Professional Documents

Culture Documents

Trakmaster Fuel Cells Msds

Uploaded by

Syerifaizal Hj. MustaphaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Trakmaster Fuel Cells Msds

Uploaded by

Syerifaizal Hj. MustaphaCopyright:

Available Formats

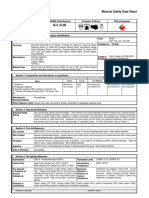

RAMSET/SPIT PULSA FUEL CELLS FOR USE WITH CABLEMASTER, TRAKMASTER,

CABLEMASTER800 AND TRAKFAST800 TOOLS

Chemwatch Independent Material Safety Data Sheet

Issue Date: 14-Oct-2013

9317SP

CHEMWATCH 8816-01

Version No:7.1.1.1

CD 2013/2 Page 1 of 9

Section 1 - CHEMICAL PRODUCT AND COMPANY IDENTIFICATION

PRODUCT NAME

RAMSET/SPIT PULSA FUEL CELLS FOR USE WITH CABLEMASTER, TRAKMASTER, CABLEMASTER800 AND TRAKFAST800 TOOLS

SYNONYMS

"SC615, C620, SC620, C625, C630, C635, C640"

PROPER SHIPPING NAME

FUEL CELL CARTRIDGES or FUEL CELL CARTRIDGES CONTAINED IN EQUIPMENT or FUEL CELL CARTRIDGES PACKED WITH

EQUIPMENT containing liquefied flammable gas

PRODUCT USE

The use of a quantity of material in an unventilated or confined space may result in increased exposure and an irritating

atmosphere developing. Before starting consider control of exposure by mechanical ventilation.

Used according to manufacturer's directions.

SUPPLIER

Company: ITW Australia Pty Ltd (Ramset)

Address:

1 Ramset Drive

Chirnside Park

VIC, 3116

Australia

Telephone: 1300 780 063

Telephone: +61 3 9726 6222

Emergency Tel:1800 039 008 (24 hrs)

Web site: www.ramset.com.au

Section 2 - HAZARDS IDENTIFICATION

STATEMENT OF HAZARDOUS NATURE

DANGEROUS GOODS. NON-HAZARDOUS SUBSTANCE. According to NOHSC Criteria, and ADG Code.

CHEMWATCH HAZARD RATINGS

Flammability

Toxicity

Body Contact

Reactivity

Chronic

SCALE:

Min/Nil=0

Low=1

Moderate=2

High=3

Extreme=4

RISK

Risk Codes

R12

R44

Risk Phrases

Extremely flammable.

Risk of explosion if heated under confinement.

SAFETY

Safety Codes

S16

S60

Safety Phrases

Keep away from sources of ignition. No smoking.

This material and its container must be disposed of as hazardous waste.

continued...

RAMSET/SPIT PULSA FUEL CELLS FOR USE WITH CABLEMASTER, TRAKMASTER,

CABLEMASTER800 AND TRAKFAST800 TOOLS

Chemwatch Independent Material Safety Data Sheet

Issue Date: 14-Oct-2013

9317SP

CHEMWATCH 8816-01

Version No:7.1.1.1

CD 2013/2 Page 2 of 9

Section 3 - COMPOSITION / INFORMATION ON INGREDIENTS

NAME

butane

propylene

CAS RN

106-97-8.

115-07-1

%

NotSpec

NotSpec

Section 4 - FIRST AID MEASURES

SWALLOWED

Avoid giving milk or oils.

Avoid giving alcohol.

Not considered a normal route of entry.

If spontaneous vomiting appears imminent or occurs, hold patient's head down, lower than their hips to help avoid possible

aspiration of vomitus.

EYE

If product comes in contact with eyes remove the patient from gas source or contaminated area.

Take the patient to the nearest eye wash, shower or other source of clean water.

Open the eyelid(s) wide to allow the material to evaporate.

Gently rinse the affected eye(s) with clean, cool water for at least 15 minutes. Have the patient lie or sit down and tilt the

head back. Hold the eyelid(s) open and pour water slowly over the eyeball(s) at the inner corners, letting the water run out of

the outer corners.

SKIN

If skin or hair contact occurs:

Flush skin and hair with running water (and soap if available).

Seek medical attention in event of irritation.

INHALED

Following exposure to gas, remove the patient from the gas source or contaminated area.

NOTE: Personal Protective Equipment (PPE), including positive pressure self-contained breathing apparatus may be required to

assure the safety of the rescuer.

Prostheses such as false teeth, which may block the airway, should be removed, where possible, prior to initiating first aid

procedures.

If the patient is not breathing spontaneously, administer rescue breathing.

NOTES TO PHYSICIAN

For acute or short term repeated exposures to petroleum distillates or related hydrocarbons:

Primary threat to life, from pure petroleum distillate ingestion and/or inhalation, is respiratory failure.

Patients should be quickly evaluated for signs of respiratory distress (e.g. cyanosis, tachypnoea, intercostal retraction,

obtundation) and given oxygen. Patients with inadequate tidal volumes or poor arterial blood gases (pO2 50 mm Hg) should be

intubated.

Arrhythmias complicate some hydrocarbon ingestion and/or inhalation and electrocardiographic evidence of myocardial injury has

been reported; intravenous lines and cardiac monitors should be established in obviously symptomatic patients. The lungs

excrete inhaled solvents, so that hyperventilation improves clearance.

A chest x-ray should be taken immediately after stabilisation of breathing and circulation to document aspiration and detect

the presence of pneumothorax.

For frost-bite caused by liquefied petroleum gas:

If part has not thawed, place in warm water bath (41-46 C) for 15-20 minutes, until the skin turns pink or red.

Analgesia may be necessary while thawing.

If there has been a massive exposure, the general body temperature must be depressed, and the patient must be immediately

rewarmed by whole-body immersion, in a bath at the above temperature.

