Professional Documents

Culture Documents

Chapter I Fhs

Uploaded by

Jagadeesan SaiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chapter I Fhs

Uploaded by

Jagadeesan SaiCopyright:

Available Formats

FUEL

HANDLING

O &M

SYSTEM

MANUAL

STAGE I &II

Thermal Power Station II (7 x 210 MW)

ISO 9001, 14001 and OHSAS 18001 certified Company

Neyveli Lignite Corporation Limited

(A Govt. of India Mini Ratna Enterprise)

NEYVELI.

Obelisk to mark the

commencement of

Thermal Power Station -II

NEYVELI LIGINITE CORPORATION

Vision

To emerge as a leading Mining and Power

Company, Continue to be a socially responsible

company and strive for operational excellence

in Mining and Exploration.

Mission

Strive towards greater cost competitiveness

and work towards continued financial strength.

Continually imbibe best practices from the

best Indian and International Organizations

engaged in Power Generation and Mining.

Be

attractive

preferred

avenues

employer

of

career

by

offering

growth

and

excellent work environment and by developing

human

resources

standards.

to

match

international

Play

an

active

role

in

society

and

be

sensitive to emerging environmental issues

NEYVELI LIGINITE CORPORATION

Quality & Environment Policy

NLC, Thermal Power Stations (Neyveli), affirm

our commitment to produce power with focus

on customer satisfaction, pollution prevention

and continual improvement.

We are committed to:

Setting

and

periodically

reviewing

the

Quality and environmental objectives and

targets

Supply quality power

as

per

committed

schedules

Incorporate

Quality

assurance

in

all

activities of our power generation

Optimal

utilization

and

conservation

of

resources such as water, fuel and auxiliary

power

Comply with all applicable legal & other

requirements with respect to Environment

Achieve

Excellence

management

by

in

environmental

elimination/reduction

of

environmental pollution

Enhance

Quality

awareness

and

among

all

Environmental

employees

and

contract workers, to promote Quality and

Environmental management

Promote new, innovative ideas on Quality

and Environment and fix benchmarks.

INDEX TO VOLUMES

I.

OPERATION & MAINTENANCE MANUAL

BOILER

1.

VOLUME A

2.

VOLUME B

BOILER OPERATION. (STAGE I)

-

BOILER OPERATION

(STAGE II)

3.

II.

VOLUME C

BOILER MAINTENANCE.

OPERATION & MAINTENANCE MANUAL

TURBINE

1.

VOLUME A

TURBINE OPERATION.

(STAGE I)

2.

VOLUME B

TURBINE OPERATION.

TURBINE MAINTENANCE.

(STAGE II)

3.

VOLUME C

III.

OPERATION & MAINTENANCE MANUAL

ELECTRICAL

1.

VOLUME A

2.

VOLUME B

ELECTRICAL OPERATION.

-

ELECTRICAL

MAINTENANCE.

IV.

OPERATION & MAINTENANCE MANUAL

PERIPHERALS

1.

VOLUME A

LIGNITE HANDLING SYSTEM.

WATER CHEMICAL TREATMENT

PLANT.

CIVIL MAINTENANCE.

SERVICES MAINTENANCE

CONTROLS &

INSTRUMENTATION.

INTRODUCTION ABOUT THERMAL

POWER STATION II

Thermal Power Station II has a total installed capacity of 1470

MW

(7 units of each 210 MW capacity). The station

was constructed in two stages: Stage I comprising the first phase of

three units and stage-II comprising the second phase of four units.

The total cost of the project including IDC worked out to 2011.26

crores. The project is constructed on an area of 207 hectares.

The Steam Generators and the Turbo Generators of Phase I were

supplied by Transelektro, Hungary in collaboration with EVT,

Germany and FrancoTosi, Italy respectively. All equipments of Phase

II are of indigenous make except the Milling and Firing Technology

for Steam Generators from EVT, Germany. The power station is

equipped with a sophisticated instrumentation system. The salient

features of Thermal Power Station II are given in Annexure-I.

The salient features of the Boiler, Turbine and generator are tabled

in the Annexure II.

The power station has been awarded the ISO 9001 : 2000

certificate of approval for Quality Management System and the ISO

14001 : 1996 for Environmental Management System by the Indian

Register Quality Systems (IRQS) in 2004.

