Professional Documents

Culture Documents

Habasitlink: Installation Instructions For Belt Types M2510, M2511, M2514, M2516

Uploaded by

rocio0 ratings0% found this document useful (0 votes)

30 views2 pagesinstalacion bandas transportadoras

Original Title

01AGuia de Instalacion M25XX

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentinstalacion bandas transportadoras

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

30 views2 pagesHabasitlink: Installation Instructions For Belt Types M2510, M2511, M2514, M2516

Uploaded by

rocioinstalacion bandas transportadoras

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

Habasit Solutions in motion

HabasitLINK

Installation instructions for belt types M2510, M2511, M2514, M2516

Please find full installation guide on www.habasitlink.com

Sprocket alignment on the shafts:

Corresponding teeth axial aligned, check by alignment mark.

If the bore is square and the number of teeth can be divided by 4,

there may be no mark.

Sprockets Positioning:

Place sprockets between min. and max. spacing (a).

Respect edge distance XL and XR.

Offset (e) given by shaft design.

Fix only the sprocket in the middle with small clearance.

Belt

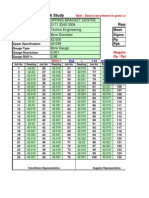

type

M2500

Sprocket spacing a

minimal

mm

inch

50

2

maximal

mm

inch

100

4

Edge distance

(minimal)

XL

XR

mm

mm

inch

inch

25

25

1

1

Check proper sprocket engagement:

The sprocket teeth must properly engage at the hinge.

Rod installation (snap fit rod retention):

Rod 5mm (0.2) with round shaped head must have a beveled end. If the belt is delivered in sections, join the

sections with alternating rod head orientation e.g. on one section all rod heads on the left side and the following

section all rod heads on the right hand side.

Pull belt sections together

Insert rod

For easy rod installation, rod end must be beveled.

Check if rod head is fully embedded.

Hammer in the rod head

Rod removal (snap fit rod retention)

Rod removal by Habasit rod removal tool (rod puller)

or side cutter.

Do not cut off the rod head.

The belt must not be under tension.

Leverage rod head out

Rod removal (by hammer and punch)

Punch out of retaining head by striking rod end opposite

to retaining head.

Hold back module edge on the opposite side.

The belt must not be under tension.

Product liability, application considerations

If the proper selection and application of Habasit products are not recommended by an authorized Habasit sales specialist, the

selection and application of Habasit products, including the related area of product safety, are the responsibility of the customer.

All indications / information are recommendations and believed to be reliable, but no representations, guarantees, or warranties

of any kind are made as to their accuracy or suitability for particular applications. The data provided herein are based on

laboratory work with small-scale test equipment, running at standard conditions, and do not necessarily match product

performance in industrial use. New knowledge and experiences can lead to modifications and changes within a short time

without prior notice.

BECAUSE CONDITIONS OF USE ARE OUTSIDE OF HABASITS AND ITS AFFILIATED COMPANIES CONTROL, WE

CANNOT ASSUME ANY LIABILITY CONCERNING THE SUITABILITY AND PROCESS ABILITY OF THE PRODUCTS

MENTIONED HEREIN. THIS ALSO APPLIES TO PROCESS RESULTS / OUTPUT / MANUFACTURING GOODS AS WELL

AS TO POSSIBLE DEFECTS, DAMAGES, CONSEQUENTIAL DAMAGES, AND FURTHER-REACHING CONSEQUENCES.

Pub. Data 6001BRO.MOD-en1107HQR

You might also like

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideFrom EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideRating: 4.5 out of 5 stars4.5/5 (8)

- Weider CrossbowDocument24 pagesWeider CrossbowAmish PatelNo ratings yet

- Chevy Differentials: How to Rebuild the 10- and 12-BoltFrom EverandChevy Differentials: How to Rebuild the 10- and 12-BoltRating: 5 out of 5 stars5/5 (8)

- SR Suntour XC Pro Forks Instructions ManualDocument8 pagesSR Suntour XC Pro Forks Instructions Manual110972ryanNo ratings yet

- Manitou 2003 Axel Service ManualDocument6 pagesManitou 2003 Axel Service Manualsloth185No ratings yet

