Professional Documents

Culture Documents

Design Criteria For Canals

Uploaded by

Muhammad ZeeshanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design Criteria For Canals

Uploaded by

Muhammad ZeeshanCopyright:

Available Formats

Feasibility Study for the Construction of 95km Irrigation

Canal from Jari Outlet to Iftikharabad District Bhimber- AJ&K

Design Criteria for Canal

RHC | AGES | 2015

DESIGN REPORT

Vol-1:Design Criteria

Feasibility Study for the Construction of 95km Irrigation

Canal from Jari Outlet to Iftikharabad District Bhimber- AJ&K

3

3.1

DESIGN REPORT

Vol-1:Design Criteria

Canals & Structures

Scope

This section describes the criteria and procedures used for the detailed design of 95

Km canal, its irrigation network and appurtenant hydraulic structures. The design of all

works will follow the same engineering principles as explained in the design criteria

until and unless some special conditions encountered during the execution. The

design criteria, including formulae, coefficients and constants will be used in all

hydraulic designs as applicable.

3.2

Design Discharge of Main Canal

Design discharge of the main canal is 417 which was worked out as command area

irrigation requirements in a study by NESPAK in year 2006 cusecs under the study

Assessment of Irrigation Water Requirement for Government of AJ&K from Mangla

Reservoir and Upper Jhelum Canal (Table-5.26).

3.3

Longitudinal Water Surface Slope of Main Canal

To bring maximum area under command by gravity irrigation, main canal as well as

distribution canals have to be as flat as far as possible consistent with the need for

minimum velocities to transport the sediment and to minimize its settlement in the

canal.

With these considerations, the longitudinal water surface slope in the main canal has

been fixed as 0.01 % (1 in 10,000).

3.4

3.4.1

Canal Alignment

Main Canal

The topography along the anticipated route of 95 Km main canal principally comprises

on parts of potohar plateu, residual hill, foothill, plain and starches land. Under these

conditions alignment of the main canal would logically follow the contours of terrain.

The selected alignment of main canal will be fine tuned considering the following

major requirements:

Avoid sharp bends;

Crossing the drainage nullahs, channels and roads en-route

perpendicular and drains perpendicular to the centerline of main canal,

Avoid settlements or sites of special significance (e.g. archaeologically important

sites);

Avoid heavy cut and fill areas to optimize excavation and borrow material fill

quantities so as to minimize cost.

3.4.2

possibly

Distributaries, Minors & Watercourses

Like every other irrigation channel, a distributary or minor should be aligned on the

local watershed and its command area confined between drainage lines. Following

basic considerations have governed planning of distribution system: -

RHC | AGES | 2015

3-1

Feasibility Study for the Construction of 95km Irrigation

Canal from Jari Outlet to Iftikharabad District Bhimber- AJ&K

DESIGN REPORT

Vol-1:Design Criteria

Alignment of distributaries adopted would:

a. Have shortest length as well as ensure effective distribution of water to the land.

b. Avoid villages, roads, cart tracks, mosques, graveyards and other valuable

properties, as far as possible.

Distributary off-take would be located at the highest point so as to command

maximum area.

Off-take regulators of distributaries/minors would be located at a point away from

curves in the parent channel.

Alignment would attempt to provide minimum depth of cutting or filling. In order to

stick to this criterion, fall structures of varying heights would be provided, where

required.

Alignment would have minimum number of curves and acute curves would be

avoided particularly. It is a known fact that such channels experience non-uniform

velocity as well as silting on inner side of curve.

Alignment would cater for the commanded area in such a way that length of the

watercourses does not exceed 2 miles. Where required, minors would be

introduced.

Alignment would be such that it does not give rise to Chaks with long watercourse

as well as help to create contour Chaks reducing thereby leveling and grading

requirements.

Alignment would avoid any costly cross drainage works.

Escapes would be provided at proper places to act as safety valves.

3.4.2.1 Layout Procedures for Distributary Command

Outlets (Moghas) of appropriate type would be provided from a distributary or minor.

(No direct outlets would be allowed from the Main Canal). Capacity of each outlet,

which is dependent on the size of commanded area would be limited to 3.0 cusecs

considering the water allowance and ease of handling by the farmers. Tail clusters

shall be provided on the tail of minor/distributary, where required.

For layout of water courses, one spot level per acre of the command area would be

obtained with contour interval of 1ft on the survey map. Considering the water

allowable and discharge limitation of 3 cusecs, Chak size would vary between 250400 acres of CCA.

In order to determine FSL in the distributary at an outlet location, highest point in the

related chak would be considered.

RHC | AGES | 2015

3-2

DESIGN REPORT

Feasibility Study for the Construction of 95km Irrigation

Canal from Jari Outlet to Iftikharabad District Bhimber- AJ&K

3.4.3

Vol-1:Design Criteria

Bend Radii

As suggested by USBR, for lined channels, radius to the canal centerline should be

three to seven times the water surface width (the larger ratio for larger capacity)

depending on the size or capacity of canal.

Radius of curvature is also linked with free board by certain authors. Due to rise in

water levels on outer side of the curve the free board can be affected. It can be

calculated as below: -

v 2b

h

gR

Where,

h =

change in water surface elevation across channel (ft)

v =

sub-critical average velocity (ft/s)

b =

width of channel (ft)

g =

acceleration due to gravity (ft2/s)

R = distance from curve center to the channel center line (radius of the curve

in ft.)

Effect of rise in water level on outside of curve is negligible when the ratio of the

radius of curvature to the distance to the center of the canal is greater than three

times the bed width of the channel.

Table 3.1: Values of minimum radii of channel curves for different channel capacities

3.5

Channel Capacity (cusec)

Minimum radius of curvature (ft)

Less than 10

325

10 to 100

500

100 to 1000

1000

Canal Cross Sections

3.5.1 Prism Geometry

3.5.1.1 Main Canal & Distributaries

The main canal and distributaries shall be constructed as in-situ concrete lined

trapezoidal section. The water prism of these canals shall be worked out using

Mannings formula. This formula, which was empirically derived towards the end of the

19th century, relates discharge to area of flow, the slope of the energy line, the shape

of the channel and the roughness of the boundaries of the channel. Mannings formula

is:

RHC | AGES | 2015

1.486 2 / 3 1 / 2

R S

n

3-3

DESIGN REPORT

Feasibility Study for the Construction of 95km Irrigation

Canal from Jari Outlet to Iftikharabad District Bhimber- AJ&K

Vol-1:Design Criteria

Where:

V =

Flow velocity (ft/s)

n =

Mannings roughness coefficient

S =

longitudinal water surface slope (ft./ft)

R =

hydraulic radius = A/P (ft.)

P =

wetted perimeter of the flow (ft.)

