Professional Documents

Culture Documents

Process Burner Spacing

Uploaded by

kanuparthyjCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Process Burner Spacing

Uploaded by

kanuparthyjCopyright:

Available Formats

jzink.

qxd

6/6/06

10:20 AM

Page 1

THERMAL TECHNOLOGY

Process burner spacing

Burner-to-burner interaction can increase NOx emissions and cause flame

impingement on process tubes. Predictive tools and rules of thumb have been

developed to help identify when there may be interaction problems

Mahmoud Fleifil, Michael Lorra, Charles E Baukal, Jeff A Lewallen and Daniel E Wright

John Zink Company LLC

urner-to-burner interaction is a

phenomenon that is characterised

by the creation of a dense fire

cloud, an increase in NOx emissions and

an altered heat flux distribution in the

furnace. It occurs frequently in multipleburner heaters, where vertical cylinder

heaters have been observed to have the

severest interactions. Although this

problem has been around for a while, it

has not been well understood. Only adhoc solutions have been introduced to

mitigate it. However, a comprehensive

study has now been completed, which

reveals a dimensionless interaction

parameter that could identify conditions

that are likely to produce burner-toburner interaction. Observations of

interactions were made on lab-scale,

small-scale and full-scale burners to

validate the parameter.

Two case studies are presented using

CFD modelling. The first study shows

that interaction was unlikely in a

vertical cylindrical furnace where the

spacing between burners was decreased.

The other study confirms interaction

observed in the field and suggests

modifications that were successfully

implemented and led to the elimination

of burner-to-burner interaction. Specific

rules of thumb, which are based on

experience, are given to predict the

likelihood of interactions in ethylenecracking furnaces.

The problem

In response to the increased demand to

reduce NOx emissions from industrial

heaters, new burner technologies have

been developed to meet the more

1

stringent emissions regulations. Most of

these technologies use some type of

furnace gas recirculation (Figure 1) to

reduce the flame temperature, so that

thermal NOx emissions can be reduced

2

substantially. However, diluting the fuelair mixture with furnace gases results in

lower burning rates, which often makes

the flames significantly longer. Both

longer flames and increased volumetric

3

heat release density (Btu/hr/ft or

3

MW/m ) in the newer multi-burner

industrial furnaces have led to frequent

occurrences

of

a

phenomenon

often referred to as

burner-to-burner

(BtoB) interaction.

The occurrence of this phenomenon is

indicated by the formation of a large,

bright yellow fire cloud and by an

increase in NOx emissions compared to

single-burner performance. Although

this problem has been observed in all

types of multi-burner heaters, it is much

more severe in vertical cylindrical heaters

compared to other types such as cabin

heaters.

It would be desirable to obtain a

simple rule of thumb to characterise and

predict the onset of BtoB interaction.

However, the complexity of the problem

limits the application of each rule to the

specific case from which it was deduced.

Some of the BtoB interaction rules that

have been proposed for vertical

cylindrical heaters are based on the

heat-release rate and the geometrical

dimensions of the furnace. The rule

usually takes the form of a criterion

value that demarcates the absence of

interaction from the onset of

interaction. Figure 2 shows the

dimensions discussed in the following

rules. One such rule uses the heat release

of a single burner per unit distance

between two adjacent burners (Btu/hr/ft

or MW/m). A second rule uses the total

heat release of the heater per unit area

2

2

(Btu/hr/ft or MW/m ) of the outermost

Figure 2 Plan view of a vertical cylindrical furnace with

dimensions used in rules of thumb (B = burner and T = tube)

Figure 1 Schematic of furnace gas recirculation

1

P T Q Q2 2006

w w w. e p t q . c o m

jzink.qxd

6/6/06

10:20 AM

Page 2

THERMAL TECHNOLOGY

Figure 3 Condition of interaction between two adjacent diffusion flames. Lf < Zc (no flame interaction); Lf > Zc (flame interaction)

burner circle, which is the circle that

passes through the centres of the

outermost burners. A third rule uses the

total heat release of the heater per unit

2

2

area (Btu/hr/ft or MW/m ) of the tube

circle, which is the circle that passes

through the centres of the heater

process tubes. A fourth rule uses the

total heat release per unit volume of the

3

3

heater (Btu/hr/ft or MW/m ).

In extreme cases, when the criterion

value is close to zero for no interaction

and relatively large for full interaction,

these rules can correctly predict the

performance of a multi-burner heater.

However, predicting the accurate

conditions for the onset of interaction is

a challenge for any of these rules. In

other words, it is easy to predict the

sufficient conditions (extreme cases) for

interaction, but it is difficult to predict

the necessary conditions (onset

conditions) for the interaction. These

rules

fail

for

two

reasons:

oversimplification of the problem and

failure to account for all significant

parameters. For instance, during a

research study of this phenomenon, it

was observed that BtoB interaction

depends on both fuel pressure and fuel

composition, while none of the above

rules account for such a dependence.

