Professional Documents

Culture Documents

Alice Alweny

Uploaded by

Iga_DanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Alice Alweny

Uploaded by

Iga_DanCopyright:

Available Formats

X

General Notes

14.800

w2pvo

Dining room

D3 PVO

2.986

OUT

300 min.

150

Length, L

FALL 1:40

650

125 mm Thick Conc. Base (1:3:6 Mix) where

Depth to invert level is not more than 1500

200mm Thick where depth to invert level

exceeds 1500mm.

150 min.

230mm Block work

Solid Conc. Brickwork wall

Rendered both sides with

(1:3 mix)Cement Plaster

R

1.100

1.500

1.100

D1 PVO

NOTE: Inlet and Outlet pipe diameters to

Septic Tank to be equal.

600 x 450mm cast iron covers complete with frames

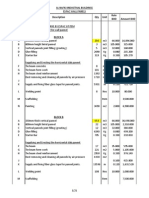

SIZES AND CAPACITY OF SEPTIC TANK AND SOAK PIT

NO. NO. of

users

2.400 0.200

2.400 0.200

0.200

0.200

230X690XL concrete strip foundations (mix1:3:6) to receive 230mm thick plinth walls.

Foundation depth to be determined on site and to be not less than 750mm.

5.400

100mm thick R.C cover slab.

SECTION THRU X - X (Scale 1:100)

SEPTIC TANK

P

1

2

3

4

5

6

7

8

9

10

11

12

13

14

NB

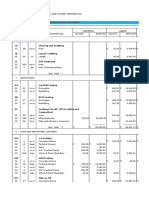

FOOTINGS;

9.400

230 150

Hardcore

25mm cement sand screed (mix 1:3) on 150mm thick over site

concrete (mix 1:3:6) on well compacted and blinded 200mm

thick hardcore on well rammed murram base.

1.500

Verandah

1.250

CONC. FOUNDATION BASE (1:3:6 MIX)/20mm AGG.

TO BE OF THICKNESS SPECIFIED. (150 Min.)

Longitudinal Section of Septic Tank

FLOOR SLAB;

w2pvo

1.500

150 230

FOUNDATION CONSTRUCTION ;

0.200

1.200

w2pvo

SECTION C-C

IN

230 150

650

GL Support bracket

armstarre & sanded & built

into 230 Block work

50mm Precast Conc. slab

Solid Conc, Blockwork Rendered

Both internally and Externally with

Cement plaster (1:4 Mix)

150

Precast R.C Inlet Baffle

To Soak Pit

Cover Slab to protect 100mm min. above

ADOPT

SLOPE

INLETof

DRAIN

gorund

level

toOF

ingress

storm water.

5000 min

0.386

WALLING IN ACCORDANCE WITH

TABLE II ABOVE

Render (1:4 mix)

Cement Plaster

5.000

0.200

150 150

M.H 4

150

WORKING LEVEL

1:3 Cem. Mortar Render

Steel Floated

cer. flr.tiles

3.200

M.H 3

IN

Conc. Foundation

Mix 1:3:6

1.500

M.H 2

100mm dia half round channel

Vent filled with non return valve

If required by Local Government

(600 x 600 )mm Cast Iron

Covers (56 lb wt)

Determined by slope of ground and fall

and length of drain

Breath, B

Master

Bedroom

1.950

(600 x 600 )mm Cast Iron

Covers (56 lb wt)

150

4.000

Sitting room

cer. flr.tiles

Plan Under Concrete Slab Cover

950 min.