Mannings roughness coefficient n is an important parameter and should be realistic.

If n value is lower than realistic both for side slope and bed, the canal, could

experience heading up, encroachment of free board, decrease in discharge capacity

and siltation in bed. Such conditions must be avoided for effective operation and

maintenance.

Table 3.2: Values of Mannings Roughness Coefficient, n, for Various Materials (Ref

V.T. Chow)

Type of Channel and Description

Minimum

Normal

Maximum

Float Finished Concrete

0.013

0.015

0.016

Concrete Finish with Gravel on Bottom

0.015

0.017

0.020

Straight and Uniform Excavated Earth

Channel in Clean but weathered Condition

0.018

0.022

0.025

Straight and Uniform Excavated Channel

with Short Grass and Few Weeds

0.022

0.027

0.033

The consultants have proposed mannings n value of 0.016 for design of concrete

lined main canal and distributaries.

Change of Distributary Canal Section: For purpose of distributary design, most

important consideration in selection of reaches would be that variation in the sections

of two adjoining reaches would not be excessive. Towards tail of the channel, where

discharge is small, these reaches must be short. Near the head, the reaches would be

longer. As a rough rule, the reaches would be so set that the section of the channel

would not change by more than 10 % in width as well as depth from one reach to the

next.

3.5.1.2 Minors & Watercourses

With regard to lined canals, in-situ canal lining is particularly well suited to main canal

and distributaries but as flows get smaller towards the tail ends, it is much more

practical to use a prefabricated / precast system for water distribution. Precast

parabolic canal segments shall be for minors and watercourses. Their hydraulic

design shall be carried out using Mannings equation.

3.5.2 Side Slopes

The major limitations to the steepness of hard lined channel side slopes are slippage

of the lining and soil stability. Slippage may be caused by insufficient friction between

RHC | AGES | 2015

3-4

DESIGN REPORT

Feasibility Study for the Construction of 95km Irrigation

Canal from Jari Outlet to Iftikharabad District Bhimber- AJ&K

Vol-1:Design Criteria

the lining and the sub-grade in combination with effects of external hydrostatic

pressure. The following side slopes may be adopted.

Table 3.3: Side Slopes for Lined Channels

Flow Depth, D (ft)

Side slope (1V:xH)

< 3.0

3.0 to 8.0

1.0

1.0 to 1.5

> 8.0

1.5 to 2.0

The consultants have adopted concrete lined side slopes of 1:1.5 for the main canal.

3.5.3 Freeboard

3.5.3.1 Main Canal

Freeboard for the canal lining and banks shall be in accordance with the USBR

guidelines and based on the maximum flow prevailing in a reach.

In main canal the proposed freeboard shall be 2.0 ft. which includes 1.0 ft. lining

freeboard and 1.0 ft. bank freeboard. Similarly minimum clearance under bridge decks

or girders shall be kept as 2.0 ft.

In reaches where the main canal is crossing nullah / hill torrent through a cross

drainage structure, there would be possibility of raised water levels / afflux on the

upstream side of nullah. At such locations the bank of main canal facing nullah

upstream shall be converted into flood embankment. The crest level of flood

embankment will be provided with the minimum freeboard of 3.0 ft. from highest flood

level in the nullah to protect against over-topping.

3.5.3.2 Distributaries, Minors & Watercourses

For distributaries, minors and watercourses, the recommended freeboards are as

follows:

Table 3.4: Recommended Bank Top Freeboard

Canal

Freeboard (ft.)

Distributaries

1.50

Minors

1.25

Watercourse

0.75

3.5.4 Berm Width

The berm is the narrow strip of land on either side of the canal, between the canal

prism and toe of the embankment. Berms are generally provided in unlined canals

RHC | AGES | 2015

3-5

DESIGN REPORT

Feasibility Study for the Construction of 95km Irrigation

Canal from Jari Outlet to Iftikharabad District Bhimber- AJ&K

Vol-1:Design Criteria

where depth, D of flow, is greater than 3.0 ft. In lined channels berms are clearly not

required to accommodate change in channel prism or additional discharge.

In main canal, 1.0 ft. wide concrete berm shall be provided on the lining top to

stabilize the toe of earthen bank.

Stabilizing berms of different sizes (based on slope stability requirements) shall be

provided in high earth-fill embankments and deep cut slopes along the main canal as

per geotechnical design criteria.

3.5.5 Canal Embankments

Figure 3.1: Typical Cross section

Embankments would be constructed out of the spoil material from excavation of the

main canal and from borrow areas along the alignment. After establishing the cross

section of canal embankment, before plotting the actual phreatic, line of hydraulic

gradient (assumed line of saturation in the embankment body to which porous soils

offer less resistance to percolation) will be drawn on the cross-section starting from

flood water level at riverside up to the exit face at land side. It is customary that HGL

must not only fall within the embankment but should have a minimum cover of 2 ft. To

adjust this, new embankments will be resized whereas for existing embankments a

back berm (or pushta) will provided to keep the hydraulic gradient within the crosssection.

Hydraulic gradient lines for various types of soils are considered as follows:

Table 3.5: Hydraulic gradient lines for various types of soils

Type of soil

Good soil (Clay)

RHC | AGES | 2015

HGL slope (V:H)

1:4

3-6

DESIGN REPORT

Feasibility Study for the Construction of 95km Irrigation

Canal from Jari Outlet to Iftikharabad District Bhimber- AJ&K

Vol-1:Design Criteria

Average soil (sandy loam)

1:5

Bad soil (Clayey loam)

1:6

Fine silt

1:6

Fine sand

1:8

Coarse sand

1 : 10

The proposed hydraulic gradient for canal and the distributaries is proposed as1 in 5

for both lined and unlined sections. Bank back slopes are chosen to maintain the

seepage phreatic surface at least 0.3m (1ft) within the toe of the embankment for

canals in fill.

For the Main canal, and any branch / distributary canals where patrol roads are

required, one patrol road 20 ft. wide on the top of a bank shall be provided. Non-patrol

bank width is adopted as 12ft.

Table 3.6: Recommended Non Patrol Bank Top Widths

Canal

Main

Branch

Distributary

Minor

Watercourse

3.6

Canal Lining

3.6.1

Lining Thickness and Concrete Strength

(ft)

10.0 to 12.0

8.0 to 10

5.0

3.0

2.0

Main canal lining shall be un-reinforced 4 inches thick concrete placed on the

moistened and compacted sub-grade whereas thickness of un-reinforced lining for

Distributaries and Minors shall be 3 inches.

The concrete for lining shall have minimum cylinder compressive strength of the 3,000

psi at 28-days.

3.6.2

Joints

Longitudinal contraction/ dummy joints formed as V- grooves and filled with

elastomeric sealant would be provided on canal slopes at one-third and two-third

distances from the toe.

