Professional Documents

Culture Documents

Masterflow 410

Uploaded by

leodegarioporralOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Masterflow 410

Uploaded by

leodegarioporralCopyright:

Available Formats

( )

degussa. creating essentials

MASTERFLOW

410

High strength, free flowing epoxy grout

Excellent fatigue resistance.

Description

Compatibility with equipment subject to

extensive thermal movement.

MASTERFLOW 410 is a solvent free epoxy

High resistance to dynamic loads and

resin grout formulated to withstand static and

chemical attack.

dynamic loads in a wide variety of applications.

Non-shrink and tolerant of damp surfaces.

The product is three component and easily

mixed on site to a pourable consistency.

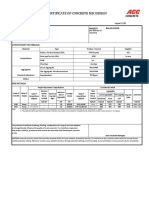

Typical properties*

MASTERFLOW 410 is suitable for an

application thickness range of 40-120mm where

* Properties listed are only for guidance and are not a

guarantee of performance.

high flow characteristics are required.

Pot life:

Thickness may be reduced to 20mm when flow

Compressive

strength

BS 6319 Part 2:

is not required.

at 25C

at 40C

24 hrs

3 days

70 min

40 min

88 N/mm

92 N/mm

7 days

96 N/mm

Flexural strength

BS 6319 Part 3:

Tensile strength

BS 6319 Part 7:

Density:

Typical applications

Anchors and fixing bolts

Crane and transporter rails.

Cure:

New and old machine base plates.

25 N/mm

at 25C

at 40C

13 N/mm

2175kg/m

7 Days

3 Days

Structural filling of holes and cavities in

concrete.

Packaging / yield

Industrial equipment and machinery subject

to static or dynamic forces.

MASTERFLOW 410 is supplied in 15kg and

Equipment where chemical and acid spillage

30kg units, which yield approximately 7 and 14

occurs.

litres respectively.

Pile cap waterproofing (at >20mm thickness)

Composition

Advantages

Bisphenol A epoxy resin base, a low viscosity

No priming required.

liquid reactor which when mixed with the inert

High tensile, flexural and compressive

aggregate forms an easily pourable and mobile

strength.

grout.

Excellent adhesion to steel and concrete.

Rapid installation and strength gain to

ensure early commissioning of equipment.

- - : -

http://www.bazarmaharem.com

E-Mail: info@bazarmaharem.com

( )

degussa. creating essentials

Placing:

Chemical resistance

Place immediately after mixing, into the

The resistance of MASTERFLOW 410 to most

prepared area in such a manner that it has the

common corrosive chemicals is excellent:

shortest distance to flow. For longer pours a

Dilute and concentrated alkalis

suitable head of pressure may be required.

Most dilute acids

Ensure the area to be grouted is not completely

Oil and petrol

sealed, and any displaced air can be expelled.

Ammonia

Pour continuously from one end only.

Formaldehyde

Saline solutions

Allow the grout to set prior to removal of

Mineral oil, vegetable and animal fats

formwork (normally after 6 hours). Where

placement exceeds depths of 120mm,

Application procedure

application should be carried out in layers. The

second layer to be applied after 6 hours.

Surface preparation:

As with all epoxy resin applications the quality

Limitations

of surface preparation has a direct effect on the

performance and durability of the system.

Do not apply MASTERFLOW 410 when the

Concrete surfaces should be sound,

contact surfaces are less than 10C. If the

dimensionally stable, clean, free from laitance,

ambient temperature is less than 10C then

paint, oil, grease, mould release agent and

artificial heating may be used.

residual curing compound. Metal surfaces or

Equipment care

components to be bedded, should be free from

any rust or scaling. Formwork, if used, should

Clean all equipment promptly with CLEANING

be wrapped in polythene to ensure a clean

SOLVENT NO. 2. Any excess cured material

release.

will have to be mechanically removed.

Mixing:

Storage

Do not split packs or alter the ratio of resin

components in any way. Mix with a slow speed

Store under cover, out of direct sunlight, and

drill and paddle. Add the contents of the reactor

protect from extremes of temperature. In

container to the base component in a suitable

tropical climates the product must be stored in

mixing vessel, ensuring complete transfer of

an air conditioned environment. Failure to

both resin components.

comply with the recommended storage

conditions may result in premature deterioration

Mix for one minute before slowly adding the

of the product or packaging. For specific

aggregate and continue mixing until a flowing,

storage advice consult Degussa's Technical

pourable consistency is achieved. Do not

Services Department.

overmix as that may entrain air.

- - : -

http://www.bazarmaharem.com

E-Mail: info@bazarmaharem.com

( )

degussa. creating essentials

Safety precautions

As with all chemical products, care should be

taken during use and storage to avoid contact

with eyes, mouth, skin and foodstuffs (which

can also be tainted with vapour until product is

fully cured or dried). Treat splashes to skin and

eyes immediately. If accidentally ingested,

seek medical attention. Reseal containers after

use. For specific storage and disposal

instructions refer to the Material Safety Data

Sheet.

