Professional Documents

Culture Documents

Install Rotary Gas Meters

Uploaded by

Jose Manuel CastroOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Install Rotary Gas Meters

Uploaded by

Jose Manuel CastroCopyright:

Available Formats

INSTALLATION & MAINTENANCE

BULLETIN No. 601

September 11, 2014 Rev.15

Installation Instructions

for

Line Mounted ROMET Meters

RM600 RM56000

RM16 RM1600

This bulletin covers the general installation of all

ROMET rotary meters.

A Romet meter is a precise gas volume measuring

instrument (cash register), manufactured to very

tight tolerances. Rough handling of the meter must

be avoided to prevent damage.

To prevent external/internal damage, dirt or oil

contamination of the meter, always transport the

meter in a protective container with the meter

capped at both opening ends, including the

instrument drive assembly (if applicable), and

WITHOUT oil.

Always add oil after the meter has been correctly

installed at the meter site.

Installation of a Romet rotary meter is a relatively

simple procedure if the meter set is properly

constructed. The piping and flange position of the

meter set should be such that there is adequate

area spacing between the meter and any pipe, wall

or any other possible obstruction. This spacing will

allow for ease of maintenance or the addition or

removal of devices; such as, a meter module,

batteries or any other auxiliary instruments.

Furthermore, all full faced pipe flanges installed

(raised flanges are not recommended) must be

level and spaced so that the meter together with

the top and bottom gaskets can be positioned

between the flanges easily and with the least

amount of air gap (maximum 1/16 (1.6 mm) per

linear foot (30.5 cm) of flange) before tightening. If

the meter is not level, it is possible to improperly fill

the oil reservoirs or over-stress the meter after

tightening the flange bolts. This condition may

cause the meter to read incorrectly or result in

complete meter failure.

Care must also be taken to ensure that the piping

and flanges are aligned correctly in relation to the

meter (maximum 1/16 (1.6mm) in all directions).

DO NOT use the meter to correct misaligned piping

or flanges. Excessive misalignment or distance

between piping or flanges may over-stress the

meter body when the flange bolts are tightened.

Severe over-stress may cause the meter to read

incorrectly or result in complete meter failure.

The use of a spool piece is recommended to help

level and align piping and/or flanges in relation to

the meter before meter installation. These spools

are available from Romet.

To protect the meter (and any other critical

devices) from internal damage, the gas passing

through a meter set must be clean (i.e. free of rust,

scale, grease, pipe paste, wadding, weld beads,

etc.).

G10 G1000

The use of a filter (e.g. Romet Screen T filter,

typically 80 mesh/178 micron size) or strainer

installed upstream of the meter set is strongly

recommended to insure adequate internal meter

protection.

Before installing a Romet meter, a quick check

should be performed.

First, remove the meter from the protective

container and check the overall condition for any

possible damage or any other problems. Remove

the capping from each end of the meter openings.

Lightly blow some air into the inlet of the meter.

This should cause the impellers to rotate freely and

eventually come to a gradual stop.

Should the impellers stop suddenly or not rotate

after blowing into the meter, it will be necessary to

carefully

remove

any

obstruction

before

installation. If this is not possible, the meter should

be returned to the service shop for further

examination.

Ensure that the meter is mounted in the correct gas

flow arrow direction and position. Meters are

normally installed using the following hardware

items listed in Table 1.

The use of incorrect

hardware may result in meter error or failure. All

bolts should be tighten in a X pattern, in stages, up

to a typical torque value of 20 ft lbs (27 Nm). Some

Romet meters are supplied with nippled

connections at the inlet and outlet. These meters

are built and tested with the connecting nipples in

place.

Care must be taken to avoid further

tightening or loosening of these nipples to prevent

meter damage. Install auxiliary instrumentation as

required.