Transverse construction joints and profile walls on slopes and in bed spaced 15 feet

apart and longitudinal construction joints and profile walls would be provided at the

centre of bed and along toes.

3.6.3

Canal Structures for Flow Regulation & Control

These structures may be described as follows:

RHC | AGES | 2015

3-7

Feasibility Study for the Construction of 95km Irrigation

Canal from Jari Outlet to Iftikharabad District Bhimber- AJ&K

DESIGN REPORT

Vol-1:Design Criteria

Cross regulators to head up water in the parent channel to divert some of it

through an off take channel, like a distributary

Distributary head regulator to control the amount of water flowing in to off take

channel

Drops and falls to lower the water level of the canal

Escapes, to allow release of excess water from the canal system

Figure 3.2: Canal Structures for Flow Regulation and Control

3.6.3.1 Cross Regulators (Checks)

The main functions of cross regulator are to: i.

Enable effective regulation of the canal system as a whole.

ii.

iii.

Help in closing the breaches in the lower sections of the canal.

iv.

v.

Help raise water level and feed the off-taking distributaries operating in rotation

to their maximum authorized discharge, when the water level in Main Canal is

lower than 67% of the design discharge.

Prevent possibilities of breaches in the tail reaches by absorbing fluctuations in

various upper reaches of the canal system.

Provide road crossing to facilitate communications.

The number and width of spans should allow the design discharge to pass without

causing backup or drawdown of flow. Crest level of head regulator should equal, or be

higher than, the upstream bed level. Upstream and downstream transitions can

reduce head losses and non-separation of flow downstream.

RHC | AGES | 2015

3-8

Feasibility Study for the Construction of 95km Irrigation

Canal from Jari Outlet to Iftikharabad District Bhimber- AJ&K

DESIGN REPORT

Vol-1:Design Criteria

For the distribution system, flow velocity though check structures using stop logs

should be limited to about 3.6 ft/s. With gates the velocity may be increased to about 5

ft/s. The use of stop logs is not recommended for flows greater than 50 cusecs.

3.6.3.2 Distributary Head Regulators (Turnouts)

Main functions of a head regulator are: i.

To control supplies entering into a distributary from Main Canal.

ii.

To control entry of sediment into the distributary.

iii.

To work as a meter for the measurement of discharge.

iv.

To act as a check and help in shutting off the supplies when the distributary is

required to be closed.

v.

Head regulator diverts water from the supply channel to a smaller channel.

The structure usually comprises an inlet, a conduit to convey water through the

bank of the supply channel and an outlet transition. Gates are usually used in

the inlet to control the flow. Crest level of the distributary head regulator is

generally kept 1ft to 2 ft higher than crest level of cross regulator.

Figure 3.3: Cross Regulator and Head Regulator

RHC | AGES | 2015

3-9

Feasibility Study for the Construction of 95km Irrigation

Canal from Jari Outlet to Iftikharabad District Bhimber- AJ&K

DESIGN REPORT

Vol-1:Design Criteria

Figure 3a: Cross Regulator and Head Regulator

Off-taking Alignment: The angle at which a distributary canal off-takes from the parent

canal has to be decided carefully. The best angle is when the distributary takes off smoothly,

as shown in Figure 4(a). Another alternative is to provide both channels (off-taking and parent)

at an angle to the original direction of the parent canal (Figure 4b). When it becomes

necessary for the parent canal to follow a straight alignment, the edge of the canal rather

than the centre line should be considered

in deciding the angle of off-take (Figure 4c).

Head Regulator

Cross Regulator

Figure 3.4: Alignment Types of off taking canal from parent canal

RHC | AGES | 2015

3-10

Feasibility Study for the Construction of 95km Irrigation

Canal from Jari Outlet to Iftikharabad District Bhimber- AJ&K

DESIGN REPORT

Vol-1:Design Criteria

To prevent excessive entry of silt deposition at the mouth of the off-take, the entry

angle should be kept to between 60 and 90 degree. The water entering in to the offtaking distributary canal from the parent canal may also draw suspended sediment

load. The distributary should preferably be designed to draw sediment proportional to

its flow, for maintaining non-siltation of either the parent canal or itself.

3.6.3.3 Canal Falls (Drops)

Main functions of a canal fall are: i.

To lower the water level of canal by dissipating hydraulic energy.

ii.

To negotiate the change in bed elevation of the canal necessitated by difference of

ground slope and canal slope.

iii.

To work as a meter for the measurement of discharge.

Figure 3.5: Typical location for providing canal drop or fall

Location of Fall / Drop: The location of fall is primarily influenced by the topography

of the area and the desirability of combining a fall with other masonry structures such

as bridges, regulators etc. Economy in the cost of excavation is to be considered.

Ideally, there should be balance between excavation and filling. In case of channels

which irrigate the command area directly, a fall should be provided before the bed of

the channel comes into filling. The full supply level of a channel can be kept below

ground level for a distance of about 1500 ft. downstream of fall as command in this

reach can be irrigated by the channels off-taking upstream of the fall.

Types of Canal Fall: The following two types of canal falls shall be considered for

this project:

RHC | AGES | 2015

3-11

Feasibility Study for the Construction of 95km Irrigation

Canal from Jari Outlet to Iftikharabad District Bhimber- AJ&K

DESIGN REPORT

Vol-1:Design Criteria

1) Glacis Fall

A glacis fall usually consists of an inlet transition, a control section, a glacis drop, a

stilling basin and an outlet transition. The inlet portion of the structure transitions the

flow from the channel upstream to the control section. The control section is required

to prevent draw-down of the upstream flow and to prevent racing and scouring of the

upstream channel. The inlet and/or control section should have cutoffs and/or

sufficient length to provide the required percolation path as computed by Lanes

weighted creep method. The glacis section connects to the stilling basin, and the

outlet transition ensures against separation of flow and formation of waves. To provide

tailwater for the hydraulic jump, the water surface at the outlet must be controlled. The

downstream transition may be used to provide backwater by raising the floor of the

transition.

Unless the falls are gated, or have provision for stop logs only percolation, scour and

uplift are likely to be critical. For small lined channels, the channel lining protects

against both scour and percolation failure. For larger lined channels, it would be

prudent to assume that the lining fails and provide cut offs and/or upstream seepage

aprons.

Figure 3.6: Longitudinal Section of Glacis Fall

a.Transitions

Transitions prevent formation of waves which can be troublesome as they travel

through the glacis drop section and energy dissipater, and prevent flow separation

and eddies downstream. As a general consideration the maximum deflection angle in

the water surface should be about 1:1 (inlet section) and 1:3 to 1:4 (outlet section).

