Professional Documents

Culture Documents

Output Summary: See Runtime Message Report For Warning Messages

Uploaded by

Simranjeet SinghOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Output Summary: See Runtime Message Report For Warning Messages

Uploaded by

Simranjeet SinghCopyright:

Available Formats

Output Summary

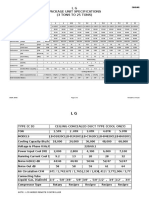

Xist Ver. 6.00

Page 1

Released to the following HTRI Member Company:

DuPont

hq8702

10/21/2013 11:31 SN: 1500213455

MKH Units

: Summary Unit

Rating - Horizontal TEMA BEU Shell With Single-Segmental Baffles

No Data Check Messages.

See Runtime Message Report for Warning Messages.

Process Conditions

Cold Shellside

Fluid name

Flow rate

(1000-kg/hr)

Inlet/Outlet Y (Wt. frac vap.)

Inlet/Outlet T

(Deg C)

Inlet P/Avg

(kgf/cm2A)

dP/Allow.

(kgf/cm2)

Fouling

(m2-hr-C/kcal)

0.000

101.98

65.624

0.837

Hot Tubeside

107

312.821 *

0.000

199.99

0.000

226.66

6.924

1.285

1.055

0.000400

341

306.892 *

0.000

135.27

6.281

1.476

0.000400

Exchanger Performance

Shell h

Tube h

Hot regime

Cold regime

EMTD

(kcal/m2-hr-C)

(kcal/m2-hr-C)

(--)

(--)

(Deg C)

1392.92

1921.29

Sens. Liquid

24.3

Actual U

Required U

Duty

Area

Overdesign

Shell Geometry

TEMA type

Shell ID

Series

Parallel

Orientation

Baffle type

Baffle cut

Baffle orientation

Central spacing

Crosspasses

Tube Geometry

Tube type

Tube OD

Length

Pitch ratio

Layout

Tubecount

Tube Pass

(--)

(mm)

(mm)

(--)

(deg)

(--)

(--)

Thermal Resistance, %

Shell

Tube

Fouling

Metal

29.28

27.26

37.15

6.31

407.21

394.18

17.5506

1788.47

3.30

Baffle Geometry

BEU

1250.00

3

1

0.00

(--)

(mm)

(--)

(--)

(deg)

(kcal/m2-hr-C)

(kcal/m2-hr-C)

(MM kcal/hr)

(m2)

(%)

(--)

(Pct Dia.)

(--)

(mm)

(--)

Single-Seg.

27.00

Perpend.

500.000

9

Nozzles

Plain

19.050

6096.

1.2500

90

1690

Shell inlet

Shell outlet

Inlet height

Outlet height

Tube inlet

Tube outlet

(mm)

(mm)

(mm)

(mm)

(mm)

(mm)

193.675

193.675

99.900

103.462

304.801

304.801

4

Velocities, m/s

Shellside

Tubeside

Crossflow

Window

Flow Fractions

0.55

1.67

0.71

0.64

A

B

C

E

F

0.095

0.502

0.115

0.144

0.144

\\HYRS2\shared\SBU_ALL\CLEANT~1\27A50~1.0IS\20B14~1.1PR\IT0901~2\155515~1.POS\HEATEX~1\71-E-2~1\71-E-24A-C - Process Design Preliminary (SOR).htri

Series Summary

Xist Ver. 6.00

Page 2

Released to the following HTRI Member Company:

DuPont

hq8702

10/21/2013 11:31 SN: 1500213455

MKH Units

: Summary Unit

Rating - Horizontal Multipass Flow TEMA BEU Shell With Single-Segmental Baffles

Unit #

2.99

426.78

414.38

5.2793

1514.17

2082.49

0.279

0.429

21.4

3.70

412.97

398.23

6.2114

1420.56

1980.25

0.278

0.419

26.1

3.22

381.89

369.97

6.0600

1254.38

1717.54

0.279

0.437

25.7

171.54

199.99

226.66

199.85

0.0000

0.0000

0.0004

0.0000

136.25

171.54

203.93

171.01

0.0000

0.0000

0.0000

0.0000

101.98

136.25

171.01

135.27

0.0000

0.0000

0.0000

0.0000

Performance

Overdesign

Overall U

Required U

Duty

Shellside h

Tubeside h

Shellside delta P

Tubeside delta P

EMTD

(%)

(kcal/m2-hr-C)

(kcal/m2-hr-C)

(MM kcal/hr)

(kcal/m2-hr-C)

(kcal/m2-hr-C)

