Professional Documents

Culture Documents

Re11260 2005-08

Uploaded by

claudioandrevalverdeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Re11260 2005-08

Uploaded by

claudioandrevalverdeCopyright:

Available Formats

Radial piston pump,

fixed displacement

RE 11260/08.05

Replaces: 07.02

1/8

Type PR4

Sizes 0.40 to 2.00 cm3

Component series 1X

Maximum operating pressure 700 bar

R4_d

PR4-1X/1,00-450WA01M01

Table of contents

Contents

Features

Page

Self-priming, valve-controlled

Ordering code

Very low noise

Symbol

Function, section

Long service life due to hydrodynamically lubricated plain bearings

Very compact design, therefore installation-friendly dimensions

Technical data, noise pressure level

Characteristic curves

Unit dimensions

Installation notes

Engineering notes

Commissioning notes

Information on available spare parts:

www.boschrexroth.com/spc

Can be combined with fixed and variable displacement vane

pumps

5 sizes

2/8

Bosch Rexroth AG

Hydraulics

PR4

RE 11260/08.05

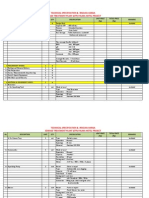

Ordering code

PR 4 1X

01

01

Type of component

Pump, radial

= PR

Series

Further details in clear text

=4

Component series

Component series 10 to 19

= 1X

(10 to 19: unchanged installation and

connection dimensions)

Component size

Component size pressure stage

(maximum)

0.40 cm3

0.63 cm3

1.00 cm3

1.60 cm3

2.00 cm3

01 =

M=

V=

01 =

= 0.40-700

= 0.63-700

= 1.00-450

= 1.60-250

= 2.00-175

Direction of rotation

Clockwise and counter-clockwise rotation

A=

G=

=W

Note:

All five sizes are pumps with 3 pistons!

Symbol

P

Number of pressure ports

1 pressure port

Seal material

NBR seals

FKM seals

Pipe connection

Pipe thread to ISO 228/1

Shaft version

Cylindrical shaft end

Splined shaft end for

combination with vane pumps

Hydraulics Bosch Rexroth AG

RE 11260/08.05 PR4

3/8

Function, section

These pumps are valve-controlled, self-priming radial piston

pumps with fixed displacement.

They basically consist of housing (1), eccentric shaft (2) and

pump elements (3), with suction valve (4), pressure valve (5)

and piston (6).

Suction and displacement process

Pistons (6) are arranged radially to eccentric shaft (2). Piston

(6) is guided in cylinder (7) and pressed by spring (8) onto eccentric (2). During the downward stroke of piston (6), the work-

ing chamber (9) in cylinder (7) increases in size. The resulting

negative pressure lifts suction valve plate (4.1) from the sealing edge. This opens the connection between suction chamber (10) to working chamber (9). The working chamber fills with

fluid. During the upward movement of piston (6), the suction

valve closes and pressure valve (5) opens. Fluid can now flow

via pressure port (P) to the system.

"X"

9

7

8

2

S

10

10

4.1

9

6

7

"X"

4/8

Bosch Rexroth AG

Hydraulics

PR4

RE 11260/08.05

Technical data (for applications outside these parameters, please consult us!)

min 1

Speed range

Operating pressure Inlet

bar

0.8 to 1.5 absolute

bar

Size 0.40

Size 0.63

Size 1.00

Size 1.60

Size 2.00

Nm

10

Outlet

Max. permissible torque (drive shaft)

1000 to 3400 min 1

1000 to 3000 min 1

1000 to 2000 min 1

1000 to 2000 min 1

1000 to 2000 min 1

Size 0.40

Size 0.63

Size 1.00

Size 1.60

Size 2.00

700 bar

700 bar

450 bar

250 bar

175 bar

Installation orientation

Size 0.40-700

Horizontal installation: The suction port should be located

vertically above the pressure port. This arrangement improves

bleeding of the pump.

