Professional Documents

Culture Documents

Superchargers 4

Uploaded by

Alha Ega AnadaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Superchargers 4

Uploaded by

Alha Ega AnadaCopyright:

Available Formats

Superchargers for Diesel Engines [subscriber access]

1 / 11

DieselNet Technology Guide Air Induction for Diesel Engines

www.DieselNet.com. Copyright Ecopoint Inc. Revision 2001.07

Superchargers for Diesel

Engines

Abstract: Superchargers are mechanically, electrically, or hydraulically driven devices employed to

boost the charge air pressure in engines. A number of compressor and blower types have been used

as superchargers, including roots blowers, sliding vane compressors, screw compressors, rotary

piston pumps, spiral-type superchargers, variable displacement piston superchargers, and

centrifugal compressors.

Classification of Superchargers

Roots Blower

Sliding Vane Compressor

Screw Compressor

Rotary Piston Supercharger

Spiral-Type Supercharger

Variable Displacement Piston Supercharger

Centrifugal Compressor Supercharger

Classification of Superchargers

Superchargers are mechanically, electrically, or hydraulically driven pumps, compressors, or blowers

employed to boost the pressure of the charge air in diesel engines or of the mixture in spark ignited

engines. Most superchargers are positive displacement devices, but aerodynamic (centrifugal)

compressors are also possible. A multitude of device types can be used as superchargers, as shown in

the classification chart in Figure 1.

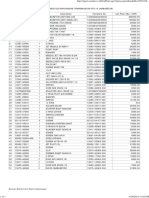

Figure 1. Types of Superchargers

The top six devices in the chart are positive displacement, while the centrifugal compressor is

classified as an aerodynamic or continuous flow device. Positive displacement devices deliver a

http://www.dieselnet.com/tech/diesel_super.html

2002-11-15

Superchargers for Diesel Engines [subscriber access]

2 / 11

specific volume of air per revolution. Since the volumetric efficiency is almost constant, air flow is

usually proportional to the supercharger or engine speed. Positive displacement devices can provide

high boost pressures without the need for high speed. Therefore, they are well suited for a mechanical

connection with the engine, such as through a gearbox or a belt/pulley drive. Each of the particular

devices has its advantages and disadvantages, that determine which supercharger is best suited for a

specific application.

Centrifugal compressors are well suited to deliver high flow volumes at relatively low pressure ratios.

With the boost pressure generally proportional to the square of the supercharger speed, centrifugal

compressors must operate at relatively high velocities. In superchargers, they are better suited for

coupling with high speed electric motors, rather than for a mechanical gearbox connection with the

engine. Centrifugal devices are also the standard type of compressors that are driven by an exhaust

gas turbine in the engine turbocharger.

Roots Blower

The Roots blower may have two or three rotors, as shown in Figure 2 [Heywood 1988]. Rotors are

straight, but can also be helical for noise suppression. As the rotors turn, air enters the displacement

volume between the rotors and the housing, as represented by line AB in Figure 3. It is then carried

across to the discharge port without compression. When the discharge port opens, the relatively hot

air volume is instantaneously delivered from the blower and the pressure rises to P2 as indicated by

line BC. In practical packages, leakage between the rotors as well as backflow from the receiver to

the inlet side of the blower take place, thus reducing its overall compression process. Therefore, the

delivery of air from the blower may be better represented by line BD [Heywood 1988]. In fact, Roots

blowers are used in applications where the pressure ratio is rather low, typically in the range of 1.01.3 [Obert 1968]. More losses would be experienced at higher pressure ratios where the use of Rootstype blowers would be questionable. However, Roots blowers are popular for their potential for high

speed operation, high mechanical efficiency, simplicity, and cost.

Figure 2. Roots Blower Supercharger

http://www.dieselnet.com/tech/diesel_super.html

2002-11-15

Superchargers for Diesel Engines [subscriber access]

3 / 11

Figure 3. Pressure-Volume Diagram for Roots Blower

A typical performance map of a Roots blower appears in Figure 4 [Heywood 1988]. Its performance is

characterized with low pressure ratio and its flow rate at constant speed is a function of the pressure

ratio. However, Roots blowers are generally noisy and their size is large. One of its more famous

applications in the USA is the two-stroke Detroit Diesel engine that powers the majority of the public

transit buses.

