Professional Documents

Culture Documents

Lecture (4)

Uploaded by

DDelGGulOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lecture (4)

Uploaded by

DDelGGulCopyright:

Available Formats

Third Lecture: 10 / 03 / 2015

Course of: Measurement of Rock Properties

An abundant class of rock materials, notably those with high clay content, are

prone to swelling, weakening or disintegration when exposed to short term

weathering processes of a wetting and drying nature. Special tests are necessary to

predict this aspect of mechanical performance. These tests are index tests: they are

best used in classifying and comparing one rock with another. The swelling strain

index should not, for example, be taken as the actual swelling strain that would

develop in situ, even under similar conditions of loading & of water content.

These tests simulate natural wetting & drying processes. Other types of test are

better suited to estimating resistance to such weathering agenda as frost, salt

crystallization or attrition (De Puy. 1965).

Where possible undisturbed rock specimens should he tested, since rock fabric

has an important effect on the other properties to be measured. Where the sample

is too weak or too broken to allow preparation of undisturbed specimens, as is

usually the case with joint-filling materials for example, the swelling tests may be

carried out on remoulded specimens. Remoulding should be according to standard

procedures for soil compaction, and the procedure followed should he described

when reporting the test results.

These tests are commonly required for classification or characterization of the softer

rock materials. They may also be used, however, for characterization of harder rocks

where the rock condition, its advanced state of weathering for example, indicates

that they are appropriate.

Third Lecture: 10 / 03 / 2015

Course of: Measurement of Rock Properties

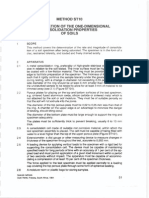

( 1 ) SUGGESTED METHOD FOR DETERMINATION OF

THE SWELLING PRESSURE INDEX UNDER

CONDITIONS OF ZERO VOLUME CHANGE

This test is intended to measure the pressure necessary to constrain an undisturbed

rock specimen at constant volume when it is immersed in water.

The apparatus may be adapted from that used for soil consolidation testing, and

consists essentially of the following:

(a) A metal ring for rigid radial restraint of the specimen, polished and lubricated

to reduce side fraction & of depth at least sufficient to accommodate the specimen.

(b) Porous plates to allow water access at top and bottom of the specimen, the top

plate of such a diameter to slide freely in the ring. Filter papers may be inserted

between specimen and plates.

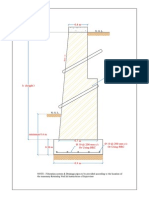

(c) A cell to contain the specimen assembly, capable of being filled with water to

a level above the top porous plate. The principal features of the cell and specimen

assembly are illustrated in Fig. 2.

(d) A micrometer dial gauge or other device reading to 0.0025 mm, mounted to

measure the swelling displacement at the central axis of the specimen.

(e) A load measuring device capable of measuring to an accuracy of 1%, the force

required to resist swelling.

Third Lecture: 10 / 03 / 2015

Course of: Measurement of Rock Properties

(f) A loading device such as a screw jack. Capable of continuous adjustment to

maintain the specimen at constant volume as swelling pressure develops. The

force should be applied through rigid members to ensure that the porous plates

remain flat, a spherical seat allowing rotation of the top porous plate.

(a)

For testing at natural initial water content, preparation should be such

as to retain water content to within 1% of its in situ value. Duplicate specimens

should be prepared from the same sample, one being used for water content

determination & the other for swell testing.

(b)

For testing at an artificially controlled initial water content the sample

may be brought to equilibrium mass in a constant humidity environment.

Duplicate specimens should then be prepared from the same sample, one being

used for water content determination & the other for swell testing.

(c) The specimen should conform closely to the geometry of a right cylinder. It

should have a diameter not less than 2.5 times its thickness. The thickness

should exceed 15 mm or ten times the maximum grain diameter, whichever is

greater. The specimen should be a close fit in the ring.

(d)

The inclination of bedding or foliation with respect to the specimen axis

should be recorded.

Third Lecture: 10 / 03 / 2015

Course of: Measurement of Rock Properties

(a) The apparatus is assembled & a small axial force say about 10 kPa is applied

to the specimen.