Vertical installation: No restrictions.

All other sizes can be installed at any position.

Shaft loading

Radial and axial forces cannot be absorbed!

Type of mounting

Face mounting

Pipe connections

Screw-in fittings

Direction of rotation (viewed to shaft end)

Counter-clockwise or clockwise, has no influence on the

direction of flow

Hydraulic fluid

HLP mineral oil to DIN 51524 part 2

Please note the regulations laid down in RE 07075!

Hydraulic fluid temperature range

C

mm2/s

Viscosity range

Max. permissible degree of contamination of the hydraulic fluid - cleanliness classes to ISO 4406 (c)

10 to 200

Class 20/18/15 1)

Weight

1)

10 to +70

kg

2.6

The cleanliness classes specified for components must be adhered to in hydraulic systems. Effective filtration prevents malfunction and, at the same time, prolongs the service life of components.

For the selection of filters, see data sheet RE 51144.

Sound pressure level in dB (A)

Sound pressure level (average value): (measured at n = 1450 min1, = 41 mm2/s and = 50 C)

74

Measured in an anechoic chamber to

DIN 45 635, part 26

70

2,00-175

66

1,60-250

1,00-450

0,63-700

Microphone pump = 1 m

62

0,40-700

58

At a system pressure below 4 bar and

a viscosity > 150 mm2/s, audible valve

noise may occur.

54

50

Distance:

100

200

300

400

500

Operating pressure in bar

600

700

Sound pressure level at system pressure < 4 bar: 58 dB(A)

Hydraulics Bosch Rexroth AG

RE 11260/08.05 PR4

Characteristic curves (measured at n = 1450 min1, = 41 mm2/s and = 50 C)

Flow

Flow in l/min

1,2

1,0

0,8

0,6

0,4

0,40 - 700

0,2

0,63 - 700

0

300

500

200

400

Operating pressure in bar

100

600

700

3,2

Flow in l/min

2,8

2,4

2,0

1,6

1,2

1,00 - 450

0,8

1,60 - 250

0,4

2,00 - 175

0

50

100

150

200

250

300

350

400

450

Operating pressure in bar

Drive power

Dirve power in kW

1,2

1,0

0,8

0,6

0,4

0,40 - 700

0,2

0,63 - 700

0

100

200

300

500

400

600

700

Operating pressure in bar

Dirve power in kW

1,2

1,0

0,8

0,6

0,4

1,00 - 450

0,2

1,60 - 250

2,00 - 175

50

100

150

200

250

300

Operating pressure in bar

350

400

450

5/8

6/8

Bosch Rexroth AG

Hydraulics

RE 11260/08.05

PR4

Unit dimensions: Nominal dimensions in mm (inch)

2,204)

G1/4; 12 (0,472)

30 (1,181)

26 (1,023)

15 (0,590)

60 (2,362)

45

45

2

G1/2; 14 (0,551)

34 (1,338)

1 Pressure port P

Seal kit (NBR):

Seal kit (FKM)

2 Suction port S

Material no. R900312138

Material no. R900313049

3 Plate spring 5 x 6.5 DIN 6888

(valid for all sizes)

(valid for all sizes)

110 (4,330)

078)

00,0

2,48

0,2 (

63

M6; 10 (0,393)

18 (0,708)

38 (1,496)

14j6 (0,551 +0,00031

0,00018 )

56 (

19 (0,748)

16 (0,629)

Spline

10 x 12 DIN 5481

+0,0

50h8 (1,968 0,0015 )

69 (2,716)

Hydraulics Bosch Rexroth AG

RE 11260/08.05 PR4

7/8

Installation notes

Drive

Fluid tank

El. motor + pump mounting bracket + coupling + pump

Adjust the useful capacity of the tank to the operating conditions

S

P

The permissible fluid temperature must not be exceeded; if

required, provide cooler

Lines and connections

Remove protective plug from pump

No radial and axial forces permitted on the pump drive shaft!