- Mid Sem Test-II, CS8004 - Cyber Law & Ethics - MCQsDocument10 pagesMid Sem Test-II, CS8004 - Cyber Law & Ethics - MCQsTimNo ratings yet

- Financial Analyst Job DescriptionDocument8 pagesFinancial Analyst Job Descriptionfinancemanagement702No ratings yet

- Cherry Aerospace SpecsDocument28 pagesCherry Aerospace SpecsPriit PuuramNo ratings yet

- Habasit PDFDocument100 pagesHabasit PDFchikoopandaNo ratings yet

- O Ring Catalogue 2022Document179 pagesO Ring Catalogue 2022Muhammad Kamran AsgharNo ratings yet

- Omega Elastomeric Couplings - Installation ManualDocument2 pagesOmega Elastomeric Couplings - Installation ManualmmkattaNo ratings yet

- Mechanical Seal Installation InstructionDocument4 pagesMechanical Seal Installation InstructionSandi AslanNo ratings yet

- Jaw Rrs Spacer Install Guide August 2012Document5 pagesJaw Rrs Spacer Install Guide August 2012vishnugopalSNo ratings yet

- Hydrocam Bolt TensionerDocument74 pagesHydrocam Bolt TensionerDjeison SeccoNo ratings yet

- CCK - W33 - Mounting - Withdrawal Sleeve - Mechanical MountingDocument14 pagesCCK - W33 - Mounting - Withdrawal Sleeve - Mechanical Mountingpmf engineering limitedNo ratings yet

- 471 Harness InstallDocument2 pages471 Harness InstallMahrukh Mumtaz HussainNo ratings yet

- Vision Metron Stem Technical DocumentsDocument2 pagesVision Metron Stem Technical DocumentsDong DangNo ratings yet

- Salsa Cross InstructionsDocument2 pagesSalsa Cross InstructionsdirtydealerNo ratings yet

- Stem Installation Instructions: Top View Top Cap 5mm Spacer Steere Tube 2mm Above The Stem ClampDocument2 pagesStem Installation Instructions: Top View Top Cap 5mm Spacer Steere Tube 2mm Above The Stem ClampHugoMSTNo ratings yet

- Fork ArmDocument26 pagesFork ArmtulogmulatNo ratings yet

- Owners Manual Judy 2000Document6 pagesOwners Manual Judy 2000groening1993No ratings yet

- Large Medium ExternalfixatorsDocument42 pagesLarge Medium ExternalfixatorsZulfadli Salleh0% (1)

- CJ Install Guide July2012Document4 pagesCJ Install Guide July2012refeiNo ratings yet

- Acoples FLOWSERVE - Instalación PDFDocument12 pagesAcoples FLOWSERVE - Instalación PDFJenny Cecilia Ureña ZuriNo ratings yet

- Ba 42-06Document16 pagesBa 42-06Thameemul BuhariNo ratings yet

- RS Reba User ManualDocument63 pagesRS Reba User ManualRadu Nica0% (1)

- PDFDocument10 pagesPDFPaul HuaraychiriNo ratings yet

- Prodigy Eng-Sp Owners ManualDocument44 pagesProdigy Eng-Sp Owners ManualAlejandro Paz PerazzaNo ratings yet

- Riflescope Owner'S Guide: Model #: BT6245FG / BT6245F / BT5154 / BT4305 / BT1040 7-18Document48 pagesRiflescope Owner'S Guide: Model #: BT6245FG / BT6245F / BT5154 / BT4305 / BT1040 7-18JungleTeacherNo ratings yet

- AG05 ManualDocument9 pagesAG05 ManualRobertosocorro RamirezNo ratings yet

- Saf Holland Xl-fw482Document16 pagesSaf Holland Xl-fw482fdpc1987No ratings yet

- RockShox Dart User ManualDocument37 pagesRockShox Dart User Manualgeri052No ratings yet

- Type 180 8000352-03 - REV-DDocument17 pagesType 180 8000352-03 - REV-DTuvia LeNo ratings yet

- Operation Manual: Mag-Con™Document8 pagesOperation Manual: Mag-Con™hamid hoorshadNo ratings yet