4.000

Bedroom

w2pvo

230

230mm Block work

SECTION C-C

M.H 1

2.400 0.200

D2 PVO

ELEVATION O1

12.000

w3pvo

5.000

D2 PVO

SIDE

0.200

100 mm Half Round

Channel

WALLING IN ACCORDANCE

WITH TABLE II ABOVE

5.700

5.000

OUTLET CHAMBER

Cast Iron Cover

0.200

0.200

1.500

0.500

6.000

SECTION D-D

INLET CHAMBER

0.600

D3 PVO

0.200

10.300

ELEVATION O2

SIDE

2.800

1.000

D2 PVO

150

D2 PVO

wc/sho

100 mm Half Round

Channel

Conc. Foundation

Mix 1:3:6

D2 PVO

100 mm dia. Cast Iron

outlet Pipes

Semi-Circular Channel

cer. flr.tiles

3.000

100 mm dia. Cast Iron

Inlet Pipes

75

D3 PVO

Bedroom

Conc. 1:3:6

A

To Soak Pit

1:3 Cem. Mortar Render

Steel Floated

cer. flr.tiles

100 mm Salt Glazed

Stone Pipe

150

cer. flr.tiles

150mm Block work

VENT

Breath, B

150 min.

4.000

Kitchen

D

100 mm Salt Glazed

Stone Pipe

1/2 U min.

w1pvo

26.deg.roof pitch. Echo-tile roofing sheets on 100x50mm purlins on 150x50mm rafters with

100x50mm struts and ties on 150x50mm tie beam resting on 100x75mm wall plates.

250x25mm fascia $ berge boards.

CEILING;

Metal lathe plastered ceiling fixed onto 100x50mm ceiling joists and 50x50mm branderings

230

wc/sho

150

w3pvo

wc/sho

1.450

1. All dimensions are in mm unless stated otherwise.

2. All work is to be carried out in accordance with

council regulations.

3. All figured dimensions to be taken in preference

to scaled dimensions

4. All walls bellow 200 mm to be reinforced with

hoop iron at every alternative course.

5. Provide damp proof course (DPC) under all walls.

6. P.V. indicates permanent ventilation

7. All drainage passing under building and drive

area to be of pvc pipe and encased in concrete.

Cast Iron Cover

Cast Iron Cover

600

w3pvo

1.500

ROOF SPECIFICATIONS

150

w2pvo

D2 PVO

0.200

Length, L

1.783

4.000

0.200

1.500

0.200

1.517

0.200

0.200

1.300

1.300

3.000

0.200

0.500 1.000 0.5000.700 0.900 0.407 1.200

1.844

0.200

4.000

4.200

SEPTIC TANK TOP PLAN

GROUND FLOOR (Residential House)

Scale 1:100

SOAKPIT

T

CAPACITY

(L)

DIAMETER EFF. DEPTH

350

900

6

350

450

1200

600

1000

1500

3000

495

15

500

655

2400

1200 1250

1200

1830

3500

495

30

500

655

3400

1700 1250

1700

1830

3510

45

495

500

655

4760

2080 1250

2080

2500

3860

60

495

600

655

4800

2400 1250

2400

3000

4280

75

575

600

825

4950

2450 1500

2450

3000

5400

90

575

600

825

5300

3000

2700 1500

2700

6480

100

575

600

825

5600

2800 1600

2800

3500

6480

745

2000 3470

200

600

1155

6940

3470

5000

8570

745

300

800

1155

8460

4230

2000 4230

6000

10700

745

400

800

1155

9800

4900

2000 4900

7500

11400

745

500

800

1155

10940 5470

2000 5470

7500

11900

600

745

800

1155

12000 6000

2000 6000

7500

12200

700

745

800

1155

12940 6470

2000 6470

7500

13000

ASSUMED 45.46 LITRES/ PERSON 24hrs and ABSORTION RATE OF AVERAGE SOIL 22.73

RUN PERCOLATION TRENCH LENGTHS SUBJECT TO SITE SOIL CONDTION.

SOAK PIT SECTION

8. All inspection chambers in drive area to have

heavy duty covers.

9. Check all dimensions on site.

10. All sanitary work to be in accordance with MOH

rules and regulations.

11. 500 gauge polythene sheeting and anti-termite

treatment to be provided under the ground floor

concrete slab.

12. All reinforced work is to be in accordance with

the structural engineers details.

13. The trench should be inspected and approved

by the structural engineer before laying the

concrete strip slab.