Motor and pump must be exactly aligned!

Always use a coupling that is suitable for compensating for

shaft offsets!

When installing the coupling, avoid axial forces, that is, do

not hammer or press the coupling onto the shaft! Use

the female thread of the drive shaft!

We recommend the use of seamless precision steel pipes

according to DIN 2391 and pipe connections that can be

loosened

Select the clear width of pipes according to the connections

(suction velocity 1 to 1.5 m/s)

For inlet pressure, see page 4

Thoroughly clean pipes and fittings before their installation

Recommendation for piping

S

Suction line

min 50 mm

Installation positions

B3

The returning oil must under no circumstances be reaspired directly, i.e. select the largest possible distance

between suction and return line

The return oil outlet must always be immersed in the oil

Ensure suction-tight installation of the pipes

Filters

B5

S

If possible, use return line or pressure filters.

(Use suction filters only in conjunction with an underpressure

switch/clogging indicator)

P

Hydraulic fluid

Please observe our regulations according to data sheet

RE 07075

V1

We recommend the use of branded hydraulic oils

Different oil grades must not be mixed, since this can result

in decomposition and deterioration of the lubricating properties

The fluid must be changed at certain intervals depending on

the operating conditions. This involves cleaning of the fluid

tank from residues.

S

8/8

Bosch Rexroth AG

Hydraulics

PR4

RE 11260/08.05

Engineering notes

Comprehensive notes and suggestions can be found in The

Hydraulic Trainer, Volume 3 RE 00281, "notes on the planning

and design of hydraulic systems".

When using radial piston pumps, the following notes should be

observed in particular.

Technical data

All technical data given depend on manufacturing tolerances

and are valid in conjunction with certain boundary conditions.

Please note that certain deviations are therefore possible, and

that technical data may vary when boundary conditions (e.g.

viscosity) change.

Noise

The sound pressure level values given on page 4 were measured in line with DIN 45635 part 26. This means that only the

noise emitted by the pump is shown. Influences by the surroundings (such as place of installation, piping, etc.) were eliminated. The values always refer to only one pump

Caution!

Due to the power unit design and influences at the final place

of installation of the pump, the noise pressure level is usually 5

to 10 dB(A) higher than the value of the pump itself.

Characteristic curves

Characteristic curves for flow and required power.

When dimensioning the drive motor, observe the permissible

maximum data.

Commissioning notes

Bleeding

All radial piston pumps of type PR4 are self-priming.

Fill the housing with filtered oil via port S.

Important notes

Adjustments, maintenance and repair of the pump may only

be carried out by authorised, trained and instructed personnel!

For initial commissioning, set the pump to pressureless circulation. To this end, disconnect the pressure hose and route

it to the tank.

Use only genuine Rexroth spare parts!

Before initial commissioning, the pump must be bled in order

to protect it from damage.

When carrying out any work on the pump (e.g. installation

or removal), the system must be switched off and depressurised!

Switch over to pressureless circulation or route the pressure

line or pressure hose back to the tank.

Briefly switch the pump on (inching mode).

Should the pump not displace bubble-free oil after approx.

20 seconds, re-check the system. After having reached operating values, check the pipe connections for leakage. Check

the operating temperature.

Take note of the generation of noise.

The pump may only be operated at the permissible data.

The pump may only be operated when in perfect condition!

Unauthorised conversions or changes that affect safety and

function are not permitted!

Attach protective guards (e.g. coupling protection)!

Any existing protective guards must not be removed!

The generally valid safety regulations and regulations for the

prevention of accidents must be strictly observed!

Commissioning

Check that the system is properly and correctly installed.

Start the pump under no-load conditions and let it displace

fluid for some seconds at zero pressure to ensure sufficient

lubrication.

In no case may the pump be operated without fluid!