BtoB interaction, sometimes referred

to as flame-to-flame interaction (FtoF),

is a complex phenomenon that makes

the behaviour of the multiple-flame

configuration very different from that of

an individual flame. Increased flame

length, increased NOx emissions, poor

mixing, modified heat flux distribution

and

decreased

surrounding

gas

entrainment are some of the results of

FtoF interaction. While aerodynamic

interaction of the jets in a multiple-jet

system is considered to be the most

important factor that governs FtoF

interaction, the presence of combustion

is also a major factor. In other words, the

shape of the flame not only responds to

the turbulence in the surrounding

medium, but also to the combustion

itself, which creates eddies that can

affect neighbouring flames.

In vertical cylindrical heaters, the

BtoB spacing is more critical than in boxtype heaters, because the burner spacing

has an impact on the flue gas flow into

the centre of the furnace. If the spacing

between burners is too small, the

interaction of the flames can actually

block the flow of flue gases from the

circumference of the furnace into the

centre. This generates a low-pressure

zone in the centre of the furnace that

can effectively pull the flames toward

the centre of the furnace. This increases

the tendency for the flames to merge

together and create a large fire cloud that

can impinge on process tubes. Another

effect is the creation of a reducing

(oxygen-deficient) atmosphere in the

centre of the furnace. Since the flue gases

are blocked, the O2 concentration

decreases at the centre, leading to

increased CO formation on that side of

the flame and creating the potential for

increased flame lengths. Longer flames

can also alter the design heat flux

distribution, as more heat is transferred

higher in the furnace. NOx emissions

may also increase because there are

insufficient flue gases on the inside of

the burner circle that can be pulled into

the flames. Many low-NOx burners use

furnace gas entrainment to reduce the

flame temperature, which reduces NOx

emissions.

An

extensive

theoretical

and

experimental

investigation

was

completed to develop a suitable

Computational fluid

dynamics (CFD) is a

powerful tool for analysing

complicated fluid flow

problems in combustion

2

P T Q Q2 2006

criterion for identifying interaction in

vertical cylindrical heaters. Details of

that investigation are given elsewhere.3

The developed criterion depends on

both physical and chemical parameters;

namely, the geometry of the burners

and the fuel composition. Interaction is

defined here as the influence of flames

on each other that leads to the creation

of a yellow flame cloud (due to the

formation of soot particles) between

burners. A dimensionless number was

developed that can be used as a measure

for the interaction strength. Both labscale and small-scale burners were used

in the experimental investigation.

Consider two diffusion flames, as

shown in Figure 3, that are adjacent to

each other. There is a critical height at

which jets interact (Zc). The flame

height is designated here as Lf. If the

flame height is less than the critical

height (Lf < Zc), no FtoF interaction will

occur. If the flame height is greater than

the critical height (Lf > Zc), the flames

will interact. FtoF interaction of a group

of diffusion flames arranged in a circle,

as in a vertical cylindrical furnace, can

be characterised in a similar manner.

Experimental study

Twelve lab-scale burners were built. Each

was a single-jet burner with its diffusion

flame stabilised on a conical bluff body

downstream of the fuel jet. The objective

of testing with a simple lab-scale burner

was to study the FtoF interaction on a

fundamental basis and to verify the

interaction criterion for configurations

with a large number of burners. These

burners were tested in a small lab

furnace equipped with sensors for

measuring fuel pressure, temperature,

flow rate, flue gas temperature, furnace

draft, wet and dry gas analysis of excess

oxygen, carbon monoxide and nitrogen

oxides.

The parameters were varied to study

their effects on FtoF interaction

independently. Interaction among the

jzink.qxd

6/6/06

10:21 AM

Page 3

THERMAL TECHNOLOGY

flames was characterised by the existence

of a yellow fire cloud between adjacent

flames. The strength of interaction was

evaluated by direct visual observation of

the yellow cloud. A somewhat subjective

interaction index was used to scale the

strength of the interaction. FtoF

interaction was observed to increase as

the fuel pressure decreased, for the same

heat release rate. FtoF interaction

increased as the burner circle diameter

decreased. The dependence of the

dimensionless interaction parameter on

the number of burners was governed by a

spacing

ratio,

defined

as

the

dimensionless ratio of the burner

diameter to the distance between two

adjacent burners. Two configurations

were tested to investigate the impact of

the number of burners on FtoF

interaction. Four and six burners were

used where the distance between

adjacent burners was kept equal in both

configurations. The interaction in the

case of six burners was weaker than that

with four burners. Excess air had an

insignificant effect on the strength of the

FtoF interaction.