Figure 4. Performance Map of a Roots Blower

Roots blowers may have good volumetric efficiency (about 90%) as well as reasonable mechanical

efficiency (85%). However, their isentropic efficiency is barely 65% and strongly contributes to the

blowers low overall efficiency of about 55% [Taylor 1985][Ronzi 1995].

Sliding Vane Compressor

In the sliding vane compressor, slots in the rotor house thin silicon carbide vanes that move in a radial

direction (Figure 5) [Heywood 1988]. Their motion is dictated by centrifugal force that results from the

high speed rotation of the rotor. The rotor itself is mounted eccentrically in the housing. Therefore,

the high speed rotation of the rotor causes the vanes to move towards the housing thus trapping air

between two vanes, the housing, and the rotor.

http://www.dieselnet.com/tech/diesel_super.html

2002-11-15

Superchargers for Diesel Engines [subscriber access]

4 / 11

Figure 5. Sliding Vane Compressor

Air enters through the inlet port of the sliding vane compressor and immediately occupies a crescentlike volume as shown in Figure 5. As the rotor continues its rotation which is controlled by its

eccentricity relative to the housing, trapped air undergoes a volume increase followed by compression

(decreasing volume) at the point of delivery. The capacity of the sliding vane compressor depends on

several factors. Among them is the amount of eccentricity, the volume of air inducted (which depends

on the size of the housing and rotor), number of vanes, and its speed. As in the case of the Roots

blower, actual compressor performance suffers from leakage between the blades and the housing,

especially at low speeds where little centrifugal force is experienced, thus reducing the sealing

between the vanes and the housing.

Heating results from the friction of the rotors against the housing. Unless this heat is dissipated

through cooling, it is transferred to the air thus decreasing its density and increasing its volume. This

development eventually reduces the compressor efficiency and adds to the engine cooling system

load. A performance map for the sliding vane compressor is shown in Figure 6 [Heywood 1988]. It is

worth noting that the compressor isentropic efficiency (c) is rather low.

Figure 6. Sliding Vane Compressor Performance Map

The overall efficiency of the sliding vane compressor is only 40%. This low performance is due to a

combination of low volumetric efficiency (85%), mechanical efficiency (about 65%), and an

isentropic efficiency of just 60% [Taylor 1985].

Screw Compressor

At the first glance, the screw type compressor, Figure 7, may have a strong resemblance to the Roots

blower [Heywood 1988]. They do indeed share similar features such as a housing and a rotor. The rotor

in the screw compressor is precision machined to maintain very tight tolerances between the rotor and

the housing.

http://www.dieselnet.com/tech/diesel_super.html

2002-11-15

Superchargers for Diesel Engines [subscriber access]

5 / 11

Figure 7. Screw Compressor

As the rotor turns, air is inducted through ports arranged around the cylindrical housing and occupies

the volume between two consecutive screws and the housing. This air is delivered through a

discharge port, as shown in Figure 7. The delivery pressure is a function of the rotor speed and the

discharge port flow area. Screw compressors have a rotational speed that ranges from 3,000 to 30,000

rpm, and generate substantial heat from friction between the rotor and the housing. Measures are

usually taken to dissipate that heat to maintain the compressors mechanical integrity. Screw

compressors enjoy high volumetric efficiencies as long as their clearances are kept extremely small.

Performance of the screw compressor depends on the rotor speed as long as leakage can be kept to a

minimum. This leads to a relatively flat performance characteristic over a wide speed range as seen in

Figure 8 [AlliedSignal 1996].