As a Central Power Generating System, the station caters to the

power needs of the Southern Region. The power allocation from the

station to the Southern states of

Tamil Nadu, Andhra Pradesh,

Karnataka, Kerala and Pondichery and to NLC Mines is based on GOI

guidelines with changes in actual share notified from time to time.

The fixed share of the beneficiaries are as follows. The actual share

will vary depending on the pattern of distribution of the unallocated

part among the beneficiaries based on their requisitioning.

Andhra Pradesh

18.84%

Karnataka

13.54%

Kerala

10.41%

Tamil Nadu

30%

Pondicherry

5.44%

NLC Mines

6.8%

Unallocated:

14.97%

ACKNOWLEDGEMENT

PREFACE / FORWARD

WATER CHEMICAL TREATAMENT PLANT

OPERATION MANUAL

CONTENTS:

STAGE -I

CHAPTER I

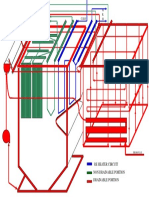

Lignite Handling System (LHS)

CHAPTER II

Oil Handling System

CHAPTER III

Constituents Of Fuel Oil And Their

Characteristics

CHAPTER IV

Description of Oil Handling System

CHAPTER V

Technical Data Of Process Equipments &

Accessories

CHAPTER VI

Fuel Oil Filters

STAGE - II

CHAPTER VII

Fuel Oil Handling System /LDO & FO

CHAPTER VIII

Furnace Oil Systems

CHAPTER IX

Operation of LDO System

CHAPTER X

Operation of Furnace Oil System

CHAPTER XI

Technical Data Process Equipments &

Accessories

FUEL

HANDLING

SYSTEM

OPERATION

STAGE I

INDEX

Sl.No.

TOPIC

PAGE No.

CHAPTER - I

1.

Lignite Handling System (LHS) Stage I

1.1.

General Description

1.2.

Receiving System

1.3.

Transfer System

1.4.

Crusher House

1.5.

Mulsifier system

11

1.6.

Dust Suppression System

11

1.7.

Lignite Handling System (LHS) Operation

1.8.

Magnetic Separator

15

1.9.

Metal Detectors

15

1.10. Conveyor

12

16

CHAPTER II

2.

Oil Handling System

19

2.1.

Introduction

19

2.2.

Description

2.3.

Characteristics of fuel oil

Sl.No.

21

21

TOPIC

PAGE No.

CHAPTER III

3.

Constituents of fuel oil and their characteristics

28

3.1.

Carbon

28

3.2.

Hydrogen

29

3.3.

Sulphur

29

3.4.

Water and Sediment

30

3.5.

Ash

30

3.6.

Specification of furnace oil (IS:1593 Quality)

31

CHAPTER IV

4.

Description of oil handling system

33

4.1.

Decanting pump house

33

4.2.

Fuel oil tanks

4.3.

Floor coil heater in fuel oil tank

4.4.

Suction Heater

4.5.

Pressurising Pump House

4.6

Drain tank and Drain pump

35

35

36

37

39

CHAPTER V

5.

Technical data of process equipments & Accessories 41

5.1

Decanting pump suction strainer

41

5.2.

Decanting pump

42

5.3.

Fuel oil storage tanks

42

5.4.

Floor coil heater

43

5.5.

Fuel oil suction heater

43

5.6.

Fuel oil suction filters

44

Sl.No.

TOPIC

PAGE No.

5.7.

Fuel oil pressurising pump

5.8.

Drive motor

5.9.

Drain oil tank

44

45

45

5.10. Filter before drain pump

5.11. Drain oil pump

45

46

CHAPTER - VI

6.

Fuel oil filters

48

6.1.

Putting the filter in to service

6.2.

Filter cleaning procedure

49

6.3.

Starting of pressurising oil pumps

49

6.4.

Stopping of the fuel oil pressurising pump

48

50

6.5.

Commissioning of fuel oil pressurising

50

pumps Oil lines

6.6.

Routine checks and precautions during

52

normal operation

6.7.

Decommissioning of the oil system

53

6.8.

Emptying the oil pipes

54

6.9.