(kgf/cm2)

(kgf/cm2)

(C)

Process Conditions

Inlet T, Shell

Outlet T, Shell

Inlet T, Tube

Outlet T, Tube

Inlet Y, Shell

Outlet Y, Shell

Inlet Y, Tube

Outlet Y, Tube

(C)

(C)

(C)

(C)

(Wt. fraction)

(Wt. fraction)

(Wt. fraction)

(Wt. fraction)

Geometry

Shell type

Parallel

Effective area

Shell orientation

Shell ID

Shellside fluid

Baffle type

Baffle cut

Baffle orientation

Central spacing

Crosspasses

Tube type

Tube Pass

Tubecount

Tube length

Tube OD

Tube layout angle

Pitch ratio

(--)

(--)

(m2)

(--)

(mm)

(--)

(--)

(Pct Dia.)

(--)

(mm)

(--)

(--)

(--)

(--)

(mm)

(mm)

(--)

(--)

E

E

E

1

1

1

595.773

596.345

596.350

Horizontal

Horizontal

Horizontal

1250.00

1250.00

1250.00

Cold

Cold

Cold

Single-Seg. Single-Seg. Single-Seg.

27.00

27.00

27.00

Perpend.

Perpend.

Perpend.

500.000

500.000

500.000

9

9

9

Plain

Plain

Plain

4

4

4

1690

1690

1690

6096.

6096.

6096.

19.050

19.050

19.050

90

90

90

1.2500

1.2500

1.2500

\\HYRS2\shared\SBU_ALL\CLEANT~1\27A50~1.0IS\20B14~1.1PR\IT0901~2\155515~1.POS\HEATEX~1\71-E-2~1\71-E-24A-C - Process Design Preliminary (SOR).htri

HEAT EXCHANGER SPECIFICATION SHEET

Customer

Address

Plant Location

Service of Unit

Size

1250.00 x 6095.93 mm

Surf/Unit (Gross/Eff) 1849.66 / 1788.47 m2

Page 3

MKH Units

Job No.

Reference No.

Proposal No.

Date

10/21/2013

Rev

Item No.

Type BEU

Horz. Connected In

1 Parallel

3 Series

Shell/Unit

3

Surf/Shell (Gross/Eff) 616.55 / 596.16 m2

PERFORMANCE OF ONE UNIT

Shell Side

Tube Side

341

312821

306892

136.026

312821

306756

306892

312821

Fluid Allocation

Fluid Name

107

Fluid Quantity, Total

kg/hr

Vapor (In/Out)

Liquid

Steam

Water

Noncondensables

Temperature (In/Out)

C

101.98

199.99

226.66

135.27

Specific Gravity

0.8066

0.7371

0.6773

0.7520

Viscosity

cP

0.8987

0.3136

0.0143 V/L 0.2332

0.5305

Molecular Weight, Vapor

Molecular Weight, Noncondensables

Specific Heat

kcal/kg-C

0.5117

0.6075

0.5426 V/L 0.655

0.5609

Thermal Conductivity

kcal/hr-m-C

0.0960

0.0857

0.0282 V/L 0.088

0.0968

Latent Heat

kcal/kg

47.4878

Inlet Pressure

kgf/cm2A

65.624

6.924

Velocity

m/s

0.55

1.67

Pressure Drop, Allow/Calc kgf/cm2

1.055

0.837

1.476

1.285

Fouling Resistance (min) m2-hr-C/kcal

0.000400

0.000400

Heat Exchanged kcal/hr

MTD (Corrected)

24.3 C

17550611

Transfer Rate, Service

394.18 kcal/m2-hr-C Clean

650.03 kcal/m2-hr-C

407.21 kcal/m2-hr-C

Actual

CONSTRUCTION OF ONE SHELL

Sketch (Bundle/Nozzle Orientation)

Shell Side

Tube Side

Design/Test Pressure

kgf/cm2G

86.498 /

66.998 /

Design Temperature

C

227.00

258.00

No Passes per Shell

1

4

Corrosion Allowance

mm

Connections

In

mm

1 @ 193.675

1 @ 304.801

Size &

Out

mm

1 @ 193.675

1 @ 304.801

Rating

Intermediate

@

@

Tube No.

Thk(Avg) 2.108 mm

Length 6096. mm

Pitch 23.812 mm

Layout 90

845U OD 19.050 mm

Tube Type

Plain

Material 321 STAINLESS STEEL (18 CR,10 NI)

Shell

ID 1250.00 mm

OD

mm

Shell Cover

Channel or Bonnet

Channel Cover

Tubesheet-Stationary

Tubesheet-Floating

Floating Head Cover

Impingement Plate

None

Baffles-Cross

Type SINGLE-SEG.