Figure 8. Performance Map of a Screw Compressor

Rotary Piston Supercharger

The rotary piston supercharger is an internal-shaft rotary piston device where the shaft rotates

eccentrically inside a cylindrical housing (item A in Figure 9) [Bosch 1986]. In the example shown, the

outer rotor has three teeth (B). The driven inner rotor (C) has two teeth (lobes) and rotates

eccentrically within the outer rotor (B). The rotors have a ratio of 3:2 and do not contact each other

while rotating. The level of internal compression is determined by the timing of the outer rotor

clearing the outlet edge (D) and allowing compressed air to escape into the delivery duct. The

compressed volume of air is represented by hatched area (E) while area (F) represents the evacuated

volume. Area G represents the fill volume that is exposed to the inlet duct as the rotors continue to

rotate. A pair of cylindrical gears synchronize the motion of the rotors and prevent them from

contacting each other.

The isentropic efficiency of rotary pistons superchargers is about 65% while its volumetric efficiency

is about 90%. These superchargers are usually belt-driven and can reach speeds of 15,000 rpm. They

are capable of delivering boost up to approximately 80 kPa (12 psi).

http://www.dieselnet.com/tech/diesel_super.html

2002-11-15

Superchargers for Diesel Engines [subscriber access]

6 / 11

Figure 9. Rotary Piston Supercharger

Spiral-Type Supercharger

The spirals are arranged in a flat-sided casing having a shaft that rotates eccentrically. Sandwiched in

between the fixed spirals are moving displacer walls attached to a disc that is connected to an

eccentric pin roller bearing (Figure 10). As the drive shaft rotates, the displacer performs an

oscillating circular motion of double eccentricity. Air entering the blower moves from one working

chamber to the next performing filling, transporting, and expelling of the air at a hub, then delivering

it through its discharge. The rotation of the eccentric and the rotor is through a toothed belt, as shown

in Figure 10 [Bosch 1986].

http://www.dieselnet.com/tech/diesel_super.html

2002-11-15

Superchargers for Diesel Engines [subscriber access]

7 / 11

Figure 10. Details of a Spiral (Scroll)-Type Supercharger

The overall efficiency of this supercharger is about 55%. Its isentropic efficiency is 68% and its

volumetric efficiency is close to 90%. The speed range for this type of supercharger is 0-13,000 rpm,

and it can deliver up to 12 psi boost pressure. The spiral-type supercharger is often referred to as the

scroll-type supercharger. The casing of the supercharger is die cast aluminum and the displacer is

made of die cast magnesium.

Variable Displacement Piston Supercharger

This supercharger was developed in the mid-1990s and has a design that incorporates four radially

arranged rectangular pistons (Figure 11) [Ronzi 1995]. The pistons are driven within their respective

chambers in a circular motion referred to as nutation. The chambers are free to move laterally to

allow for the piston side movement. The chambers movement opens and closes inlet and outlet

passages at the top of the cylinders. The design also incorporates a sliding pin mechanism that allows

adjusting the eccentricity, thus permitting the piston stroke to be varied.

http://www.dieselnet.com/tech/diesel_super.html

2002-11-15

Superchargers for Diesel Engines [subscriber access]

8 / 11

Figure 11. Conceptual Drawing of a Variable Displacement Piston Supercharger

The overall efficiency of this supercharger is greater than the scroll-type, about 65%. Its isentropic,

mechanical, and volumetric efficiencies are about 80, 80, and 90%, respectively. The speed range for

this type of supercharger is a relatively low 0-5,000 rpm, and it can deliver up to 100 kPa (15 psi) in

boost pressure.

Centrifugal Compressor Supercharger

The centrifugal compressor is normally used with an exhaust-driven turbine [Heywood 1988]. However,

it is also used independent from an exhaust-driven application. In one configuration it may be driven

by a high speed electric motor, and in another it could be driven hydraulically. It consists mainly of a

single stage radial compressor through which air is pulled from the ambient. The air accelerates to a

high velocity and flows radially outward via a stationary diffuser stage toward a shell-shaped housing

called the volute as shown in Figure 12 [Bosch 1986]. The volute is shaped in such a way that its

diameter, as well as its cross-sectional flow area is always increasing. For this reason, the air velocity

decreases, and its kinetic energy is converted to potential energy as manifested in increasing pressure.