Small-scale burners

The objective of testing with small-scale

diffusion burners was to study the FtoF

interaction on a true process burner

design and to verify the interaction

criterion for all the relevant parameters.

The following control parameters were

varied: heat release, fuel pressure, fuel

composition, excess air, burner circle

diameter and number of burners. Six fuel

compositions of various combinations of

natural gas (>90% CH4), hydrogen and

propane were tested.

In these experiments, FtoF interaction

was evaluated by direct visual

observation of the yellow fire cloud

between the flames. Changing both the

heat-release rate and fuel pressure, with a

fixed fuel nozzle diameter, did not affect

FtoF interaction significantly. Keeping

the heat-release rate per burner constant,

a parametric study was then carried out

in which only one control parameter

was varied at a time. Interaction

increased when: fuel pressure decreased,

burner circle diameter decreased, the

number of burners increased and the

excess O2 increased. Fuels with more

propane tended to have higher

interaction than fuels with more

hydrogen, which tended to have lower

interaction. Fuels with more natural gas

had interactions in-between. This

corresponds with flame length, as

propane tends to make flames longer,

while hydrogen tends to make flames

shorter, for a given burner configuration.

circle diameter in a

vertical cylindrical furnace

from

8.667.43ft

(2.642.26m) to determine

if FtoF interaction would

be a problem. The burner

circle is centred at the

middle of the furnace and

goes through the centre of

each burner. The furnace

had six burners mounted

in the floor in a circular

pattern, surrounded by

tubes next to the wall

(Figure 4). The yellow ring

between the burners and

Figure 4 Cutaway view of six low-NOx burners mounted the tubes is known as a

in the floor of a VC furnace

Reed wall. Its purpose is to

control the gas flow in the

Three distinct interaction regimes furnace and minimise the chance for

were found: non-interaction, transition flame impingement on the tubes.

and strong interaction. The interaction

Each burner was fired at 9.3MMBtu/hr

parameter could be used to demarcate (2.7MW). Two different fuel composithe transition from no interaction to tions were fired simultaneously through

strong interaction.

each burner. One fuel had approximately 40% hydrogen and 44%

Full-scale field burners

methane, with some other minor

Data were collected from 12 field components. The other fuel was about

installations, which had full-sized 23% methane and 61% nitrogen, with

process burners of the same design as other minor constituents. Each burner

the small-scale burners. There were both was operated with 15% excess air. The

interacting and non-interacting cases. exhaust gas temperature was about

Using the field data, the dimensionless 1600F (870C).

interaction parameter was computed for

Turbulence, equilibrium combustion

each case. The three interaction regimes chemistry and thermal radiation were

were evident, although the transition included in the CFD model. The flame

regime was narrower. The narrow boundary for the calculated flame

transition regime was due to the pattern (not show here) is defined in

subjectivity involved in visually this case as the location where the

indexing the fire cloud as well as the computed carbon monoxide concensmall number of cases that fell into this tration is 1500ppm by volume on a wet

transition regime.

basis, indicating that no FtoF

interaction was predicted after reducing

Numerical studies

the burner circle diameter. Other results

Computational fluid dynamics (CFD) is also predicted no flame impingement

a

powerful

tool

for

analysing on the process tubes.

complicated fluid flow problems in

The second study involved an

4

5

combustion. CFD has been used operating furnace in a refinery. The

extensively to study burners and heaters problem observed in a xylene reboiler

in the process industries. One

particular topic of interest has

been FtoF interaction. The

following two examples illustrate

some of the issues and results. The

first example shows a case where

reducing the spacing between

burners did not cause FtoF

interaction. The second example

shows how CFD was used to

simulate

an

existing

FtoF

interaction problem in an

operating heater and the solution

to that problem by modification

of the burners.

CFD was used to study the Figure 5 Cutaway view of a xylene reboiler with

effects of reducing the burner six floor-mounted low-NOx burners

3

P T Q Q2 2006

jzink.qxd

6/6/06

10:22 AM

Page 4

THERMAL TECHNOLOGY

was that the flames from the ultra-low

NOx burners were very long and had the

potential to damage the process tubes in

the convection section at the top of the

furnace. This phenomenon had

previously been observed in vertical/

cylindrical furnaces with ultra-low NOx

burners. The problem was related to the

flow pattern within the furnace, as it did

not allow complete mixing of the

combustion air with the fuel, but rather

distorted the flame prior to burnout.

The geometry of the vertical

cylindrical furnace is shown in Figure 5.

The small wall around the burners is a

Reed wall and is used to heat the cold

flue gases coming from the tubes. This

helps

enhance

flame

stability.