After the meter has been properly installed,

approved meter oil must be added to all

appropriate oil reservoirs to prevent possible meter

errors or damage. Depending on the meter type

and mounting position (vertical or horizontal), the

required oil volumes will be different. DO NOT over

or under fill oil reservoirs. For the thrust cover end

and the magnetic housing (not found on all meter

types), oil must be added so that the oil reaches the

centre point of the correct oil level gauge (OLG) in

use. For the module cover, the oil must reach the

appropriate RED oil level line (note - centre point of

the OLG for standard counter modules).

DO NOT fill electronic sections with oil.

Note: After meter start up, some oil levels may drop

a little and/or form a thin bubble or meniscus layer

due to oil splash happening within the oil reservoir.

- Refer to Oil Loss Bulletin, Rev. OL-0111.

Approved meter oil: High VI R&O AW ISO VG 15

red, is available from Romet in one quart (litre)

plastic bottles. Other approved oil: Shell Morlina S2

BL 10. Use only one type of oil (never mix different

oils together). The addition of oil additives will

change oil properties which may cause the meter to

read incorrectly or result in complete meter failure.

Ensure all oil plugs (and any other connections) are

properly tightened and secured before pressurizing

the meter set.

When the meter installation has been completed,

the meter set should be pressurized SLOWLY

(maximum 5 psig or 35 kPa per second) up to the

allowable operating pressure specified to avoid

internal over-speed or slamming of the meter.

Should the installation be subject to sudden

INSTANT ON-OFF loads, a properly sized

restricting orifice or venturi flow nozzle should be

MODULE COVER

DO NOT FILL ELECTRONIC

SECTIONS WITH OIL

MAGNETIC HOUSING

installed downstream of the meter to protect the

meter from damage.

Check for any gas leaks or other possible problems.

After start up, the readout counter or drive should

be running smoothly and in the correct direction

when the required gas flow condition has been

reached.

Note: For further information, refer to Romet

Installation & Maintenance RM or G series

booklets. Since this publication is a general

guide, always refer to your companys standard

practices for other details. This Bulletin is based on

actual field problems encountered and gas industry

standards.

Warning: Tampering or modifying design of

product may cause a potentially

hazardous situation.

METER BODY

THRUST COVER

GAS FLOW

ARROW

BACKUP

COUNTER

THRUST COVER +

BACKUP COUNTER

ME

Y

TAR T.C. TER

RO

T.C.

MODEL NO.

CAP.

C.F.H.

F

L

MAX. OP. PRES.

P.S.I.

ROMET Ltd.

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

401206

SERIAL NO.

ROMET LTD. MISSISSAUGA ONT.

ROMET

3000

O

W

MADE IN CANADA

RM 3000

1 2

3 4

7 8

READOUT X 0.22222

=CU.FT.

REFERENCE ONLY

NON COMP. VOLUME

1 2 3 4 5 6 7 8

OLG

(OIL LEVEL GAUGE)

MECHANICAL METER

MOUNTING POSITIONS

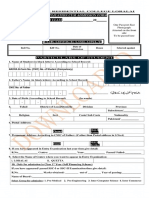

TABLE 1 HARDWARE SPECIFICATION TABLE

STANDARD FLOW

FLANGE/GASKETS

(FULL FACE)

HORIZONTAL

MOUNTING

FLOW

FROM TOP

TO BOTTOM

ROMET LTD.

FLOW

FROM LEFT

TO RIGHT

R O M E T

1 2 3 4 5 6 7 8

OR

GROUND SURFACE

REVERSED FLOW

VERTICAL

MOUNTING

ROMET LTD.

HORIZONTAL

MOUNTING

FLOW

FROM RIGHT

TO LEFT

R O M E T

1 2 3 4 5 6 7 8

FLOW

FROM BOTTOM

TO TOP

OR

GROUND SURFACE

INCORRECT MOUNTING

R O M E T

R O M E T

ROMET LTD.

