Professional Documents

Culture Documents

Common Position Paper 2012 Signed B7 PDF

Uploaded by

carbasemyOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Common Position Paper 2012 Signed B7 PDF

Uploaded by

carbasemyCopyright:

Available Formats

_____________________________________________________________________________________________

Fuel Requirements for Diesel Fuel Injection Systems

Diesel Fuel Injection Equipment Manufacturers

Common Position Statement 2012

Please note that this statement supersedes all previous joint statements

Background

The continuous world-wide tendency to increase engine performance and reduce emissions has necessitated

the development of new generations of enhanced diesel fuel injection equipment, supporting the

achievement of stringent legislation targets. Rising injection pressures and multiple injections result in

higher operating temperatures, increased contact pressures and reduced clearances. Minimum standards of

fuel quality are essential to maintain durability and emission compliance over a longer duration.

International standards have been established defining fuel quality and continue to be revised on an as

needed basis. Alterations to fuel quality, e.g. by increasingly severe refinery hydro-processing being

introduced to remove sulphur also reduce the content of aromatics and destroy surface active compounds

and antioxidants. Removal of these beneficial compounds effects boundary lubrication, commonly known

as lubricity, and inherent oxidation stability and must be compensated for. Fuel parameters such as cetane

number, viscosity, density, lubricity, oxidation stability, sulphur and aromatic content together with the

absence of free water and dirt contamination are key parameters required to ensure performance of

equipment in the field.

Biofuels are becoming increasingly available to end-users. In Europe (EU) and in the United States of

America (USA), as well as in other countries, fuel sources such as rapeseed methyl ester (RME), soybean

methyl ester (SME), palm oil methyl ester (PME) and others, collectively known as fatty acid methyl esters

(FAME), are being used as alternatives and extenders for mineral oil derived fuels. Furthermore, the EU

Biofuels Directive 2003/30/EC requires member states to ensure that a minimum proportion of biofuels is

placed on the market. It must be recognized that the physical and chemical characteristics of bio

components are significantly different to conventional fuels and that care must be taken in their

specification and use.

Diesel fuel injection equipment (FIE) manufacturers fully support the development of alternative sources of

fuel. Where possible, compatible components were provided and validated. However, many vehicles,

engines and equipment are not designed to run on them. It is recommended to refer to the vehicle and

engine manufacturers Limitations of Use documents for guidance. Prior to use, users should also check

whether appropriate biofuel quality is guaranteed.

General Diesel Fuel Quality

Standards: The European fuel standard EN 590:2009 embodies the latest fuel quality requirements. Fuel

injection equipment manufacturers' products might not meet the expected lifetime performance and

emissions targets if EN 590:2009 fuel or fuel with similar properties to the EN 590:2009 specification is not

used. The responsibility therefore must fall to the equipment user and/or the fuel supplier to ensure that the

fuels used are compatible with the fuel system and objectives of the emissions legislation.

Fuel Requirements for Diesel Fuel Injection Systems Joint FIE Manufacturers Statement, issued in March 2012

_____________________________________________________________________________________________

Users of diesel engines are reminded that fuel standards apply only to the point of delivery from the

distribution network, generally from the pump nozzle of the filling station. From this point on it is the

users responsibility to protect the fuel from free water and dirt contamination to enable engines to achieve

their designed performance, emission, and durability targets. Engine/vehicle manufacturers should provide

appropriate fuel conditioning depending on application, duty cycle, territory, and climate.

Additives: Fuel standards are performance based. Meeting the standard specifications is a minimum

requirement. In order to further improve fuel quality, the use of additives in the appropriate amount is

helpful provided that harmful side-effects can be excluded (e.g. internal injector deposits). Additives

demonstrated to have harmful effects that result in field issues must not be used, even if the blended fuel

meets the performance standard. It is the responsibility of the fuel provider to exclude harmful side-effects.

Lubricity: It is essential that the lubricity of the fuel as measured by the HFRR test specified in ISO

12156-1 meets the requirement of a wear scar diameter not greater than 460 microns. In addition, it is

recommended by the Diesel FIE manufacturers, that first fill of the fuel tank should be with fuel with

good lubricity characteristics (HFRR < 400 m) in order to guarantee good run-in of the injection system

components. The US diesel specification (ASTM D975-11) and others includes a lubricity value of 520 m

maximum (according to ASTM D6079-11). Fuel with a lubricity exceeding 460 m can adversely affect the

lifetime of some fuel lubricated injection system components.

