings yet

- Chap1 Indus ElectronicsDocument47 pagesChap1 Indus ElectronicsSantosh Kumar BejugamNo ratings yet

- InstrumentationDocument8 pagesInstrumentationtingpaduNo ratings yet

- Nov 2011 Atul1Document10 pagesNov 2011 Atul1Rajeev RawatNo ratings yet

- PLC Ladder Logic for Restaurant Paging SystemDocument24 pagesPLC Ladder Logic for Restaurant Paging SystemM Hamza NadeemNo ratings yet

- PalmSens3: Portable Potentiostat/Galvanostat/EIS AnalyzerDocument10 pagesPalmSens3: Portable Potentiostat/Galvanostat/EIS AnalyzerAlejandro PereiraNo ratings yet

- Temperature Measurement CircuitsDocument22 pagesTemperature Measurement Circuitsestraj1954No ratings yet

- Report of W.T.F.D.Document59 pagesReport of W.T.F.D.Ashokupadhye1955No ratings yet

- Effective Multi-Tap TransformerDocument8 pagesEffective Multi-Tap Transformer15101980No ratings yet

- CISE 312 Instrumentation Engineering Lab ManualDocument89 pagesCISE 312 Instrumentation Engineering Lab ManualPandimadevi SelvakumarNo ratings yet

- EAS AM Software Users ManualDocument14 pagesEAS AM Software Users ManualKHAIRIL ASNURNo ratings yet

- Design and Implementation of an Electric Fan with Heat and Motion SensorsDocument10 pagesDesign and Implementation of an Electric Fan with Heat and Motion SensorsEfryl LapinaNo ratings yet

- InnoCare T Service ManualDocument19 pagesInnoCare T Service ManualTony NavaNo ratings yet

- 02 - Tester Hardware PDFDocument20 pages02 - Tester Hardware PDFdeepakNo ratings yet

- Interview Questions InstrumentDocument53 pagesInterview Questions InstrumentQamar Hassan IqbalNo ratings yet

- Using Digital Potentiometers in Adjustable Step-Down DC-DC Converter DesignsDocument9 pagesUsing Digital Potentiometers in Adjustable Step-Down DC-DC Converter Designsmelwyn_thomasNo ratings yet

- Interfacing of Temperature Sensor LM 35Document9 pagesInterfacing of Temperature Sensor LM 35shubham309No ratings yet

- XBEE Based Transformer Protection and Oil TestingDocument3 pagesXBEE Based Transformer Protection and Oil TestingijsretNo ratings yet

- What Is DebouncingDocument7 pagesWhat Is DebouncingDimuthu Nuwan AbeysingheNo ratings yet

- Working Principle: 1) System CheckDocument8 pagesWorking Principle: 1) System CheckHans IngoleNo ratings yet

- Ab 02601460148Document3 pagesAb 02601460148International Journal of computational Engineering research (IJCER)No ratings yet

- Engine Status Monitoring System Using Real Time Clock (ds1307)Document4 pagesEngine Status Monitoring System Using Real Time Clock (ds1307)International Journal of computational Engineering research (IJCER)No ratings yet

- A Review On Various Transformer Testing SystemsDocument4 pagesA Review On Various Transformer Testing Systemsijsret100% (1)

- N30O Digital Panel Meter User ManualDocument61 pagesN30O Digital Panel Meter User ManualAlphaNo ratings yet

- Servo MotorDocument6 pagesServo Motorimtiaz eemelNo ratings yet

- DC Motor Speed ControlDocument5 pagesDC Motor Speed ControlAnita WulansariNo ratings yet

- UNIT5 2 MarksDocument7 pagesUNIT5 2 MarksJeeva JeevaNo ratings yet

- GSM Based Distribution Transformer Monitoring and Controlling System Ijariie1748Document3 pagesGSM Based Distribution Transformer Monitoring and Controlling System Ijariie1748Velu SamyNo ratings yet

- Control SystemsDocument9 pagesControl Systemsabednigo titusNo ratings yet

- Sensor interfacing techniquesDocument16 pagesSensor interfacing techniquesRaja VenkateshNo ratings yet

- Low Cost PC Based Real Time Data Logging System Using Pcs Parallel Port For Slowly Varying SignalsDocument7 pagesLow Cost PC Based Real Time Data Logging System Using Pcs Parallel Port For Slowly Varying SignalsSindhu VelayudhamNo ratings yet

- SET UP LOOKOUT, ZETRON M1700 AND M1716Document7 pagesSET UP LOOKOUT, ZETRON M1700 AND M1716Watón PabloNo ratings yet