%Cut (Diam) 27.00

Spacing(c/c) 500.000

Inlet 550.000 mm

Baffles-Long

Seal Type

Supports-Tube

U-Bend

Type

Bypass Seal Arrangement

Tube-Tubesheet Joint

Expansion Joint

Type

Rho-V2-Inlet Nozzle

kg/m-s2

Bundle Entrance

Bundle Exit

kg/m-s2

Gaskets-Shell Side

Tube Side

-Floating Head

Code Requirements

TEMA Class

kg

Remarks:

Note: Reported duty and flow rates include a user-specified multiplier of 1.10.

Reprinted with Permission (v6 )

\\HYRS2\shared\SBU_ALL\CLEANT~1\27A50~1.0IS\20B14~1.1PR\IT0901~2\155515~1.POS\HEATEX~1\71-E-2~1\71-E-24A-C - Process Design Preliminary (SOR).htri

You might also like

- Steam CondenserDocument2 pagesSteam CondenserAlphaEcc EngineeringTeamNo ratings yet

- Tema SheetDocument2 pagesTema SheetMurad ALiNo ratings yet

- Htri Trial PDFDocument39 pagesHtri Trial PDFcroprobosNo ratings yet

- Htri FileDocument24 pagesHtri FileEalumalai Muthu100% (1)

- Air Exchanger TDDocument9 pagesAir Exchanger TDRajput PratiksinghNo ratings yet

- Aspen 1 PDFDocument6 pagesAspen 1 PDFQamar AbbasNo ratings yet

- Tranter PHE GCD-09 X 43Document4 pagesTranter PHE GCD-09 X 43alokNo ratings yet

- Chiller 300 CMH 25% OverdesignDocument1 pageChiller 300 CMH 25% Overdesignsch203No ratings yet

- E 0211Document23 pagesE 0211Thinh ViproNo ratings yet

- Thermic Fluid HXDocument40 pagesThermic Fluid HXamruta21No ratings yet

- TEMA SheetDocument2 pagesTEMA SheetFrancisco RenteriaNo ratings yet

- TANK Module: Sample PrintoutDocument17 pagesTANK Module: Sample PrintoutAnonymous J1vjrU2No ratings yet

- HTRI Thermal Design Sheet of BEU Type Shell Tube Heat Exchanger PDFDocument14 pagesHTRI Thermal Design Sheet of BEU Type Shell Tube Heat Exchanger PDFSivi NallamothuNo ratings yet

- Tbg620k 50hz enDocument4 pagesTbg620k 50hz enEhsanur RahmanNo ratings yet

- Heat Exchanger Specification Sheet: MM M M Performance of One UnitDocument1 pageHeat Exchanger Specification Sheet: MM M M Performance of One UnitLucia D'AmbrosioNo ratings yet

- Heat Exchanger Specification Sheet SI Units: C:/Users/thangtq/Desktop/new - HtriDocument1 pageHeat Exchanger Specification Sheet SI Units: C:/Users/thangtq/Desktop/new - HtriTrần Quang ThắngNo ratings yet

- Thermal DesignDocument1 pageThermal Designparag7676No ratings yet

- Engineering Declaration Unit # 2 JindalDocument16 pagesEngineering Declaration Unit # 2 JindalVIBHAV100% (1)

- Air-Cooled Heat Exchanger Specification SheetDocument4 pagesAir-Cooled Heat Exchanger Specification SheetPanca KurniawanNo ratings yet

- Preheater - Spec SheetDocument1 pagePreheater - Spec SheetKAMININo ratings yet

- Reboiler 1Document12 pagesReboiler 1kishna009No ratings yet

- TANK Module Package: Sample PrintoutDocument20 pagesTANK Module Package: Sample PrintoutSIVANo ratings yet

- Heat Exchanger Specification Sheet: Shell Side Tube Side Performance of One UnitDocument2 pagesHeat Exchanger Specification Sheet: Shell Side Tube Side Performance of One UnitMuthuKumar ArunachalamNo ratings yet

- Performance NT100M HVDocument1 pagePerformance NT100M HVAnonymous 3fTYXaW7WNo ratings yet

- Tech Description Cogen UnitDocument32 pagesTech Description Cogen Unitthawdar100% (1)

- TBG616K PDFDocument4 pagesTBG616K PDFTyler GoodwinNo ratings yet

- Reciprocating CompressorDocument6 pagesReciprocating CompressorEDUARDONo ratings yet