Equilibrium combustion chemistry,

turbulence and thermal radiation were

used in these computations.

Figure 6a shows a CFD simulation of

the burners as they were originally

installed. The figure shows an isosurface of OH, which is a good indicator

of flame shape. The results reveal that

the flames from adjacent burners

merged together to produce a single

long flame, which was confirmed by

observations of the operating furnace.

This burner had two primary fuel tips

that fired fuel inside the burner tile, and

four secondary fuel tips firing outside

the tile. The solution to this flame

interaction problem was to change the

burner so that only three of the

secondary tips actually fired. The CFD

results for that configuration are shown

in Figure 6b. This solution was

implemented and tested in the

operating furnace and found to yield

qualitatively the same result the

flames became distinct and burned out

at the appropriate height. FtoF

Figure 6 Elevation view of CFD predictions of flame shape: (left) unmodified burners and

(right) modified burners

interaction was negated, which reduced

the flame length and eliminated flame

impingement on the process tubes.

Ethylene furnaces

One example of an application where

FtoF interaction is an issue is in

ethylene-cracking

furnaces.

One

common type of low-NOx burner used

in the floor of these furnaces

incorporates fuel staging and furnace

gas recirculation (Figure 7a). While this

combination of techniques reduces NOx,

it also tends to increase flame length.

Longer flames move the location of the

peak heat flux higher in the furnace and

decrease the heat flux at the floor of the

furnace. These burners are so effective at

pulling in surrounding furnace gases

that, if spaced too closely together, they

can compete for the same gases. This

can cause NOx emissions to increase and

flame quality to decrease. On extremely

tight spacing, the burners can negatively

impact the natural furnace fluid flow

currents, leading to FtoF interaction and

flame impingement on process tubes.

Another burner was developed to

Figure 7 Burner used in ethylene-cracking furnaces with fuel staging and (left) uncontrolled and (right) controlled furnace gas recirculation

4

P T Q Q2 2006

jzink.qxd

6/6/06

10:22 AM

Page 5

THERMAL TECHNOLOGY

help control the interaction of low-NOx

burners that incorporate furnace gas

recirculation, where the spacing

between burners is tight. These burners

control the recirculation of furnace

gases by using a venturi and internal

ducting, and introduce the fuel and

furnace gas mixture vertically (Figure

7b). These burners have low NOx

emissions, with better radiant heat flux

profiles and flame quality than the

previous design. They also allow closer

burner-to-burner spacing.

Burner technologies must be correctly

applied to get predictable and reliable

performance from the furnace. This

includes low NOx, no flame impingement and the desired heat flux

distribution in the furnace. There are

two parameters that can be used to

predict burner performance in this

application: heat release per burner as a

function of burner spacing and total

heat release for the furnace geometry.

The first of the two parameters is

called linear heat intensity (LHI). It

quantifies flame intensity along a

furnace wall or along the length of the

furnace. LHI is calculated by taking the

heat release of all the floor burners in a

row and dividing by the length of the

furnace. Typical units for this would be

MMBtu/hr/ft or MW/m. For example, if

there are ten burners in a row, each

firing 10MMBtu/hr (2.91MW), and the

total length of the row is 30ft (9.1m),

the LHI would be (10 burners) x

(10MMBtu/hr/burner)/30ft = 3.33MM

Btu/hr/ft (3.2MW/m). The LHI can be

used to determine the extent of possible

burner-to-burner interactions and how

much NOx emissions may increase

compared to NOx measurements from a

single-burner test where there is no FtoF

interaction.

Different burner designs are more or

less sensitive to LHI. Generally speaking,

all burner technologies will work

predictably when the LHI values are less

than

2MMBtu/hr/ft

(1.9MW/m).

Between 2 and 3.5MMBtu/hr/ft (1.9 and

3.4MW/m), the burner technology plays

an important role and the burner

vendor should be consulted and

previous experience of the type of

burner at similar LHI levels considered.

The previous example suggests that

BtoB interaction would be a concern

for the conditions specified. Above

4MMBtu/hr/ft

(3.8MW/m),

BtoB

interaction is likely and makes it

difficult to predict burner and heater

performance.

The second parameter, called hearth

heat intensity (HHI), is a measure of

Burner-to-burner interaction

can increase NOx emissions,

cause flame impingement

on process tubes and alter

the heat flux distribution in

the furnace

flame intensity for a given floor area. HHI

is calculated by taking the heat release of

all floor burners in a furnace and

dividing by the floor area inside the box.

Typical units for HHI would be

2

2

MMBtu/hr/ft or MW/m . For example, if

there are ten burners firing 10MMBtu/hr

(2.9MW), each in a total floor area of

2

2

400ft (37m ), the HHI would be (10

2

burners) x (10MMBtu/hr/burner)/400ft

2

2

= 0.25MMBtu/hr/ft (0.79MW/m ). The

HHI measures the furnace-to-burner

coupling effect. If the HHI is too high,

the potential for flame rollover increases.