Bosch Rexroth AG

Hydraulics

Zum Eisengieer 1

97816 Lohr am Main, Germany

Phone +49 (0) 93 52 / 18-0

Fax

+49 (0) 93 52 / 18-23 58

documentation@boschrexroth.de

www.boschrexroth.de

This document, as well as the data, specifications and other information

set forth in it, are the exclusive property of Bosch Rexroth AG. It may not be

reproduced or given to third parties without its consent.

The data specified above only serve to describe the product. No statements concerning a certain condition or suitability for a certain application

can be derived from our information. The information given does not

release the user from the obligation of own judgment and verification. It

must be remembered that our products are subject to a natural process of

wear and aging.

You might also like

- Axial Piston Motors: Series Fixed Displacement M24 Design D Goldcup M30 Design A Service InformationDocument24 pagesAxial Piston Motors: Series Fixed Displacement M24 Design D Goldcup M30 Design A Service InformationjosueNo ratings yet

- Fixed Displacement Pump Technical SpecsDocument20 pagesFixed Displacement Pump Technical SpecsTaz Juan GNo ratings yet

- Hydraulic Cylinders: Tie Rod Design / Mill Type and Mill Type For Potentially Explosive AreasDocument48 pagesHydraulic Cylinders: Tie Rod Design / Mill Type and Mill Type For Potentially Explosive AreasSatish G SNo ratings yet

- Hagglunds CBMDocument36 pagesHagglunds CBMKuba PałaszNo ratings yet

- R999000375 Medien Web EN 2016-01-28 PDFDocument104 pagesR999000375 Medien Web EN 2016-01-28 PDFSachin RamadasanNo ratings yet

- Variable Plug-In Motor A6VE Series 63: RE 91606/2020-12-15 Replaces: 06.2012Document36 pagesVariable Plug-In Motor A6VE Series 63: RE 91606/2020-12-15 Replaces: 06.2012Andrea NobisNo ratings yet

- Rexroth A4VG PumpDocument16 pagesRexroth A4VG PumpFrancisco OcantoNo ratings yet

- TEC - TA05NALDEA #125869 v1 MT 2721 0 312 02 7507 - ConstruccionDocument110 pagesTEC - TA05NALDEA #125869 v1 MT 2721 0 312 02 7507 - ConstruccionandinoNo ratings yet

- Motor RexrotDocument6 pagesMotor RexrotSilvio RomanNo ratings yet

- Hydraulex Product Line Metaris ProductDocument2 pagesHydraulex Product Line Metaris Productwilly montoyaNo ratings yet

- Valvula Frenado BVD PDFDocument12 pagesValvula Frenado BVD PDFFernando Tapia GibsonNo ratings yet

- R911379309 04 PDFDocument140 pagesR911379309 04 PDFcano720No ratings yet

- Primena Application: Belarus DeutzDocument6 pagesPrimena Application: Belarus DeutzDragan LazicNo ratings yet

- Ronald Luis Quisurco PDFDocument5 pagesRonald Luis Quisurco PDFmoisesNo ratings yet

- ASEP Unit SpecificationDocument4 pagesASEP Unit SpecificationMcSOLA ONo ratings yet

- Instruction Manual Cims MK Iii: CIMS MK III Is Mechanically and Electrically 100% Compatible With CIMS MK IIDocument24 pagesInstruction Manual Cims MK Iii: CIMS MK III Is Mechanically and Electrically 100% Compatible With CIMS MK IISuresh GarapatiNo ratings yet

- Everything You Need to Know About External Gear PumpsDocument7 pagesEverything You Need to Know About External Gear PumpsPrince ShanNo ratings yet

- Bosch Rexroth S 6 S 10 S 20 S 30 Inline Check ValveDocument4 pagesBosch Rexroth S 6 S 10 S 20 S 30 Inline Check ValveOARIASCONo ratings yet

- A31037l PDFDocument24 pagesA31037l PDFAlejandro DhoNo ratings yet

- Range of Products: Detailed ReleaseDocument36 pagesRange of Products: Detailed ReleaseBsaltda GestionNo ratings yet