2700

5400

10800

16200

27000

27000

32400

35000

72000

10800

144000

18000

218000

252000

\300MM

SEPTIC TANK DETAILS not to scale

SIDE ELEVATION 01

FRONT ELEVATION

1.200

1500

900

1.500

500

W3-pvo

LABEL (MARK)

W1-pvo

OVERALL SIZE (mm) 500mm x 900mm high

Standard Aluminium

Casement,Glass panelled

Window

DESCRIPTION

NO. REQUIRED

W2-pvo

1500mm x 1500mm high

1500mm

1500mm

SILL HEIGHT (mm)

1.500

WINDOW TYPE

WINDOW SCHEDULE

1500mm x 2000mm high

1500mm

Standard Aluminium

Casement,Glass panelled

High level Window

Standard Aluminium

Casement,Glass panelled

High level Window

01

05

03

No.

PROJECT

PROPOSED RESIDENTIAL

HOUSE ON PLOT

NO._

BLOCK NO._ TO BE

BUILT IN LUMULI, SEETA,

WAKISO DISTRICT

1500mm x 2400mm high

Standard Aluminium

Casement,Steel panelled,

Glass door

with steel-door lock

900mm x 2100mm high

Framed timber flush door

800mm x 2100mm high

Framed timber flush door

pedestrian

exit/entrance

precast concrete

coping

cer. flr.tiles

40x40 mm ms section

Sitting room

735

50x50mm ms

50x50 mm ms

40x40mm ms

section

300

precast concrete

coping

2,700

Bedroom

precast concrete

coping

precast concrete

coping

dpc

Master

Bedroom

1,600

dpc

planters

Boundary Wall Elevation

scale 1:50

ground level

0.230

0.150

ground level

dpc 150 from

ground level

ground level

ground level

3.000

0.300

0.230

Verandah

0.230

0.690

Section p-p (scale 1:20)

Boundary Wall Floor plan

(Scale 1:25)

FLOOR PLAN

X

0.230

0.230

230

3.000

0.270

150

cer. flr.tiles

0.230

0.300

dpc 150 from

ground level

HIP ROOF LAYOUT

690

Section P-P

(Scale 1:25)

2.100

Drawing Title

ARCHITECTURAL DRAWINGS

Scale

NO. REQUIRED

3.600

Project Consultants

DESCRIPTION

FRONT ELEVATION (GATE)

(scale:- 1:50)

LABEL (MARK)

3.600

SIDE

MH 1

0.900

DOOR TYPE

ELEVATION O1

cer. flr.tiles

2.100

0.8

2,400

Bedroom

DOOR SCHEDULE

cer. flr.tiles

190

cer. flr.tiles

Dining room

2.400

Kitchen

0.9

wc/sho

170

wc/sho

wc/sho

SOAK

WAY PIT

SIDE

ELEVATION O2

SEPTIC TANK

MH 2

06

MH 4

OVERALL SIZE (mm)

MH 3

CLIENT

MRS. ALICE ALWENY

03

2,400

01

D1-pv

D2

1,500

D3

BACK ELEVATION

SIDE ELEVATION 02

Revisions

1:100,

Date.

Drawn by.

Raymond. O

Checked by.

TPJ

Sheet

Number

1/1

You might also like

- House Plan 1Document1 pageHouse Plan 1Daniel Taiti KimathiNo ratings yet

- Bill of QuantitiesDocument20 pagesBill of QuantitiesArnold Tunduli86% (7)

- New Zealand Soakage Design Manual - Auckland CityDocument11 pagesNew Zealand Soakage Design Manual - Auckland CityFree Rain Garden ManualsNo ratings yet

- Plumbing External BoqDocument9 pagesPlumbing External BoqBajibabu Prodduturi50% (2)

- Annex V-Bill of Quantities (BoQ)Document18 pagesAnnex V-Bill of Quantities (BoQ)SCReddy100% (1)