Shock may occur during rewarming.

for gas exposures:

-------------------------------------------------------------BASIC TREATMENT

------------------------------------------------------------- Establish a patent airway with suction where necessary.

Watch for signs of respiratory insufficiency and assist ventilation as necessary.

Administer oxygen by non-rebreather mask at 10 to 15 l/min.

Monitor and treat, where necessary, for pulmonary oedema .

continued...

RAMSET/SPIT PULSA FUEL CELLS FOR USE WITH CABLEMASTER, TRAKMASTER,

CABLEMASTER800 AND TRAKFAST800 TOOLS

Chemwatch Independent Material Safety Data Sheet

Issue Date: 14-Oct-2013

9317SP

CHEMWATCH 8816-01

Version No:7.1.1.1

CD 2013/2 Page 3 of 9

Section 5 - FIRE FIGHTING MEASURES

EXTINGUISHING MEDIA

DO NOT EXTINGUISH BURNING GAS UNLESS LEAK CAN BE STOPPED SAFELY:

OTHERWISE: LEAVE GAS TO BURN.

FOR SMALL FIRE:

Dry chemical, CO2 or water spray to extinguish gas (only if absolutely necessary and safe to do so).

DO NOT use water jets.

FOR LARGE FIRE:

Cool cylinder by direct flooding quantities of water onto upper surface until well after fire is out.

DO NOT direct water at source of leak or venting safety devices as icing may occur.

FIRE FIGHTING

FOR FIRES INVOLVING MANY GAS CYLINDERS:

To stop the flow of gas, specifically trained personnel may inert the atmosphere to reduce oxygen levels thus allowing the

capping of leaking container(s).

Reduce the rate of flow and inject an inert gas, if possible, before completely stopping the flow to prevent flashback.

DO NOT extinguish the fire until the supply is shut off otherwise an explosive re-ignition may occur.

If the fire is extinguished and the flow of gas continues, used increased ventilation to prevent build-up, of explosive

atmosphere.

-------------------------------------------------------------GENERAL

------------------------------------------------------------- Alert Fire Brigade and tell them location and nature of hazard.

May be violently or explosively reactive.

Wear breathing apparatus plus protective gloves.

Consider evacuation.

FIRE/EXPLOSION HAZARD

HIGHLY FLAMMABLE: will be easily ignited by heat, sparks or flames.

Will form explosive mixtures with air

Fire exposed containers may vent contents through pressure relief valves thereby increasing fire intensity and/ or vapour

concentration.

Vapours may travel to source of ignition and flash back.

Combustion products include: carbon monoxide (CO), carbon dioxide (CO2), other pyrolysis products typical of burning organic

material.

FIRE INCOMPATIBILITY

Avoid contamination with oxidising agents i.e. nitrates, oxidising acids, chlorine bleaches, pool chlorine etc. as ignition may

result.

HAZCHEM

2Y

Section 6 - ACCIDENTAL RELEASE MEASURES

MINOR SPILLS

Avoid breathing vapour and any contact with liquid or gas. Protective equipment including respirator should be used.

DO NOT enter confined spaces where gas may have accumulated.

Shut off all sources of possible ignition and increase ventilation.

Clear area of personnel.

MAJOR SPILLS

Clear area of all unprotected personnel and move upwind.

Alert Emergency Authority and advise them of the location and nature of hazard.

May be violently or explosively reactive.

Wear full body clothing with breathing apparatus.

Remove leaking cylinders to a safe place.

Fit vent pipes. Release pressure under safe, controlled conditions

Burn issuing gas at vent pipes.

DO NOT exert excessive pressure on valve; DO NOT attempt to operate damaged valve.

Personal Protective Equipment advice is contained in Section 8 of the MSDS.

continued...

RAMSET/SPIT PULSA FUEL CELLS FOR USE WITH CABLEMASTER, TRAKMASTER,

CABLEMASTER800 AND TRAKFAST800 TOOLS

Chemwatch Independent Material Safety Data Sheet

Issue Date: 14-Oct-2013

9317SP

CHEMWATCH 8816-01

Version No:7.1.1.1

CD 2013/2 Page 4 of 9

Section 7 - HANDLING AND STORAGE

PROCEDURE FOR HANDLING

Containers, even those that have been emptied, may contain explosive vapours.

Do NOT cut, drill, grind, weld or perform similar operations on or near containers.

Electrostatic discharge may be generated during pumping - this may result in fire.

Ensure electrical continuity by bonding and grounding (earthing) all equipment.

Restrict line velocity during pumping in order to avoid generation of electrostatic discharge (<=1 m/sec until fill pipe

submerged to twice its diameter, then <= 7 m/sec).

Avoid splash filling.

Consider use in closed pressurised systems, fitted with temperature, pressure and safety relief valves which are vented for

safe dispersal.

The tubing network design connecting gas cylinders to the delivery system should include appropriate pressure indicators and

vacuum or suction lines.

Fully-welded types of pressure gauges, where the bourdon tube sensing element is welded to the gauge body, are recommended.

Before connecting gas cylinders, ensure manifold is mechanically secure and does not containing another gas. Before

disconnecting gas cylinder, isolate supply line segment proximal to cylinder, remove trapped gas in supply line with aid of

vacuum pump.

Avoid generation of static electricity. Earth all lines and equipment.

DO NOT transfer gas from one cylinder to another.

SUITABLE CONTAINER

Cylinder:

Ensure the use of equipment rated for cylinder pressure.

Ensure the use of compatible materials of construction.

Valve protection cap to be in place until cylinder is secured, connected.

Fuel cell cartridge

STORAGE INCOMPATIBILITY

Compressed gases may contain a large amount of kinetic energy over and above that potentially available from the energy of

reaction produced by the gas in chemical reaction with other substances.

Avoid reaction with oxidising agents.

STORAGE REQUIREMENTS

Store in original containers in approved flame-proof area.