1080 Matheson Blvd. East, Mississauga, ON L4W 2V2 Canada

Phone 905-624-1591 Fax 905-624-5668 USA 1-800-387-3201

www.rometlimited.com romet@rometlimited.com

VERTICAL

MOUNTING

1 2 3 4 5 6 7 8

BOLTS

(STEEL, ZINC PLATED)

RM600-RM1500

11 x 1.5 long Hex Head

ANSI class 125/150 2

RM16-RM40

SAE Grade 5

RM2000-RM3000

11 x 1.75 long Hex Head

ANSI class 125/150 2

RM55-RM85

SAE Grade 5

RM5000-RM7000

11 x 2 long Hex Head

ANSI class125/150 3

RM140-RM200

SAE Grade 5

RM11000-RM23000

11 x 2 long Hex Head

ANSI class 125/150 4

RM300-RM650

SAE Grade 5

RM25000-RM56000

10 x 2.5 long Hex Head

ANSI class 125/150 6

RM700-RM1600

SAE Grade 5

M16 x 35mm long Hex Head

G10 G25

PN16 40mm

DIN 931 Grade 8.8

M16 x 45mm long Hex Head

G40

PN16 40/50 mm

DIN 931 Grade 8.8

M16 x 45mm long Hex Head

G65

PN16 50mm

DIN 931 Grade 8.8

M16 x 50mm long Hex Head

G100

PN16 80mm

DIN 931 Grade 8.8

M16 x 50mm long Hex Head

G160

PN16 80/100 mm

DIN 931 Grade 8.8

M16 x 50mm long Hex Head

G250 - G400

PN16 100 mm

DIN 931 Grade 8.8

M20 x 60mm long Hex Head

G400/150-G1000

PN16 150 mm

DIN 931 Grade 8.8

All bolts should be installed with approved anti-seize grease and standard steel zinc plated flat washers.

METER MODEL

ROMET LTD.

HORIZONTAL

METER MOUNT

1 2 3 4 5 6 7 8

VERTICAL

METER MOUNT

OIL LEVEL

(CENTRE POINT)

GROUND SURFACE

R O M E T

OIL LEVEL

(RED LINE)

ROMET LTD.

1 2 3 4 5 6 7 8

OLG (VERTICAL)

OLG (HORIZONTAL)

1 2 3 4 5 6 7 8

OLG

FOR STD ID

MODULES ONLY

You might also like

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Installation Instructions For Line Mounted ROMET Meters: RM600 - RM56000 RM16 - RM1600 G10 - G1000Document2 pagesInstallation Instructions For Line Mounted ROMET Meters: RM600 - RM56000 RM16 - RM1600 G10 - G1000Eies Líderes En CapacitaciónNo ratings yet

- Romet RM5000Document2 pagesRomet RM5000Edwin Luna MontecinosNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Installation Bulletin 601 - RM - Rev.21Document2 pagesInstallation Bulletin 601 - RM - Rev.21ravirebba9695No ratings yet

- GM Maint CatalogDocument38 pagesGM Maint CatalogjosueNo ratings yet

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideFrom EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideRating: 4.5 out of 5 stars4.5/5 (8)

- G Series Industrial and Chemical Owners ManualDocument20 pagesG Series Industrial and Chemical Owners ManualbayuNo ratings yet

- Delco Radio Owner's Manual Model 633; Delcotron Generator InstallationFrom EverandDelco Radio Owner's Manual Model 633; Delcotron Generator InstallationNo ratings yet

- Series RM Rate-Master Flowmeters: Specifications - Installation and Operating InstructionsDocument2 pagesSeries RM Rate-Master Flowmeters: Specifications - Installation and Operating InstructionsDJoko Trend RedsNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Mechanical Instruction ManualDocument16 pagesMechanical Instruction ManualMorarescu AndreiNo ratings yet

- 'TTA IOM R22 Jan10Document28 pages'TTA IOM R22 Jan10Luong DaoNo ratings yet

- General Maintenance Procedures: Caution!Document14 pagesGeneral Maintenance Procedures: Caution!Henry HuayhuaNo ratings yet