Trouble shooting

55

6.10. Measure of safety precautions for accident

57

prevention

FUEL

HANDLING

SYSTEM

OPERATION

STAGE II

INDEX

Sl.No.

TOPIC

PAGE No.

CHAPTER - 7

7.

Fuel Oil Handling System / LDO & FO

60

7.1.

Introduction

60

7.2.

Fuel oils

61

7.3.

LDO System

62

CHAPTER - VIII

8.

Furnace oil systems

68

8.1.

Furnace oil decanting

68

8.2.

Suction Heater

68

8.3.

Oil Pressurising Pumps

70

8.4.

Secondary Heaters

71

8.5.

Drain Oil System

73

CHAPTER - IX

9.

Operation of LDO System

76

9.1.

Decanting of LDO

76

9.2.

Operation of LDO suction filter

77

9.3.

Operation of LDO pressuring pump

78

9.4.

Operation of LOD pressuring pump filter

79

Sl.No.

TOPIC

PAGE No.

CHAPTER - X

10.

Operation of furnace oil system

81

10.1. Operation of suction water

81

10.2. Operation of suction filter

82

10.4. Operation of secondary heaters

83

10.3. Operation of fuel oil pressuring pumps

83

CHAPTER - XI

11.

Technical data process equipments & Accessories

11.1. LDO tanks

85

85

11.2. LDO decanting pump suction filter

11.3. LDO decanting pumps

11.4.

LDO pressurizing pumps suction filter

85

85

86

11.5. LDO pressurising pumps

86

11.6. Fuel oil pressurising pump suction filter

87

11.7. Fuel oil pressurizing pumps

88

11.8. Secondary heaters

88

11.9. Drain oil tank

89

11.10.

Drain oil pump filter

89

11.11.

Drain oil pumps

90

You might also like

- Turbine RAS - Back Pressure Turbine 4Document33 pagesTurbine RAS - Back Pressure Turbine 4hemant visheNo ratings yet

- Operation and Instruction ManualDocument21 pagesOperation and Instruction ManualZamir Danilo Morera ForeroNo ratings yet

- Major Process Equipment Maintenance and RepairFrom EverandMajor Process Equipment Maintenance and RepairRating: 4 out of 5 stars4/5 (4)

- User Manual: SMC-450 Extrusion Kerb Slipforming MachineDocument14 pagesUser Manual: SMC-450 Extrusion Kerb Slipforming Machineshan ooiNo ratings yet

- CPCLDocument13 pagesCPCLNitharshniNo ratings yet

- 005 LPG Om & Sop PDFDocument109 pages005 LPG Om & Sop PDFRakesh Kumar100% (7)

- EATCO - Suez Petrochemicals Complex - Gas To Polyolefins IIDocument180 pagesEATCO - Suez Petrochemicals Complex - Gas To Polyolefins IIAndrzej SzymańskiNo ratings yet

- HarryDocument118 pagesHarryashusyadavNo ratings yet

- Company Profile123Document8 pagesCompany Profile123Ved PrakashNo ratings yet

- 1int. To CompDocument6 pages1int. To CompDiyaNegiNo ratings yet

- Mathura Refinery ReportDocument82 pagesMathura Refinery ReportAbhisheik Tripathi80% (5)

- HPCL REPORT On Electrical MaintenanceDocument68 pagesHPCL REPORT On Electrical MaintenanceSudheerNo ratings yet

- Arpita GantryDocument120 pagesArpita GantryAkshay Gottlieb100% (1)

- Vocational Training Report I.O.C.L Haldia Refinary: Jadavpur UniversityDocument54 pagesVocational Training Report I.O.C.L Haldia Refinary: Jadavpur Universityrahul aseriNo ratings yet

- Arpita GantryDocument120 pagesArpita GantryBrown EmmanuelNo ratings yet

- Wastewater Treatment ReportDocument35 pagesWastewater Treatment ReportAditya ChopraNo ratings yet

- Summer Training Presentation: ON Distillation Unit OF Mathura RefineryDocument14 pagesSummer Training Presentation: ON Distillation Unit OF Mathura RefineryGovindPatelNo ratings yet