DO NOT store in pits, depressions, basements or areas where vapours may be trapped.

No smoking, naked lights, heat or ignition sources.

Keep containers securely sealed. Contents under pressure.

Store away from incompatible materials.

Store in a cool, dry, well ventilated area in an upright position.

Avoid storage at temperatures higher than 49 deg C.

Protect containers against physical damage and check regularly for leaks.

Observe manufacturer's storing and handling recommendations.

Section 8 - EXPOSURE CONTROLS / PERSONAL PROTECTION

EXPOSURE CONTROLS

Source

___________

Australia Exposure Standards

Material

___________

Ramset/Spit Pulsa Fuel Cells for

use with CableMaster,

TrakMaster, CableMaster800 and

TrakFast800 tools (Butane)

The following materials had no OELs on our records

propylene:

TWA ppm

_______

800

Notes

_______

American

Conference of

Governmental

Industrial

Hygienists

(ACGIH)4, 5 is

the

documentation

source

CAS:115- 07- 1

MATERIAL DATA

RAMSET/SPIT PULSA FUEL CELLS FOR USE WITH CABLEMASTER, TRAKMASTER, CABLEMASTER800 AND TRAKFAST800 TOOLS:

Sensory irritants are chemicals that produce temporary and undesirable side-effects on the eyes, nose or throat.

Historically occupational exposure standards for these irritants have been based on observation of workers' responses to various

continued...

RAMSET/SPIT PULSA FUEL CELLS FOR USE WITH CABLEMASTER, TRAKMASTER,

CABLEMASTER800 AND TRAKFAST800 TOOLS

Chemwatch Independent Material Safety Data Sheet

Issue Date: 14-Oct-2013

9317SP

CHEMWATCH 8816-01

Version No:7.1.1.1

CD 2013/2 Page 5 of 9

Section 8 - EXPOSURE CONTROLS / PERSONAL PROTECTION

airborne concentrations.

BUTANE:

For butane:

Odour Threshold Value: 2591 ppm (recognition)

Butane in common with other homologues in the straight chain saturated aliphatic hydrocarbon series is not characterised by

its toxicity but by its narcosis-inducing effects at high concentrations. The TLV is based on analogy with pentane by comparing

their lower explosive limits in air.

Odour Safety Factor(OSF)

OSF=0.22 (n-BUTANE).

PROPYLENE:

May act as a simple asphyxiants; these are gases which, when present in high concentrations, reduce the oxygen content in

air below that required to support breathing, consciousness and life; loss of consciousness, with death by suffocation may

rapidly occur in an oxygen deficient atmosphere.

CARE: Most simple asphyxiants are odourless or possess low odour and there is no warning on entry into an oxygen deficient

atmosphere.

NOTE: This substance has been classified by the ACGIH as A4 NOT classifiable as causing Cancer in humans.

PERSONAL PROTECTION

RESPIRATOR

Type AG Filter of sufficient capacity. (AS/NZS 1716 & 1715, EN 143:2000 & 149:2001, ANSI Z88 or national equivalent)

EYE

Safety glasses with side shields.

Chemical goggles.

Contact lenses may pose a special hazard; soft contact lenses may absorb and concentrate irritants. A written policy document,

describing the wearing of lens or restrictions on use, should be created for each workplace or task. This should include a

review of lens absorption and adsorption for the class of chemicals in use and an account of injury experience. Medical and

first-aid personnel should be trained in their removal and suitable equipment should be readily available. In the event of

chemical exposure, begin eye irrigation immediately and remove contact lens as soon as practicable. Lens should be removed at

the first signs of eye redness or irritation - lens should be removed in a clean environment only after workers have washed

hands thoroughly. [CDC NIOSH Current Intelligence Bulletin 59], [AS/NZS 1336 or national equivalent].

HANDS/FEET

When handling sealed and suitably insulated cylinders wear cloth or leather gloves.

OTHER

The clothing worn by process operators insulated from earth may develop static charges far higher (up to 100 times) than the

minimum ignition energies for various flammable gas-air mixtures. This holds true for a wide range of clothing materials

including cotton.

Avoid dangerous levels of charge by ensuring a low resistivity of the surface material worn outermost.

BRETHERICK: Handbook of Reactive Chemical Hazards.

Protective overalls, closely fitted at neck and wrist.

Eye-wash unit.

IN CONFINED SPACES:

Non-sparking protective boots

Static-free clothing.

Some plastic personal protective equipment (PPE) (e.g. gloves, aprons, overshoes) are not recommended as they may produce

static electricity.

For large scale or continuous use wear tight-weave non-static clothing (no metallic fasteners, cuffs or pockets), non sparking

safety footwear.

ENGINEERING CONTROLS

Engineering controls are used to remove a hazard or place a barrier between the worker and the hazard. Well-designed

engineering controls can be highly effective in protecting workers and will typically be independent of worker interactions to

provide this high level of protection.

The basic types of engineering controls are:

Process controls which involve changing the way a job activity or process is done to reduce the risk.

Enclosure and/or isolation of emission source which keeps a selected hazard "physically" away from the worker and ventilation

that strategically "adds" and "removes" air in the work environment.

continued...

RAMSET/SPIT PULSA FUEL CELLS FOR USE WITH CABLEMASTER, TRAKMASTER,

CABLEMASTER800 AND TRAKFAST800 TOOLS

Chemwatch Independent Material Safety Data Sheet

Issue Date: 14-Oct-2013

9317SP

CHEMWATCH 8816-01

Version No:7.1.1.1

CD 2013/2 Page 6 of 9

Section 9 - PHYSICAL AND CHEMICAL PROPERTIES

APPEARANCE

Metal pressurised cylinder with compressed gas.

PHYSICAL PROPERTIES

Gas.

Does not mix with water.