Cleanliness: The fine tolerances needed to produce high injection pressures demand good fuel cleanliness,

with increasing emphasis on small particle sizes. The fuel injection equipment manufacturers encourage the

standardization bodies in the EU and US to elaborate a precise test method for the determination of total

contamination and for particle counting required to ensure the demand for improved fuel cleanliness of

future FIE systems is met.

Deposits: Local and temporary deviations in fuel composition, additivation and/or contamination are

responsible for in-system deposits, which impede the precise dynamics of the high pressure injection

equipment. Such deposits affect vehicle performance, leading to complaints by the end customer. Two

predominant types of deposits have been identified: metal-based salts and soaps as well as polymeric

organic material with specific additive-related structural elements.

Among the metal containing deposits sodium is prevalent; with even trace contamination having an effect.

Sodium contamination can be involuntarily transferred from refinery, pipeline transportation, fuel drying,

storage and distribution.

Deposits on the internal surfaces can also be formed by chemical reaction/polymerisation of additives with

acidic fuel components. Nitrogen functionalised additives, e.g. detergents of the polyisobutylene succinimide (PIBSI) type were identified to form conversion products of higher molecular weight.

EN590:2009 section 5.4.3 states Diesel fuel shall be free from any adulterant or contaminant that may

render the fuel unacceptable for use in diesel engine vehicles. It is the task and responsibility of the fuel

industry (refineries, additive producers, pipeline operators, transport sector and fuel storage facilities) to

apply increased diligence and protective measures to prevent deposit related incidents and ensure the fuel is

suitable for use in modern high pressure fuel injection systems.

It should be noted that exposure of fuel to surfaces containing copper (Cu), zinc (Zn) or lead (Pb) can

adversely affect fuel quality and should be minimised.

Fuel Requirements for Diesel Fuel Injection Systems Joint FIE Manufacturers Statement, issued in March 2012

_____________________________________________________________________________________________

Fatty Acid Methyl Ester (FAME)

Standards: The European FAME standard EN 14214:2009 provides minimum quality requirements and

limits relevant side products and tramp chemicals from FAME processing. In order to reduce the risk of

premature failure of the fuel system, FAME must conform to EN 14214:2009, regardless whether used as

100 % fuel (B100) or as a blending component.

The European diesel fuel standard EN 590:2009 includes diesel blends with up to 7 % FAME (B7). All

injection equipment is released for admixtures up to a maximum of 7 % FAME (meeting EN 14214:2009)

with the resulting blend meeting the EN 590:2009 standard.

A more extensive revision of EN 14214:2009 is ongoing to facilitate blending of up to 10 % FAME (B10).

The FIE manufacturers support the development of a European B10 standard rather than individual norms

of the member states, and do not approve national decrees. The discussion about introducing higher blends

is dominated by compatibility concerns with the existing fleet, consequently limiting release of higher

blend rates to special vehicle applications only.

CEN is working on a feasibility study and preliminary specification for B30. B30 is intended for use in

captive fleets only, as already practised in France for some years. An approval for the use of any blend with

a high FAME content or of B100 requires a customised validation for the intended application(s).

The FIE manufacturers registered that the use of fatty acid ethyl esters (FAEE) is proposed in France.

Knowledge about the characteristics of FAEE is still very limited, and testing with FAEE or FAEE blends

in fuel systems has only been performed exemplarily. Progress in the normalisation of FAEE on the

European level under CEN is required in order to create a reference basis for validation.

In the US, the quality of fatty acid esters is defined in the ASTM D6751-11b standard provided for different

fatty acid alkyl esters (FAAE) intended for use in blends at concentrations of up to 20 %. Two additional

standards have been developed to describe qualities of the blended fuels up to B5 (ASTM D975-11) and

from B6 to B20 (ASTM D7467-10), respectively.

The use of B5 according to ASTM D975-11 is tolerated by the FIE manufacturers, although the absence of

a stability requirement is seen as a large risk that should be reduced as soon as possible. Blends containing

in excess of 5 % (V/V) FAAE (ASTM D6751-11b) require positive validation of specific issues associated

with higher concentrations of low stability FAME (also in view of the fact that ASTM D6751-11b allows

the use of fatty acid alkyl esters [other than methyl esters], which are not yet successfully evaluated).