- Water Tower BQDocument1 pageWater Tower BQIsaac Mureithi MainaNo ratings yet

- Canopy Area Boq.Document6 pagesCanopy Area Boq.SAIDI NYAHEGONo ratings yet

- BQ Ibs GroupDocument14 pagesBQ Ibs GroupSäbrinä ShukrìNo ratings yet

- Sample BQ For TNBDocument30 pagesSample BQ For TNBKar Keh Kelly67% (6)

- Al Shams BOQ For ValuationDocument191 pagesAl Shams BOQ For ValuationcostemaraNo ratings yet

- Revised BQDocument5 pagesRevised BQIsaac Mureithi MainaNo ratings yet

- Animal Feed EFFORTDocument16 pagesAnimal Feed EFFORTHaftamu Tekle100% (1)

- Cico Office: Qatar Decoration Offices & ShowroomsDocument13 pagesCico Office: Qatar Decoration Offices & ShowroomsJhay ManeclangNo ratings yet

- BOQ Lotus Hotel Final 080709Document26 pagesBOQ Lotus Hotel Final 080709Jane NixonNo ratings yet

- BOQ Office and ResidentialDocument864 pagesBOQ Office and ResidentialmustafeNo ratings yet

- Yes Ra Bill - Iv 23-6-13Document3 pagesYes Ra Bill - Iv 23-6-13renuvenkat007No ratings yet

- Green House (Final) Est & MT For 4 Part Bills 1.60-Cumbum - With FinaDocument181 pagesGreen House (Final) Est & MT For 4 Part Bills 1.60-Cumbum - With FinarkpragadeeshNo ratings yet

- La Royal SupplyDocument7 pagesLa Royal SupplyDEVSHILPI ARCHITECTSNo ratings yet

- One Storey Residential - Cost EstimateDocument18 pagesOne Storey Residential - Cost EstimatePapsi Pap100% (1)

- Amount BHD SL No Description Qty Unit Rate BHDDocument21 pagesAmount BHD SL No Description Qty Unit Rate BHDmunnummaNo ratings yet

- Bill of Quantities: Proposed 3 Unit House at No. 40, St. Mary'S Lane, Colombo - 15Document26 pagesBill of Quantities: Proposed 3 Unit House at No. 40, St. Mary'S Lane, Colombo - 15Dushyantha JayawardenaNo ratings yet

- Annex A Financial Offer Form BOQ Renovation To Theatre and Maternity Wards Rwamwanja HC III ForDocument2 pagesAnnex A Financial Offer Form BOQ Renovation To Theatre and Maternity Wards Rwamwanja HC III ForEMINAT PRINCENo ratings yet

- Labour Rate RecommendedDocument106 pagesLabour Rate RecommendedDhiyanesh Waran78% (18)

- Karen 2 - Road Works Phase TwoDocument7 pagesKaren 2 - Road Works Phase TwopeterNo ratings yet

- Bill No. 4 - Cluster A, C & EDocument183 pagesBill No. 4 - Cluster A, C & EmimrusfanNo ratings yet

- Atdp Es 000212Document35 pagesAtdp Es 000212peetholNo ratings yet

- Bill of Engineering Measurements Item Description Unit Quantity Rate (N) Amount (N) Bill 1: Excavation and Earth WorkDocument7 pagesBill of Engineering Measurements Item Description Unit Quantity Rate (N) Amount (N) Bill 1: Excavation and Earth Workaaismail100% (1)

- BoqDocument55 pagesBoqKrm ChariNo ratings yet

- Architecture PlanDocument12 pagesArchitecture PlanVail Lunor100% (1)

- Bill of Quantities (Example)Document18 pagesBill of Quantities (Example)Chan Siew ChongNo ratings yet

- BQ of The Hotel Project To Study (Mandalay Hill)Document68 pagesBQ of The Hotel Project To Study (Mandalay Hill)PhyoHeinNo ratings yet