State

Melting Range (C)

Boiling Range (C)

Flash Point (C)

Decomposition Temp (C)

Autoignition Temp (C)

Upper Explosive Limit (%)

Lower Explosive Limit (%)

Compressed Gas

Not Available

- 48 to - 1 (butane)

- 80 approx (propene)

Not Available

Not Available

11.7

1.5

Volatile Component (%vol)

Not Available

Molecular Weight

Viscosity

Solubility in water (g/L)

pH (1% solution)

pH (as supplied)

Vapour Pressure (kPa)

Specific Gravity (water=1)

Relative Vapour Density

(air=1)

Evaporation Rate

Not Available

Not Available

Immiscible

Not Applicable

Not Applicable

700 @20C

Not Available

Not Available

Not Available

Section 10 - STABILITY AND REACTIVITY

CONDITIONS CONTRIBUTING TO INSTABILITY

Presence of incompatible materials.

Product is considered stable.

Hazardous polymerisation will not occur.

For incompatible materials - refer to Section 7 - Handling and Storage.

Section 11 - TOXICOLOGICAL INFORMATION

POTENTIAL HEALTH EFFECTS

ACUTE HEALTH EFFECTS

SWALLOWED

Accidental ingestion of the material may be damaging to the health of the individual.

Not normally a hazard due to physical form of product.

Considered an unlikely route of entry in commercial/industrial environments.

Central nervous system (CNS) depression may include general discomfort, symptoms of giddiness, headache, dizziness, nausea,

anaesthetic effects, slowed reaction time, slurred speech and may progress to unconsciousness. Serious poisonings may result in

respiratory depression and may be fatal.

EYE

There is some evidence to suggest that this material can cause eye irritation and damage in some persons.

Not considered to be a risk because of the extreme volatility of the gas.

SKIN

Repeated exposure may cause skin cracking, flaking or drying following normal handling and use.

Open cuts, abraded or irritated skin should not be exposed to this material.

Entry into the blood-stream, through, for example, cuts, abrasions or lesions, may produce systemic injury with harmful effects.

Examine the skin prior to the use of the material and ensure that any external damage is suitably protected.

INHALED

Inhalation of vapours may cause drowsiness and dizziness. This may be accompanied by sleepiness, reduced alertness, loss of

reflexes, lack of co-ordination, and vertigo.

Inhalation of vapours or aerosols (mists, fumes), generated by the material during the course of normal handling, may be damaging

to the health of the individual.

There is some evidence to suggest that the material can cause respiratory irritation in some persons. The body's response to such

irritation can cause further lung damage.

Inhalation of non-toxic gases may cause:

CNS effects: headache, confusion, dizziness, stupor, seizures and coma;

respiratory: shortness of breath and rapid breathing;

cardiovascular: collapse and irregular heart beats;

gastrointestinal: mucous membrane irritation, nausea and vomiting.

continued...

RAMSET/SPIT PULSA FUEL CELLS FOR USE WITH CABLEMASTER, TRAKMASTER,

CABLEMASTER800 AND TRAKFAST800 TOOLS

Chemwatch Independent Material Safety Data Sheet

Issue Date: 14-Oct-2013

9317SP

CHEMWATCH 8816-01

Version No:7.1.1.1

CD 2013/2 Page 7 of 9

Section 11 - TOXICOLOGICAL INFORMATION

Inhalation of high concentrations of gas/vapour causes lung irritation with coughing and nausea, central nervous depression with

headache and dizziness, slowing of reflexes, fatigue and inco-ordination.

Central nervous system (CNS) depression may include general discomfort, symptoms of giddiness, headache, dizziness, nausea,

anaesthetic effects, slowed reaction time, slurred speech and may progress to unconsciousness. Serious poisonings may result in

respiratory depression and may be fatal.

CHRONIC HEALTH EFFECTS

There has been some concern that this material can cause cancer or mutations but there is not enough data to make an assessment.

Principal route of occupational exposure to the gas is by inhalation.

TOXICITY AND IRRITATION

inhalation of the gas.

CARCINOGEN

propylene

International Agency for

Research on Cancer (IARC) Agents Reviewed by the IARC

Monographs

Group

Not classifiable as

to its

carcinogenicity to

humans

Section 12 - ECOLOGICAL INFORMATION

This material and its container must be disposed of as hazardous waste.

Ecotoxicity

Ingredient

butane

Persistence:

Water/Soil

LOW

propylene

LOW

Persistence: Air

Bioaccumulation

Mobility

No Data

Available

LOW

LOW

HIGH

LOW

No Data

Available

Section 13 - DISPOSAL CONSIDERATIONS

Evaporate or incinerate residue at an approved site.

Return empty containers to supplier.

Ensure damaged or non-returnable cylinders are gas-free before disposal.

Section 14 - TRANSPORTATION INFORMATION

Labels Required: FLAMMABLE GAS

HAZCHEM:

2Y (ADG7)

ADG7:

Class or Division:

UN No.:

Special Provision:

Portable Tanks & Bulk

Containers Instruction:

Packagings & IBCs Packing Instruction:

2.1

3478

328 338

None

Subsidiary Risk:

Packing Group:

Limited Quantity:

Portable Tanks & Bulk

Containers - Special

Provision:

P004

Packagings & IBCs Special Packing

Provision:

Name and Description: FUEL CELL CARTRIDGES or FUEL CELL CARTRIDGES

CONTAINED IN EQUIPMENT or FUEL CELL CARTRIDGES PACKED WITH

EQUIPMENT, containing liquefied flammable gas

None

None

120 ml

None

None

continued...