(b) The cell is then flooded with water to cover the top porous plate, & the swelling

force is recorded as a function of time elapsed.

(c) The applied force is regularly adjusted to maintain zero specimen swell

throughout the test. The thickness of the specimen should be maintained to

within 0.01 mm.

(d) Swelling force should continue to be recorded until it reaches 3 constant level

or passes a peak.

The swelling pressure index is calculated as follows:

Where: F = maximum axial swelling force recorded during the test.

A = cross sectional area of the specimen.

Results should be presented for at least three specimens per sample. The report

should include the following information for each specimen:

(a) The swelling pressure index.

(b) The initial water content of the specimen; whether this corresponds to the

natural water content, and if so the method of storage prior to testing.

(c) The diameter and thickness of the specimen together with the inclination of

bedding or foliation with respect to the specimen axis.

Third Lecture: 10 / 03 / 2015

Course of: Measurement of Rock Properties

( 2 ) SUGGESTED METHOD FOR DETERMINATION OF

THE SWELLING STRAIN INDEX FOR A RADIALLY

CONFINED SPECIMEN WITH AXIAL SURCHARGE

This test is intended to measure the axial swelling strain developed against a

constant axial pressure or surcharge, when a radially confined, undisturbed rock

specimen is immersed in water.

(a) The initial thickness and diameter of the specimen are recorded to 0.1%.

(b) The apparatus is assembled and the specimen loaded axially to a surcharge

pressure of 3 kPa.

(c) The cell is then flooded with water to cover the top porous plate, and the

swelling displacement recorded as a function of time elapsed.

(d) Swelling displacement should continue to be recorded until it reaches a

constant level or passes a peak.

The swelling strain index is calculated as follows:

100%

Where: d = maximum swelling displacement recorded during the test.

L = initial thinness of the specimen.

Third Lecture: 10 / 03 / 2015

Course of: Measurement of Rock Properties

Results should be presented for at least three specimens per sample. The report

should clearly indicate that the specimen was radially confined during the swelling

test. The report should include the following information for each specimen:

(a) The swelling strain index.

Third Lecture: 10 / 03 / 2015

Course of: Measurement of Rock Properties

Changes in rock properties due to processes of chemical and mechanical breakdown

(e.g. Exfoliation, hydration, solution, oxidation, abrasion etc.) can be very important

in engineering applications. A good index test of rock degradability is the Slake

Durability Index.

1. Sample consisting of 10 spheroidal lumps each approx. 50 g is placed in the

drum and weighed.

2. Drum is placed in trough filled with water at 20C to a level just below drum axis

and rotated at 20 rpm for 10 minutes.

3. Drum is removed and material retained dried at 105C

4. Cycle is repeated and the dried material retained after 2 cycles weighed.

Third Lecture: 10 / 03 / 2015

Course of: Measurement of Rock Properties

Third Lecture: 10 / 03 / 2015

Course of: Measurement of Rock Properties

You might also like

- A-Z Survival Items Post SHTFDocument28 pagesA-Z Survival Items Post SHTFekott100% (1)

- Constant & Falling Head Permeability TestDocument14 pagesConstant & Falling Head Permeability TestIkhwan Z.89% (72)

- ASTM D2842 06 Water Absorption Test MethodDocument10 pagesASTM D2842 06 Water Absorption Test MethodAnonymous BXmahb50% (1)

- Mechanics of Materials 7th Edition Beer Johnson Chapter 6Document134 pagesMechanics of Materials 7th Edition Beer Johnson Chapter 6Riston Smith95% (96)

- Triaxial TestDocument18 pagesTriaxial TestTiong V YenNo ratings yet

- CE 121 LAB 2 Density Specific Gravity and Absorption of Fine and Coarse AggregatesDocument14 pagesCE 121 LAB 2 Density Specific Gravity and Absorption of Fine and Coarse AggregatesNatsu RefilNo ratings yet

- Risk Management: Questions and AnswersDocument5 pagesRisk Management: Questions and AnswersCentauri Business Group Inc.No ratings yet