- 04 Appendix 2 To PTC - Bill of MeterialsDocument18 pages04 Appendix 2 To PTC - Bill of Meterialsvigines89No ratings yet

- Heat Exchanger Specification Sheet: Performance of One Unit Shell Side Tube SideDocument1 pageHeat Exchanger Specification Sheet: Performance of One Unit Shell Side Tube SideMuthuKumar ArunachalamNo ratings yet

- Case 1 e 002 D - H Rev 0Document16 pagesCase 1 e 002 D - H Rev 0Oswaldo GuerraNo ratings yet

- Heat Exchanger Rating Data Sheet Dumai UnitsDocument1 pageHeat Exchanger Rating Data Sheet Dumai UnitsagusnnnNo ratings yet

- Datasheet of Equipment - ANNAMDocument8 pagesDatasheet of Equipment - ANNAMhuyly34No ratings yet

- Bracket Design For ReactorDocument32 pagesBracket Design For ReactorbrencejunNo ratings yet

- Gas Shutoff Valves: FeaturesDocument2 pagesGas Shutoff Valves: FeaturesDidik RiswantoNo ratings yet

- Cooling Tower Data Sheet REV-00Document12 pagesCooling Tower Data Sheet REV-00Anonymous ZnuMEWN1No ratings yet

- Heat Exchanger Specification Sheet: Performance of One Unit Shell Side Tube SideDocument2 pagesHeat Exchanger Specification Sheet: Performance of One Unit Shell Side Tube SidehaosfNo ratings yet

- Copeland Selection Software: Performance at Specified Operating Point Data at 50 HZDocument3 pagesCopeland Selection Software: Performance at Specified Operating Point Data at 50 HZkica148No ratings yet

- Design of Shell & Tube HXDocument40 pagesDesign of Shell & Tube HXprateek_bhoirNo ratings yet

- Heat HXerDocument2 pagesHeat HXerGade JyNo ratings yet

- C22 D5 - 20kva 16KWDocument3 pagesC22 D5 - 20kva 16KWSlobodan KojicNo ratings yet

- Cooling - Tower and Boiler CalculationDocument47 pagesCooling - Tower and Boiler CalculationDavid LambertNo ratings yet

- BoqDocument18 pagesBoqPradeep Yallanki100% (1)

- J200uc GBDocument5 pagesJ200uc GBTan Ho DuyNo ratings yet

- 40KW Diesel Generator Datasheet J40u (English) PDFDocument4 pages40KW Diesel Generator Datasheet J40u (English) PDFojopoderosoNo ratings yet

- Process Design of CondenserDocument5 pagesProcess Design of CondenserVivek VĩvĕNo ratings yet

- TBG 616Document4 pagesTBG 616sdiaman50% (2)

- Specification LG Package UnitsDocument5 pagesSpecification LG Package UnitsShaikhMazharAhmed100% (1)

- Nuevo Flujo: 95000 KG/H de Aceite: Heat Exchanger Especification SheetDocument1 pageNuevo Flujo: 95000 KG/H de Aceite: Heat Exchanger Especification SheetErik Arias CoronelNo ratings yet

- Boiler DataDocument28 pagesBoiler DataMonique ThomasNo ratings yet

- Unit-4 TG Desk Engineer'S Log BookDocument6 pagesUnit-4 TG Desk Engineer'S Log BookJai GuptaNo ratings yet

- Tyco PCB RelaysDocument6 pagesTyco PCB RelaysgfiareNo ratings yet

- 30KW Diesel Generator Datasheet T30u (English) PDFDocument4 pages30KW Diesel Generator Datasheet T30u (English) PDFojopoderosoNo ratings yet

- Assignment 1: Shell and Tube Heat Exchanger Overall Heat Exchanger Value, U ValueDocument27 pagesAssignment 1: Shell and Tube Heat Exchanger Overall Heat Exchanger Value, U ValueAravind NaiduNo ratings yet

- Case Studies in Mechanical Engineering: Decision Making, Thermodynamics, Fluid Mechanics and Heat TransferFrom EverandCase Studies in Mechanical Engineering: Decision Making, Thermodynamics, Fluid Mechanics and Heat TransferRating: 5 out of 5 stars5/5 (2)

- Marine Electrical Practice: Marine Engineering SeriesFrom EverandMarine Electrical Practice: Marine Engineering SeriesRating: 4 out of 5 stars4/5 (8)

- Libherr CraneDocument157 pagesLibherr Craneali67% (3)