The transitions should be symmetrical about the centreline of the canal.

b.Control Section

To prevent sediment deposition upstream of the fall a high crest is avoided, and

(shallow) vertical transitions to and from the glacis provided. Racing of flow upstream

of the fall is prevented by constriction of the flow. The appropriate discharge formula

should be used.

c.Glacis Section

RHC | AGES | 2015

3-12

DESIGN REPORT

Feasibility Study for the Construction of 95km Irrigation

Canal from Jari Outlet to Iftikharabad District Bhimber- AJ&K

Vol-1:Design Criteria

The usual section for the glacis section is rectangular. As friction in the glacis is

negligible, the continuity equation and Bernoullis (energy balance) equation may be

used to compute the flow variables (v2 and y2) at the bottom of the glacis by

balancing with the top of the glacis. The energy balance and continuity equations,

given below, are solved by trial and error for v2 and y2.

y1 + Z + v12/2g = y2 + v22/2g (energy balance)

Q = v1 A1

=v2 A2

(continuity)

where:

y1

= depth of flow upstream at location 1 [ft]

= difference in height between locations 1 and 2.

v1

= flow velocity upstream of glacis at location 1 [ft/s]

= discharge [ft3/s]

= gravitational constant, 32.2 [ft/s2]

d.Stilling Basin

The stilling basin ensures that energy of flow is dissipated in a hydraulic jump.

Horizontal USBR type stilling basins shall be usually provided.

2) Vertical-Drop Fall

The vertical-drop fall uses a raised crest to head up water on the upstream of the

canal section and allows it fall with an impact in a pool of water on depressed floor

which acts like a cushion to dissipate the excess energy of the fall.

Figure 3.7: Longitudinal section of vertical-drop fall

a Transitions

Transitions are required to link the drop section with the channel upstream and

downstream. These should be symmetrical about the centre line of the drop. As head

loss is not an issue these transitions may be abrupt.

e.Control Section

RHC | AGES | 2015

3-13

DESIGN REPORT

Feasibility Study for the Construction of 95km Irrigation

Canal from Jari Outlet to Iftikharabad District Bhimber- AJ&K

Vol-1:Design Criteria

To prevent sediment deposition upstream of the drop a high crest is avoided. Draw

down and racing of flow upstream of the drop may be prevented by a horizontal

constriction of the flow. The free flow broad crested weir formula is applicable and

used to determine the width of the control section, bc:

Q =

3.09 b h1.5

Where:

Q

design discharge (ft3/s)

upstream depth of flow (ft)

crest width (ft)

f. Stilling Basin

The stilling basin downstream of the vertical - drop fall shall be a cistern type. The

cistern is defined as that portion of the fall structure in which surplus flow energy of

the water leaving the crest is dissipated and subsequent turmoil stilled, before the

water passes into lower level channel. Cistern is very efficient when drop is sufficient

so that falling stream becomes almost vertical.

The length Lc and depth x of the cistern can be determined only by empirical

expressions given by different investigators.

The symbols used in these

relations and their values are

in meters

To prevent the falling nappe from adhering to the masonry face of the fall, aeration of

the nappe is necessary and is provided by pipes embedded in wing walls just

downstream of crest.

RHC | AGES | 2015

3-14

DESIGN REPORT

Feasibility Study for the Construction of 95km Irrigation

Canal from Jari Outlet to Iftikharabad District Bhimber- AJ&K

Vol-1:Design Criteria

Selection of Canal Fall: The following criterion shall be applied for the selection of

appropriate type of canal fall:

Drop Height (ft)

3.6.3.4

Type

Distributaries

1.50

Minors

1.25

Watercourse

0.75

Canal Escapes

Canal Escapes are side channels provided for the following purposes:

To release the excess water from the canal

To operate as a temporary control during construction of the canal. As each section

between the escapes is commissioned, flows would pass down the canal and out

of these escapes into a nearby nullah until the next section is commissioned.

To pass the canal full supply discharge to the nullah in the event of sudden closure

of the cross regulator downstream.

To facilitate canal evacuation for periodic inspection during O&M.

To flush sediment which accumulates in the canal reach upstream due to heading

up.

To work as a safety valve in case of canal breach downstream.

To pass accidental inflows either from overtopping of any super- passage flume or

from breach of the right flood protection embankment of Main Canal.

Escapes are designed for full supply designed discharge at head of the canal reach.

Locations are selected according to the physical topography of the terrain, where

there is enough difference in elevation to drain the canal discharge into a nullah.

Figure 3.8: Longitudinal section of different Escapes

RHC | AGES | 2015

3-15

Feasibility Study for the Construction of 95km Irrigation

Canal from Jari Outlet to Iftikharabad District Bhimber- AJ&K

DESIGN REPORT

Vol-1:Design Criteria

Canal Outlets

3.5.6 Location

An outlet would, in general, be located upstream of a drop /control structure. It would

be at the upstream boundary of the Chak/main watercourse so that maximum area is

commanded.

3.5.7 Command Area

As already mentioned, command area of an outlet would be kept between 250 acres

and 400 acres of CCA with limiting maximum discharge of Mogha as 3.0 cusecs.

3.5.8 Types of Outlets

Following five types of outlet, depending upon situation and location, would be used in

the distribution system of the Project:i.

Adjustable Orifice Semi Module (AOSM).

ii.

Open Flume with Roof Block (OFRB).

iii.

Open Flume (OF) Upstream of Fall/Drop Structure

iv.

Open Flume at Tail Cluster

v.

Pipe or Barrel Outlet

In the first four types i.e. AOSM, OFRB or OF, the discharge, though dependent on the

water level in the parent channel, is independent of the water level in the watercourse,

so long as the Minimum Modular Head (mmh) required for its working is available.

In the fifth type of outlet i.e. pipe or barrel outlet, the discharge is a function of

difference between water surface in the channel and the watercourse, if the

downstream end is submerged. In case of free fall, the difference in the canal water

surface and centre of pipe at exit would control the discharge.

All outlets within 200 ft upstream of fall structures would be designed as Open Flumes

(OF).

3.5.8.1 AOSM Outlet

Generally, all outlets shall be of AOSM type except the outlets at tail upstream of fall

and those which have small working heads. Open flume (OF) type would be adopted

where AOSM type cannot be used. AOSM type of outlet is a long throated flume with

a roof block, capable of vertical adjustment, introduced into the upper end of the

parallel throat. So long as the standing wave is steady and remains clear of the exit of

the orifice, the discharge co-efficient does not alter. The roof block is so shaped that

the jet is made to fill the exit of the orifice and jet contraction is suppressed. Cast iron

or pre-cast RCC roof block would be used. Roof block would have its upstream end at

distance of three (3) inches down the throat from the crest and its bottom at a height

of y (varies) above the crest.