- TopyDocument64 pagesTopyChristiano Calijorne de BarrosNo ratings yet

- Manitou ManualDocument6 pagesManitou Manualtuplow50% (2)

- Winwood: Carbon Fiber Fork Installation InstructionsDocument3 pagesWinwood: Carbon Fiber Fork Installation Instructionsjolu189No ratings yet

- 01600A 5 GPM 1" Impact Wrench: See Impact Accessories Next PageDocument22 pages01600A 5 GPM 1" Impact Wrench: See Impact Accessories Next PageMaria Teresa Fernández OlavarrietaNo ratings yet

- MD Manu Maintenance Web Am enDocument42 pagesMD Manu Maintenance Web Am enFranco MieresNo ratings yet

- Belt ConveyorDocument3 pagesBelt ConveyorGuru Raja Ragavendran NagarajanNo ratings yet

- OM 002 Belt Conveyor Idler Instruct 6E74091AB9993Document9 pagesOM 002 Belt Conveyor Idler Instruct 6E74091AB9993gopi_ggg20016099No ratings yet

- Ag-900 GunDocument24 pagesAg-900 GunROMERJOSENo ratings yet

- 0000007995.6018 en 0313Document72 pages0000007995.6018 en 0313Petros IosifidisNo ratings yet

- Hughes Torque Converter Installation InstructionsDocument3 pagesHughes Torque Converter Installation InstructionsMichael VasquezNo ratings yet

- Walk-behind-concrete-saw-Service ManualDocument20 pagesWalk-behind-concrete-saw-Service ManualNick KrugerNo ratings yet

- AXL - AxlesDocument7 pagesAXL - AxlesDavid GaciaNo ratings yet

- Owner S Manual: Suspension Front Fork W. Coil Spring or MCUDocument2 pagesOwner S Manual: Suspension Front Fork W. Coil Spring or MCUformilNo ratings yet

- 03175Document24 pages03175Daniel Valenzuela ArredondoNo ratings yet

- Understanding Roller Chain Wear Life - The Diamond Chain CompanyDocument4 pagesUnderstanding Roller Chain Wear Life - The Diamond Chain CompanyAhmad Nil ForoushanNo ratings yet

- NS ACR Stem Installation Instructions: Published - Oct, 2018. ZS210.v0 © Full Speed AheadDocument2 pagesNS ACR Stem Installation Instructions: Published - Oct, 2018. ZS210.v0 © Full Speed Aheadwarick mNo ratings yet

- General Laboratory ProceduresDocument64 pagesGeneral Laboratory ProceduresAli AlmakramiNo ratings yet

- Msi Belt ScaleDocument21 pagesMsi Belt ScaleApriasanNo ratings yet

- Fenner Precision Timing Belt Technical ManualDocument40 pagesFenner Precision Timing Belt Technical ManualsaddlemanNo ratings yet

- Ludeca Thoughts On Dowel Pins in Machine FeetDocument4 pagesLudeca Thoughts On Dowel Pins in Machine FeetskakerNo ratings yet

- HammerDocument20 pagesHammerdatnguyen789jNo ratings yet

- LEF - Limited End Float Installation GuideDocument2 pagesLEF - Limited End Float Installation Guidekresimir.mikoc9765No ratings yet

- Prensa Kurt D688Document17 pagesPrensa Kurt D688Arnulfo Larragoitia Martinez100% (1)

- Indy Universal 3-Speed Shifter (Tall) : Installation InstructionsDocument6 pagesIndy Universal 3-Speed Shifter (Tall) : Installation InstructionsMarcelo Diaz WongNo ratings yet

- Tabla Tension Correas GatesDocument4 pagesTabla Tension Correas Gatesvibrador0% (1)

- Operating/assembly Instructions Sport-Thieme Parallel BarsDocument4 pagesOperating/assembly Instructions Sport-Thieme Parallel BarsIsti NisaNo ratings yet

- Why Industrial Bearings Fail: Analysis, Maintenance, and PreventionFrom EverandWhy Industrial Bearings Fail: Analysis, Maintenance, and PreventionNo ratings yet

- Band Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsFrom EverandBand Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsRating: 5 out of 5 stars5/5 (1)

- THYSSENKRUPP ElevatorDocument3 pagesTHYSSENKRUPP Elevatorhamid taher50% (2)