Note

Field service, where provided, does not

constitute supervisory responsibility. For

additional information contact your local

Degussa representative.

Degussa reserves the right to have the true

cause of any difficulty determined by accepted

test methods.

Quality

All products produced by Degussa certified

manufacturing facilities, are produced to

conform to systems designed to meet

internationally recognised quality standards.

04/2005 Degussa-IR

REQUEST AND REFER TO RECOMMENDED

INSTALLATION PROCEDURES FOR MASTERFLOW

EPOXY GROUTS PRIOR TO USE

- - : -

http://www.bazarmaharem.com

E-Mail: info@bazarmaharem.com

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- PIP STE05121 - Anchor Bolt Design GuideDocument55 pagesPIP STE05121 - Anchor Bolt Design Guidenistiana100% (4)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Equipment Band List - Fugro - W Hotel - 09dec2017Document1 pageEquipment Band List - Fugro - W Hotel - 09dec2017leodegarioporralNo ratings yet

- Infinite Quotation - Barrio Fiesta 2020Document3 pagesInfinite Quotation - Barrio Fiesta 2020leodegarioporralNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Payment Acknowledgement Receipt - 2022-002 - JL&LJDocument4 pagesPayment Acknowledgement Receipt - 2022-002 - JL&LJleodegarioporralNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Infinite Band Profile 2020Document1 pageInfinite Band Profile 2020leodegarioporralNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Barrio Fiesta Lineups - 16nov2017Document23 pagesBarrio Fiesta Lineups - 16nov2017leodegarioporralNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Arch Bridge DesignDocument38 pagesArch Bridge DesignHüseyin Varol100% (1)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Luca (1) - Selection of Stainless SteelDocument14 pagesLuca (1) - Selection of Stainless SteelleodegarioporralNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- PIP STE03350 Vertical Vessel Foundation Design Guide 12-2008 (Last Upd) PDFDocument33 pagesPIP STE03350 Vertical Vessel Foundation Design Guide 12-2008 (Last Upd) PDFbute79100% (3)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Graham - Steels For Reinforcement of ConcreteDocument42 pagesGraham - Steels For Reinforcement of ConcreteleodegarioporralNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Bridges ME 2012 Draft AgendaDocument11 pagesBridges ME 2012 Draft AgendaleodegarioporralNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- 05 DigiBanker Activation SheetDocument1 page05 DigiBanker Activation SheetleodegarioporralNo ratings yet

- Doha Bridge ConferenceDocument6 pagesDoha Bridge ConferenceleodegarioporralNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Chris (1) - Development of New Design CodesDocument52 pagesChris (1) - Development of New Design CodesleodegarioporralNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Laptop Discounted QuotationDocument3 pagesLaptop Discounted QuotationleodegarioporralNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Hilti Hit-Re 500-SDDocument17 pagesHilti Hit-Re 500-SDmon012No ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Instructions D 35103Document12 pagesInstructions D 35103leodegarioporralNo ratings yet

- Hif 16005Document11 pagesHif 16005tbananoNo ratings yet

- Concrete Pavement Construction Basics: Tech NoteDocument12 pagesConcrete Pavement Construction Basics: Tech NoteAbhijeet LimayeNo ratings yet

- DNSTW Brochure PDFDocument2 pagesDNSTW Brochure PDFleodegarioporralNo ratings yet

- Full ThesisDocument136 pagesFull ThesisAlemayehu DargeNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 18-07-001 Bir FaqDocument2 pages18-07-001 Bir FaqleodegarioporralNo ratings yet

- AER Form Version 3.3.18Document11 pagesAER Form Version 3.3.18leodegarioporralNo ratings yet

- Residential Wiring GuideDocument32 pagesResidential Wiring Guidefree bird100% (1)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Bill of Materials/Cost Estimate: Project: 2 Storey Residence, Enclave 2 LocationDocument8 pagesBill of Materials/Cost Estimate: Project: 2 Storey Residence, Enclave 2 Locationleodegarioporral100% (1)

- Scour at Coastal StructuresDocument17 pagesScour at Coastal StructuresRamkumarNo ratings yet

- SteelWise Anchor RodsDocument3 pagesSteelWise Anchor RodsvNo ratings yet

- Sample Minute of MeetingDocument1 pageSample Minute of MeetingleodegarioporralNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Nationwide Fish Ports ProjectDocument151 pagesNationwide Fish Ports ProjectleodegarioporralNo ratings yet

- Free Wi Fi Project TOR PDFDocument25 pagesFree Wi Fi Project TOR PDFleodegarioporralNo ratings yet

- WBLFFDocument10 pagesWBLFFMohd IzatNo ratings yet

- Shapoorji Pallonji & Co. LTD: Summer Training ReportDocument51 pagesShapoorji Pallonji & Co. LTD: Summer Training ReportBharat Chandra SahuNo ratings yet