- 830katalog enDocument28 pages830katalog enarekzerebeckiNo ratings yet

- Re92060 2014-04Document28 pagesRe92060 2014-04Ibrahim GökmenNo ratings yet

- Proportional Pressure Reducing Valve, Pilot-Operated: RE 29282, Edition: 2019-02, Bosch Rexroth AGDocument16 pagesProportional Pressure Reducing Valve, Pilot-Operated: RE 29282, Edition: 2019-02, Bosch Rexroth AGRonald Rayme VenturaNo ratings yet

- Specs PDFDocument32 pagesSpecs PDFNiels LandaNo ratings yet

- Hyva Lift User Manual For HookloadersDocument666 pagesHyva Lift User Manual For HookloadersCarlos ReyesNo ratings yet

- Re 15190Document24 pagesRe 15190Ahmed Abd ElhakeemNo ratings yet

- Rcoa1806 03 03Document36 pagesRcoa1806 03 03Fernando Sabino100% (1)

- Cat Hy14 1600 Denison Products PDFDocument438 pagesCat Hy14 1600 Denison Products PDFEmiliano MercadoNo ratings yet

- Re 22058Document16 pagesRe 22058ShortcutterNo ratings yet

- Analisis de Falla de Bomba de PistonesDocument159 pagesAnalisis de Falla de Bomba de PistonesAngelica Vergara0% (1)

- Bomba Pistao Variavel A4vg PDFDocument72 pagesBomba Pistao Variavel A4vg PDFtawfeeqsylanNo ratings yet

- VOLVO COMPACT WHEEL LOADERS L40B, L45BDocument12 pagesVOLVO COMPACT WHEEL LOADERS L40B, L45BSaif100% (1)

- Denison Hydraulics Directional Control Valve Cetop 03: Series 4D01 Design BDocument0 pagesDenison Hydraulics Directional Control Valve Cetop 03: Series 4D01 Design BZMCONTROLNo ratings yet

- OPERATION, MAINTENANCE and SERVICE INSTRUCTIONS for CAB TILT HYDRAULIC SYSTEMDocument22 pagesOPERATION, MAINTENANCE and SERVICE INSTRUCTIONS for CAB TILT HYDRAULIC SYSTEMpankituna5487No ratings yet

- A10VO Variable Displacement Piston Pump PDFDocument23 pagesA10VO Variable Displacement Piston Pump PDFJoffre Lautaro Benavides Seminario100% (1)

- Hägglunds - Choice of Hydraulic Fluid PDFDocument2 pagesHägglunds - Choice of Hydraulic Fluid PDFAnibal RiosNo ratings yet

- Re 91401Document20 pagesRe 91401JozefNo ratings yet

- Ra91604 02-04 AA6VMDocument64 pagesRa91604 02-04 AA6VMgonzalo andres HernandezNo ratings yet

- Re 15350 - 2017-02 - SPDC - ViewDocument20 pagesRe 15350 - 2017-02 - SPDC - ViewQ Llanos HenryNo ratings yet

- Power Control LR2, LR3, LR2N and LR3N: Replaces: 05.95Document64 pagesPower Control LR2, LR3, LR2N and LR3N: Replaces: 05.95Irina VarzouNo ratings yet

- Full Text 02Document112 pagesFull Text 02Như Nguyễn Trần ThảoNo ratings yet

- Catálogo RexrothDocument228 pagesCatálogo RexrothJard CarvalhoNo ratings yet

- Katalog - Rexroth - Bosch - 2016Document76 pagesKatalog - Rexroth - Bosch - 2016sava88No ratings yet

- TRITORC New 2017 Hydraulic and Bolting Catalogue PDFDocument45 pagesTRITORC New 2017 Hydraulic and Bolting Catalogue PDFSun ChenNo ratings yet

- Technical Manual ICVD 1111Document24 pagesTechnical Manual ICVD 1111Angelo MedinaNo ratings yet