RAMSET/SPIT PULSA FUEL CELLS FOR USE WITH CABLEMASTER, TRAKMASTER,

CABLEMASTER800 AND TRAKFAST800 TOOLS

Chemwatch Independent Material Safety Data Sheet

Issue Date: 14-Oct-2013

9317SP

Air Transport IATA:

ICAO/IATA Class:

UN/ID Number:

Special provisions:

Cargo Only

Packing Instructions:

Passenger and Cargo

Packing Instructions:

Passenger and Cargo

Limited Quantity

Packing Instructions:

CHEMWATCH 8816-01

Version No:7.1.1.1

CD 2013/2 Page 8 of 9

Section 14 - TRANSPORTATION INFORMATION

2.1

3478

A146

ICAO/IATA Subrisk:

Packing Group:

None

-

217

Maximum Qty/Pack:

Passenger and Cargo

Maximum Qty/Pack:

Passenger and Cargo

Limited Quantity

Maximum Qty/Pack:

15 kg

217

Forbidden

1 kg

Forbidden

Shipping name:FUEL CELL CARTRIDGES or FUEL CELL CARTRIDGES CONTAINED IN EQUIPMENT or FUEL CELL CARTRIDGES PACKED

containing liquefied flammable gas

Maritime Transport IMDG:

IMDG Class:

2.1

IMDG Subrisk:

None

UN Number:

3478

Packing Group:

None

EMS Number:

F- D, S- U

Special provisions:

328 338

Limited Quantities:

120 ml

Shipping name:FUEL CELL CARTRIDGES or FUEL CELL CARTRIDGES CONTAINED IN EQUIPMENT or FUEL CELL CARTRIDGES PACKED

containing liquefied flammable gas

Section 15 - REGULATORY INFORMATION

Indications of Danger:

F+

Extremely flammable

POISONS SCHEDULE None

REGULATIONS

Regulations for ingredients

butane (CAS: 106-97-8) is found on the following regulatory lists;

"Acros Transport Information","Australia Exposure Standards","Australia FAISD Handbook - First Aid Instructions, Warning

Statements, and General Safety Precautions","Australia Hazardous Substances","Australia High Volume Industrial Chemical List

(HVICL)","Australia Inventory of Chemical Substances (AICS)","Australia National Pollutant Inventory","Australia Standard for the

Uniform Scheduling of Medicines and Poisons (SUSMP) - Appendix E (Part 2)","Australia Standard for the Uniform Scheduling of

Medicines and Poisons (SUSMP) - Schedule 5","International Council of Chemical Associations (ICCA) - High Production Volume List",

"International Numbering System for Food Additives","OECD List of High Production Volume (HPV) Chemicals","Sigma-AldrichTransport

Information"

propylene (CAS: 115-07-1) is found on the following regulatory lists;

"Australia FAISD Handbook - First Aid Instructions, Warning Statements, and General Safety Precautions","Australia Hazardous

Substances","Australia High Volume Industrial Chemical List (HVICL)","Australia Inventory of Chemical Substances (AICS)",

"Australia National Pollutant Inventory","Australia Standard for the Uniform Scheduling of Medicines and Poisons (SUSMP) Appendix E (Part 2)","Australia Standard for the Uniform Scheduling of Medicines and Poisons (SUSMP) - Schedule 5","International

Agency for Research on Cancer (IARC) - Agents Reviewed by the IARC Monographs","International Council of Chemical Associations

(ICCA) - High Production Volume List","OECD List of High Production Volume (HPV) Chemicals","Sigma-AldrichTransport Information"

No data for Ramset/Spit Pulsa Fuel Cells for use with CableMaster, TrakMaster, CableMaster800

and TrakFast800 tools (CW: 8816-01)

Section 16 - OTHER INFORMATION

Classification of the preparation and its individual components has drawn on official and authoritative sources as well as

independent review by the Chemwatch Classification committee using available literature references.

A list of reference resources used to assist the committee may be found at:

www.chemwatch.net/references.

The (M)SDS is a Hazard Communication tool and should be used to assist in the Risk Assessment. Many factors determine whether

the reported Hazards are Risks in the workplace or other settings.

This document is copyright. Apart from any fair dealing for the purposes of private study, research, review or

criticism, as permitted under the Copyright Act, no part may be reproduced by any process without written

continued...

RAMSET/SPIT PULSA FUEL CELLS FOR USE WITH CABLEMASTER, TRAKMASTER,

CABLEMASTER800 AND TRAKFAST800 TOOLS

Chemwatch Independent Material Safety Data Sheet

Issue Date: 14-Oct-2013

9317SP

permission from CHEMWATCH. TEL (+61 3) 9572 4700.

Issue Date: 14-Oct-2013

Print Date: 15-Oct-2013

This is the end of the MSDS.

CHEMWATCH 8816-01

Version No:7.1.1.1

CD 2013/2 Page 9 of 9

Section 16 - OTHER INFORMATION

You might also like

- Construction Quality ManagementDocument85 pagesConstruction Quality Managementconstruction managment91% (23)

- AEG - JSA - 107 - Oxygen Acetylene Torch PDFDocument2 pagesAEG - JSA - 107 - Oxygen Acetylene Torch PDFanon_421433640No ratings yet

- Excavator Daily Inspection Check List Rev 0Document1 pageExcavator Daily Inspection Check List Rev 0Zhafran diniyNo ratings yet

- JSEA FOR EARTH WORK (Alumina Silo Area)Document13 pagesJSEA FOR EARTH WORK (Alumina Silo Area)MD AbdullahNo ratings yet

- Kitchen Safety: Preventing Cuts, Burns, Spills & MoreDocument21 pagesKitchen Safety: Preventing Cuts, Burns, Spills & MoreTara NahNo ratings yet

- Occupational Hazards Water Treatment ProcessesDocument14 pagesOccupational Hazards Water Treatment ProcessesMohamed Salem100% (1)

- Drilling Process PDFDocument2 pagesDrilling Process PDFmool rajNo ratings yet

- Gas Cutting SetDocument1 pageGas Cutting SetProjects DepartmentNo ratings yet

- HSE Alert - LTI Fall From Heights TBTDocument12 pagesHSE Alert - LTI Fall From Heights TBTrodman823No ratings yet