Discharge of this type of outlet is computed by the formula:

RHC | AGES | 2015

3-16

Feasibility Study for the Construction of 95km Irrigation

Canal from Jari Outlet to Iftikharabad District Bhimber- AJ&K

DESIGN REPORT

Vol-1:Design Criteria

q 7.3 * Bt * y * ( Hs ) 1 2

Where

q =

Discharge of outlet (ft3/s)

Bt =

Width of the orifice (gullet) in ft (minimum width is 0.20 ft)

Height of bottom of roof block above crest in ft.

y is usually between 1.5 Bt and 2 Bt as far as possible and in no case y should

exceed 0.5 H where H is the height of full supply level in channel above the crest

of the outlet.

Hs =

depression of roof block below water surface level in the parent channel

in feet = (H-y).

Setting of the outlet would be equal to 0.80 of the full supply depth. At this setting, its

sediment drawl capacity would be is 109.7 percent.

Minimum modular head (MMH) required for this type of outlet = 0.82* Hs Bt/2

Figure 3.9: Typical Arrangement for AOSM Outlet

RHC | AGES | 2015

3-17

DESIGN REPORT

Feasibility Study for the Construction of 95km Irrigation

Canal from Jari Outlet to Iftikharabad District Bhimber- AJ&K

Vol-1:Design Criteria

3.5.8.2 Open Flume Outlet with Roof Block (OFRB)

This type of outlet is provided where AOSM cannot be used on account of small

working head available. This outlet is simply a smooth weir with throat constructed

sufficiently long to ensure that the controlling section remains within the parallel throat

at all discharges up to maximum.

The discharge is given by the formula:

q C * Bt * H

Where,

q

Discharge of the outlet in ft3/s.

Bt

Width of outlet in ft (minimum 0.20 ft).

Height of the water level in the channel above crest level.

C

=

Co-efficient, which remains constant as long as the MMH required

for modularity is available. Values of C are as under:

For Bt 0.20 ft to 0.30 ft

2.90

For Bt 0.30 ft to 0.40 ft

2.95

For Bt 0.40 ft

3.00

Setting of the outlet would be kept equal to 0.9 times the full supply depth. In order to

check the over-withdrawal by the outlet, a roof block would always be fixed in the

gullet. The roof block would have its upstream end at a distance of H down the throat

from the crest and its bottom at a height of 0.7 H above the crest. Upstream bottom

corner of the block would be rounded to a radius of 1-1/2 inches. The Minimum

Modular Head (MMH) required for this type of outlet is 0.2 H.

As width of outlet is limited to minimum of 0.20 feet, it is not possible to design the

outlets with 0.90 full supply depth setting for discharges lower than those shown below

for different full supply depths: D (ft)

3

Q (ft /s)

1.0

1.5

2.0

2.5

3.0

3.5

4.0

0.50

0.91

1.80

2.25

2.70

3.15

3.60

3.5.8.3 Open Flume (OF) Outlet Upstream of Fall/Drop Structures

All outlets within 200 ft upstream of a fall structure for lined sections and 500 ft for

unlined section would be designed as open flume (OF) without roof block. In such

cases, the crest level of open flume outlet would be the same as that of bed in the

parent channel.

3.5.8.4 Open Flume (OF) Outlet at Tail Cluster

At tail, open flume without roof block would be used. H, the height of full supply level

in the channel above crest level of the OF outlet would kept as 1.00 ft or 0.75 ft in an

unavoidable case. Zero of the gauge would be fixed at crest level. Gauge reading at

RHC | AGES | 2015

3-18

Feasibility Study for the Construction of 95km Irrigation

Canal from Jari Outlet to Iftikharabad District Bhimber- AJ&K

DESIGN REPORT

Vol-1:Design Criteria

tail would,

therefore,

directly

indicate

whether or

not the tail

is getting

its

authorized

discharge.

Crests of

all outlets

at

tail

would be

kept at the

same

level.

Figure 3.10: Typical Arrangement for Open Flume Outlet without Roof Block

Figure 3.11: Typical Arrangement of Tail Cluster Outlets

RHC | AGES | 2015

3-19

DESIGN REPORT

Feasibility Study for the Construction of 95km Irrigation

Canal from Jari Outlet to Iftikharabad District Bhimber- AJ&K

Vol-1:Design Criteria

3.5.8.5 Pipe or Barrel Outlet

This type of outlet works as semi module, if it has a free fall. In drowned condition, it

works non-modular.

Use of this type of outlet is avoided, as far as possible. Its use would be justified in

case of lift outlets when the working head available or the discharge of the outlet is so

small that a semi-modular outlet cannot be designed.

Discharge of pipe or barrel outlet is given by the formula:

q=

CA (H )

Where,

q

discharge of outlet in (ft3/s)

area of the pipe or barrel in ft2.

H

=

distance in feet from the water level in the channel to the centre of

the pipe or barrel, in case the outlet has free fall; and if it is drowned i.e. it

discharges into a watercourse in which the water level is above top of the

barrel, then "H" is the difference in levels in the channel and the watercourse.

C

=

co-efficient which is taken as 5.0 for free fall outlet and 6.4 for

drowned outlet.

Figure 3.12: Typical Plan & cross-section of an Outlet

3.6

Cross-Drainage Structures

Cross drainage structures are constructed to negotiate an aligned channel over, below

or at the same level of stream crossing that channel. These structures can be

classified under the following three broad categories:

RHC | AGES | 2015

3-20

DESIGN REPORT

Feasibility Study for the Construction of 95km Irrigation

Canal from Jari Outlet to Iftikharabad District Bhimber- AJ&K

1)

Structures for a carrier channel over a natural stream

Culverts)

Vol-1:Design Criteria

(Aqueducts and

2) Structures for a carrier channel below a natural stream (Super-passages and

Siphons)

2) Structures for a carrier channel crossing a natural stream at same level (Level

Crossings)

3.6.1 Aqueducts

An aqueduct is a cross-drainage structure constructed where the drainage flood level

is below the bed of canal. Small drains may be taken under the canal through culverts

but for streams crossings it is economical to flume the canal over the stream.

The structure would consist of: flume / trough to carry the canal water, supported on

piers or piles foundation; sometimes a bridge to maintain continuity of the canal road

supported; foot bridge on trough walls; upstream and downstream flared out

transitions in canal; upstream guide banks in the stream to guide the flow through the

crossing without inducting excessive scour; upstream and downstream stone aprons;

stone pitching for slope protection.

Figure 3.13: Typical Plan & cross-section of an Aqueduct

3.6.2 Superpassages

Where the canal section is primarily in cut as it crosses a nullah, the storm runoff

water would be conveyed over the canal, clear of the canal water surface. Such

structure called super-passage is appropriate where the nullah invert level is between

canal bed level and full supply level (FSL) or above FSL. The canal section geometry

would be kept unchanged to minimize head losses.