- GM 6t70 UpdatesDocument45 pagesGM 6t70 UpdatesThePokeOne100% (9)

- Reduced Size MVR DATA SHEETDocument7 pagesReduced Size MVR DATA SHEETsxpNo ratings yet

- Exhaust System: SectionDocument11 pagesExhaust System: SectionRafaelCazalesFuentesNo ratings yet

- Automatic Gas Manifolds Installation, Operation & Maintenance ManualDocument20 pagesAutomatic Gas Manifolds Installation, Operation & Maintenance ManualtaibkNo ratings yet

- Armstrong Installation43.80 VIL I&ODocument14 pagesArmstrong Installation43.80 VIL I&Osas999333No ratings yet

- 1" Mechanical Fuel Meter: User'S ManualDocument7 pages1" Mechanical Fuel Meter: User'S ManualENT ENTNo ratings yet

- Warning: Installation Instructions For Level MaintainersDocument4 pagesWarning: Installation Instructions For Level MaintainersDiego Fernando Pedroza UribeNo ratings yet

- ATS73 Maint ManDocument12 pagesATS73 Maint Manpr_oilNo ratings yet

- MX Series Oval Gear Flowmeter: Instruction ManualDocument32 pagesMX Series Oval Gear Flowmeter: Instruction ManualRómulo Zevallos GutiérrezNo ratings yet

- Accutherm FMG FMT LX Turbine Meter 014091110605Document16 pagesAccutherm FMG FMT LX Turbine Meter 014091110605RafaelNo ratings yet

- 06T Semihermetic Screw CompressorDocument8 pages06T Semihermetic Screw CompressorAbu Malak CiprianoNo ratings yet

- GM Maint Catalog PDFDocument38 pagesGM Maint Catalog PDFMarcelo ArayaNo ratings yet

- Multistage Vertical Inline Pumps PM1, PM3, PM5 Series: Specifications Information and Repair Parts ManualDocument12 pagesMultistage Vertical Inline Pumps PM1, PM3, PM5 Series: Specifications Information and Repair Parts ManualAnibal QuezadaNo ratings yet

- Om004 Om008 Integral ManualDocument9 pagesOm004 Om008 Integral ManualistopiNo ratings yet

- Operating and Maintenance Manual LPG: M-285 Rev. G P.D. Oscillating Piston Flowmeter 1 4D-MD LP GasDocument20 pagesOperating and Maintenance Manual LPG: M-285 Rev. G P.D. Oscillating Piston Flowmeter 1 4D-MD LP GasCarlos RondonNo ratings yet

- Hot-Tap Saddle: Installation InstructionsDocument2 pagesHot-Tap Saddle: Installation InstructionsSusan Sue Berrospi MerinoNo ratings yet

- 2 Installation Maintenance - FantechDocument12 pages2 Installation Maintenance - FantechLoi Chan TuNo ratings yet

- Mark V Target Strain Gage Flowmeter Installation, Operation and Maintenance ManualDocument24 pagesMark V Target Strain Gage Flowmeter Installation, Operation and Maintenance Manualابزار دقیقNo ratings yet

- A/T - No Reverse/3rd or 5th Gear/MIL ON/DTC P0776Document6 pagesA/T - No Reverse/3rd or 5th Gear/MIL ON/DTC P0776Carlos CuellarNo ratings yet

- 0242 0001 4@1Document4 pages0242 0001 4@1Polaris BridgemanNo ratings yet

- Plunger Pump Service Manual: Installation and Start-Up InformationDocument6 pagesPlunger Pump Service Manual: Installation and Start-Up InformationSubhendu KarNo ratings yet

- Running & Servicing Pumps !: Technical Notes of Interest To Marine EngineersDocument11 pagesRunning & Servicing Pumps !: Technical Notes of Interest To Marine EngineersVijay GeddadaNo ratings yet