- La Royal LaborDocument7 pagesLa Royal LaborDEVSHILPI ARCHITECTSNo ratings yet

- Estimate For Providing, Lowering, Laying and Jointing of 110mm, 200mm and 250 MM Dia - Di Pipeline of SawriR.R.wss-1 From WTP To ChimurDocument6 pagesEstimate For Providing, Lowering, Laying and Jointing of 110mm, 200mm and 250 MM Dia - Di Pipeline of SawriR.R.wss-1 From WTP To Chimurmilind lohitNo ratings yet

- Toilet Details R1 A2Document1 pageToilet Details R1 A2Irshad KhanNo ratings yet

- Tanks BOQ FinalDocument19 pagesTanks BOQ Finalmustafe0% (1)

- Chummary Quarters at KilinochchiDocument44 pagesChummary Quarters at KilinochchiMohamed Faiz Issma LebbeNo ratings yet

- Final CIDCO Schedule (10-11)Document187 pagesFinal CIDCO Schedule (10-11)deepakhartalkarNo ratings yet

- Park Lane 21-2-2014 (JB) (2014 - 03 - 21 05 - 45 - 57 UTC)Document30 pagesPark Lane 21-2-2014 (JB) (2014 - 03 - 21 05 - 45 - 57 UTC)Thomas JohnsonNo ratings yet

- GAte House BoQDocument9 pagesGAte House BoQoseni momoduNo ratings yet

- Mitra InstituteDocument8 pagesMitra InstituteVMBUILDERS MANJERINo ratings yet

- 457Document117 pages457Rajesh ChowhanNo ratings yet

- DSR 2012 SupplementDocument2 pagesDSR 2012 SupplementDeeksha Bahl DiwanNo ratings yet

- Element - 111 - 579-Bill of Quantity For Constructing Main House of MosqueDocument8 pagesElement - 111 - 579-Bill of Quantity For Constructing Main House of MosqueKapros Junior AphrodiceNo ratings yet

- Spec - ACODocument5 pagesSpec - ACOReza MohebbiNo ratings yet

- Babrchara BazarDocument11 pagesBabrchara BazarEngr SwapanNo ratings yet

- iwCmY6WPaXBR - BOQ RABAI 220KV FINALDocument11 pagesiwCmY6WPaXBR - BOQ RABAI 220KV FINALkajale.shrikantNo ratings yet

- 110 - Process Plant Bill of QuantitiesDocument76 pages110 - Process Plant Bill of Quantitieskresimir.mikoc9765100% (1)

- Brickwork BQ For External WorksDocument9 pagesBrickwork BQ For External WorksKhairul HazwanNo ratings yet

- Element - 111 - 128-Petrol Station BOQDocument6 pagesElement - 111 - 128-Petrol Station BOQMrweNo ratings yet

- Estimate of SBTWDocument17 pagesEstimate of SBTWSaral MajumderNo ratings yet

- Ndma-Project-Kubi Qalo-PricedDocument7 pagesNdma-Project-Kubi Qalo-PricedpartoneinvestmentNo ratings yet

- Bill of Quantities OlvrDocument8 pagesBill of Quantities OlvrOliver Otieno100% (1)

- Water Tank To Column Detail: Advanced Diploma of Building Design Footing Layout Student Accommodation S01Document7 pagesWater Tank To Column Detail: Advanced Diploma of Building Design Footing Layout Student Accommodation S01hmaisano1100% (1)

- QUOTATION Mabelah HealhtDocument6 pagesQUOTATION Mabelah HealhtDelwar Hossain100% (1)

- Surface Water DrainageDocument5 pagesSurface Water DrainageNazirah NazeriNo ratings yet

- Elemental Bill of Quantities For 3 Bedroom Apartment BlockDocument29 pagesElemental Bill of Quantities For 3 Bedroom Apartment BlockAliyu Shehu83% (71)

- Advances in Solid Oxide Fuel Cells XFrom EverandAdvances in Solid Oxide Fuel Cells XMihails KusnezoffNo ratings yet

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- Reference FormDocument1 pageReference FormIga_DanNo ratings yet

- CV - DR Andrew Balyeku - June 2018 BDocument4 pagesCV - DR Andrew Balyeku - June 2018 BIga_DanNo ratings yet