- Permeability TestDocument5 pagesPermeability TestgmoozNo ratings yet

- Falling Head PermeabilityDocument7 pagesFalling Head PermeabilityArjun Kumar100% (1)

- Soil TestingDocument35 pagesSoil TestingJoan-na may Montaño100% (1)

- CE 121 LAB #2 Density, Specific Gravity, and Absorption of Fine and Coarse AggregatesDocument14 pagesCE 121 LAB #2 Density, Specific Gravity, and Absorption of Fine and Coarse AggregatesAngel Umali Gacutan100% (2)

- English 8 q3 w1 6 FinalDocument48 pagesEnglish 8 q3 w1 6 FinalJedidiah NavarreteNo ratings yet

- Concrete Column Design Flow ChartsDocument10 pagesConcrete Column Design Flow Chartsayoub bahmani k100% (4)

- Constant Falling Head Permeability Test Lab ReportDocument12 pagesConstant Falling Head Permeability Test Lab ReportHaziq Zuhaimi100% (3)

- Design of Spread FootingDocument14 pagesDesign of Spread Footingghulamqader100% (1)

- LABREP 7a - DAVIDDocument13 pagesLABREP 7a - DAVIDKristina DavidNo ratings yet

- Concrete Beam Design Flow ChartsDocument16 pagesConcrete Beam Design Flow Chartsayoub bahmani k80% (5)

- Lab Manual Foundation EngineeringDocument39 pagesLab Manual Foundation Engineeringartiraha100% (1)

- Constant N Permeability ReportDocument24 pagesConstant N Permeability Reportilasensei50% (2)

- Corporate Members List Iei Mysore Local CentreDocument296 pagesCorporate Members List Iei Mysore Local CentreNagarjun GowdaNo ratings yet

- How Should We Allocate Scarce Resources Over Our Business Portfolio?Document20 pagesHow Should We Allocate Scarce Resources Over Our Business Portfolio?Vivek AryaNo ratings yet

- ASHRAE Final Operating Room 508 PDFDocument13 pagesASHRAE Final Operating Room 508 PDFSilisteanu AndreiNo ratings yet

- Evolution of Management AccountingDocument35 pagesEvolution of Management AccountingNuqiah Fathiah Seri100% (1)

- Reflection - Reading and Writing 3Document3 pagesReflection - Reading and Writing 3Quỳnh HồNo ratings yet

- Astm C119-16Document8 pagesAstm C119-16Manuel Antonio Santos Vargas100% (2)

- TMH-6 - ST10Document10 pagesTMH-6 - ST10ATHOLSCHWARZNo ratings yet

- Permeabilidad en Celda TriaxialDocument7 pagesPermeabilidad en Celda TriaxialLuis Lemus MondacaNo ratings yet

- Standard Oedometer TestDocument8 pagesStandard Oedometer TestHiro Cerce Wilhelm ALDEN Abareta TonioNo ratings yet

- Constant Head Permeability TestDocument12 pagesConstant Head Permeability Testanis098No ratings yet

- Mu-Cidc Pgri Program: Mewar UniversityDocument9 pagesMu-Cidc Pgri Program: Mewar UniversityDeepanshu GargNo ratings yet

- Constant Head Permeability TestDocument12 pagesConstant Head Permeability TestJawad HussainNo ratings yet

- SUniaxial Compression Test 1979Document4 pagesSUniaxial Compression Test 1979Alejandro425No ratings yet

- Experiment-3 Using The Weighing in Water Method To Determine Particle Density and Water Absorption of Coarse AggregateDocument8 pagesExperiment-3 Using The Weighing in Water Method To Determine Particle Density and Water Absorption of Coarse AggregateanushaNo ratings yet

- Rock Properties: Dr. R.K.Dutta Apced NIT HamirpurDocument109 pagesRock Properties: Dr. R.K.Dutta Apced NIT HamirpurAastha SoniNo ratings yet

- Laboratory WorksDocument32 pagesLaboratory WorksCliff Jude ZehnderNo ratings yet