The centrifugal compressor is ideal for providing high mass flow rates at relatively low pressure ratio

of less than 3.5 that is normally the case in internal combustion engine applications.

http://www.dieselnet.com/tech/diesel_super.html

2002-11-15

Superchargers for Diesel Engines [subscriber access]

9 / 11

Figure 12. Centrifugal Compressor

Figure 13 is a performance map for a centrifugal compressor [Heywood 1988]. This map relates the

compressors air flow characteristics with its pressure ratio. The topographical contour lines indicate

islands of constant efficiency. The area to the left of the operating range of the compressor is an area

of unstable operation. The surge line is the line that separates the stable from the unstable operating

regime on the left side of the compressor. Performance at constant compressor speeds is also

indicated in the compressor map. The performance is limited on the right side of the map by choking

that occurs at each of the compressor speeds. Choking is the inability to flow any more air through

the compressor blades or the diffuser channels. Normally one would want the compressor to operate

at its highest possible mechanical efficiency at any speed. A line that would connect the most

efficient points at each operating speed can be referred to as the most efficient operating line.

Therefore, the resultant line that attempts to describe the optimum operation of a compressor is

referred to as the operating line. However, in most cases we may settle for a point on a constant

speed line that may not be the most efficient for specific design reasons.

http://www.dieselnet.com/tech/diesel_super.html

2002-11-15

Superchargers for Diesel Engines [subscriber access]

10 / 11

Figure 13. Performance Map of a Centrifugal Compressor

Figure 14 is a photograph of an electrically-driven centrifugal supercharger. The motor is a brushless,

permanent magnet, high speed motor capable of up to 40,000 rpm using short bursts of relatively high

current to achieve good response time [Turbodyne 1995].

Figure 14. Electrically-Driven Centrifugal Compressor

(Courtesy of Turbodyne Systems, Inc.)

References

AlliedSignal, 1996. "Turbocharging Systems", Sales Brochure AS6PS6

Bosch, 1986. "Automotive Handbook", Society of Automotive Engineers, Warrendale, PA, 2nd Edition

Heywood, J.B., 1988. "Internal Combustion Engine Fundamentals", McGraw-Hill, New York

Obert, E.F., 1968. "Internal Combustion Engines", International Text Book

http://www.dieselnet.com/tech/diesel_super.html

2002-11-15

Superchargers for Diesel Engines [subscriber access]

11 / 11

Ronzi, W., Ericson, B., McNaughton, J. M., 1995. "Supercharger Bench Testing", General Motors Institute and Eaton

Corporation, Internal Report

Taylor, C.F., 1985. "The Internal Combustion Engine in Theory and Practice", M.I.T. Press, Volume 2, Revised Edition

Turbodyne, 1995. "Performance For Your Engine And The Environment", Turbodyne Systems, Inc., Carpinteria, California

###

http://www.dieselnet.com/tech/diesel_super.html

2002-11-15

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Subjective Marking Form: Worldskills Competition 2007 D1Document2 pagesSubjective Marking Form: Worldskills Competition 2007 D1Alha Ega AnadaNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Suzuki genuine crankshaft and engine partsDocument1 pageSuzuki genuine crankshaft and engine partsAlha Ega AnadaNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- CV Feri PDFDocument1 pageCV Feri PDFAlha Ega AnadaNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Mitsubishi L300: Varian Baru dengan Banyak Pilihan dan Fitur UnggulanDocument2 pagesMitsubishi L300: Varian Baru dengan Banyak Pilihan dan Fitur UnggulanIndarTo Setyo Budi UtomoNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Carburetor Spin Part ListDocument1 pageCarburetor Spin Part ListAlha Ega AnadaNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- FuelDocument73 pagesFuelsandystaysNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- 14 AVANZA / XENIA Power Window Circuit DiagramDocument1 page14 AVANZA / XENIA Power Window Circuit DiagramAlha Ega AnadaNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Int - Light & Rad Fan PDFDocument1 pageInt - Light & Rad Fan PDFAlha Ega AnadaNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- T1 V1 F10 I1 F11 C1 F9 I2 W1 I3 W2: Position of Parts in Engine CompartmentDocument5 pagesT1 V1 F10 I1 F11 C1 F9 I2 W1 I3 W2: Position of Parts in Engine CompartmentAlha Ega AnadaNo ratings yet