- Installation and Operating InstructionsDocument20 pagesInstallation and Operating InstructionsArtūrs CeimersNo ratings yet

- Service Tool Catalog: Performance PartsDocument90 pagesService Tool Catalog: Performance PartsOsvaldo Vargas Vergara100% (2)

- 35391B RevaDocument234 pages35391B RevaFelipe FloresNo ratings yet

- Peart 150 Underpressure Drilling Machine Operating InstructionsDocument21 pagesPeart 150 Underpressure Drilling Machine Operating InstructionsRyan LeckieNo ratings yet

- Autoclave - Tools, Installation. Operation and MaintenanceDocument16 pagesAutoclave - Tools, Installation. Operation and Maintenancemaz234No ratings yet

- Install PipingDocument5 pagesInstall PipingDan CosacNo ratings yet

- Rotametro KeyDocument2 pagesRotametro Keydocumentos.envirotestNo ratings yet

- Magnetel Instructions 115-820Document6 pagesMagnetel Instructions 115-820juma1987No ratings yet

- Maytag Neptune MAH3000AWW Washing Machine Service ManualDocument157 pagesMaytag Neptune MAH3000AWW Washing Machine Service Manualrhondafos100% (2)

- PETRO TCS Ops Manual 700-40 45Document52 pagesPETRO TCS Ops Manual 700-40 45paulm3565No ratings yet

- Bosh Gear PumpDocument96 pagesBosh Gear Pumpkavadarci14No ratings yet

- Bosch Gear PumpDocument57 pagesBosch Gear PumpMaximus Maxis0% (1)

- Pump Technical Data SheetDocument24 pagesPump Technical Data SheetM Farid Fakhrudduja100% (1)

- Manual For Induction Motors and Generators 3BFP000050R0101 REV F ENGLISH LowresDocument152 pagesManual For Induction Motors and Generators 3BFP000050R0101 REV F ENGLISH LowresAlfredo Del Rio LambisNo ratings yet

- Automatic Transaxle Troubleshooting GuideDocument293 pagesAutomatic Transaxle Troubleshooting GuideOmar RodriguezNo ratings yet

- Inst General FantechDocument12 pagesInst General FantechCau VoNo ratings yet

- Rta 15Document7 pagesRta 15George DomusciuNo ratings yet

- Manual Rotámetro - 0.02 - 1.2 LPM Key InstrumentsDocument2 pagesManual Rotámetro - 0.02 - 1.2 LPM Key InstrumentsMax SdNo ratings yet

- Smith MN 01011Document8 pagesSmith MN 01011John UrdanetaNo ratings yet

- Brands Vilter Manual VMC 400 SeriesDocument234 pagesBrands Vilter Manual VMC 400 SeriesJose Ricardo Prado SandovalNo ratings yet

- Re 15224Document12 pagesRe 15224Ahmed Abd ElhakeemNo ratings yet

- 3736a g9t Common Rail SystemDocument180 pages3736a g9t Common Rail SystemKornelija Balandė50% (2)

- Procedimiento TecnicoDocument1 pageProcedimiento TecnicoJose Manuel CastroNo ratings yet

- Procedimiento TecnicoDocument1 pageProcedimiento TecnicoJose Manuel CastroNo ratings yet

- Sensor de CorrienteDocument1 pageSensor de CorrienteJose Manuel CastroNo ratings yet

- Corector RometDocument2 pagesCorector RometJose Manuel CastroNo ratings yet

- Corrosion en La Vida CotidianaDocument2 pagesCorrosion en La Vida CotidianaJose Manuel CastroNo ratings yet

- Spiral Wound Gaskets Donit TesnitDocument0 pagesSpiral Wound Gaskets Donit Tesnitjhony1523No ratings yet

- Course Description NACEDocument1 pageCourse Description NACEJose Manuel CastroNo ratings yet

- Procedimiento TecnicoDocument1 pageProcedimiento TecnicoJose Manuel CastroNo ratings yet