- Chhuon Aasman Ko, Zameen Se Judhkar.: Presenting The World TractorDocument2 pagesChhuon Aasman Ko, Zameen Se Judhkar.: Presenting The World TractorgitamamNo ratings yet

- Application Center Fork-Lift TrucksDocument10 pagesApplication Center Fork-Lift TrucksQXNNo ratings yet

- HY11-3362 Press Control PPCC UKDocument40 pagesHY11-3362 Press Control PPCC UKLucas Cardoso100% (1)

- Bosch Rexroth Axial Piston Pump CatalogDocument10 pagesBosch Rexroth Axial Piston Pump CatalogTiagoNo ratings yet

- Ficha Técnica Control de Accionamiento de Traslación de Vehículos de Ruedas DRC Bosch Rexroth Inglés PDFDocument36 pagesFicha Técnica Control de Accionamiento de Traslación de Vehículos de Ruedas DRC Bosch Rexroth Inglés PDFvivsNo ratings yet

- GMD 16 20 Operators ManualDocument80 pagesGMD 16 20 Operators ManualVladimir ArsicNo ratings yet

- Axial Piston Single Pumps: Service ManualDocument70 pagesAxial Piston Single Pumps: Service ManualCicero Daniel SantosNo ratings yet

- Denison Calzoni Type MRT Mrte MRTFDocument24 pagesDenison Calzoni Type MRT Mrte MRTFSilvio RomanNo ratings yet

- 3 PTL MBD SimulationDocument8 pages3 PTL MBD SimulationSumit SheoranNo ratings yet

- PVB PVBQ A10vso PVHDocument38 pagesPVB PVBQ A10vso PVHWilliam ValenciaNo ratings yet

- Hydraulic Brake Systems and Components For Off-Highway Vehicles and EquipmentDocument10 pagesHydraulic Brake Systems and Components For Off-Highway Vehicles and EquipmentJenner Volnney Quispe ChataNo ratings yet

- Rexroth PumpsDocument24 pagesRexroth PumpsAmanda SmithNo ratings yet

- Assortiment Rexroth PDFDocument176 pagesAssortiment Rexroth PDFFoto TortasNo ratings yet

- Brueninghaus Hydromatik Rexroth A4VSG Pump: Closed Circuit Variable Hydraulic Piston A4VG PumpDocument14 pagesBrueninghaus Hydromatik Rexroth A4VSG Pump: Closed Circuit Variable Hydraulic Piston A4VG PumpLuciano AlencastroNo ratings yet

- Physical and Mechanical Properties of PLA, and Their Functions in Widespread Applications - A Comprehensive ReviewDocument27 pagesPhysical and Mechanical Properties of PLA, and Their Functions in Widespread Applications - A Comprehensive ReviewAnonymous 3tHSzpj1PdNo ratings yet

- Catalog HydrSeals PDE3350-GB Pgs63-66Document4 pagesCatalog HydrSeals PDE3350-GB Pgs63-66claudioandrevalverdeNo ratings yet

- Esquema Arduino UNO R3Document1 pageEsquema Arduino UNO R3stangne1No ratings yet

- Atmega328 - P Avr Mcu With Picopower Technology - Seleção RegisterDocument123 pagesAtmega328 - P Avr Mcu With Picopower Technology - Seleção RegisterclaudioandrevalverdeNo ratings yet

- 5370 pgs168-169 - Part - 1Document2 pages5370 pgs168-169 - Part - 1claudioandrevalverdeNo ratings yet

- Manual Galgas ExtensometricasDocument90 pagesManual Galgas ExtensometricasDiego Leonardo GonzálezNo ratings yet

- YGE 60cell 29b 35mmDocument2 pagesYGE 60cell 29b 35mmtiagonbcNo ratings yet

- Operating Instructions and Specifications: Deutsch FrançaisDocument24 pagesOperating Instructions and Specifications: Deutsch FrançaisclaudioandrevalverdeNo ratings yet