- Microcontroller Based 3-Phase Motor Monitoring and Protection SystemDocument12 pagesMicrocontroller Based 3-Phase Motor Monitoring and Protection SystemSagar JamkarNo ratings yet

- Chapter Electric Fuel Injection SystemDocument92 pagesChapter Electric Fuel Injection Systemcamionetanissanz20No ratings yet

- Ballast Design Software - Ballast Soft PC Im 02Document6 pagesBallast Design Software - Ballast Soft PC Im 02controllineNo ratings yet

- Real - Time Envirnorment Monitoring System and Data Logger Using Arm ProcessorDocument5 pagesReal - Time Envirnorment Monitoring System and Data Logger Using Arm ProcessorInternational Journal of computational Engineering research (IJCER)No ratings yet

- Low Power 1.8V 0.18μm CMOS SAR ADCDocument5 pagesLow Power 1.8V 0.18μm CMOS SAR ADCMiguel BrunoNo ratings yet

- Chapter Two (Instrumentation)Document26 pagesChapter Two (Instrumentation)tsehay girmaNo ratings yet

- Distribution Transformer Monitoring Using GPRSDocument6 pagesDistribution Transformer Monitoring Using GPRSElse Feba PaulNo ratings yet

- MAR 144MB Instruction Manual GuideDocument42 pagesMAR 144MB Instruction Manual GuideRonald Acu CNo ratings yet

- Circuit Breaker AnalyzerDocument10 pagesCircuit Breaker AnalyzerarifNo ratings yet

- A Microcontroller Based Portable Dose Rate Meter Using GM CounterDocument11 pagesA Microcontroller Based Portable Dose Rate Meter Using GM CounterSaibNo ratings yet

- Unit 5Document38 pagesUnit 5rohanrec92No ratings yet

- Medidor de Energía ND20Document72 pagesMedidor de Energía ND20Wilson Irigoin fernandezNo ratings yet

- Arduino Measurements in Science: Advanced Techniques and Data ProjectsFrom EverandArduino Measurements in Science: Advanced Techniques and Data ProjectsNo ratings yet

- CRM On AirtelDocument142 pagesCRM On AirtelVishnu SureshNo ratings yet

- CRM PDFDocument225 pagesCRM PDFVishnu SureshNo ratings yet

- Financial ManagementDocument419 pagesFinancial ManagementVishnu SureshNo ratings yet

- Short Descriptions On The 18 Parvas PDFDocument6 pagesShort Descriptions On The 18 Parvas PDFSri Gowtham100% (1)

- Question Bank of Business Communications - 1markDocument33 pagesQuestion Bank of Business Communications - 1marklakkuMS83% (6)

- IRI-22207-Chennai - Trivandrum SUPER AC ExpressDocument1 pageIRI-22207-Chennai - Trivandrum SUPER AC ExpressVishnu SureshNo ratings yet

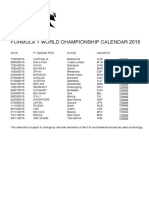

- Formula 1 Calendar 2015 - ENGDocument1 pageFormula 1 Calendar 2015 - ENGVishnu SureshNo ratings yet

- PMIRDocument124 pagesPMIRhashvishuNo ratings yet

- Observation: Modes P3 Sensor P3 Theoretical Output Led 1 Led2Document4 pagesObservation: Modes P3 Sensor P3 Theoretical Output Led 1 Led2Vishnu SureshNo ratings yet

- Son of SatyamurthyDocument1 pageSon of SatyamurthyVishnu SureshNo ratings yet

- SCDL Business Communication Solved AssignmentDocument7 pagesSCDL Business Communication Solved Assignmentrakesh prabhakarNo ratings yet

- Padmarajan MoviesDocument1 pagePadmarajan MoviesVishnu Suresh100% (1)

- App ListDocument2 pagesApp ListVishnu SureshNo ratings yet

- WebsitesDocument4 pagesWebsitesVishnu SureshNo ratings yet

- Anti Ragging AffidavitDocument4 pagesAnti Ragging AffidavitVishnu SureshNo ratings yet

- App ListDocument2 pagesApp ListVishnu SureshNo ratings yet

- App ListDocument2 pagesApp ListVishnu SureshNo ratings yet

- AuthorDocument3 pagesAuthorVishnu SureshNo ratings yet

- Padmarajan MoviesDocument1 pagePadmarajan MoviesVishnu Suresh100% (1)

- Padmarajan MoviesDocument1 pagePadmarajan MoviesVishnu Suresh100% (1)

- Mechanical Vapor RecompressionDocument9 pagesMechanical Vapor Recompressionnarayana reddy0% (1)