- Fuel Gas Efficiency BMP - Efficient Use of Fuel Gas in Engines (Module 7) PDFDocument76 pagesFuel Gas Efficiency BMP - Efficient Use of Fuel Gas in Engines (Module 7) PDFKopi BrisbaneNo ratings yet

- Iocl ReportDocument24 pagesIocl Reportharimadhav568No ratings yet

- UntitledDocument14 pagesUntitledAmit Kumar KashyapNo ratings yet

- Guidelines For Specification of Generating EquipmentDocument81 pagesGuidelines For Specification of Generating Equipmentcrowjik5672100% (1)

- Manual Motor CousterDocument69 pagesManual Motor CousterRenner Tabraj EspinozaNo ratings yet

- Power Generation: Coal-Fired: Bently Nevada Asset Condition MonitoringDocument12 pagesPower Generation: Coal-Fired: Bently Nevada Asset Condition MonitoringsirtrungNo ratings yet

- Vincotte-EnMS Certification - PresentationDocument31 pagesVincotte-EnMS Certification - PresentationmatrixmazeNo ratings yet

- Serv7105 V01N05Document30 pagesServ7105 V01N05Hamid EssarboutiNo ratings yet

- Training Report BudniDocument49 pagesTraining Report BudniKartik MauryaNo ratings yet

- Prateek BHEL ReportDocument40 pagesPrateek BHEL ReportsaurabhkabdalNo ratings yet

- VBR LM2500 MetalSCAN Presentation AustraliaDocument18 pagesVBR LM2500 MetalSCAN Presentation AustraliaAbrahan BaezaNo ratings yet

- Milat Profile - Final VersionDocument24 pagesMilat Profile - Final VersionE BNo ratings yet

- Inplant Training Report PDFDocument31 pagesInplant Training Report PDFHemalatha MardiNo ratings yet

- Internship Report 2022Document25 pagesInternship Report 2022trick masterNo ratings yet

- Ravi Bhel ReportDocument33 pagesRavi Bhel ReportPayal SinghNo ratings yet

- Deh System CommissioningDocument11 pagesDeh System Commissioningdreamboy87No ratings yet

- Company Profile 2015-2016Document21 pagesCompany Profile 2015-2016Berkat Mulia Wiratama PtNo ratings yet

- DH3-31MAX-T-SCT-0021 Commissioning Procedure of EH Oil System REV.0Document6 pagesDH3-31MAX-T-SCT-0021 Commissioning Procedure of EH Oil System REV.0hungNo ratings yet

- Feedwater Pump Turbine Controls and Oil System Maintenance Guide PDFDocument196 pagesFeedwater Pump Turbine Controls and Oil System Maintenance Guide PDFsamsNo ratings yet

- 02ngvng1e Ford Motor CompanyDocument16 pages02ngvng1e Ford Motor Companyeko handoyoNo ratings yet

- TDS-Maintenance ManualDocument51 pagesTDS-Maintenance ManualAlejandro Hernadez100% (2)

- IOCL Report 2011Document56 pagesIOCL Report 2011Ajay ShekhawatNo ratings yet

- Ministry of Petroleum and Natural Gas: Indian Oil Corporation LimitedDocument19 pagesMinistry of Petroleum and Natural Gas: Indian Oil Corporation LimitedAmit SinghNo ratings yet

- Handbook On Oil Cooling Blower (OCB) of Three Phase Eelectric Locomotive-May 2018Document55 pagesHandbook On Oil Cooling Blower (OCB) of Three Phase Eelectric Locomotive-May 2018Aravind JNo ratings yet

- Project Report On NTPC and Its Control Mechanism: Sourabh SwamiDocument29 pagesProject Report On NTPC and Its Control Mechanism: Sourabh SwamiSourabh SwamiNo ratings yet

- Profit Controller SuncorwhitepaperDocument6 pagesProfit Controller SuncorwhitepapermelvokingNo ratings yet

- A-0 - Orientation of Training ProgramDocument35 pagesA-0 - Orientation of Training ProgramkoppulavijaykumarNo ratings yet

- Apoorva Training Report (2nd Yr)Document50 pagesApoorva Training Report (2nd Yr)Mridula MultaniaNo ratings yet