- 3.0 Metrology: 3.3 Lab TestDocument6 pages3.0 Metrology: 3.3 Lab TestWasana LakmaliNo ratings yet

- Reduction of Concrete Sorptivity With Age Through CarbonationDocument7 pagesReduction of Concrete Sorptivity With Age Through CarbonationSritam SwapnadarshiNo ratings yet

- Argillaceous Swellingxocks - Methods For Laboratory TestingDocument16 pagesArgillaceous Swellingxocks - Methods For Laboratory Testingvenkatraman20No ratings yet

- Model Question Bank: Faculty of Engineering and Computing SciencesDocument10 pagesModel Question Bank: Faculty of Engineering and Computing SciencesAkshay MehtaNo ratings yet

- Triaxial Compression TestDocument17 pagesTriaxial Compression Testsajjad.ghazai2001No ratings yet

- Influence of Swell On Stress-Strain Behaviour of Expansive Soils Under Various Confining PressureDocument7 pagesInfluence of Swell On Stress-Strain Behaviour of Expansive Soils Under Various Confining PressureIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalNo ratings yet

- Astm - D425Document4 pagesAstm - D425Sergio Daniel Barea NuñezNo ratings yet

- Geng166 0343Document14 pagesGeng166 0343pleyvaze100% (1)

- Consolidation TestDocument17 pagesConsolidation TestAyodele AjayiNo ratings yet

- Carpenter&Stephenson 1986Document7 pagesCarpenter&Stephenson 1986veenau 1No ratings yet

- This Method Covers Procedures For Testing Aggregate For Resistance To Abrasion Using Los Angeles Test MachineDocument15 pagesThis Method Covers Procedures For Testing Aggregate For Resistance To Abrasion Using Los Angeles Test MachineDDelGGulNo ratings yet

- Swell Pressure Test: 1. ObjectiveDocument4 pagesSwell Pressure Test: 1. Objectiveraviteja036No ratings yet

- Sampling & Testing ProceduresDocument86 pagesSampling & Testing ProcedurescruzserNo ratings yet

- Constant Head Permeability Procedure - 09-08-12Document5 pagesConstant Head Permeability Procedure - 09-08-12Portia ShilengeNo ratings yet

- Test 09Document6 pagesTest 09Ateafac Anastasia NjuafacNo ratings yet

- Geoinformatics (2) ..Document12 pagesGeoinformatics (2) ..Dinesh SNo ratings yet

- Triaxial Shear TestDocument5 pagesTriaxial Shear TestBellaNo ratings yet

- Aggregate TestDocument11 pagesAggregate TestSavinda Ranathunga100% (1)

- Assignment - 8 - BSETC-021R19-4 - Muhammad Zohaib Khan PDFDocument24 pagesAssignment - 8 - BSETC-021R19-4 - Muhammad Zohaib Khan PDFEngr MahwishNo ratings yet

- SM ManualDocument70 pagesSM ManualMubeen AliNo ratings yet

- Experiment No. 2 California Bearing RatioDocument7 pagesExperiment No. 2 California Bearing RatioPatricia TubangNo ratings yet

- Durability of Block Paving in A Marine EnvironmentDocument8 pagesDurability of Block Paving in A Marine EnvironmenttobitigbaNo ratings yet

- Determination of Consistency of Cement: ObjectiveDocument26 pagesDetermination of Consistency of Cement: ObjectiveSruthiNo ratings yet

- Concrete Permeability TestDocument6 pagesConcrete Permeability TestKanishka SarkarNo ratings yet

- Lab7 ReportDocument4 pagesLab7 ReporthelensongyNo ratings yet

- Permeability TestDocument13 pagesPermeability TestVicky KhadkeNo ratings yet

- Disclosure To Promote The Right To InformationDocument8 pagesDisclosure To Promote The Right To InformationUTTAL RAYNo ratings yet

- Estimation of Water Sorptivity As Durability Index For Ultra High Strength Reactive Powder ConcreteDocument4 pagesEstimation of Water Sorptivity As Durability Index For Ultra High Strength Reactive Powder ConcreteyeshwanthvkumarNo ratings yet