FAME Stability: The reduced stability of FAME is of particular concern. Aged or poor quality FAME

contains organic acids like formic acid and polymerisation products. The acids attack many components,

and the polymers can lead to plugged filters, sediments and sticking moving parts drastically reducing the

service life of the FIE. Long standstill periods bear the risk of reaching the point when the ageing reserve of

the fuel inside the tank and FIE is depleted. Extra measures are recommended like well-timed monitoring of

fuel stability or precautionary fuel exchange, followed by an idling operation when such extended periods

of inactivity are anticipated. This also affects seasonally operated equipment such as harvesters or

emergency generators and vehicles to be exported overseas. For this reason FAME-free EN 590 fuel is

highly recommended for first fill or extended inactive periods.

Fuel stability is best described by the parameter ageing reserve, determined as induction period (IP)

according to the EN 15751:2009 test method. B5 and B7 with an IP of 20 h has been demonstrated to be

sufficiently stable for standard usage conditions in Europe. The stakeholders of CEN/TC19/WG24 conFuel Requirements for Diesel Fuel Injection Systems Joint FIE Manufacturers Statement, issued in March 2012

_____________________________________________________________________________________________

sidered it essential to maintain the fuel stability level of B5 and B7 also for B10 and B30 and agreed to

adapt future fuel standards accordingly.

In the US, ASTM D975-11 standard for diesel (B0 to B5) does not contain any mandatory stability

requirement; the standards for B6 to B20 blends (ASTM D7467-10) and for pure FAME (ASTM D675111b) do not include sufficient stability safeguards present in both the EN 590:2009 and EN 14214:2009

standards. ASTM D6751-11b for FAME requires a minimum IP of 3 hrs, which is half of that required by

EN 14214:2009, and for B6 to B20 blends an induction period of 6 hrs is fixed in ASTM D7467-10,

compared to 20 hrs in EN 590:2009. It is expected that the operating performance and lifetime of fuel

injection systems will be adversely affected by using fuels with reduced stability. To secure sufficient

stability of diesel/FAME blends world-wide the FIE manufacturers request comparable regulations for

every diesel fuel specification that allows blending of FAME. FIE manufacturers are powerless to prevent

issues originating from the use of insufficiently stable fuel. Fuel suppliers need to take appropriate

measures for stabilising fuels and are responsible for ensuring that the level of oxidation stability is

sufficient to prevent damage due to depletion of oxidation reserve during use.

FAME Impurities: As FAME is being produced from an increasing number of new feedstock uncertainties

are associated with additional impurities that might not become evident until vehicle operation. Further

concerns are minor components of FAME with high molecular weight like steryl glycosides leading to filter

plugging and use of diesel or FAME additives with interacting chemistries. There are also several possible

risks associated with fuel delivery and supply chain, such as accumulated metal ion impurities affecting the

quality of the final blend at the point of sale.

FAME Compatibility: Material issues may occur on older vehicles, designed before the use of FAME was

considered. As FAME concentrations increase, compatibility issues become more likely with filters, hoses

and seals being the most likely components affected.

Other Biofuels: The FIE manufacturers support the use of bioparaffins obtained by hydro-treatment or coprocessing of plant oil. Due to their paraffinic nature and high fuel and transport system compatibility,

bioparaffins are also well-suited for blends with biogenic portions above 7 %. High blend rates of (bio-)

paraffins or use in their pure form require extra validation. The necessary validation extent will depend on

the parameters and limits defined in the CEN Workshop Agreement CWA 15940:2009 and in the future

CEN Technical Specification of paraffinic diesel fuel and FAME blending.

The FIE manufacturers note that their high pressure injection equipment is not designed to run on

unesterified plant oil, even if such fuel meets all requirements defined in the CEN Workshop Agreement

CEN/TC WS 56 or in existing national standards such as DIN V 51605.