RHC | AGES | 2015

3-21

Feasibility Study for the Construction of 95km Irrigation

Canal from Jari Outlet to Iftikharabad District Bhimber- AJ&K

DESIGN REPORT

Vol-1:Design Criteria

The structure would consist of: trough to carry the nullah water, supported on piers or

piles foundation; downstream bridge to maintain continuity of the canal road

supported; foot bridge on trough walls; stilling basin for energy dissipation; upstream

and downstream flared out transitions; upstream guide banks to guide the flow

through the crossing without inducting excessive scour; upstream and downstream

stone aprons; stone pitching for slope protection; upstream and downstream cutoffs;

downstream PCC blocks over inverted filter, and reinforced concrete canal lining

underneath the trough.

Figure 3.14: Typical Cross-section of a Super-passage

Flume width to pass the nullah design discharge would be governed by heading up of

flood water on the upstream side. The crest of flume/trough shall be fixed with subcritical flow and generating maximum velocity of 8 ft/sec. Guide banks would provide a

free board of 3.0 feet above the raised water level.

3.6.3 Culverts

Where the canal section is completely in fill, the nullah water be freely flowing under

the canal through concrete barrels. The structure would comprise: multiple barrels

carrying nullah water under canal section; upstream head wall; downstream

transitions; downstream cistern floor; upstream and downstream stone aprons; stone

pitching for slope protection; and cutoffs.

Many irrigation structures incorporate a culvert or a bridge in order to facilitate

vehicular access within the scheme. Where a road crosses a channel at some

distance from any other structure, it will be necessary to provide an independent

culvert or bridge. Road crossings usually comprise either pipe or box culverts to

convey channel water under the road.

The culvert acts as a constriction and creates a backwater effect to the approach flow,

causing a pondage of water above the culvert entrance. The flow within the barrel

itself may have a free surface with subcritical or supercritical conditions depending on

the length, roughness, gradient, and upstream and downstream water levels of the

culvert. If the upstream head (H) is sufficiently large the flow within the culvert may or

RHC | AGES | 2015

3-22

Feasibility Study for the Construction of 95km Irrigation

Canal from Jari Outlet to Iftikharabad District Bhimber- AJ&K

DESIGN REPORT

Vol-1:Design Criteria

may not fill the barrel, and its hydraulic performance depends upon the combination of

entrance and friction losses, length of barrel, and the downstream backwater effects.

3.6.3.1 Design Considerations for Pipe Culverts

Pipe culverts are often designed to flow full, with the pipe soffit submerged by at least

8 inches both upstream and downstream. The pipe typically has a fall of 0.05 m.

Figure 3.15: Flow through a Culvert

Table 3.7: Types of flow in the Barrel of Pipe Culvert (Chow, 1983)

For culverts under patrol roads within an irrigation scheme, the minimum depth of

cover to the pipe should be about 0.90 m. If this is impracticable, then consideration

should be given to:

surrounding the pipe in concrete;

using smaller pipes (for example by using 2 x 0.60 m diameter pipes instead of a

single 0.90 m diameter pipe)

RHC | AGES | 2015

3-23

Feasibility Study for the Construction of 95km Irrigation

Canal from Jari Outlet to Iftikharabad District Bhimber- AJ&K

DESIGN REPORT

Vol-1:Design Criteria

Transitions are required at both the inlet and outlet of the culvert barrel. An

accelerating water velocity usually occurs at the inlet, and a decelerating velocity at

the outlet. Transitions reduce head losses and prevent channel erosion by making the

velocity changes less abrupt.

Pipe collars may be required to reduce seepage flows along the outside of the pipe.

This should be checked using Lanes seepage path length method, particularly for any

culvert where the channel water surface is significantly higher than the potential point

of relief of the percolating water. Pipe collars may also be necessary to discourage

rodents from burrowing along the pipe.

Channel erosion protection is required in earthen channels, and usually takes the form

of dry stone pitching placed upstream and downstream of the transitions. In addition,

for large flows, cutoffs may be provided to the transition structures extending below

scour depth.

3.6.3.2 Design Considerations for Box Culverts

Box culverts can be single or multiple, with square or rectangular section. They can be

constructed from reinforced concrete, or comprise concrete floor and roof slabs with

masonry walls. The minimum height of the culvert should be about 3 ft. since anything

smaller than this is probably more easily constructed using concrete pipes. Box

culverts are normally designed for free flow, with the water surface below soffit level.

Head loss across the culvert can be calculated by summing entry and exit losses, plus

friction loss in the culvert which may be determined using Mannings equation.

Box culverts can be designed to flow full, in which case both the upstream and

downstream soffits should be drowned by at least 8 inches to prevent gulping.

It is recommended that the culvert invert is, in any case, not depressed more than d/4

below the bed level, where d = depth of flow in the culvert.

RHC | AGES | 2015

3-24

You might also like

- Design of Check DamDocument5 pagesDesign of Check DamNaveen Yadav90% (10)

- Check Dam Design Boosts IrrigationDocument21 pagesCheck Dam Design Boosts Irrigationrajanravi83100% (1)

- Chapter 2 2 GroynesDocument20 pagesChapter 2 2 GroynesGetahun Tadesse100% (1)

- Design River Intake TowerDocument24 pagesDesign River Intake TowerDikshant SinghNo ratings yet

- ROData XL700Document16 pagesROData XL700siddhasivaNo ratings yet

- Designs of Canals and CM&CD WorksDocument61 pagesDesigns of Canals and CM&CD WorksVenkataLakshmiKorrapatiNo ratings yet

- Canal Alignment & Design Canal SectionDocument26 pagesCanal Alignment & Design Canal SectionAshishNo ratings yet

- Is.6966.1.1989. Hydraulic Design Indian StandardDocument19 pagesIs.6966.1.1989. Hydraulic Design Indian StandarderamitdhanukaNo ratings yet

- Design of Irrigation CanalsDocument28 pagesDesign of Irrigation CanalsRaja Rishi100% (4)

- Design of CanalDocument23 pagesDesign of CanalPrashant PatilNo ratings yet

- Design of Surplus WeirDocument41 pagesDesign of Surplus WeirNiveditha0% (1)

- Canal DesignDocument34 pagesCanal Designniranjan100% (2)

- Design of Syphon AqueductDocument110 pagesDesign of Syphon AqueductD.V.Srinivasa Rao100% (12)

- Design of Irrigation StructuresDocument21 pagesDesign of Irrigation StructuresJames K. KirahukaNo ratings yet

- Hydraulic Structure - 2 Chapter-4Document43 pagesHydraulic Structure - 2 Chapter-4Debela Kebede Kera100% (1)