- Bulking of Sand Means Increase in ItDocument6 pagesBulking of Sand Means Increase in ItDENCONo ratings yet

- Linear ShrinkageDocument4 pagesLinear Shrinkagelim.chrisNo ratings yet

- Full Report Head ConstantDocument12 pagesFull Report Head ConstantArisan Iqma100% (2)

- Laboratory Manual: Name: Roll No.: Semester: Academic YearDocument58 pagesLaboratory Manual: Name: Roll No.: Semester: Academic YearDipankar NathNo ratings yet

- A Modified Hoek-Franklin Triaxial Cell For Rock Permeability MeasurementsDocument3 pagesA Modified Hoek-Franklin Triaxial Cell For Rock Permeability MeasurementsvhgaitanNo ratings yet

- Oedometer Test: ConceptDocument3 pagesOedometer Test: ConceptMiguel BenítezNo ratings yet

- V Compaction: Courtesy of U.S. WICK DRAIN, INCDocument74 pagesV Compaction: Courtesy of U.S. WICK DRAIN, INCramlanNo ratings yet

- Fluid Mixing II: A Symposium Organised by the Yorkshire Branch and the Fluid Mixing Processes Subject Group of the Institution of Chemical Engineers and Held at Bradford University, 3-5 April 1984From EverandFluid Mixing II: A Symposium Organised by the Yorkshire Branch and the Fluid Mixing Processes Subject Group of the Institution of Chemical Engineers and Held at Bradford University, 3-5 April 1984No ratings yet

- AttachmentJ QualityAssurancePlanDocument9 pagesAttachmentJ QualityAssurancePlanDDelGGulNo ratings yet

- Z1Document2 pagesZ1DDelGGulNo ratings yet

- 132Kv SC DC Twin Teal Plate Drawings - Volume 1Document2 pages132Kv SC DC Twin Teal Plate Drawings - Volume 1DDelGGulNo ratings yet

- AttachmentJ QualityAssurancePlanDocument9 pagesAttachmentJ QualityAssurancePlanDDelGGulNo ratings yet

- GGGDocument1 pageGGGDDelGGulNo ratings yet

- Ch8, Hardness TestingDocument1 pageCh8, Hardness TestingDDelGGulNo ratings yet

- Water - Letter No.03Document1 pageWater - Letter No.03DDelGGulNo ratings yet

- How To Find Value of Core TestDocument2 pagesHow To Find Value of Core TestDDelGGulNo ratings yet

- Chapter 40Document368 pagesChapter 40DDelGGulNo ratings yet

- Design Standards of Mitas CompanyDocument1 pageDesign Standards of Mitas CompanyDDelGGulNo ratings yet

- ACI - 318M-05 Sec 5.1.1 - 5.6.5.5 - .5.6.5.4 DDocument1 pageACI - 318M-05 Sec 5.1.1 - 5.6.5.5 - .5.6.5.4 DDDelGGulNo ratings yet

- ACI - 318M-05 Sec 5.1.1 - 5.6.5.5 - .5.6.5.4 DDocument1 pageACI - 318M-05 Sec 5.1.1 - 5.6.5.5 - .5.6.5.4 DDDelGGulNo ratings yet

- To Whom It May ConcernDocument1 pageTo Whom It May ConcernDDelGGulNo ratings yet

- Specification 2Document1 pageSpecification 2DDelGGulNo ratings yet

- ACI Sec. 5.1.1Document4 pagesACI Sec. 5.1.1DDelGGulNo ratings yet

- 1.2.duhok Power Plant-Duhok Center - r4!20!09 - 12Document30 pages1.2.duhok Power Plant-Duhok Center - r4!20!09 - 12DDelGGulNo ratings yet

- Questions Answer: Ex. 5 (Insulation Design) A - Min. Arcing Horn GapDocument5 pagesQuestions Answer: Ex. 5 (Insulation Design) A - Min. Arcing Horn GapDDelGGulNo ratings yet