If the intensity of the heat on the floor of

the furnace is higher than the burner can

sustain, a short circuit in the naturally

occurring furnace currents can occur,

creating the potential for flame rollover.

This rollover will reduce efficiencies and

run lengths, and in severe cases reduce

tube life.

Generally speaking, there will be

minimal burner-to-furnace interaction

when the HHI values are less than

2

2

0.3MMBtu/hr/ft (0.95MW/m ). Between

2

0.3 and 0.45MMBtu/hr/ft (0.95 and

2

1.4MW/m ), the possibility for negative

interaction exists and each burner

technology should be compared to

existing furnaces to determine the

possibility and extent of the interaction.

2

2

Above 0.5MMBtu/hr/ft (1.6MW/m ),

burner-to-furnace interaction is likely

and heater performance parameters such

as efficiency and run length will be

difficult to predict reliably. For the

previous

example

with

HHI

=

2

0.25MMBtu/hr/ft , the rule of thumb

suggests minimal interaction for those

conditions.

Conclusions

Burner-to-burner interaction can increase

NOx emissions, cause flame impingement on process tubes and alter the heat

flux distribution in the furnace. This

problem has become more prevalent as

low-NOx burner designs use more fuel

staging and furnace gas recirculation and

firing rate densities increase. Empirical

rules of thumb have been developed, but

are often limited to fairly specific

5

P T Q Q2 2006

geometric configurations and operating

conditions. As the result of an extensive

experimental investigation, a general

interaction

parameter

has

been

developed to help predict when there

may be an interaction problem for a wide

range of operating conditions. CFD

modelling can be used to both predict

potential problems and to recommend

solutions. Rules of thumb have been

developed for ethylene-cracking furnaces

to predict when there is an increased risk

of interaction problems.

References

1 Baukal C (editor), Industrial Burners Handbook, CRC Press, Boca Raton, Florida, 2004.

2 Baukal C, Industrial combustion pollution and

control, Marcel Dekker, New York, 2004.

3 Fleifil M, Karan J, Colannino J, Demystifying burner-burner interactions in industrial

vertical cylindrical process heaters,

presented at the AFRC-JFRC Joint

International Combustion Symposium,

Maui, Hawaii, 1013 October 2004.

4 Baukal C E, Gershtein V Y, Li X (editors),

Computational fluid dynamics in industrial

combustion, CRC Press, Boca Raton, Florida,

2001.

5 Henneke M, Smith J D, Jayakaran J D, Lorra

M, Computational fluid dynamics (CFD)

based combustion modeling, Chapter 9,

The John Zink Combustion Handbook, Baukal

C (editor), CRC Press, Boca Raton, Florida,

2001.

Mahmoud Fleifil has been an acoustics

engineer at John Zink Company LLC in

Tulsa, Oklahoma, USA, since 1999 and

has a PhD from MIT.

Email: mahmoud.fleifil@johnzink.com

Michael Lorra is a senior CFD engineer at

John Zink Company LLC in Tulsa,

Oklahoma, USA, and has a PhD from

Ruhr-Universitaet Bochum, Germany.

Email: michael.lorra@johnzink.com

Charles E Baukal, PE is director of the

John Zink Institute in Tulsa, Oklahoma,

USA, and has a PhD from the University of

Pennsylvania.

Email: charles.baukal@johnzink.com

Jeff A Lewallen, PE is a senior design

engineer at John Zink Company LLC in

Tulsa, Oklahoma, USA, and has a BS in

mechanical engineering from the

University of Tulsa.

Email: jeff.lewallen@johnzink.com

Daniel E Wright is the ethylene market

director at John Zink Company LLC in

Tulsa, Oklahoma, USA, and has a BS in

chemical engineering from BYU.

Email: daniel.wright@johnzink.com

You might also like

- Flow, Mixing and Heat Transfer in Furnaces: The Science & Applications of Heat and Mass Transfer Reports, Reviews & Computer ProgramsFrom EverandFlow, Mixing and Heat Transfer in Furnaces: The Science & Applications of Heat and Mass Transfer Reports, Reviews & Computer ProgramsK. H. KhalilNo ratings yet

- Phase Equilibrium in Mixtures: International Series of Monographs in Chemical EngineeringFrom EverandPhase Equilibrium in Mixtures: International Series of Monographs in Chemical EngineeringNo ratings yet

- Handbook of Thermal Conductivity, Volume 2: Organic Compounds C5 to C7From EverandHandbook of Thermal Conductivity, Volume 2: Organic Compounds C5 to C7No ratings yet