- Course Description NACEDocument1 pageCourse Description NACEJose Manuel CastroNo ratings yet

- Lab ViewDocument1 pageLab ViewJose Manuel CastroNo ratings yet

- WebDocument6 pagesWebJose Manuel CastroNo ratings yet

- Scotchkote FD Datasheet 2013Document2 pagesScotchkote FD Datasheet 2013Jose Manuel CastroNo ratings yet

- Liquid Turbine BrochureDocument12 pagesLiquid Turbine Brochuresinagh704885No ratings yet

- Torque Planas FlexsealDocument2 pagesTorque Planas FlexsealjrvmaxyNo ratings yet

- Omd PDFDocument62 pagesOmd PDFCarlos TarquinoNo ratings yet

- Omd PDFDocument62 pagesOmd PDFCarlos TarquinoNo ratings yet

- Manual (1) de Verificacion de Revestiminto de Tuberias Ante La CorrosionDocument27 pagesManual (1) de Verificacion de Revestiminto de Tuberias Ante La CorrosionJose Manuel CastroNo ratings yet

- Wincal Manual 103719-0 Rev eDocument30 pagesWincal Manual 103719-0 Rev eJose Manuel CastroNo ratings yet

- D450166T012 06 Education Training Section LRDocument70 pagesD450166T012 06 Education Training Section LRJose Manuel CastroNo ratings yet

- Dresser Imcw (Userterminal) Handbook (Pho29) 9Document78 pagesDresser Imcw (Userterminal) Handbook (Pho29) 9Jose Manuel CastroNo ratings yet

- Omd PDFDocument62 pagesOmd PDFCarlos TarquinoNo ratings yet

- Dresser Imcw (Userterminal) Handbook (Pho29) 9Document78 pagesDresser Imcw (Userterminal) Handbook (Pho29) 9Jose Manuel CastroNo ratings yet

- 262 Aperflux 101 MT EngDocument37 pages262 Aperflux 101 MT EngJose Manuel CastroNo ratings yet

- Dresser Imcw (Userterminal) Handbook (Pho29) 9Document78 pagesDresser Imcw (Userterminal) Handbook (Pho29) 9Jose Manuel CastroNo ratings yet

- Torque Reduction Subt RsDocument2 pagesTorque Reduction Subt RsJose Manuel CastroNo ratings yet

- GasAlertMax XT II - OpsManual (D6558 0 EN) PDFDocument23 pagesGasAlertMax XT II - OpsManual (D6558 0 EN) PDFJose Manuel CastroNo ratings yet

- OMD & Dp-Ir: Heath Survey Tracker Software Installation & Survey Tracker Use InstructionsDocument20 pagesOMD & Dp-Ir: Heath Survey Tracker Software Installation & Survey Tracker Use InstructionsJose Manuel CastroNo ratings yet

- SCMS 7035Document5 pagesSCMS 7035Jose Manuel CastroNo ratings yet

- EquationDocument11 pagesEquationJose Manuel CastroNo ratings yet

- Galvanic Series: Why Metals Corrode?Document7 pagesGalvanic Series: Why Metals Corrode?Rey Francis FamulaganNo ratings yet

- Current Concepts in Orthopaedic Biomaterials and Implant FixationDocument24 pagesCurrent Concepts in Orthopaedic Biomaterials and Implant FixationS.ENo ratings yet

- Top 305 Companies in Pune RegionDocument39 pagesTop 305 Companies in Pune RegionNiraj Thakkar0% (1)

- The Changing World of OleochemicalsDocument9 pagesThe Changing World of OleochemicalsMarta Szymańska100% (1)

- Distillation Lecture Note-2Document20 pagesDistillation Lecture Note-2BasseyNo ratings yet

- Admission Form All 2019 1Document8 pagesAdmission Form All 2019 1Riz WanNo ratings yet

- FlexEJ Brochure Elaflex 10 2011Document41 pagesFlexEJ Brochure Elaflex 10 2011harlyganNo ratings yet