- Questions Answer: Ex. 5 (Insulation Design) A - Min. Arcing Horn GapDocument5 pagesQuestions Answer: Ex. 5 (Insulation Design) A - Min. Arcing Horn GapDDelGGulNo ratings yet

- Caravana X ModelDocument1 pageCaravana X ModelDDelGGulNo ratings yet

- إضافات الخرسانةDocument34 pagesإضافات الخرسانةAhmed IbrahimNo ratings yet

- Introduction ADocument10 pagesIntroduction ADDelGGulNo ratings yet

- Chapter Two 22Document3 pagesChapter Two 22DDelGGulNo ratings yet

- Istinat ModelDocument1 pageIstinat ModelDDelGGulNo ratings yet

- Retaining WallDocument1 pageRetaining WallDDelGGulNo ratings yet

- Aisc Asd-89 Example 002Document5 pagesAisc Asd-89 Example 002Anitha Hassan KabeerNo ratings yet

- الجهد العالىDocument172 pagesالجهد العالىMohamed BelallNo ratings yet

- Design by Written by ProfessorDocument8 pagesDesign by Written by ProfessorDDelGGulNo ratings yet

- Determination of Hydroxymethylfurfural (HMF) in Honey Using The LAMBDA SpectrophotometerDocument3 pagesDetermination of Hydroxymethylfurfural (HMF) in Honey Using The LAMBDA SpectrophotometerVeronica DrgNo ratings yet

- SSC 211 ED Activity 4.1Document4 pagesSSC 211 ED Activity 4.1bernard bulloNo ratings yet

- How Do I Predict Event Timing Saturn Nakshatra PDFDocument5 pagesHow Do I Predict Event Timing Saturn Nakshatra PDFpiyushNo ratings yet

- Review On Antibiotic Reidues in Animl ProductsDocument6 pagesReview On Antibiotic Reidues in Animl ProductsMa. Princess LumainNo ratings yet

- Chapter 3-CP For Armed Conflict SituationDocument23 pagesChapter 3-CP For Armed Conflict Situationisidro.ganadenNo ratings yet

- FBISE Grade 10 Biology Worksheet#1Document2 pagesFBISE Grade 10 Biology Worksheet#1Moaz AhmedNo ratings yet

- Annotated Bibliography 2Document3 pagesAnnotated Bibliography 2api-458997989No ratings yet

- Color Coding Chart - AHGDocument3 pagesColor Coding Chart - AHGahmedNo ratings yet

- 7 Ways To Support Your Babys Learning Today Monti KidsDocument19 pages7 Ways To Support Your Babys Learning Today Monti KidsMareim A HachiNo ratings yet

- Appsc Aee Mains 2019 Electrical Engineering Paper III 1fcbb2c9Document12 pagesAppsc Aee Mains 2019 Electrical Engineering Paper III 1fcbb2c9SURYA PRAKASHNo ratings yet

- Lab Activity 5Document5 pagesLab Activity 5Jasmin CeciliaNo ratings yet

- Mufti ReligionMilitancy WebDocument0 pagesMufti ReligionMilitancy WebAyaz Ahmed KhanNo ratings yet

- TM9-1904 - Ammunition Inspection Guide - 1944 PDFDocument414 pagesTM9-1904 - Ammunition Inspection Guide - 1944 PDFhodhodhodsribdNo ratings yet

- List of Practicals Class Xii 2022 23Document1 pageList of Practicals Class Xii 2022 23Night FuryNo ratings yet

- Malaybalay CityDocument28 pagesMalaybalay CityCalvin Wong, Jr.No ratings yet

- Quadratic SDocument20 pagesQuadratic SAnubastNo ratings yet

- Quality Assurance Plan-75FDocument3 pagesQuality Assurance Plan-75Fmohamad chaudhariNo ratings yet

- Supreme Court Case Analysis-Team ProjectDocument5 pagesSupreme Court Case Analysis-Team ProjectJasmineA.RomeroNo ratings yet

- Policy Implementation NotesDocument17 pagesPolicy Implementation NoteswubeNo ratings yet

- Math - Snowflake With ProtractorsDocument4 pagesMath - Snowflake With Protractorsapi-347625375No ratings yet