- Hydraulic Structures - Design of AqueductDocument5 pagesHydraulic Structures - Design of AqueductAsif Muhammad100% (1)

- Hydraulic Analysis DrainageDocument26 pagesHydraulic Analysis Drainagenhiyzhar monimoNo ratings yet

- Barrage DesignDocument30 pagesBarrage DesignFaisal Junaid0% (1)

- Unit VI Chapter 12-River Training Structures (2 Lectures) SyllabusDocument17 pagesUnit VI Chapter 12-River Training Structures (2 Lectures) SyllabusAnirudh ShirkeNo ratings yet

- Canal Outlets&Modules Worked Out ExampesDocument34 pagesCanal Outlets&Modules Worked Out ExampesrsherazNo ratings yet

- Eng. H.A.Jayantha de Silva Di's Office AnuradhapuraDocument3 pagesEng. H.A.Jayantha de Silva Di's Office AnuradhapuraAnuradha GunawardhanaNo ratings yet

- Canal Syphon ProgrammeDocument29 pagesCanal Syphon Programmechitransh200289% (9)

- Detail Hydrology Report of Arun River BridgeDocument18 pagesDetail Hydrology Report of Arun River Bridgeeverestking100% (1)

- 31 Design of Surplus of Weirs Dams PDFDocument166 pages31 Design of Surplus of Weirs Dams PDFaskcmiitmNo ratings yet

- CulvertsDocument14 pagesCulvertsrameshbabu_1979No ratings yet

- Hydrologic & Hydraulic AnalysisDocument7 pagesHydrologic & Hydraulic AnalysisJove RevocalNo ratings yet

- 5 A Surface Irrigation System PDFDocument65 pages5 A Surface Irrigation System PDFsewmehon amareNo ratings yet

- Volume-I Micro Irrigation ProjectDocument65 pagesVolume-I Micro Irrigation ProjectStudent Admissions100% (1)

- Chapter 7 Diversion WeirsDocument36 pagesChapter 7 Diversion WeirsMohamoud AbdulahiNo ratings yet

- DLRB DESN PROC Ver.1-5.11.2020Document11 pagesDLRB DESN PROC Ver.1-5.11.2020S N satyanarayanaNo ratings yet

- Barrage 215Document112 pagesBarrage 215Malik NabilNo ratings yet

- Canal FallsDocument20 pagesCanal FallsRajesh KhadkaNo ratings yet

- TRRLDocument1 pageTRRLFRANCIS CONRADNo ratings yet

- Bridge Hydrology ClassDocument16 pagesBridge Hydrology ClassAbhishek100% (1)

- 8B SWMMDocument22 pages8B SWMMMatija MavrovićNo ratings yet

- Stepped Channel DesignDocument6 pagesStepped Channel DesignVivek GuptaNo ratings yet

- Earthen EmbankmentDocument24 pagesEarthen EmbankmentKunal KumarNo ratings yet

- Design of Check DamDocument4 pagesDesign of Check DamArnab Saha50% (2)

- WRI7 - 8 - 9 - Hydrograph Analysis, Unit Hydrograph, S-Hydrograph, Numerical ProblemsDocument13 pagesWRI7 - 8 - 9 - Hydrograph Analysis, Unit Hydrograph, S-Hydrograph, Numerical ProblemsmustafaNo ratings yet

- Chapter Four 4. Irrigation Canals and DesignDocument8 pagesChapter Four 4. Irrigation Canals and DesignBrooke AbebeNo ratings yet

- Weir Estimate Without GateDocument8 pagesWeir Estimate Without GateManan Parikh100% (1)

- Design of BarrageDocument27 pagesDesign of BarrageZ_Jahangeer100% (1)

- DesignDocument76 pagesDesignsanibkoolNo ratings yet

- Rock Sizing For Culvert Outlets PDFDocument0 pagesRock Sizing For Culvert Outlets PDFwrobinsonf2scomNo ratings yet

- NIT - C5 - Design Flood (24 Slides) - (PASHA - BHAI) ™Document24 pagesNIT - C5 - Design Flood (24 Slides) - (PASHA - BHAI) ™LikhitaKaranam100% (1)

- Design of Small DamsDocument5 pagesDesign of Small DamsNarendra Singh BhandariNo ratings yet

- Hydraulic Structure UNIT 2Document74 pagesHydraulic Structure UNIT 2rvkumar3619690100% (1)

- SAMPLE Design Statement of A Earthern Canal - Distributary No-10 Offtaking From Machagaon Canal in The District of Jagatsighpur, Odisha State, India.Document82 pagesSAMPLE Design Statement of A Earthern Canal - Distributary No-10 Offtaking From Machagaon Canal in The District of Jagatsighpur, Odisha State, India.Parthasarathi DalaiNo ratings yet

- Canal Syphon (Barrel)Document21 pagesCanal Syphon (Barrel)Rajinder Singh100% (1)

- Engineering Hydrology: Engr. Anum Khalid Civil Engineering Department University of Engineering and Technology LahoreDocument13 pagesEngineering Hydrology: Engr. Anum Khalid Civil Engineering Department University of Engineering and Technology LahoreAshhad ShafiqueNo ratings yet

- Weir Dsign and LayoutDocument5 pagesWeir Dsign and LayoutBehar Abduraheman100% (1)

- Unit VI C. D. Works Chapter 11 (3 Lectures) Syllabus: 1. IntroductionDocument14 pagesUnit VI C. D. Works Chapter 11 (3 Lectures) Syllabus: 1. IntroductionAnirudh ShirkeNo ratings yet

- 6300 LectureNotes PDFDocument312 pages6300 LectureNotes PDFAbera MamoNo ratings yet

- Chute Spillway 2Document6 pagesChute Spillway 2Fasil GeberemeskelNo ratings yet

- AqueductDocument36 pagesAqueductAnonymous r63bVFCc0% (1)

- Embankment Dams 1Document7 pagesEmbankment Dams 1Schmooz ErNo ratings yet

- Chap 5 and 6Document4 pagesChap 5 and 6Daisy MaghanoyNo ratings yet

- Srinagr Power ChanelDocument3 pagesSrinagr Power Chaneljhon smithNo ratings yet

- Is 7784 1 1993 PDFDocument18 pagesIs 7784 1 1993 PDFkalli2rfdfNo ratings yet

- 9 Design of Main Canal and Structures (New)Document58 pages9 Design of Main Canal and Structures (New)Emmanuel Ferry Borre75% (4)

- Optimum Hydraulic and Structural Design of Inverted SiphonDocument15 pagesOptimum Hydraulic and Structural Design of Inverted SiphonMuhammad EhtshamNo ratings yet