- Blooms Taxonomy VerbsDocument2 pagesBlooms Taxonomy VerbsrevarzuNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Relay Locations (Engine Room R/B) (Engine Room J/B)Document1 pageRelay Locations (Engine Room R/B) (Engine Room J/B)Alha Ega AnadaNo ratings yet

- Carbu Karburator New Smash SchemeDocument1 pageCarbu Karburator New Smash SchemeAlha Ega AnadaNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Power sources and rear wiper controls in Avanza and XeniaDocument1 pagePower sources and rear wiper controls in Avanza and XeniaAlha Ega AnadaNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Int - Light & Rad FanDocument1 pageInt - Light & Rad FanAlha Ega AnadaNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- SSTsDocument3 pagesSSTsAlha Ega AnadaNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Accelerator Control System OverviewDocument4 pagesAccelerator Control System OverviewAlha Ega AnadaNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- 12 HWACHEON CATALOG: CUTEX-160 SPECIFICATIONSDocument1 page12 HWACHEON CATALOG: CUTEX-160 SPECIFICATIONSAlha Ega AnadaNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- Philips Avent Pacifier Design Contest Rules-1Document7 pagesPhilips Avent Pacifier Design Contest Rules-1Alha Ega AnadaNo ratings yet

- COver BPR Beat LamaDocument1 pageCOver BPR Beat LamaAlha Ega AnadaNo ratings yet

- Torsi Pengencangan 1Document2 pagesTorsi Pengencangan 1Alha Ega AnadaNo ratings yet

- Entryprox Ii PDFDocument96 pagesEntryprox Ii PDFAlha Ega AnadaNo ratings yet

- Suzuki Electronic Parts CatalogueDocument1 pageSuzuki Electronic Parts CatalogueAlha Ega AnadaNo ratings yet

- Sec 09 ACCESSORIES PDFDocument13 pagesSec 09 ACCESSORIES PDFAwhal RamadhanNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Cover Supra X 125 FIDocument1 pageCover Supra X 125 FIAlha Ega AnadaNo ratings yet

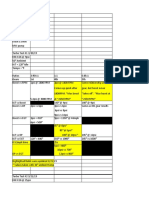

- Mio Lama: BLK Kudus Jl. Conge - Ngembalrejo 99 KUDUSDocument1 pageMio Lama: BLK Kudus Jl. Conge - Ngembalrejo 99 KUDUSAlha Ega AnadaNo ratings yet

- Cover BPR Megapro LamaDocument1 pageCover BPR Megapro LamaAlha Ega AnadaNo ratings yet

- Tvs Neo XR: BLK Kudus Jl. Conge - Ngembalrejo 99 KUDUSDocument1 pageTvs Neo XR: BLK Kudus Jl. Conge - Ngembalrejo 99 KUDUSAlha Ega AnadaNo ratings yet

- CamScanner App Scans Documents EasilyDocument2 pagesCamScanner App Scans Documents EasilyAlha Ega AnadaNo ratings yet

- Rear Axle: SectionDocument4 pagesRear Axle: SectionAlha Ega AnadaNo ratings yet

- BasrahDocument19 pagesBasrahDurban Chamber of Commerce and IndustryNo ratings yet

- Analyse Compressor MapDocument6 pagesAnalyse Compressor MapMichał BajdaNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- GP200SDocument155 pagesGP200SLina JiaNo ratings yet

- Compresores Hermticos Tecumseh Lunite Hermetique 5 17062015Document1 pageCompresores Hermticos Tecumseh Lunite Hermetique 5 17062015rafael velandi velandiNo ratings yet

- Pneumatics - Air CompressionDocument10 pagesPneumatics - Air CompressionNikolas FabryNo ratings yet