- Joseph Orikoi WangooloDocument5 pagesJoseph Orikoi WangooloIga_DanNo ratings yet

- Road Maintenance Schedule For The Month of JulyDocument9 pagesRoad Maintenance Schedule For The Month of JulyIga_DanNo ratings yet

- CV - DR Andrew Balyeku - June 2018 BDocument4 pagesCV - DR Andrew Balyeku - June 2018 BIga_DanNo ratings yet

- CV Joselyn BigirwaDocument4 pagesCV Joselyn BigirwaIga_DanNo ratings yet

- Joseph Orikoi WangooloDocument5 pagesJoseph Orikoi WangooloIga_DanNo ratings yet

- S.3 Agriculture Beef ProductionDocument9 pagesS.3 Agriculture Beef ProductionIga_DanNo ratings yet

- S.3 Agriculture Beef ProductionDocument9 pagesS.3 Agriculture Beef ProductionIga_DanNo ratings yet

- Reference FormDocument1 pageReference FormIga_DanNo ratings yet

- CV Joselyn BigirwaDocument4 pagesCV Joselyn BigirwaIga_DanNo ratings yet

- Uga Ddpiii Prodoc 0808 enDocument116 pagesUga Ddpiii Prodoc 0808 enIga_DanNo ratings yet

- Road Maintenance Schedule For The Month of JulyDocument9 pagesRoad Maintenance Schedule For The Month of JulyIga_DanNo ratings yet

- IGA DAN Curriculum Vitae 20180411Document15 pagesIGA DAN Curriculum Vitae 20180411Iga_Dan100% (1)

- Final Year Project, Iga DanDocument67 pagesFinal Year Project, Iga DanIga_DanNo ratings yet

- Order #109801765 Fourth Amendment To The U.S. ConstitutionDocument12 pagesOrder #109801765 Fourth Amendment To The U.S. ConstitutionIga_DanNo ratings yet

- KFP Compliance Matrix 17th Mar 2017Document26 pagesKFP Compliance Matrix 17th Mar 2017Iga_DanNo ratings yet

- Hydraulic and Road DesignDocument3 pagesHydraulic and Road DesignIga_DanNo ratings yet

- How Boys Are Specialised Into Being Good Men: UGANDADocument10 pagesHow Boys Are Specialised Into Being Good Men: UGANDAIga_DanNo ratings yet

- The Process of Globalization and Its Impacts On International Business ActivitiesDocument8 pagesThe Process of Globalization and Its Impacts On International Business ActivitiesIga_Dan100% (1)

- Ug 2008 077 en Adf BD WP Uganda Caiip IIDocument27 pagesUg 2008 077 en Adf BD WP Uganda Caiip IIIga_DanNo ratings yet

- Iga Buzi Card 1Document1 pageIga Buzi Card 1Iga_DanNo ratings yet

- Bombo Drains OutstandingDocument1 pageBombo Drains OutstandingIga_DanNo ratings yet

- History of AfricaDocument9 pagesHistory of AfricaIga_DanNo ratings yet

- Iga Dan Monthly Monitoring FormDocument2 pagesIga Dan Monthly Monitoring FormIga_DanNo ratings yet

- Ratana Outdoor FurnitureDocument107 pagesRatana Outdoor FurnitureNova TechieNo ratings yet

- 12-Samss-008 2020Document6 pages12-Samss-008 2020asimazami69No ratings yet

- Registered Earthworks Supervisor Course: E-LearningDocument1 pageRegistered Earthworks Supervisor Course: E-LearningnobleNo ratings yet

- TR2381 Rev.7Document158 pagesTR2381 Rev.7Maffone Numerouno0% (1)

- Concresive ZR: Single Component Polyurethane Based Zinc Rich Primer For SteelDocument2 pagesConcresive ZR: Single Component Polyurethane Based Zinc Rich Primer For Steelmohamed ayadNo ratings yet