- High-Pressure Fluid Phase Equilibria: Phenomenology and ComputationFrom EverandHigh-Pressure Fluid Phase Equilibria: Phenomenology and ComputationNo ratings yet

- Handbook of Thermal Conductivity, Volume 1: Organic Compounds C1 to C4From EverandHandbook of Thermal Conductivity, Volume 1: Organic Compounds C1 to C4Rating: 5 out of 5 stars5/5 (1)

- Process Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentFrom EverandProcess Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentNo ratings yet

- Zeeco Burner Division DB SeriesDocument6 pagesZeeco Burner Division DB Series1mmahoneyNo ratings yet

- Energy and Process Optimization for the Process IndustriesFrom EverandEnergy and Process Optimization for the Process IndustriesNo ratings yet

- Correctly Modeling and Calculating Combustion Efficiencies in Fired EquipmentDocument23 pagesCorrectly Modeling and Calculating Combustion Efficiencies in Fired Equipmentfawmer61No ratings yet

- IFP Materials PDFDocument65 pagesIFP Materials PDFProcess EngineerNo ratings yet

- Reliance - Flare Gas Recovery IMPDocument6 pagesReliance - Flare Gas Recovery IMPsvnaik14No ratings yet

- Chapter 3. Natural-Draft-Fired HeatersDocument10 pagesChapter 3. Natural-Draft-Fired Heaterskim haksongNo ratings yet

- Physical and Chemical Equilibrium for Chemical EngineersFrom EverandPhysical and Chemical Equilibrium for Chemical EngineersRating: 5 out of 5 stars5/5 (1)

- Heat ExchangerDocument12 pagesHeat ExchangeremergingengineerNo ratings yet

- Good Heater Specifications Pay OffDocument6 pagesGood Heater Specifications Pay Offrvkumar61100% (1)

- Column Hydraulics NotesDocument4 pagesColumn Hydraulics NotessatishchemengNo ratings yet

- QB Johnson Water Bath HeaterDocument3 pagesQB Johnson Water Bath HeaterSantosh AdadaNo ratings yet

- 2nd Part of CalculationDocument26 pages2nd Part of CalculationLohith NatarajNo ratings yet

- SCR Reactor Performance Profiling and Results Analysis PDFDocument7 pagesSCR Reactor Performance Profiling and Results Analysis PDFkangsungjinNo ratings yet

- Design and Operating - Fouling CDU HeatersDocument8 pagesDesign and Operating - Fouling CDU HeatersFranklin Santiago Suclla Podesta100% (2)

- HTFS Presentation 2Document57 pagesHTFS Presentation 2Divyesh Patel100% (1)

- Improve Vacuum Heater Reliability: Hydrocarbon ProcessingDocument4 pagesImprove Vacuum Heater Reliability: Hydrocarbon Processingros56No ratings yet

- Design and Rating of Fired HeatersDocument33 pagesDesign and Rating of Fired HeatersRishabh Jain100% (1)

- Article - 1001191 Managing Fouling in Refinery PDFDocument13 pagesArticle - 1001191 Managing Fouling in Refinery PDFDavid Diaz PadillaNo ratings yet

- High Emissivity CoatingDocument12 pagesHigh Emissivity CoatingĐoàn TrangNo ratings yet

- CH 4 Pressure Drop in Heat ExchangersDocument14 pagesCH 4 Pressure Drop in Heat Exchangersapi-3765936100% (5)

- First U.K. National Conference on Heat Transfer: The Institution of Chemical Engineers Symposium Series, Volume 2.86From EverandFirst U.K. National Conference on Heat Transfer: The Institution of Chemical Engineers Symposium Series, Volume 2.86No ratings yet

- Reformer Sagar PresentationDocument43 pagesReformer Sagar Presentationsagarlambariya123456No ratings yet

- Computational Techniques for Chemical Engineers: International Series of Monographs in Chemical EngineeringFrom EverandComputational Techniques for Chemical Engineers: International Series of Monographs in Chemical EngineeringNo ratings yet

- Shell and Tube Heat Exchanger DesignDocument3 pagesShell and Tube Heat Exchanger Design1AdityaPathania1No ratings yet

- Heurtey Petrochem: Coker Furnace Run LengthDocument24 pagesHeurtey Petrochem: Coker Furnace Run LengthFayaz MohammedNo ratings yet

- Thermosiphon OperationDocument63 pagesThermosiphon OperationRajesh100% (1)

- 8 - HEURTEY PETROCHEM Flux Distribution in Fired Heaters A Case StudyDocument27 pages8 - HEURTEY PETROCHEM Flux Distribution in Fired Heaters A Case Studyfawmer61No ratings yet