- Turbocharger HolsetDocument2 pagesTurbocharger HolsetBoštjan ŠumenjakNo ratings yet

- Datashett Impeller FanDocument1 pageDatashett Impeller FanDust IndoNo ratings yet

- Compressor SurgeDocument3 pagesCompressor SurgeajaysapruNo ratings yet

- HUN-ISO 14001 Certificate-EN 20251031 - 26-6675Document1 pageHUN-ISO 14001 Certificate-EN 20251031 - 26-6675zozimolnarNo ratings yet

- Compressor ControlsDocument167 pagesCompressor ControlsAnonymous 70lCzDJvNo ratings yet

- Chicago Pneumatic CPVSD 10 15 20 IEC Spare Parts List C55 DD 9828093047 00Document84 pagesChicago Pneumatic CPVSD 10 15 20 IEC Spare Parts List C55 DD 9828093047 00AlexNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Assignment 1-1 PDFDocument3 pagesAssignment 1-1 PDFTsegaye PaulosNo ratings yet

- New Catalog Updated 2Document1 pageNew Catalog Updated 2koyo rubberNo ratings yet

- Turbocharger and SuperchargerDocument13 pagesTurbocharger and Superchargernishantdubey11830% (1)

- MCM Fault CodesDocument14 pagesMCM Fault CodesPauloFeitozaNo ratings yet

- SuperchargerDocument24 pagesSuperchargerpravat dalai100% (1)

- PT Nissandi Kompresindo compressed air solutionsDocument25 pagesPT Nissandi Kompresindo compressed air solutionsMuhdi100% (1)

- PDS390S-4B1, Hal 20Document4 pagesPDS390S-4B1, Hal 20AkmalNo ratings yet

- Concentrating AreaDocument1 pageConcentrating AreafaisalNo ratings yet

- Turbo Testing OM617Document36 pagesTurbo Testing OM617antonio maloNo ratings yet

- Screw Compressor DataDocument6 pagesScrew Compressor Datamochamad iwanNo ratings yet

- Supercharging of Diesel EnginesDocument6 pagesSupercharging of Diesel EnginesPolavarapu Srinivasa RaoNo ratings yet

- Molitfelnic 2019 CompressedDocument927 pagesMolitfelnic 2019 Compressedparintele CRISTIAN H.100% (10)

- 3.10 Air Compressor Piping Iso DrawingDocument1 page3.10 Air Compressor Piping Iso DrawingCuong Tran0% (1)

- Elgi Air Compressor Parts Catalogue - Google SearchDocument2 pagesElgi Air Compressor Parts Catalogue - Google SearchSharad KokateNo ratings yet

- 9 Brochure Turbochargers and CartridgesDocument20 pages9 Brochure Turbochargers and CartridgesAdrian NNo ratings yet

- LPRVP - Admissible Load On BranchesDocument2 pagesLPRVP - Admissible Load On Branchesrebelde1986No ratings yet

- Compressor Handbook - Hydrocarbon Processing - 1969Document104 pagesCompressor Handbook - Hydrocarbon Processing - 1969VS271290% (10)

- Doubt FullDocument14 pagesDoubt Fullr09033No ratings yet

- ABB Turbocharger Approved Oil GuideDocument4 pagesABB Turbocharger Approved Oil GuideGerson NevesNo ratings yet

- The Grid: The Fraying Wires Between Americans and Our Energy FutureFrom EverandThe Grid: The Fraying Wires Between Americans and Our Energy FutureRating: 3.5 out of 5 stars3.5/5 (48)

- Industrial Piping and Equipment Estimating ManualFrom EverandIndustrial Piping and Equipment Estimating ManualRating: 5 out of 5 stars5/5 (7)

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 5 out of 5 stars5/5 (1)

- Renewable Energy: A Very Short IntroductionFrom EverandRenewable Energy: A Very Short IntroductionRating: 4.5 out of 5 stars4.5/5 (12)

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesFrom EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesRating: 4.5 out of 5 stars4.5/5 (21)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialFrom EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNo ratings yet