Fuel Requirements for Diesel Fuel Injection Systems Joint FIE Manufacturers Statement, issued in March 2012

You might also like

- 01.03.01 Coolant TR0199991209109 - enDocument18 pages01.03.01 Coolant TR0199991209109 - enEbied Yousif AlyNo ratings yet

- Technology Forum - Indoneusa - Gas Engines (Oct.2014) V2Document42 pagesTechnology Forum - Indoneusa - Gas Engines (Oct.2014) V2Frana HadiNo ratings yet

- Machinery Lubrication November December 2017 PDFDocument89 pagesMachinery Lubrication November December 2017 PDFJorge Cuadros BlasNo ratings yet

- Petro Canada Lubricants Handbook 2012 English PDFDocument212 pagesPetro Canada Lubricants Handbook 2012 English PDFsoumya ghoshNo ratings yet

- Shell Turbo T46 PDFDocument2 pagesShell Turbo T46 PDFdionisio emilio reyes jimenezNo ratings yet

- Engine Oil ChartDocument1 pageEngine Oil ChartprsovNo ratings yet

- Approved Lubrication DDocument2 pagesApproved Lubrication DMostafa MohamedNo ratings yet

- En Additin RC 2540Document3 pagesEn Additin RC 2540Dinesh babuNo ratings yet

- Natural Gas Engines LubricationDocument9 pagesNatural Gas Engines Lubricationjameel babooramNo ratings yet

- Your Extras and Medical Claim Form: SECTION A: Your DetailsDocument3 pagesYour Extras and Medical Claim Form: SECTION A: Your DetailsTGNo ratings yet

- API Oil Guide 2010Document4 pagesAPI Oil Guide 2010amsoilromaniaNo ratings yet

- Investigation Into Early Loss of Lubricant Viscosity in Agitator Gear Box at CIL Plant at Goldfields Ghana LimitedDocument4 pagesInvestigation Into Early Loss of Lubricant Viscosity in Agitator Gear Box at CIL Plant at Goldfields Ghana LimitedInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- ATF LubricantDocument35 pagesATF LubricantTung NguyenNo ratings yet

- VTK Varnish Potential Test Kits PDFDocument1 pageVTK Varnish Potential Test Kits PDFEduardo CramerNo ratings yet

- Rev 3 - KEL 8 - Tugas 2 Lubricant & BearingDocument7 pagesRev 3 - KEL 8 - Tugas 2 Lubricant & BearingHasan Ahmad Zaky100% (1)

- Report On Oil Types and Applications: 3 YearDocument5 pagesReport On Oil Types and Applications: 3 YearMahmoud KassabNo ratings yet

- Viscosity ClassificationsDocument6 pagesViscosity ClassificationsDarmawan PutrantoNo ratings yet

- Petro Canada Duron HP - 15w-40 PDFDocument10 pagesPetro Canada Duron HP - 15w-40 PDFPubcrawl100% (1)

- Engine Oil ViscosityDocument1 pageEngine Oil ViscosityJainendra kumarNo ratings yet

- HP Lubes GuideDocument196 pagesHP Lubes GuideJen Ekx100% (1)

- Maintenance Tips On OilDocument12 pagesMaintenance Tips On OilAndrea StoneNo ratings yet

- Russian Jp54 Aviation Kerosene Colonial Grade 54 Component Unit MIN MAX AdditivesDocument1 pageRussian Jp54 Aviation Kerosene Colonial Grade 54 Component Unit MIN MAX AdditivesPunggawa storiesNo ratings yet

- Auma GreaseDocument1 pageAuma GreaseQuoc HungNo ratings yet

- Shell Melina S30: Performance, Features & BenefitsDocument2 pagesShell Melina S30: Performance, Features & BenefitsStefas DimitriosNo ratings yet

- Clean Oil GuideDocument28 pagesClean Oil GuideAlex VulpeNo ratings yet

- Mil L 2105DDocument17 pagesMil L 2105Dkamal arabNo ratings yet

- EIC N 1001 0 Hydraulic FluidsDocument13 pagesEIC N 1001 0 Hydraulic FluidsCharitha LiyanagamaNo ratings yet

- Base Stocks 基础油Document18 pagesBase Stocks 基础油Yesica RozoNo ratings yet

- Product Information Navigo 6 So: DescriptionDocument2 pagesProduct Information Navigo 6 So: DescriptionCOMITYNo ratings yet

- Velvex Industrial Oil - Nandan Petrochem LTDDocument27 pagesVelvex Industrial Oil - Nandan Petrochem LTDNandan Petrochem Ltd0% (1)

- Additiv 730 Additiv 830 (For Engine Oil) TdsDocument2 pagesAdditiv 730 Additiv 830 (For Engine Oil) TdsahmetNo ratings yet

- PH 474A-K - Synthetic Gear Oil - Extreme Pressure (EP)Document4 pagesPH 474A-K - Synthetic Gear Oil - Extreme Pressure (EP)dfbdfbfdbfbNo ratings yet