- Building SSR 2011 12 PDFDocument403 pagesBuilding SSR 2011 12 PDFRavi KumarNo ratings yet

- Foam ConcreteDocument16 pagesFoam Concretemanpreet kaurNo ratings yet

- Summer Training Project On ACC CementsDocument77 pagesSummer Training Project On ACC Cementsabhinav pandey69% (13)

- Rodel Lab Reflection CMTDocument2 pagesRodel Lab Reflection CMTRodel ElicotNo ratings yet

- Abstract Sheet 23-09-2022Document16 pagesAbstract Sheet 23-09-2022Rajesh Bhat - Estimation Dept. KBP CivilNo ratings yet

- Amendments/Modifications/Additions To Existing Clauses of The General Technical Specifications Section 100 - GeneralDocument92 pagesAmendments/Modifications/Additions To Existing Clauses of The General Technical Specifications Section 100 - GeneralKiran AEE BvrmNo ratings yet

- Seismic Performance Assessment of Non-Compliant SMRF Reinforced Concrete Frame: Shake-Table Test StudyDocument42 pagesSeismic Performance Assessment of Non-Compliant SMRF Reinforced Concrete Frame: Shake-Table Test StudyR T.INo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- VefvevDocument1 pageVefvevfaizal azizNo ratings yet

- Dinamarca Anexo Ao en DS en 1992-1-1 DK NA 2011Document33 pagesDinamarca Anexo Ao en DS en 1992-1-1 DK NA 2011labNo ratings yet

- JSW Severfield ProfileDocument28 pagesJSW Severfield ProfileRahul Kumar100% (1)

- Mix Design 45 & 55Document1 pageMix Design 45 & 55syed AffanNo ratings yet

- Pidicrete CF 121 (m1)Document1 pagePidicrete CF 121 (m1)nickdash09No ratings yet

- Discoloration of Concrete PDFDocument0 pagesDiscoloration of Concrete PDFJimmy LopezNo ratings yet

- Hn. Sans1200ldDocument19 pagesHn. Sans1200ldTackie-Martey OlokweiNo ratings yet

- Technoslide Elastomeric-Plain-Sliding-Bearings-For-Bridges-Structures-BrochureDocument13 pagesTechnoslide Elastomeric-Plain-Sliding-Bearings-For-Bridges-Structures-BrochureRm1262No ratings yet

- Design - Construction Magazine (January To March 2020)Document104 pagesDesign - Construction Magazine (January To March 2020)Renz ManaloNo ratings yet

- Tyre ReportDocument10 pagesTyre ReportFeroz GullNo ratings yet

- OMN Coating Resins SolventBased PS Americas PDFDocument1 pageOMN Coating Resins SolventBased PS Americas PDFNatalia RodriguezNo ratings yet

- Pervious Concrete (Research)Document42 pagesPervious Concrete (Research)Jay SalesNo ratings yet

- Emmanuel Kofi Amissah (10506982)Document102 pagesEmmanuel Kofi Amissah (10506982)AgrivinaAbelNoviraNo ratings yet

- Ok PDFDocument122 pagesOk PDFduTyah seerionNo ratings yet

- RIPSTAR 155-v3Document2 pagesRIPSTAR 155-v3john paulNo ratings yet

- Post Tensioned Concrete Case Study PDFDocument6 pagesPost Tensioned Concrete Case Study PDFShaurya Chauhan0% (1)

- C566 PDFDocument3 pagesC566 PDFNaura RasyidaNo ratings yet

- Design of An INTZE TankDocument78 pagesDesign of An INTZE TankSTAR PRINTING100% (1)

- Adhesives and SealantsDocument28 pagesAdhesives and SealantsAnkita GhodkeNo ratings yet

- Grouts Standards and TestingDocument12 pagesGrouts Standards and TestingmithileshNo ratings yet

- 180 TOP Concrete Technology & Design of Concrete SDocument49 pages180 TOP Concrete Technology & Design of Concrete SQaria shehzadiNo ratings yet

- Sully: The Untold Story Behind the Miracle on the HudsonFrom EverandSully: The Untold Story Behind the Miracle on the HudsonRating: 4 out of 5 stars4/5 (103)

- The Fabric of Civilization: How Textiles Made the WorldFrom EverandThe Fabric of Civilization: How Textiles Made the WorldRating: 4.5 out of 5 stars4.5/5 (57)

- Hero Found: The Greatest POW Escape of the Vietnam WarFrom EverandHero Found: The Greatest POW Escape of the Vietnam WarRating: 4 out of 5 stars4/5 (19)

- The Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaFrom EverandThe Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaNo ratings yet

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindFrom EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindNo ratings yet

- A Place of My Own: The Architecture of DaydreamsFrom EverandA Place of My Own: The Architecture of DaydreamsRating: 4 out of 5 stars4/5 (242)

- Faster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestFrom EverandFaster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestRating: 4 out of 5 stars4/5 (28)