- Synthesis and Discriminative Stimulus Properties of N(6)-Alkyl Norlysergic Acid DerivativesDocument4 pagesSynthesis and Discriminative Stimulus Properties of N(6)-Alkyl Norlysergic Acid Derivativesmik100% (1)

- 11th Chemistry EM - Public Exam 2022 - Model Question Paper - English Medium PDF DownloadDocument3 pages11th Chemistry EM - Public Exam 2022 - Model Question Paper - English Medium PDF DownloadAshwini Shankar KumarNo ratings yet

- Chapter 4 and 5Document51 pagesChapter 4 and 5Kyla Gabrielle TutoNo ratings yet

- Wolter Jetfan Broschuere English 2017 PDFDocument15 pagesWolter Jetfan Broschuere English 2017 PDFViệt Đặng XuânNo ratings yet

- Trouble Shooting EngineDocument34 pagesTrouble Shooting EngineDesta Andri MuryonoNo ratings yet

- Kimo Kigaz 200 Combustion Gas Analyzer DatasheetDocument4 pagesKimo Kigaz 200 Combustion Gas Analyzer DatasheetayannathompsoneqsNo ratings yet

- Sample IPM PlanDocument4 pagesSample IPM PlanEricNo ratings yet

- Biocides in Gas & Oil 2017: Prepared By: Biocide Information Limited EmailDocument39 pagesBiocides in Gas & Oil 2017: Prepared By: Biocide Information Limited EmailSérgio - ATC do BrasilNo ratings yet

- Titrimetric Methods of AnalysisDocument28 pagesTitrimetric Methods of AnalysisPraveen Kumar Avvaru100% (2)

- Deal-Grove Model for Thermal Oxide GrowthDocument13 pagesDeal-Grove Model for Thermal Oxide GrowthChithraParameswaranNo ratings yet

- Lesson 2 Dna Structure and Dna ExtractionDocument8 pagesLesson 2 Dna Structure and Dna ExtractionGreatel Elijah TorregosaNo ratings yet

- Utilization of Sugarcane Bagasse Ash and Rice Husk Ash On Compressive Strength and Durability of Sustainable Pavement Quality ConcreteDocument10 pagesUtilization of Sugarcane Bagasse Ash and Rice Husk Ash On Compressive Strength and Durability of Sustainable Pavement Quality ConcreteEditor IJTSRDNo ratings yet

- Process Integration Using Pinch Analysis: A Cement Industry Case StudyDocument4 pagesProcess Integration Using Pinch Analysis: A Cement Industry Case StudyReggie DueñasNo ratings yet

- Toxic Substances and Disease Registry MRLs for March 2016Document16 pagesToxic Substances and Disease Registry MRLs for March 2016KodeChandrshaekharNo ratings yet

- Experiment 6 Lab ReportDocument21 pagesExperiment 6 Lab ReportmarkkkkkNo ratings yet

- CHEMISTRY LAB VIVA QuestionsDocument3 pagesCHEMISTRY LAB VIVA QuestionsUjjWal MahAjan55% (20)

- Oil Debate Chromatography PPT 2Document17 pagesOil Debate Chromatography PPT 2Eridha TriwardhaniNo ratings yet

- Liquefied Gas HandbookDocument38 pagesLiquefied Gas HandbookAndri Suharto100% (1)

- Groundwater ContaminationDocument25 pagesGroundwater ContaminationjoshjethNo ratings yet

- NanotechnologyDocument28 pagesNanotechnologyCordelia Marisse ReyesNo ratings yet

- Thermogravimetric Analysis (TGA) Methodology of Calculating TheDocument15 pagesThermogravimetric Analysis (TGA) Methodology of Calculating TheHamed HamidpourNo ratings yet

- Chemical Reactions and Energy ChangesDocument6 pagesChemical Reactions and Energy ChangesMiku HatsuneNo ratings yet