- Two Component Semi-Rigid Foam: NCL Pu Flex-2Document2 pagesTwo Component Semi-Rigid Foam: NCL Pu Flex-2Syerifaizal Hj. MustaphaNo ratings yet

- Confined Space Rescue PlanDocument4 pagesConfined Space Rescue PlanbalasubramaniamNo ratings yet

- 1 - Hazardous Materials Eng - UnlockedDocument19 pages1 - Hazardous Materials Eng - UnlockedAbubakr MohamedNo ratings yet

- PMP Audit ChecklistDocument6 pagesPMP Audit ChecklistSyerifaizal Hj. MustaphaNo ratings yet

- Mos - P.U InjectionDocument1 pageMos - P.U InjectionSyerifaizal Hj. MustaphaNo ratings yet

- Diesel Fuel MsdsDocument5 pagesDiesel Fuel MsdsAngelNo ratings yet

- EMS Audit ChecklistDocument4 pagesEMS Audit ChecklistSyerifaizal Hj. MustaphaNo ratings yet

- OB Afety NalysisDocument5 pagesOB Afety NalysisNaveed WarraichNo ratings yet

- SH Audit ChecklistDocument5 pagesSH Audit ChecklistSyerifaizal Hj. MustaphaNo ratings yet

- Job Safety Analysis for High Pressure TestingDocument5 pagesJob Safety Analysis for High Pressure TestingSaiyad RiyazaliNo ratings yet

- Testing of Bituminous MixturesDocument70 pagesTesting of Bituminous MixturesGlenn SendicoNo ratings yet

- Surface Blasting Safety Procedures ManualDocument21 pagesSurface Blasting Safety Procedures ManualRajanbabu100% (1)

- Permit No.: Binzagr National Distribution CenterDocument1 pagePermit No.: Binzagr National Distribution CenteryashNo ratings yet

- Daily Checklist Bulldozerpdf PDF FreeDocument1 pageDaily Checklist Bulldozerpdf PDF FreeRama Asmara TariganNo ratings yet

- SH - Shop Drawings Tracking ListDocument6 pagesSH - Shop Drawings Tracking ListSyerifaizal Hj. MustaphaNo ratings yet

- JSEA FOR DISMNTLING OF MACHINES (Central Work Shop)Document16 pagesJSEA FOR DISMNTLING OF MACHINES (Central Work Shop)B&R HSE BALCO SEP SiteNo ratings yet

- Notes - The Most Common Irregular VerbsDocument1 pageNotes - The Most Common Irregular VerbsSyerifaizal Hj. MustaphaNo ratings yet

- Indigo (The Search For True Understanding and Balance)Document197 pagesIndigo (The Search For True Understanding and Balance)Trunk Boolean100% (1)

- QMS Audit ChecklistDocument4 pagesQMS Audit ChecklistSyerifaizal Hj. MustaphaNo ratings yet

- Master List of Construction DrawingsDocument94 pagesMaster List of Construction DrawingsSyerifaizal Hj. MustaphaNo ratings yet

- Causes & DefinitionsDocument11 pagesCauses & DefinitionsSayed DarwishNo ratings yet

- Green Building Index Malaysia Assessment CriteriaDocument22 pagesGreen Building Index Malaysia Assessment CriteriaGholai KhocezkhoNo ratings yet

- Risk Assessment-KioskDocument3 pagesRisk Assessment-Kioskmubeen hassanNo ratings yet

- MOS UnloadingDocument3 pagesMOS UnloadingSyerifaizal Hj. MustaphaNo ratings yet

- 0545SP LUISRODRIGUEZ SELF-PACED U7 RN2 PruebaDocument84 pages0545SP LUISRODRIGUEZ SELF-PACED U7 RN2 PruebafilipfilipondioNo ratings yet

- ShoringDocument1 pageShoringSyerifaizal Hj. MustaphaNo ratings yet

- Petrochina International Jabung Ltd. Job Safety Analysis: Hse-Icg/Pcj-3075-Ca/Jsa.013Document5 pagesPetrochina International Jabung Ltd. Job Safety Analysis: Hse-Icg/Pcj-3075-Ca/Jsa.013Yosua SitumorangNo ratings yet

- Hira - CivilDocument20 pagesHira - Civilmurthy100% (1)

- Grand Toolbox (Monthly)Document3 pagesGrand Toolbox (Monthly)Suresh Praba PNo ratings yet

- John Burke - Safe Work at HeightDocument32 pagesJohn Burke - Safe Work at HeightRoman DuranNo ratings yet

- Welding JSADocument2 pagesWelding JSAMD AbdullahNo ratings yet

- Fire Safety Plan BookletDocument40 pagesFire Safety Plan BookletSofiqNo ratings yet

- Manual Handling Safety TipsDocument1 pageManual Handling Safety TipsNishadh NishNo ratings yet

- Office Fire Risk Assessment: AGP-OSHF-RA-01 - Rev.02Document3 pagesOffice Fire Risk Assessment: AGP-OSHF-RA-01 - Rev.02ramodNo ratings yet

- HSE-ICG/PCJ-3075-CA/JSA/015Document4 pagesHSE-ICG/PCJ-3075-CA/JSA/015Yosua SitumorangNo ratings yet

- Excavation Safety Dos and DontsDocument4 pagesExcavation Safety Dos and DontsVidya SagarNo ratings yet

- GE PTW Confined SpacesDocument2 pagesGE PTW Confined SpacesKural MurugesanNo ratings yet

- Confined Space Entry Permit DetailsDocument2 pagesConfined Space Entry Permit DetailsradeepNo ratings yet

- MSDS - Asada Threading Oiil Red - ENDocument7 pagesMSDS - Asada Threading Oiil Red - ENnghiaNo ratings yet

- Ocp BatchingDocument1 pageOcp BatchingAarya Mishra TiwariNo ratings yet

- GENCHI INDIA PVT.LTD JOB HAZARDS ANALYSISDocument2 pagesGENCHI INDIA PVT.LTD JOB HAZARDS ANALYSISsakthi venkatNo ratings yet