- Guide To Contamination StandardsDocument8 pagesGuide To Contamination Standardsrama.best274No ratings yet

- BearingDocument326 pagesBearingdhirajchhetri2010100% (1)

- 1546 1572Document27 pages1546 1572claudioandrevalverdeNo ratings yet

- Ra 11260 2005-08 06-07-12 13.58Document8 pagesRa 11260 2005-08 06-07-12 13.58claudioandrevalverdeNo ratings yet

- Yingli 125 145wDocument2 pagesYingli 125 145wclaudioandrevalverdeNo ratings yet

- B 0521Document4 pagesB 0521claudioandrevalverdeNo ratings yet

- BD Profile Rod Seal Technical DataDocument4 pagesBD Profile Rod Seal Technical DataclaudioandrevalverdeNo ratings yet

- Catalog HydrSeals PDE3350-GB PGS90-91Document2 pagesCatalog HydrSeals PDE3350-GB PGS90-91claudioandrevalverdeNo ratings yet

- Catálogo Master FloDocument12 pagesCatálogo Master FloclaudioandrevalverdeNo ratings yet

- SIMULIA Abaqus 6.14 6.14-1 .6142SE Install InstructionsDocument12 pagesSIMULIA Abaqus 6.14 6.14-1 .6142SE Install InstructionsBogdan Constantin AlbuNo ratings yet

- KFGT Series Foil Strain Gages With Temperature Sensor: Aminimum Quantity 5 PieceDocument2 pagesKFGT Series Foil Strain Gages With Temperature Sensor: Aminimum Quantity 5 PiececlaudioandrevalverdeNo ratings yet

- PhplotDocument456 pagesPhplotVictor GuimarãesNo ratings yet

- 5370 pgs75-78 - Part - 1Document4 pages5370 pgs75-78 - Part - 1claudioandrevalverdeNo ratings yet

- DEMCO Gate Valves BrochureDocument56 pagesDEMCO Gate Valves BrochureRonald PrietoNo ratings yet

- Bae Photon Propulsion STAIF2 Paper CirculationDocument22 pagesBae Photon Propulsion STAIF2 Paper CirculationclaudioandrevalverdeNo ratings yet

- Low fluidity heterophasic copolymer with good impact propertiesDocument1 pageLow fluidity heterophasic copolymer with good impact propertiesclaudioandrevalverdeNo ratings yet

- British Standard Pipe - Wikipedia, The Free EncyclopediaDocument1 pageBritish Standard Pipe - Wikipedia, The Free EncyclopediaclaudioandrevalverdeNo ratings yet

- Air Driven Hydraulic PumpsDocument32 pagesAir Driven Hydraulic Pumpsdejanr111No ratings yet

- Introduction To Greek CaryrichDocument92 pagesIntroduction To Greek CaryrichclaudioandrevalverdeNo ratings yet

- Scientific Molding WhitepaperDocument10 pagesScientific Molding WhitepaperclaudioandrevalverdeNo ratings yet

- Grupo 04 Anéis Elásticos para Retenção em Furos DIN 472: Fabril Técnica de Elementos Padronizados LTDADocument6 pagesGrupo 04 Anéis Elásticos para Retenção em Furos DIN 472: Fabril Técnica de Elementos Padronizados LTDAJakolinoNo ratings yet

- Feed Water SystemDocument26 pagesFeed Water SystemPhạm QuyếnNo ratings yet

- CAT 928Hz Wheel Loader PDFDocument16 pagesCAT 928Hz Wheel Loader PDFIGNACIONo ratings yet

- Anil Bhat 125Document125 pagesAnil Bhat 125harsh yadavNo ratings yet

- Single Multi Stage CompressorsDocument7 pagesSingle Multi Stage CompressorsV.m. ChenthilNo ratings yet

- Dcim-B02 832 01 07 02Document12 pagesDcim-B02 832 01 07 02ОлександрNo ratings yet