- A Place of My Own: The Architecture of DaydreamsFrom EverandA Place of My Own: The Architecture of DaydreamsRating: 4 out of 5 stars4/5 (241)

- Einstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseFrom EverandEinstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseRating: 4.5 out of 5 stars4.5/5 (50)

- Building Construction Technology: A Useful Guide - Part 1From EverandBuilding Construction Technology: A Useful Guide - Part 1Rating: 4 out of 5 stars4/5 (3)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialFrom EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNo ratings yet

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationFrom EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationRating: 4 out of 5 stars4/5 (18)

- An Architect's Guide to Construction: Tales from the Trenches Book 1From EverandAn Architect's Guide to Construction: Tales from the Trenches Book 1No ratings yet

- The Complete Guide to Alternative Home Building Materials & Methods: Including Sod, Compressed Earth, Plaster, Straw, Beer Cans, Bottles, Cordwood, and Many Other Low Cost MaterialsFrom EverandThe Complete Guide to Alternative Home Building Materials & Methods: Including Sod, Compressed Earth, Plaster, Straw, Beer Cans, Bottles, Cordwood, and Many Other Low Cost MaterialsRating: 4.5 out of 5 stars4.5/5 (6)

- Hyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionFrom EverandHyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionRating: 4.5 out of 5 stars4.5/5 (3)

- The Laws of Thermodynamics: A Very Short IntroductionFrom EverandThe Laws of Thermodynamics: A Very Short IntroductionRating: 4.5 out of 5 stars4.5/5 (10)

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedFrom EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedRating: 5 out of 5 stars5/5 (1)

- The Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseFrom EverandThe Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseRating: 5 out of 5 stars5/5 (3)

- Introduction to Applied Thermodynamics: The Commonwealth and International Library: Mechanical Engineering DivisionFrom EverandIntroduction to Applied Thermodynamics: The Commonwealth and International Library: Mechanical Engineering DivisionRating: 2.5 out of 5 stars2.5/5 (3)

- How to Estimate with RSMeans Data: Basic Skills for Building ConstructionFrom EverandHow to Estimate with RSMeans Data: Basic Skills for Building ConstructionRating: 4.5 out of 5 stars4.5/5 (2)

- Control of Power Electronic Converters and Systems: Volume 1From EverandControl of Power Electronic Converters and Systems: Volume 1Rating: 5 out of 5 stars5/5 (1)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 3.5 out of 5 stars3.5/5 (3)

- Design of Foundations for Offshore Wind TurbinesFrom EverandDesign of Foundations for Offshore Wind TurbinesRating: 5 out of 5 stars5/5 (3)

- Engineering Critical Assessment (ECA) for Offshore Pipeline SystemsFrom EverandEngineering Critical Assessment (ECA) for Offshore Pipeline SystemsNo ratings yet

- Building Construction Technology: A Useful Guide - Part 2From EverandBuilding Construction Technology: A Useful Guide - Part 2Rating: 5 out of 5 stars5/5 (1)

- The E-Myth Contractor: Why Most Contractors' Businesses Don't Work and What to Do About ItFrom EverandThe E-Myth Contractor: Why Most Contractors' Businesses Don't Work and What to Do About ItRating: 4 out of 5 stars4/5 (16)

- Quantum Mechanics 4: Spin, Lasers, Pauli Exclusion & Barrier PenetrationFrom EverandQuantum Mechanics 4: Spin, Lasers, Pauli Exclusion & Barrier PenetrationRating: 1 out of 5 stars1/5 (1)

- Rolling Bearing Tribology: Tribology and Failure Modes of Rolling Element BearingsFrom EverandRolling Bearing Tribology: Tribology and Failure Modes of Rolling Element BearingsNo ratings yet

- Nuclear Energy in the 21st Century: World Nuclear University PressFrom EverandNuclear Energy in the 21st Century: World Nuclear University PressRating: 4.5 out of 5 stars4.5/5 (3)