- Apache Spark Fundamentals: Getting StartedDocument28 pagesApache Spark Fundamentals: Getting StartedArunachalam NarayananNo ratings yet

- Computer Science 2210 Class 9 Revised Syllabus Break Up2020-21-23Document5 pagesComputer Science 2210 Class 9 Revised Syllabus Break Up2020-21-23MohammadNo ratings yet

- Template RFP Draft (050516)Document13 pagesTemplate RFP Draft (050516)UGHANo ratings yet

- Netapp - Auto Support - LogsDocument2 pagesNetapp - Auto Support - LogsMarioNo ratings yet

- Complete PowerlineDocument164 pagesComplete PowerlineHarshal AmbatkarNo ratings yet

- Electric and Hybrid Electric Vehicles 1 Edition James D Halderman Full ChapterDocument63 pagesElectric and Hybrid Electric Vehicles 1 Edition James D Halderman Full Chaptersusie.menefee409100% (7)

- ETech Week5 Ver1Document25 pagesETech Week5 Ver1Alexis Justin YapNo ratings yet

- Software For PP / PPK Study Results: Spring Bracket Centre 2171 3240 3304Document5 pagesSoftware For PP / PPK Study Results: Spring Bracket Centre 2171 3240 3304Gurjeet SinghNo ratings yet

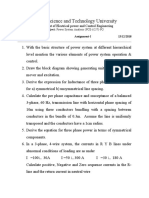

- Adama Science and Technology University: Department of Electrical Power and Control EngineeringDocument2 pagesAdama Science and Technology University: Department of Electrical Power and Control EngineeringOkezaki TemoyoNo ratings yet

- An2292 PDFDocument9 pagesAn2292 PDFMarcel BlinduNo ratings yet

- STRG6653 PDFDocument8 pagesSTRG6653 PDFAman MobilesNo ratings yet

- Thomson M300E512Document24 pagesThomson M300E512duskee4573100% (1)

- Product Manual: Manufacturer of Marine Doors and Windows Since 1943Document40 pagesProduct Manual: Manufacturer of Marine Doors and Windows Since 1943Begad MohamedNo ratings yet

- Fortios v7.0.0 Release NotesDocument91 pagesFortios v7.0.0 Release NotesSandro Henrique de OliveiraNo ratings yet

- 8 Active-JourneysDocument5 pages8 Active-JourneysZhennan ZhangNo ratings yet

- Brand PerceptionDocument105 pagesBrand Perceptionlekshmi517100% (1)

- Diesel Power PlantDocument15 pagesDiesel Power PlantJennsonFernandezNo ratings yet

- CD M&W 2008 Ed - Sect 2 - CD Valves and PrefiltersDocument12 pagesCD M&W 2008 Ed - Sect 2 - CD Valves and PrefiltersThamaraiselvan RamadossNo ratings yet

- AssetDocument13 pagesAssetrageendrathasNo ratings yet

- Admaterials Technologies Pte-Civil Operations ManagerDocument1 pageAdmaterials Technologies Pte-Civil Operations ManagerAkmalNo ratings yet

- Use Case ModelingDocument31 pagesUse Case ModelingpacharneajayNo ratings yet

- Installation of TransformerDocument24 pagesInstallation of TransformerMariel A. ReyesNo ratings yet

- AlpsDocument4 pagesAlpsciohaniNo ratings yet

- 3 - Content - Introduction To Java, JVM, JDK PDFDocument8 pages3 - Content - Introduction To Java, JVM, JDK PDFAnonymous zdY202lgZYNo ratings yet

- Systems Programming: Tutorial Eleven: Sheet-Five-SolutionsDocument23 pagesSystems Programming: Tutorial Eleven: Sheet-Five-SolutionsYoussef VictorNo ratings yet

- 2006 Toyota Sequoia Fuse Box DiagramDocument6 pages2006 Toyota Sequoia Fuse Box DiagramJohnNo ratings yet

- Low Voltage PLM Workflows - Serial Release (PM210 / PM220 / PM250)Document4 pagesLow Voltage PLM Workflows - Serial Release (PM210 / PM220 / PM250)DEEPA VISHWAKARMANo ratings yet