- Method Statement Form: Method Statement For Excavation / Dewatering of FGD (Chimney)Document4 pagesMethod Statement Form: Method Statement For Excavation / Dewatering of FGD (Chimney)poovazhaganNo ratings yet

- Lifting Support Risk AssessmentDocument10 pagesLifting Support Risk AssessmentcitraNo ratings yet

- Petronas Diesel Euro 2m Label2Document1 pagePetronas Diesel Euro 2m Label2mohdchemustafhaNo ratings yet

- Heat Stress: Dr. Lim Jac Fang Occupational & Environmental Health Department of Health, SabahDocument25 pagesHeat Stress: Dr. Lim Jac Fang Occupational & Environmental Health Department of Health, SabahAlexander KlmNo ratings yet

- Safety First: Safe Storage and Handling of Cleaning Agents and DisinfectantsDocument1 pageSafety First: Safe Storage and Handling of Cleaning Agents and DisinfectantsldmtrNo ratings yet

- Chemicals Can: Safe Handling of ChemicalsDocument1 pageChemicals Can: Safe Handling of ChemicalsJavier Quintero SaavedraNo ratings yet

- Name: SignDocument1 pageName: SignAdel AlKhedawyNo ratings yet

- Safety Orientation EssentialsDocument51 pagesSafety Orientation EssentialsTwinkle Cenn Masilungan100% (1)

- Jabil P009 Rough Terrain Crane Lifting PlanDocument9 pagesJabil P009 Rough Terrain Crane Lifting PlanViejay BalachandarNo ratings yet

- Working at Height PresentationDocument11 pagesWorking at Height PresentationAbdul Hameed OmarNo ratings yet

- Tiling Lesson 1.5.17Document7 pagesTiling Lesson 1.5.17Daryl MurrayNo ratings yet

- Pera JackhammerDocument7 pagesPera Jackhammerjumansyahamid1988No ratings yet

- Hi Tech Engineering SDN BHD Permit To Work System - Job Hazard AnalysisDocument3 pagesHi Tech Engineering SDN BHD Permit To Work System - Job Hazard AnalysisPHH9834No ratings yet

- Petrochina International Jabung Ltd. Job Safety Analysis: T On Ppe Required For A Safe JobDocument5 pagesPetrochina International Jabung Ltd. Job Safety Analysis: T On Ppe Required For A Safe JobYosua SitumorangNo ratings yet

- Z - MP-EHS-01 IRA - 03 Install HDPE Pipe Sleeve (1aug2023)Document3 pagesZ - MP-EHS-01 IRA - 03 Install HDPE Pipe Sleeve (1aug2023)Din JalilNo ratings yet

- Confined Space PermitDocument1 pageConfined Space PermitNethiyaaRajendranNo ratings yet

- Fire Prevention PlanDocument25 pagesFire Prevention PlanEMILYN DEPOLLONo ratings yet

- 1 45Document3 pages1 45nsadnan0% (1)

- Jsa Ndt-BuildingDocument5 pagesJsa Ndt-BuildingFirdaus RidzuanNo ratings yet

- Off-the-job safety tips for home and public placesDocument28 pagesOff-the-job safety tips for home and public placesFatima VeneracionNo ratings yet

- Risk Assessment For Stone WorkDocument17 pagesRisk Assessment For Stone WorkKhuda BukshNo ratings yet

- Galmet Spraypaint Aerosol SilverDocument11 pagesGalmet Spraypaint Aerosol SilverBiju_PottayilNo ratings yet

- Chemset 101 Plus MSDSDocument12 pagesChemset 101 Plus MSDSjlolhnpNo ratings yet

- Msds WD-40 3-IN-ONE PROFESSIONAL GARAGE DOOR LUBRICANTDocument8 pagesMsds WD-40 3-IN-ONE PROFESSIONAL GARAGE DOOR LUBRICANTHai HaNo ratings yet

- CREAM E-Magazine - Issue 1, January 2023Document24 pagesCREAM E-Magazine - Issue 1, January 2023Syerifaizal Hj. MustaphaNo ratings yet

- BC Bitumen Coating SDS en MYDocument8 pagesBC Bitumen Coating SDS en MYSyerifaizal Hj. MustaphaNo ratings yet

- Filing Labeling - Sample RoomDocument1 pageFiling Labeling - Sample RoomSyerifaizal Hj. MustaphaNo ratings yet

- Issue No - 4 - Cream E-MagDocument34 pagesIssue No - 4 - Cream E-MagSyerifaizal Hj. MustaphaNo ratings yet

- Davco Grout 280 Eco Sds en MyDocument9 pagesDavco Grout 280 Eco Sds en MySyerifaizal Hj. MustaphaNo ratings yet

- Issue No - 4 - Cream E-MagDocument34 pagesIssue No - 4 - Cream E-MagSyerifaizal Hj. MustaphaNo ratings yet

- CREAM E-Magazine - Issue 1, January 2023Document24 pagesCREAM E-Magazine - Issue 1, January 2023Syerifaizal Hj. MustaphaNo ratings yet

- Guide To Performance Management - 2023Document43 pagesGuide To Performance Management - 2023Syerifaizal Hj. MustaphaNo ratings yet

- RWTP-GB-AMS-L-000263-2023 - Proposal of Test Frequency For Site ImplementationDocument3 pagesRWTP-GB-AMS-L-000263-2023 - Proposal of Test Frequency For Site ImplementationSyerifaizal Hj. MustaphaNo ratings yet

- Control of RC WorksDocument52 pagesControl of RC WorksSyerifaizal Hj. MustaphaNo ratings yet

- Guide To Performance Management - 2023Document43 pagesGuide To Performance Management - 2023Syerifaizal Hj. MustaphaNo ratings yet