- Site VisitDocument10 pagesSite VisitAhmadNo ratings yet

- Project Report Battery Manufacturing PlantDocument14 pagesProject Report Battery Manufacturing PlantVasim Shaikh50% (4)

- Huafengdongli 495 4100 Series OperationmanualDocument126 pagesHuafengdongli 495 4100 Series OperationmanualEngr Osama Khan100% (5)

- Summer TrainingDocument15 pagesSummer Trainingpulkit agarwalNo ratings yet

- Golu New ProDocument27 pagesGolu New ProPrachetash SrivastavaNo ratings yet

- Advanced Control System For Crude Oil Plant - A Case StudyDocument5 pagesAdvanced Control System For Crude Oil Plant - A Case Studyquercitron_7No ratings yet

- Appendix I JD Service ManualDocument20 pagesAppendix I JD Service ManualJoao Silva50% (2)

- Internship Report - Fauji Fertilizer Company (FFC)Document49 pagesInternship Report - Fauji Fertilizer Company (FFC)Muhammad Aqeel Ashraf75% (8)

- Iqcm 2019 PDFDocument151 pagesIqcm 2019 PDFshivam johri100% (1)

- Isomerizarion, Ankylation, Polymerization: Hanoi University of Science and TechnologyDocument24 pagesIsomerizarion, Ankylation, Polymerization: Hanoi University of Science and TechnologyPhạm Quân100% (1)

- Raja Final RepotDocument24 pagesRaja Final RepotZain MunawarNo ratings yet

- Process System Value and Exergoeconomic Performance of Captive Power PlantsFrom EverandProcess System Value and Exergoeconomic Performance of Captive Power PlantsNo ratings yet

- Modeling, Control, and Optimization of Natural Gas Processing PlantsFrom EverandModeling, Control, and Optimization of Natural Gas Processing PlantsRating: 5 out of 5 stars5/5 (1)

- Boiler AnimationDocument1 pageBoiler AnimationJagadeesan SaiNo ratings yet

- Fluid CouplingDocument20 pagesFluid CouplingJagadeesan SaiNo ratings yet

- Boiler AnimationDocument1 pageBoiler AnimationJagadeesan Sai100% (1)

- Nat Dra - Cooling Tower PDFDocument43 pagesNat Dra - Cooling Tower PDFJagadeesan SaiNo ratings yet

- Chapter9 PDFDocument8 pagesChapter9 PDFJagadeesan SaiNo ratings yet

- Chapter II FhsDocument91 pagesChapter II FhsJagadeesan SaiNo ratings yet

- Tower BoilerDocument21 pagesTower BoilerJagadeesan SaiNo ratings yet

- Welcome TO THE Presentation OnDocument26 pagesWelcome TO THE Presentation OnJagadeesan SaiNo ratings yet

- 117 Pumps PDFDocument20 pages117 Pumps PDFJagadeesan SaiNo ratings yet

- 12th English 1 Blue PrintDocument3 pages12th English 1 Blue PrintGowtham RajNo ratings yet

- Guildelines For Blood Pressure, Risk Factors, Life Syle ModificationDocument12 pagesGuildelines For Blood Pressure, Risk Factors, Life Syle Modificationmsn722005No ratings yet

- Air PreheatersDocument84 pagesAir PreheatersJagadeesan SaiNo ratings yet

- AirconditioningDocument21 pagesAirconditioningJagadeesan SaiNo ratings yet

- EHC1Document30 pagesEHC1Jagadeesan SaiNo ratings yet

- CentrifugeDocument14 pagesCentrifugeJagadeesan Sai0% (1)

- Plate Type Heat ExchangerDocument28 pagesPlate Type Heat ExchangerJagadeesan Sai100% (1)

- StudytransformersDocument55 pagesStudytransformersManuel Alejandro Echeverry LopezNo ratings yet

- Turbo Supervisory SystemDocument41 pagesTurbo Supervisory SystemJagadeesan SaiNo ratings yet

- DEAERATORDocument32 pagesDEAERATORJagadeesan Sai100% (2)

- Shaft Turning GearDocument22 pagesShaft Turning GearJagadeesan Sai86% (7)