- Mazaq Key AdaabDocument49 pagesMazaq Key AdaabMuhammad ZeeshanNo ratings yet

- Ghustakh e Rasool Ki SazaDocument160 pagesGhustakh e Rasool Ki SazaIslamic Reserch Center (IRC)No ratings yet

- Working With Digital Elevation Models and Digital Terrain Models in Arcview 3.2Document10 pagesWorking With Digital Elevation Models and Digital Terrain Models in Arcview 3.2Chilo PerezNo ratings yet

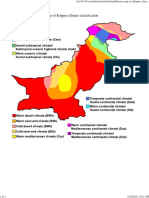

- Pakistan Map of Köppen Climate ClassificationDocument1 pagePakistan Map of Köppen Climate ClassificationMuhammad ZeeshanNo ratings yet

- RedundancyDocument5 pagesRedundancyMuhammad ZeeshanNo ratings yet

- SurahTaghabun (Ayah11 18)Document9 pagesSurahTaghabun (Ayah11 18)Muhammad ZeeshanNo ratings yet

- WR401 Head RegulatorDocument11 pagesWR401 Head RegulatorAnkit SinglaNo ratings yet

- NTS Book For GAT GeneralDocument142 pagesNTS Book For GAT GeneralMuzaffar AhsanNo ratings yet

- SurahTaghabun (Ayah11 18)Document9 pagesSurahTaghabun (Ayah11 18)Muhammad ZeeshanNo ratings yet

- Mangla Dam Raising - A ReviewDocument5 pagesMangla Dam Raising - A ReviewMuhammad Zeeshan100% (1)

- Introductory Digital Image ProcessingDocument7,949 pagesIntroductory Digital Image ProcessingMuhammad ZeeshanNo ratings yet

- How To Align A Non-Georeferenced Image To An Existing Geographic Layer or Georeferenced ImageDocument4 pagesHow To Align A Non-Georeferenced Image To An Existing Geographic Layer or Georeferenced ImagerarzansyahNo ratings yet

- ArcGIS Georeferencing An Image v10.0Document4 pagesArcGIS Georeferencing An Image v10.0Muhammad ZeeshanNo ratings yet

- Jannat Se Mehroom KR Daine Wale Chalees AmalDocument34 pagesJannat Se Mehroom KR Daine Wale Chalees AmalMuhammad ZeeshanNo ratings yet

- Most Useful WebsitesDocument4 pagesMost Useful WebsitesouynyNo ratings yet

- Definitive Guide To Lead NurturingDocument42 pagesDefinitive Guide To Lead NurturingPeter RismanNo ratings yet

- Conjunctive Use of Surface & Groundwater and Managed Aquifer Recharge TechniquesDocument40 pagesConjunctive Use of Surface & Groundwater and Managed Aquifer Recharge TechniquessakthivelNo ratings yet

- Sewage Treatment Plant in Ahmedabad Baroda Surat Rajkot - Gujarat-IndiaDocument9 pagesSewage Treatment Plant in Ahmedabad Baroda Surat Rajkot - Gujarat-IndiaShubham India - Sewage Treatment PlantNo ratings yet

- Hydro EnergyDocument28 pagesHydro EnergyAbhishek MalhotraNo ratings yet

- Flexim Case Study Anastasia Island Wastwater Treatment Plant With Air inDocument14 pagesFlexim Case Study Anastasia Island Wastwater Treatment Plant With Air inAngel AvilaNo ratings yet

- UntitledDocument15 pagesUntitledAditya VermaNo ratings yet

- CROPWAT Guide Estimates Irrigation NeedsDocument10 pagesCROPWAT Guide Estimates Irrigation NeedsamityalwarNo ratings yet

- 2013-Pump Sizing With Exercises r1Document25 pages2013-Pump Sizing With Exercises r1edhy_03No ratings yet

- Hill Roads: Design and Construction ChallengesDocument22 pagesHill Roads: Design and Construction ChallengesArjun PaudelNo ratings yet

- Trade-Wind Inversion: Tropical Meteorology Lecture Notes, Page 69Document8 pagesTrade-Wind Inversion: Tropical Meteorology Lecture Notes, Page 69Karen CondaNo ratings yet

- Lecture # 03. Irrigation Water Quality & Basic TerminologiesDocument31 pagesLecture # 03. Irrigation Water Quality & Basic TerminologiesMuhammad UsmanNo ratings yet

- Wins ReportDocument17 pagesWins ReportArnel De QuirosNo ratings yet

- Plumbing in USA 1,000 December 23Document23 pagesPlumbing in USA 1,000 December 23Abdullah Ashik AdnanNo ratings yet

- CWSRF InfographicDocument1 pageCWSRF InfographicAnonymous 0HRTZSXSXNo ratings yet

- Flood ResilientDocument12 pagesFlood Resilientmohammady10No ratings yet

- Water TariffDocument625 pagesWater TariffLlucifer ImpulseNo ratings yet

- Exercises GW Modelling Handout 2012 1Document110 pagesExercises GW Modelling Handout 2012 1Afar TubeNo ratings yet

- Basic Irrigation BookDocument300 pagesBasic Irrigation Bookhaithamelramlawi7503100% (3)

- Types of Flooding in Australia - Flash, River, CoastalDocument2 pagesTypes of Flooding in Australia - Flash, River, CoastalMissy_T0% (1)

- Lay Out New PL Press QltyDocument68 pagesLay Out New PL Press QltyDadan Hendra KurniawanNo ratings yet

- Is 10135 1985 PDFDocument16 pagesIs 10135 1985 PDFRony JoyNo ratings yet

- CH 4 Sewers DesignDocument11 pagesCH 4 Sewers DesignmavessNo ratings yet

- Riparian Rights Explained:: Land DrainageDocument2 pagesRiparian Rights Explained:: Land Drainagefrankieb99No ratings yet

- Hydraulic Grade LineDocument0 pagesHydraulic Grade LinemuazeemKNo ratings yet

- Techno-Commercial Offer 100 KLD STP, Betul Based On MBBR HybridDocument9 pagesTechno-Commercial Offer 100 KLD STP, Betul Based On MBBR HybridTech MongerNo ratings yet

- Booster Pump Flow Rate CalculationDocument2 pagesBooster Pump Flow Rate CalculationSachinMpNo ratings yet

- Sanitary Works Specifications and LayoutDocument1 pageSanitary Works Specifications and LayoutMary Joy AzonNo ratings yet

- Chapter 2Document18 pagesChapter 2Bazi habeshaNo ratings yet

- Analysis of Rainfall-Runoff Neuron Input Model With Artificial Neural Network For Simulation For Availability of Discharge at Bah Bolon WatershedDocument8 pagesAnalysis of Rainfall-Runoff Neuron Input Model With Artificial Neural Network For Simulation For Availability of Discharge at Bah Bolon WatershedErvan KamalNo ratings yet