- Lista de PecasDocument302 pagesLista de PecasPedro Lorenço JorgeNo ratings yet

- Basic Building Materials and Construction - Part IIIDocument158 pagesBasic Building Materials and Construction - Part IIIGãlväñ Fôx100% (1)

- Ings of Solation: San Francisco International Airport's New Terminal Is Protected by 267 Steel Seismic IsolatorsDocument7 pagesIngs of Solation: San Francisco International Airport's New Terminal Is Protected by 267 Steel Seismic IsolatorsJosimar OliveraNo ratings yet

- Hex House - Double - Materials List Web 1Document1 pageHex House - Double - Materials List Web 1techandtravel305No ratings yet

- Wachemo University Institute of Technology Department of Civil Engineering Geotechnical Stream Foundation Engineering-IDocument33 pagesWachemo University Institute of Technology Department of Civil Engineering Geotechnical Stream Foundation Engineering-IKubaNo ratings yet

- Drilling & Blasting NumericalDocument109 pagesDrilling & Blasting Numericalvishalguptastudy01No ratings yet

- Karuma Cavern DesignDocument6 pagesKaruma Cavern DesignBinodNo ratings yet

- Trifecta Verde en Resplandor Villas Floor Plans BrochureDocument45 pagesTrifecta Verde en Resplandor Villas Floor Plans BrochureAnirudh VNNo ratings yet

- 7 Mis Codes For Civil-MustDocument3 pages7 Mis Codes For Civil-MustRama Krishna Reddy DonthireddyNo ratings yet

- 7.NOTES Achyut KanvindeDocument10 pages7.NOTES Achyut KanvindeVarunNo ratings yet

- Abe DIY BookletDocument89 pagesAbe DIY BookletFrancois-No ratings yet

- Lecture Notes 7 Design of Truss IDocument20 pagesLecture Notes 7 Design of Truss IyellowpawpawNo ratings yet

- ArknetDocument1 pageArknetAnthony LazoNo ratings yet

- Advantages and Disadvantages of Prestressed ConcreteDocument19 pagesAdvantages and Disadvantages of Prestressed Concretebhargav reddyNo ratings yet

- Format For Inspection of Maintenance Aspects of Completed PMGSY Works by Third Tier of QMDocument4 pagesFormat For Inspection of Maintenance Aspects of Completed PMGSY Works by Third Tier of QMAtul mishraNo ratings yet

- Traction Frame Line Up: Kemenkes RI AKL NoDocument1 pageTraction Frame Line Up: Kemenkes RI AKL NoAnggaran RSUD.M.Natsir SolokNo ratings yet

- Rate Analysis For M-25 Concrete: A Material Unit Qty Rate AmountDocument3 pagesRate Analysis For M-25 Concrete: A Material Unit Qty Rate AmountSyamala BaiNo ratings yet

- EnglishDocument17 pagesEnglishgcd3955No ratings yet

- Final Paper ASCE - UHPC Segmental Bridge ConstructionDocument12 pagesFinal Paper ASCE - UHPC Segmental Bridge ConstructionyyingmunNo ratings yet

- Heating and Air Conditioning PDFDocument551 pagesHeating and Air Conditioning PDFmohanadymtNo ratings yet

- Experiment 2 KnittingDocument2 pagesExperiment 2 KnittingAvanish YadavNo ratings yet

- Imo Crew and Passenger List ...Document9 pagesImo Crew and Passenger List ...Axelexa SibyNo ratings yet

- MST-Excavation, Backfilling and Compaction For Utility LinesDocument5 pagesMST-Excavation, Backfilling and Compaction For Utility LinesAnonymous a3K3Wg100% (1)

- Second Floor Power Layout Ground Floor Power Layout: General NotesDocument9 pagesSecond Floor Power Layout Ground Floor Power Layout: General NotesIrene Ionie Rarangol - TengcoNo ratings yet

- Types of Masonry Walls in Building ConstructionDocument3 pagesTypes of Masonry Walls in Building ConstructionSayan GharNo ratings yet