- HT Cable ScheduleDocument2 pagesHT Cable ScheduletceterexNo ratings yet

- SeminarDocument13 pagesSeminarJayesh ChaudhariNo ratings yet

- Dire Dawa UniversityDocument15 pagesDire Dawa UniversityBarkhad MohamedNo ratings yet

- Rele DatasheetDocument3 pagesRele Datasheetbgl87No ratings yet

- Fluke Harmonics Standards PDFDocument3 pagesFluke Harmonics Standards PDFAnonymous oZdAPQdIJNo ratings yet

- Sizing A MV Generator Circuit Breake1Document25 pagesSizing A MV Generator Circuit Breake1Afifah Zuhroh0% (1)

- The History of The TransformerDocument12 pagesThe History of The TransformerRobin RobinNo ratings yet

- Routine Tests For Oil Immersed TransformersDocument14 pagesRoutine Tests For Oil Immersed TransformersFreddie Asiedu LarbiNo ratings yet

- Enthalpy Activity SheetDocument15 pagesEnthalpy Activity SheetPrincess Fenix Sabio100% (1)

- CLSS LB8 - Unit 8Document30 pagesCLSS LB8 - Unit 8Seema QureshiNo ratings yet

- Coordination of DTOC Relays in A Power SystemDocument6 pagesCoordination of DTOC Relays in A Power SystemHayat AnsariNo ratings yet

- CH 7. Thermodynamics - Thermo Chemistry (Chem +1)Document51 pagesCH 7. Thermodynamics - Thermo Chemistry (Chem +1)James FrancisNo ratings yet

- Fuel Cell Technologies WorldwideDocument8 pagesFuel Cell Technologies WorldwideVero FrancoNo ratings yet

- NEMA Contactor and Starter Specifications: Technical DataDocument18 pagesNEMA Contactor and Starter Specifications: Technical DataNelsonNo ratings yet

- CHE317 Intro LectureDocument32 pagesCHE317 Intro LectureKevin MulkernNo ratings yet

- Radial Distribution Test FeedersDocument5 pagesRadial Distribution Test Feedersrony rahmatullahNo ratings yet

- Chint Nc6 DatasheetsDocument3 pagesChint Nc6 DatasheetsRoberto VillegaaNo ratings yet

- THERMAL PHYSICS 1 Ideal and Real GasesDocument36 pagesTHERMAL PHYSICS 1 Ideal and Real GasesEDENINo ratings yet

- 3VT17082DA360AA0 Datasheet enDocument8 pages3VT17082DA360AA0 Datasheet enGeorge Romero Carvalho NunesNo ratings yet

- Sumanth 15Document6 pagesSumanth 15Chenchu TnvNo ratings yet

- Kristherm - Residential Split Heat PumpDocument4 pagesKristherm - Residential Split Heat PumpAbhishek PNo ratings yet

- Suntron Energy Chack ListDocument31 pagesSuntron Energy Chack ListSherry HenryNo ratings yet

- T310 - 2109070003 - InfiniSolar 3PDocument1 pageT310 - 2109070003 - InfiniSolar 3PJoão Falange JanuárioNo ratings yet

- Analysis and Design of High Step-Up DC-DC Converter With Coupled-Inductor TechniqueDocument6 pagesAnalysis and Design of High Step-Up DC-DC Converter With Coupled-Inductor Techniqueharis shehzadNo ratings yet

- Theoretical CyclesDocument56 pagesTheoretical CyclesADOBONo ratings yet

- Zheng 2017Document5 pagesZheng 2017Santhosh H ANo ratings yet

- St. Francis National High School SF I, Limay, Bataan Third Periodical Test in Science 7 NAME: - YR/SECTIONDocument2 pagesSt. Francis National High School SF I, Limay, Bataan Third Periodical Test in Science 7 NAME: - YR/SECTIONArvin Arne RodrigoNo ratings yet

- NLDC - Reactive Power Management - Dec 2013 PDFDocument161 pagesNLDC - Reactive Power Management - Dec 2013 PDFN R SHEKAR100% (1)

- The Hybridization of A Formula Race CarDocument5 pagesThe Hybridization of A Formula Race CarDaneilNo ratings yet

- 5 - Basics of Fault CalculationDocument109 pages5 - Basics of Fault Calculationharish50% (2)