- How To Select and Service Turbine OilsDocument5 pagesHow To Select and Service Turbine OilsmvanzijpNo ratings yet

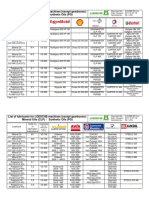

- List of Lubricants For LOESCHE-machines (Except Gearboxes) : Mineral Oils (CLP) / Synthetic Oils (PG)Document8 pagesList of Lubricants For LOESCHE-machines (Except Gearboxes) : Mineral Oils (CLP) / Synthetic Oils (PG)MossaabSelaimiaNo ratings yet

- Ss Mobilith SHCDocument2 pagesSs Mobilith SHCFarrukh JamalNo ratings yet

- Shell Omala S4 GX 220Document3 pagesShell Omala S4 GX 220Anonymous oAbjbl4HNo ratings yet

- Lubimax 1606 - MSDSDocument7 pagesLubimax 1606 - MSDSkarthibenNo ratings yet

- Berutox FB 22: Technical Product InformationDocument1 pageBerutox FB 22: Technical Product InformationMauricio SánchezNo ratings yet

- Chapter Four.1Document160 pagesChapter Four.1Marew GetieNo ratings yet

- Warning: Recommended Lube Oil Change Intervals Taking An Oil SampleDocument6 pagesWarning: Recommended Lube Oil Change Intervals Taking An Oil SamplegalaxiprinceNo ratings yet

- Lubs, Properties & TeatingDocument33 pagesLubs, Properties & Teatingjamesv52_743942786No ratings yet

- Lube Oil AnalysisDocument8 pagesLube Oil AnalysisVuthpalachaitanya KrishnaNo ratings yet

- The Next Generation Gas Engine Oil Mobil Pegasus 1005Document46 pagesThe Next Generation Gas Engine Oil Mobil Pegasus 1005Sandeep100% (1)

- Aerator PremiumDocument10 pagesAerator PremiumvijaykumarnNo ratings yet

- Mobil Unirex N Data SheetDocument3 pagesMobil Unirex N Data SheetCeliocp PinheiroNo ratings yet

- By: Muhammad Rafay IbadDocument18 pagesBy: Muhammad Rafay IbadMuhammad sherazNo ratings yet

- JAMA Engine: Mco WGDocument45 pagesJAMA Engine: Mco WGida fariyanti100% (1)

- Gear Lubrication 3Document9 pagesGear Lubrication 3rashm006ranjan100% (1)

- Effective Varnish Removal From Turbine Lubrication SystemsDocument9 pagesEffective Varnish Removal From Turbine Lubrication SystemsOsman AhmedNo ratings yet

- Indian Oil Corporation Limited: CIN - L23201MH1959GOI011388Document8 pagesIndian Oil Corporation Limited: CIN - L23201MH1959GOI011388pmcmbharat264No ratings yet

- Design Engineer's Guide - Selecting A Lubricant For Ball ScrewsDocument10 pagesDesign Engineer's Guide - Selecting A Lubricant For Ball ScrewsDat RomanNo ratings yet

- Engine Oil MythsDocument2 pagesEngine Oil Mythshpss77No ratings yet

- Fire-Resistant, Water-Free Hydraulic Re90222 - 2012-05 - 2 PDFDocument16 pagesFire-Resistant, Water-Free Hydraulic Re90222 - 2012-05 - 2 PDFDennis Huanuco CcamaNo ratings yet

- Industrial Lubricants - Viscosities Equivalent ISO-VG GradeDocument3 pagesIndustrial Lubricants - Viscosities Equivalent ISO-VG GradeArifinNo ratings yet

- Lube Analyst Next Generation: Limit Guide ParametersDocument4 pagesLube Analyst Next Generation: Limit Guide ParametersfrancisNo ratings yet

- Reprot On TrainingDocument36 pagesReprot On TrainingMd.Mahbub MorshedNo ratings yet

- Preventing Turbomachinery "Cholesterol": The Story of VarnishFrom EverandPreventing Turbomachinery "Cholesterol": The Story of VarnishNo ratings yet

- Bosch Fuel LubricityDocument4 pagesBosch Fuel LubricityvictorpoedeNo ratings yet

- 2022 Proton Iriz and Persona Facelift ASEAN NCAP Crash Test ReportDocument4 pages2022 Proton Iriz and Persona Facelift ASEAN NCAP Crash Test ReportcarbasemyNo ratings yet