- Ta-249813-021 - C - P&id - BFW Chemical Dosing Package (Phosphate)Document1 pageTa-249813-021 - C - P&id - BFW Chemical Dosing Package (Phosphate)rizwan.zamanNo ratings yet

- Operation and Maintenance Manual PDFDocument284 pagesOperation and Maintenance Manual PDFEvert Vargas Torrez80% (15)

- Ppwuk 2006 1Document36 pagesPpwuk 2006 1Nistor FlorinNo ratings yet

- Liquid Ring Vacuum Pump: LPH 55312, LPH 55316, LPH 55320Document12 pagesLiquid Ring Vacuum Pump: LPH 55312, LPH 55316, LPH 55320Edu CordonNo ratings yet

- Minor Project Plan Version 2020 1aDocument13 pagesMinor Project Plan Version 2020 1aSali ÁdámNo ratings yet

- 62.661 Triplex VFD Booster SubmittalDocument2 pages62.661 Triplex VFD Booster SubmittalwinrayesNo ratings yet

- Alemite Product CatalogDocument212 pagesAlemite Product CatalogCentral HydraulicsNo ratings yet

- Grease Separators - 1Document20 pagesGrease Separators - 1Ljiljana DjordjevićNo ratings yet

- Operation and Maintenance Manual for 1104A-4G-34T Type GovernorDocument54 pagesOperation and Maintenance Manual for 1104A-4G-34T Type GovernorFaserphi Sac100% (2)

- Technical Specification for STP of Palma Hotel ProjectDocument6 pagesTechnical Specification for STP of Palma Hotel ProjectrudiawanNo ratings yet

- Delivery Line Systems Eng PDFDocument24 pagesDelivery Line Systems Eng PDFTimothy Mcmillan0% (1)

- Pump Series D-H-M-HD-PGH ParkerDocument13 pagesPump Series D-H-M-HD-PGH ParkerDaniel MarNo ratings yet

- Predictive Maintenance Using A Digital Twin - MATLAB & SimulinkDocument7 pagesPredictive Maintenance Using A Digital Twin - MATLAB & SimulinkJohn AngelopoulosNo ratings yet

- 1 OXE InstallationManual - Rev ODM1003-180322Document68 pages1 OXE InstallationManual - Rev ODM1003-180322VNo ratings yet

- UFI Tech Pres SimpleDocument14 pagesUFI Tech Pres SimplehaaniaNo ratings yet

- SMART Digital S - DDC: Installation and Operating InstructionsDocument36 pagesSMART Digital S - DDC: Installation and Operating InstructionsIvan GarciaNo ratings yet

- 4LHA-STP marine diesel engines overviewDocument2 pages4LHA-STP marine diesel engines overviewFrederik CañabiNo ratings yet

- Quincy Qsi 50 200hp Instruction ManualDocument100 pagesQuincy Qsi 50 200hp Instruction ManualRuben NunezNo ratings yet

- RT Series Lobe Pump Catalogue PDFDocument15 pagesRT Series Lobe Pump Catalogue PDFvj4249100% (1)

- PDB R1 Therma VDocument51 pagesPDB R1 Therma VAleksander CanjugaNo ratings yet

- C-Cast Iron Volute Pumps Part 2Document21 pagesC-Cast Iron Volute Pumps Part 2JoaquínRodaNo ratings yet

- 2100 FanDocument382 pages2100 Fanmvalle100% (5)

- Total Cost of Ownership Chilled Water SystemsDocument46 pagesTotal Cost of Ownership Chilled Water Systemsalprieto2003No ratings yet

- Two Stage High/Low Hydraulic Pumps: Concentric ABDocument8 pagesTwo Stage High/Low Hydraulic Pumps: Concentric ABZakNo ratings yet

- D628 Maintenance ScheduleDocument3 pagesD628 Maintenance ScheduleDPNo ratings yet