- AFHEWebinar29-Nov-2011 - Final Fired HeaterDocument26 pagesAFHEWebinar29-Nov-2011 - Final Fired HeaterAmit Goel100% (3)

- Entrainment Calculation PDFDocument1 pageEntrainment Calculation PDFnirmal_subudhiNo ratings yet

- Fired Heaters Convection SectionDocument25 pagesFired Heaters Convection Sectionweam nour100% (1)

- Exxon Aero EnfriadoresDocument61 pagesExxon Aero EnfriadoressantiagoNo ratings yet

- Optimum Design of Turbo Expander Final-PaperDocument12 pagesOptimum Design of Turbo Expander Final-PaperGerman Gader100% (2)

- Process Heaters Furnaces and Fired Heaters PDFDocument12 pagesProcess Heaters Furnaces and Fired Heaters PDFHaris Nu'man Aulia100% (1)

- Phase Equilibria: Basic Principles, Applications, Experimental TechniquesFrom EverandPhase Equilibria: Basic Principles, Applications, Experimental TechniquesNo ratings yet

- Fired HeaterDocument28 pagesFired HeaterRapee PuaksungnoenNo ratings yet

- Heat Transfer in Packed BedDocument10 pagesHeat Transfer in Packed BedNidhi JainNo ratings yet

- Kurita Mitigating Coke FormationDocument3 pagesKurita Mitigating Coke FormationMarcelNo ratings yet

- First U.K. National Conference on Heat Transfer: The Institution of Chemical Engineers Symposium Series, Volume 1.86From EverandFirst U.K. National Conference on Heat Transfer: The Institution of Chemical Engineers Symposium Series, Volume 1.86No ratings yet

- Two Reboiler Simultaneously RunDocument16 pagesTwo Reboiler Simultaneously RunteddyNo ratings yet

- Energy Optimization Using Pinch Analysis: Practical ConsiderationsDocument10 pagesEnergy Optimization Using Pinch Analysis: Practical ConsiderationsconfyNo ratings yet

- Particle Collection: Design Practices Fluid Solids Exxon EngineeringDocument67 pagesParticle Collection: Design Practices Fluid Solids Exxon EngineeringPaula RiveraNo ratings yet

- Cold Box - Advantages To Brazed Fin ExchangersDocument13 pagesCold Box - Advantages To Brazed Fin ExchangersEdison ChoiNo ratings yet

- Ganapathy PDFDocument90 pagesGanapathy PDFpinenamuNo ratings yet

- A Proposed Comprehensive Model For Elevated Flare Flames and PlumesDocument39 pagesA Proposed Comprehensive Model For Elevated Flare Flames and PlumesAníbal MellanoNo ratings yet

- Helix ChangerDocument8 pagesHelix Changerprad_21ad100% (1)

- Textbook of Clinical NeurologyDocument374 pagesTextbook of Clinical Neurologykanuparthyj100% (9)

- Engineering With Clad MaterialsDocument22 pagesEngineering With Clad MaterialskanuparthyjNo ratings yet

- EzekielDocument230 pagesEzekielkanuparthyj100% (1)

- Theory & Design of Pressure Vessels PDFDocument319 pagesTheory & Design of Pressure Vessels PDFShree BiradarNo ratings yet

- Finite Element Method: An IntroductionDocument10 pagesFinite Element Method: An IntroductionGuru BrahmaiahNo ratings yet

- Carbon Dioxide Capture and StorageDocument443 pagesCarbon Dioxide Capture and Storagekanuparthyj100% (3)

- Being Healed at Staying AliveDocument144 pagesBeing Healed at Staying AliveIrisha BelovedNo ratings yet

- Welding Procedure PreparationDocument122 pagesWelding Procedure Preparationthe_badass1234100% (21)

- Book of Job NET With ExplanationsDocument105 pagesBook of Job NET With ExplanationskanuparthyjNo ratings yet

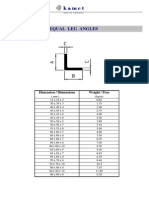

- Structural Members WeightsDocument16 pagesStructural Members WeightskanuparthyjNo ratings yet

- TANK Design DetailingDocument17 pagesTANK Design DetailingTiffany Vabiola100% (8)

- Wind Load CalculationDocument105 pagesWind Load CalculationMadusha Galappaththi100% (2)

- Wind Load Examples of Revised 875 Part 3Document110 pagesWind Load Examples of Revised 875 Part 3PRABHUTIRUPURNo ratings yet

- Newmark Spectra DesignDocument51 pagesNewmark Spectra Design26283369100% (1)

- Basic Instrumentation Measuring Devices and Basic Pid ControlDocument125 pagesBasic Instrumentation Measuring Devices and Basic Pid ControlCuong Nguyen ChiNo ratings yet