- Nissan Magnite ASEAN NCAPDocument4 pagesNissan Magnite ASEAN NCAPcarbasemyNo ratings yet

- 2020 Honda City ASEAN NCAP Crash Test ReportDocument4 pages2020 Honda City ASEAN NCAP Crash Test ReportcarbasemyNo ratings yet

- Euroncap 2020 VW Id3 DatasheetDocument17 pagesEuroncap 2020 VW Id3 DatasheetcarbasemyNo ratings yet

- 2020 Toyota Hilux ASEAN NCAP Crash Test ReportDocument4 pages2020 Toyota Hilux ASEAN NCAP Crash Test ReportcarbasemyNo ratings yet

- 2020 Isuzu D-Max Euro NCAPDocument17 pages2020 Isuzu D-Max Euro NCAPcarbasemyNo ratings yet

- New Peugeot 2008 Euro NCAP Crash TestDocument15 pagesNew Peugeot 2008 Euro NCAP Crash TestcarbasemyNo ratings yet

- 2019 Toyota Corolla Altis ASEAN NCAP Crash Test ReportDocument4 pages2019 Toyota Corolla Altis ASEAN NCAP Crash Test ReportcarbasemyNo ratings yet

- W247 Mercedes-Benz B-Class Euro NCAP Crash Test ResultDocument14 pagesW247 Mercedes-Benz B-Class Euro NCAP Crash Test ResultcarbasemyNo ratings yet

- 2019 Nissan Leaf Euro NCAP ReportDocument14 pages2019 Nissan Leaf Euro NCAP ReportcarbasemyNo ratings yet

- Proton X50 ASEAN NCAP Digital ReportDocument4 pagesProton X50 ASEAN NCAP Digital ReportcarbasemyNo ratings yet

- G01 BMW X3 AncapDocument4 pagesG01 BMW X3 AncapcarbasemyNo ratings yet

- 2020 Honda Accord ASEAN NCAPDocument4 pages2020 Honda Accord ASEAN NCAPcarbasemyNo ratings yet

- Euroncap 2016 Audi q2 DatasheetDocument11 pagesEuroncap 2016 Audi q2 DatasheetcarbasemyNo ratings yet

- 2019 Toyota Vios ASEAN NCAPDocument4 pages2019 Toyota Vios ASEAN NCAPcarbasemyNo ratings yet

- Euroncap 2017 Audi q5 DatasheetDocument11 pagesEuroncap 2017 Audi q5 DatasheetcarbasemyNo ratings yet

- Audi q5 AncapDocument4 pagesAudi q5 AncapcarbasemyNo ratings yet

- 2019 Toyota Camry ANCAP ReportDocument3 pages2019 Toyota Camry ANCAP ReportcarbasemyNo ratings yet

- Toyota Rush 2018 ASEAN NCAPDocument4 pagesToyota Rush 2018 ASEAN NCAPcarbasemyNo ratings yet

- Audi q2 AncapDocument4 pagesAudi q2 AncapcarbasemyNo ratings yet

- 2019 Toyota Camry ASEAN NCAP ReportDocument4 pages2019 Toyota Camry ASEAN NCAP ReportcarbasemyNo ratings yet

- Perodua Aruz ASEAN NCAPDocument4 pagesPerodua Aruz ASEAN NCAPcarbasemyNo ratings yet

- Kia Picanto (With AEB) Euro NCAP ReportDocument11 pagesKia Picanto (With AEB) Euro NCAP ReportcarbasemyNo ratings yet

- Proton x70 ASEAN NCAPDocument4 pagesProton x70 ASEAN NCAPcarbasemyNo ratings yet

- RFiD TouchnGo Malaysia FAQDocument10 pagesRFiD TouchnGo Malaysia FAQcarbasemyNo ratings yet

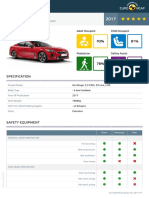

- Euroncap 2017 Kia Stinger DatasheetDocument4 pagesEuroncap 2017 Kia Stinger DatasheetcarbasemyNo ratings yet

- Volvo Xc40 AncapDocument8 pagesVolvo Xc40 AncapcarbasemyNo ratings yet

- Euroncap 2018 Volvo Xc40 DatasheetDocument14 pagesEuroncap 2018 Volvo Xc40 DatasheetcarbasemyNo ratings yet