- FlowTradersSOP PDFDocument1 pageFlowTradersSOP PDFAvinash IyerNo ratings yet

- Miners RuleDocument2 pagesMiners Ruleபிரபாகரன் ஆறுமுகம்No ratings yet

- NFA To DFA Conversion: Rabin and Scott (1959)Document14 pagesNFA To DFA Conversion: Rabin and Scott (1959)Rahul SinghNo ratings yet

- Design TheoryDocument2 pagesDesign Theoryhamidreza mohseniNo ratings yet

- BF 00571142Document1 pageBF 00571142Tymoteusz DziedzicNo ratings yet

- ACL-PDC-01 - Rev01 (Procurement Document Control)Document3 pagesACL-PDC-01 - Rev01 (Procurement Document Control)Mo ZeroNo ratings yet

- Independent University, Bangladesh: Term Paper (Group Assignment)Document16 pagesIndependent University, Bangladesh: Term Paper (Group Assignment)Johan Tausifur RahmanNo ratings yet

- KV Sainik Vihar Class 6 Science Holidays HomeworkDocument7 pagesKV Sainik Vihar Class 6 Science Holidays HomeworkABYAN ShaikNo ratings yet

- Reliance - Formulas & Calculations PDFDocument5 pagesReliance - Formulas & Calculations PDFkrishbistNo ratings yet

- Chapter 3Document12 pagesChapter 3Raymond LeoNo ratings yet

- Textbook List for Sri Kanchi Mahaswami Vidya Mandir 2020-21Document13 pagesTextbook List for Sri Kanchi Mahaswami Vidya Mandir 2020-21drsubramanianNo ratings yet

- Calicut University: B. A PhilosophyDocument6 pagesCalicut University: B. A PhilosophyEjaz KazmiNo ratings yet

- Barco High Performance MonitorsDocument34 pagesBarco High Performance Monitorskishore13No ratings yet

- Zelenbabini Darovi Ivana N Esic - CompressDocument167 pagesZelenbabini Darovi Ivana N Esic - CompressСања Р.0% (1)

- Doping Effects of Zinc On LiFePO4 Cathode MaterialDocument5 pagesDoping Effects of Zinc On LiFePO4 Cathode MaterialMarco Miranda RodríguezNo ratings yet

- Aadhaar is proof of identity, not citizenshipDocument1 pageAadhaar is proof of identity, not citizenshipPARTAPNo ratings yet

- Quiz 2 ReviewDocument17 pagesQuiz 2 ReviewabubakkarNo ratings yet

- LG - Week 1 - Operations - ManagementDocument4 pagesLG - Week 1 - Operations - ManagementMechaella Shella Ningal ApolinarioNo ratings yet

- ETEEAP Application SummaryDocument9 pagesETEEAP Application SummaryAlfred Ronuel AquinoNo ratings yet

- Jack of All Trades ArchetypeDocument2 pagesJack of All Trades ArchetypeGwazi MagnumNo ratings yet

- Big Data Analytics and Artificial Intelligence inDocument10 pagesBig Data Analytics and Artificial Intelligence inMbaye Babacar MBODJNo ratings yet

- (Acta Universitatis Gothoburgensis) Tryggve Göransson - Albinus, Alcinous, Arius Didymus (1995) PDFDocument128 pages(Acta Universitatis Gothoburgensis) Tryggve Göransson - Albinus, Alcinous, Arius Didymus (1995) PDFMarcos EstevamNo ratings yet

- PDF Manual de Reparaciones Estructurales Del Airbus A 320 CompressDocument15 pagesPDF Manual de Reparaciones Estructurales Del Airbus A 320 CompressJosé LuisNo ratings yet

- Ichiban Ushiro No Daimaou Act 7Document161 pagesIchiban Ushiro No Daimaou Act 7Haif Al HajrafNo ratings yet

- Sheet Metalworking 1 - Chapter 19Document99 pagesSheet Metalworking 1 - Chapter 19xharpreetxNo ratings yet

- ACP160DDocument14 pagesACP160Dinbox934No ratings yet

- A. Soriano Corporation 2009 Annual Stockholders Meeting Notice and AgendaDocument47 pagesA. Soriano Corporation 2009 Annual Stockholders Meeting Notice and AgendaGabriel uyNo ratings yet

- Secondary SourcesDocument4 pagesSecondary SourcesKevin NgoNo ratings yet

- Discrete Math Assignment on Recurrence Relations, Graph Theory and Boolean AlgebraDocument6 pagesDiscrete Math Assignment on Recurrence Relations, Graph Theory and Boolean AlgebralakkajaoNo ratings yet