- Bible Study GuideDocument170 pagesBible Study Guidebasionic921175% (4)

- Design of Compact Plate Fin Heat ExchangerDocument61 pagesDesign of Compact Plate Fin Heat ExchangerIndra Uchiha100% (3)

- Cathodic ProtectionDocument22 pagesCathodic ProtectionFakhr-e-Alam100% (1)

- The Martyrs-John FoxDocument72 pagesThe Martyrs-John FoxkanuparthyjNo ratings yet

- Dental Clinic - Floor Plan R3-2Document1 pageDental Clinic - Floor Plan R3-2kanagarajodisha100% (1)

- DGKCC Internship ReportDocument17 pagesDGKCC Internship ReportMuhammad AtharNo ratings yet

- Trox Quick Selection GuideDocument47 pagesTrox Quick Selection GuideErwin LouisNo ratings yet

- Operation Manual-KINGSTONE SDP-ENG-20120205 PDFDocument49 pagesOperation Manual-KINGSTONE SDP-ENG-20120205 PDFJiménezNo ratings yet

- Family Planning MethodsDocument20 pagesFamily Planning MethodsRoel Marcial100% (2)

- Classroom Activty Rubrics Classroom Activty Rubrics: Total TotalDocument1 pageClassroom Activty Rubrics Classroom Activty Rubrics: Total TotalMay Almerez- WongNo ratings yet

- Leonard Nadler' ModelDocument3 pagesLeonard Nadler' ModelPiet Gabz67% (3)

- Hamza Akbar: 0308-8616996 House No#531A-5 O/S Dehli Gate MultanDocument3 pagesHamza Akbar: 0308-8616996 House No#531A-5 O/S Dehli Gate MultanTalalNo ratings yet

- Section ADocument7 pagesSection AZeeshan HaiderNo ratings yet

- Ten Reasons To Oppose The Death PenaltyDocument5 pagesTen Reasons To Oppose The Death PenaltyAlvin ArellanoNo ratings yet

- Interventional Studies 2Document28 pagesInterventional Studies 2Abdul RazzakNo ratings yet

- PTD30600301 4202 PDFDocument3 pagesPTD30600301 4202 PDFwoulkanNo ratings yet

- Nursing Care Plan TemplateDocument3 pagesNursing Care Plan TemplateJeffrey GagoNo ratings yet

- PresentationDocument6 pagesPresentationVruchali ThakareNo ratings yet

- ReflectionDocument3 pagesReflectionapi-174391216No ratings yet

- MnemonicsDocument1 pageMnemonicsSunil Boyz-uNo ratings yet

- BIR REliefDocument32 pagesBIR REliefJayRellvic Guy-ab67% (6)

- Sullivan's Interpersonal TheoryDocument27 pagesSullivan's Interpersonal TheoryJezalen GonestoNo ratings yet

- Film Interpretation and Reference RadiographsDocument7 pagesFilm Interpretation and Reference RadiographsEnrique Tavira67% (3)

- Hypoglycemia After Gastric Bypass Surgery. Current Concepts and Controversies 2018Document12 pagesHypoglycemia After Gastric Bypass Surgery. Current Concepts and Controversies 2018Rio RomaNo ratings yet

- Sailpoint Topic Wise SyllabusDocument2 pagesSailpoint Topic Wise SyllabusKishore KodaliNo ratings yet

- Pyle 4ch Marine BTDocument4 pagesPyle 4ch Marine BTRafael VieiraNo ratings yet

- Introduction To Cobit Framework - Week 3Document75 pagesIntroduction To Cobit Framework - Week 3Teddy HaryadiNo ratings yet

- Early Childhood Education and CareDocument53 pagesEarly Childhood Education and CareBianca ALbuquerqueNo ratings yet

- Alliance For ProgressDocument19 pagesAlliance For ProgressDorian EusseNo ratings yet

- ARMY - Chapter Eight Explosive BreachingDocument25 pagesARMY - Chapter Eight Explosive Breachingrsreeth100% (1)

- MVC Training Course Prerequisite: WWW - Focustech.InDocument2 pagesMVC Training Course Prerequisite: WWW - Focustech.InLakshman Samanth ReddyNo ratings yet

- Cambridge IGCSE: PHYSICS 0625/62Document12 pagesCambridge IGCSE: PHYSICS 0625/62EffNo ratings yet

- EN 213 Vertintojui WWWDocument2 pagesEN 213 Vertintojui WWWMonika PetronytėNo ratings yet

- Symmetrir and Order. Reasons To Live According The LodgeDocument6 pagesSymmetrir and Order. Reasons To Live According The LodgeAnonymous zfNrN9NdNo ratings yet