- BC Bitumen CoatingDocument3 pagesBC Bitumen CoatingSyerifaizal Hj. MustaphaNo ratings yet

- Jadual Minggu Orientasi SRIAZA 2023 Tahap 1Document1 pageJadual Minggu Orientasi SRIAZA 2023 Tahap 1Syerifaizal Hj. MustaphaNo ratings yet

- ESG ScreenshotDocument1 pageESG ScreenshotSyerifaizal Hj. MustaphaNo ratings yet

- Take Stocks QSHE Monthly Dashboard GBU - KPI July 2022.rev.00Document43 pagesTake Stocks QSHE Monthly Dashboard GBU - KPI July 2022.rev.00Syerifaizal Hj. MustaphaNo ratings yet

- Evaluation On Training EffectivenessDocument3 pagesEvaluation On Training EffectivenessSyerifaizal Hj. MustaphaNo ratings yet

- PARVIS - Lodgement Plan PDFDocument1 pagePARVIS - Lodgement Plan PDFSyerifaizal Hj. MustaphaNo ratings yet

- GEOTECHNICAL ENGINEERING-II SHEAR STRENGTH OF SOILSDocument26 pagesGEOTECHNICAL ENGINEERING-II SHEAR STRENGTH OF SOILSHamza RizviNo ratings yet

- Math 101 Midterm Requirements for Offline StudentsDocument22 pagesMath 101 Midterm Requirements for Offline Studentsmae KuanNo ratings yet

- Laboratory Ergonomics Checklist: (DOSH Registration)Document3 pagesLaboratory Ergonomics Checklist: (DOSH Registration)Bakhtiar DollahNo ratings yet

- Journal - Development PlanDocument11 pagesJournal - Development Planadeyemi kehindeNo ratings yet

- Alix HansonDocument1 pageAlix HansonAlix HinesNo ratings yet

- Latin Extended-C: Range: 2C60-2C7FDocument3 pagesLatin Extended-C: Range: 2C60-2C7FJhie EhefNo ratings yet

- PB97142129 PDFDocument192 pagesPB97142129 PDFMike2322No ratings yet

- CICLing2011 Manning TaggingDocument19 pagesCICLing2011 Manning TaggingMuhammad AbrarNo ratings yet

- Ansys Forte Users GuideDocument284 pagesAnsys Forte Users GuideMiguelSchuchterNo ratings yet

- Philosophy and The Hitchhiker's: Guide To The GalaxyDocument4 pagesPhilosophy and The Hitchhiker's: Guide To The GalaxyAggelou MayaNo ratings yet

- Lesson 1 Definition of Quantitative Research - pdf2Document8 pagesLesson 1 Definition of Quantitative Research - pdf2Funny JuanNo ratings yet

- WLP Science 6 Q1 Week 8Document13 pagesWLP Science 6 Q1 Week 8elizaldeNo ratings yet

- Total Eclipse Annie Dillard ThesisDocument7 pagesTotal Eclipse Annie Dillard Thesislisamartinezalbuquerque100% (1)

- Magnetic Fields of Electric CurrentsDocument24 pagesMagnetic Fields of Electric Currents李安逸No ratings yet

- TERMINOLOGI HUKUM-1st LectureDocument15 pagesTERMINOLOGI HUKUM-1st LectureAal Lukmanul HakimNo ratings yet

- Proportional-Integral-Derivative and Linear Quadratic Regulator Control of Direct Current Motor Position Using Multi-Turn Based On LabviewDocument5 pagesProportional-Integral-Derivative and Linear Quadratic Regulator Control of Direct Current Motor Position Using Multi-Turn Based On LabviewGERARDO CABRERANo ratings yet

- Conclusion and RecommendationDocument6 pagesConclusion and Recommendationapril rose soleraNo ratings yet

- Política de Seguridad, Protección, Salud, Medio Ambiente y Relaciones Comunitarias (SSHEC) - 2474877Document1 pagePolítica de Seguridad, Protección, Salud, Medio Ambiente y Relaciones Comunitarias (SSHEC) - 2474877Angel Del CastilloNo ratings yet

- HEERING, P. - Tools For Investigation, Tools For InstructionDocument9 pagesHEERING, P. - Tools For Investigation, Tools For InstructionDouglas DanielNo ratings yet

- Grade 11 Informal Writing Booklet 2 NEWDocument11 pagesGrade 11 Informal Writing Booklet 2 NEWMaria-Regina UkatuNo ratings yet

- Geotechnic ReportDocument29 pagesGeotechnic ReportSolomon Mehari100% (1)

- Gothic Horrors and The Double in FrankensteinDocument13 pagesGothic Horrors and The Double in FrankensteinCiara WhelanNo ratings yet

- SEO-optimized title for English exam documentDocument5 pagesSEO-optimized title for English exam documentAyu PermataNo ratings yet

- Hardness, Wear, Impact WNP 2021Document68 pagesHardness, Wear, Impact WNP 2021AdivadewanggaNo ratings yet

- Determine The Magnitude of Statistical Variates at Some Future Point of TimeDocument1 pageDetermine The Magnitude of Statistical Variates at Some Future Point of TimeJulie Ann MalayNo ratings yet

- CES 156-2015 ES-1996 Design of Masonry Structures - Part 1-1Document129 pagesCES 156-2015 ES-1996 Design of Masonry Structures - Part 1-1China AlemayehouNo ratings yet

- Units 1-5 Progress Test A: Macmillan Education Pobrano Przez Użytkownika Iwona Szulik 140979Document4 pagesUnits 1-5 Progress Test A: Macmillan Education Pobrano Przez Użytkownika Iwona Szulik 140979Łukasz KaczkaNo ratings yet

- Compliment of SetDocument4 pagesCompliment of SetFrancisco Rosellosa LoodNo ratings yet

- Unusual and Marvelous MapsDocument33 pagesUnusual and Marvelous MapsRajarajan100% (1)