- Hemax-530 PDFDocument2 pagesHemax-530 PDFNice BennyNo ratings yet

- GL Career Academy Data AnalyticsDocument7 pagesGL Career Academy Data AnalyticsDeveloper GuideNo ratings yet

- Scan WV1DB12H4B8018760 20210927 1800Document6 pagesScan WV1DB12H4B8018760 20210927 1800Sergio AlvarezNo ratings yet

- The Confucian Transformation of Korea: Harvard-Yen Ching Institute Monograph SeriesDocument456 pagesThe Confucian Transformation of Korea: Harvard-Yen Ching Institute Monograph SeriesAnna D.No ratings yet

- Sustainable Development Precautionary PR 2Document12 pagesSustainable Development Precautionary PR 2PramodNo ratings yet

- 5 Grade: Daily MathDocument130 pages5 Grade: Daily MathOLIVEEN WILKS-SCOTT100% (3)

- CTRLX Automation BrochureDocument60 pagesCTRLX Automation BrochureNinja do SofáNo ratings yet

- Configuring Hyper-V: This Lab Contains The Following Exercises and ActivitiesDocument9 pagesConfiguring Hyper-V: This Lab Contains The Following Exercises and ActivitiesMD4733566No ratings yet

- INJkon 01 4.0 ManualDocument93 pagesINJkon 01 4.0 ManualJansirani SelvamNo ratings yet

- Be and Words From The List.: 6B Judging by Appearance Listening and ReadingDocument3 pagesBe and Words From The List.: 6B Judging by Appearance Listening and ReadingVale MontoyaNo ratings yet

- Philips HD 9 User ManualDocument3 pagesPhilips HD 9 User ManualNdangoh DerekNo ratings yet

- AMiT Products Solutions 2022 1 En-SmallDocument60 pagesAMiT Products Solutions 2022 1 En-SmallMikhailNo ratings yet

- Most Dangerous City - Mainstreet/Postmedia PollDocument35 pagesMost Dangerous City - Mainstreet/Postmedia PollTessa VanderhartNo ratings yet

- Thesis - A Surlyn® Ionomer As A Self-Healing and Self-Sensing Composite - 2011 - UKDocument194 pagesThesis - A Surlyn® Ionomer As A Self-Healing and Self-Sensing Composite - 2011 - UKAhmedNo ratings yet

- Dpb6013 HRM - Chapter 3 HRM Planning w1Document24 pagesDpb6013 HRM - Chapter 3 HRM Planning w1Renese LeeNo ratings yet

- Emcee Script For Recognition DayDocument3 pagesEmcee Script For Recognition DayRomeo Jr. LaguardiaNo ratings yet

- Ib Psychology - Perfect Saq Examination Answers PDFDocument2 pagesIb Psychology - Perfect Saq Examination Answers PDFzeelaf siraj0% (2)

- OB Case Study Care by Volvo UK 2020Document1 pageOB Case Study Care by Volvo UK 2020Anima AgarwalNo ratings yet

- Classical Theories of Economic GrowthDocument16 pagesClassical Theories of Economic GrowthLearner8494% (32)

- Capacity Analysis of Kashmir Highway IslamabadDocument71 pagesCapacity Analysis of Kashmir Highway Islamabadm saadullah khanNo ratings yet

- Stress: Problem SetDocument2 pagesStress: Problem SetDanielle FloridaNo ratings yet

- 22 Thành NG Quen Thu C Trên Ielts - FirefighterDocument2 pages22 Thành NG Quen Thu C Trên Ielts - FirefighterNinh NguyễnNo ratings yet

- Aectp 300 3Document284 pagesAectp 300 3AlexNo ratings yet

- History of Psychotherapy FinalDocument38 pagesHistory of Psychotherapy FinalMarco BonettiNo ratings yet

- Diltoids Numberletter Puzzles Activities Promoting Classroom Dynamics Group Form - 38486Document5 pagesDiltoids Numberletter Puzzles Activities Promoting Classroom Dynamics Group Form - 38486sinirsistemiNo ratings yet

- Energy BodiesDocument1 pageEnergy BodiesannoyingsporeNo ratings yet

- Control System PPT DO1Document11 pagesControl System PPT DO1Luis AndersonNo ratings yet

- Lub OIl Flushing Procedure PDFDocument44 pagesLub OIl Flushing Procedure PDFSubrahmanyam100% (1)

- Comparative Study On Analysis of Plain and RC Beam Using AbaqusDocument9 pagesComparative Study On Analysis of Plain and RC Beam Using Abaqussaifal hameedNo ratings yet