- Euroncap 2017 Kia Stinger DatasheetDocument11 pagesEuroncap 2017 Kia Stinger DatasheetcarbasemyNo ratings yet

- Toyota C-HR ASEAN NCAPDocument4 pagesToyota C-HR ASEAN NCAPcarbasemyNo ratings yet

- Link Belt 210 X3Document12 pagesLink Belt 210 X3Yew LimNo ratings yet

- Refrigerante John Deere - Cool-GardDocument4 pagesRefrigerante John Deere - Cool-GardGustavo GonzalezNo ratings yet

- Genset - 2MVA-5Document6 pagesGenset - 2MVA-5Shawn ZadehNo ratings yet

- Combustion 3 Different Fuels LabDocument3 pagesCombustion 3 Different Fuels Labapi-310769796No ratings yet

- My23 PC Warranty Manual - Final - En-1Document31 pagesMy23 PC Warranty Manual - Final - En-1testNo ratings yet

- Ling Whey Ethanol Overview 2007Document27 pagesLing Whey Ethanol Overview 2007mclarkdaleNo ratings yet

- Etna Brochure NFPA20Document8 pagesEtna Brochure NFPA20Risyda PutriNo ratings yet

- Micro Heat Exchanger: Micro Heat Exchangers, Micro-Scale Heat Exchangers, or Microstructured Heat Exchangers AreDocument3 pagesMicro Heat Exchanger: Micro Heat Exchangers, Micro-Scale Heat Exchangers, or Microstructured Heat Exchangers AreMaheen AltafNo ratings yet

- MH86 73301425 InbDocument12 pagesMH86 73301425 Inbapi-19987138No ratings yet

- Cylinder Head Valve & Cylinder Piston MotoDocument23 pagesCylinder Head Valve & Cylinder Piston MotoDeysi CardenasNo ratings yet

- Recommended Actions: Transmission or Engine Accessories (If Applicable)Document3 pagesRecommended Actions: Transmission or Engine Accessories (If Applicable)sjsshipNo ratings yet

- Gas Manifold Systems & Accessories: We Listened. We DeliveredDocument40 pagesGas Manifold Systems & Accessories: We Listened. We DeliveredKadiri OlanrewajuNo ratings yet

- Biodiesel From Animal Fat and OilDocument10 pagesBiodiesel From Animal Fat and Oilmert tıglıNo ratings yet

- ISO 8217 2010 Tables 1 Amp 2 1Document2 pagesISO 8217 2010 Tables 1 Amp 2 1Prashant Kumar SinghNo ratings yet

- Engine Cranks But Will Not StartDocument12 pagesEngine Cranks But Will Not StartEyo EtimNo ratings yet

- Lab Manual For Kinematics of MachinesDocument18 pagesLab Manual For Kinematics of Machinesshailendra_236No ratings yet

- Washing MachineDocument6 pagesWashing MachineianNo ratings yet

- Mitsubishi mt2100 210 2500 250 Parts Catalogue Engine Opt PDFDocument64 pagesMitsubishi mt2100 210 2500 250 Parts Catalogue Engine Opt PDFbtxps5100% (1)

- Guidance Gasket MaterialDocument7 pagesGuidance Gasket MaterialCrstnScribidNo ratings yet

- UnitDocument35 pagesUnitparameshNo ratings yet

- 6.electric and CNG Vehicles NotesDocument6 pages6.electric and CNG Vehicles Notesjayasruthyk6No ratings yet

- Well and Surface Models - PipephaseDocument228 pagesWell and Surface Models - PipephaseFrancois Voeux100% (1)

- Seminar On FNPP 2Document16 pagesSeminar On FNPP 2jkchavda100% (4)

- Häggloader 10HR-B 3A - MaintenanceDocument116 pagesHäggloader 10HR-B 3A - MaintenanceEmrah Mertyürek100% (1)

- Engine ManualDocument189 pagesEngine ManualIan Addyman100% (1)

- Tiggo PDFDocument1,866 pagesTiggo PDFRosanaVega100% (1)

- Final ReportDocument30 pagesFinal ReportSatish HSNo ratings yet

- Workshop Manual: (Group 23) EDC 4Document60 pagesWorkshop Manual: (Group 23) EDC 4GORD100% (2)

- Defender M52 ETMDocument23 pagesDefender M52 ETMJonathan GridleyNo ratings yet

- PC450 7e0Document1,006 pagesPC450 7e0Teresa Marina Peralta100% (8)