Professional Documents

Culture Documents

Impedance Measurement in Madrid 'S Underground Power Grid

Uploaded by

Insan AzizOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Impedance Measurement in Madrid 'S Underground Power Grid

Uploaded by

Insan AzizCopyright:

Available Formats

Presentation 02.

Impedance Measurement in Madrids Underground Power Grid

Jose Maria Madrid / Ivan Lozano / Jose Manuel Roca, Gas Natural Fenosa, Spain

Abstract

In this paper we want to show our experience in

GNF on impedance measurement of underground

cables and the influence that the soil of a big city

like Madrid has on zero sequence impedance.

This parameter, influenced by the return paths that

can be found on the ground and the type of

connection of the screens, found in a city like

Madrid with unexpected return paths through the

soil (pipelines, railways, building structures, etc. ...)

does vary significantly from the theoretical values

in zero sequence impedance.

For this study we tested all the underground cables

that we have in 220kV, 132kV and some 45kV,

finding notable differences between the theoretical

and measured values.

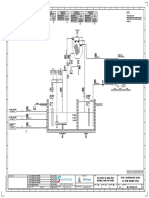

Fig. 1 Autotransformer

GNF Grid

Gas Natural Group is one of the leading

multinational companies in the gas and electricity

sector, operating in 25 countries and with more

than 20 million customers.

Following the acquisition of the electricity

company, Unin Fenosa, third in the Spanish

market, Gas Natural Fenosa has achieved its

objective of integrating the gas and electricity

business in a single company with extensive

experience in the energy sector, capable of

competing efficiently in energy markets subject to a

process of increasing integration, globalisation and

levels of competition.

In Union Fenosa we have over 40 years measuring

impedance cables with equipment manufactured

for us (see Figure 1), but in 2005, when we

acquired an OMICRON CPC 100 we intensified

this field work.

Nowadays, all the electric distribution circuits in the

city of Madrid which are the property of Gas

Natural Fenosa, are underground, with voltage

levels of 220, 132, 45 and 15kV. All 220, 132 and

45kV lines are fitted with a distance relay as main

or redundant protection. This makes it very

important for us to measure the reliability of the

impedance data lines in terms of protection

settings calculations.

Since 2006 we have been able to measure all the

220kV circuits which are for us the most critical,

and any position of 45kV that we believe needs to

be measured for its unique features.

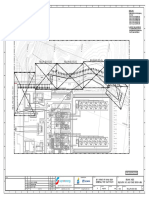

Fig. 2 CPC 100 in Azca Substation

Based on our experience, we consider the

impedance measurement of underground power

cables very important because we have found

substantial differences between the values

indicated by the manufacturer or calculated for us,

and those actually measured by us. In addition, it

allows us to detect implementation errors in the

laying of cables related to the connection of the

OMICRON 2013 International Protection Testing Symposium

Presentation 02.2

sheaths in cable joints, errors in the grounding

systems of sheaths or errors in the surge arresters.

of the cable route and installed very close to the

cable conductors, to carry the fault current during

ground faults and to limit the voltage rise of the

sheath during ground faults to an acceptable level.

As the main advantage is their simplicity, the

screens circulating insignificant current and

magnetic fields between conductors are broadly

balanced.

It is widely used in lines where it is necessary to

maximize the allowed amp capacity in the

conductor without the limitations that cause the

current screen.

Fig. 3 Cable Gallery

In this paper we will show some data in which it

can be seen that in some cases the differences are

quite significant and could give rise to over-or

under-reach.

Fig. 5 Single End connection

2. Solid Bonding:

Fig. 4 Damage detected in a Link box

Cable sheath bonding in GNF

In this case, sheaths are bonded to earth grids at

both ends (via link box). This is the common

connection on our 45kV grid.

This is generally the most common method and

does not require surge arresters, but on the other

hand it reduces the transport capacity because of

heating effects in the cable screen.

The cable grounded at both ends, makes the use

of surge arresters unnecessary and overvoltage

will not occur on the screens. It also eliminates the

need for the parallel continuity conductor used in

single bonding systems.

On the other hand current will flow through them,

thus the transport capacity will be limited by the

heating effects that occur in the screens by the

aforementioned current flow.

In GNF it is possible to normally find three types of

bonding depending mainly on the voltage level,

cable characteristic or other design purposes.

1. Single Point or Single End:

In a single end system screens are connected to

the ground only at one end of the line, which do

not offer a path for current to flow through them.

In the remaining points of the circuit, we will find a

voltage between the screen and the ground and

also between adjacent screens so that the

maximum is the far end. This voltage is dependent

on the length of the line and the circuit load. To

avoid damaging surges, surge arresters are

equipped at the none-grounded end of the line.

Single-point bonded cable installations need a

parallel ground conductor, grounded at both ends

Fig. 6 Solid Bonding

OMICRON 2013 International Protection Testing Symposium

Presentation 02.3

3. Cross Bonding:

A system is cross-bonded if the arrangements are

such that the circuit provides electrically

continuous sheath runs from earthed termination to

earthed termination but with the sheaths so

sectionalized and cross-connected in order to

reduce the sheath circulating currents.

In this type of connection voltage will be induced

between screen and earth, but no significant

current will flow.

Therefore, examining the total line length and

number of joints is required, so that the number of

sections in which the line is divided is three or a

multiple of three.

Great lengths of line where it is difficult to get the

number of sections as a multiple of three uses

Cross Bonding combined with one or two end

sections with Single Point configuration.

An advantage of this system is that for a conductor

arrangement in a triangle, the induced voltage in a

steady state in three consecutive sections of

screens is zero because it is the sum of three

equal voltages outdated 120, because the mutual

inductances between the conductors and screens

are equal in all three phases. As a result there is

no current flow through the screens.

Another advantage is that does not need a

conductor parallel ground return, as the screens

flows continuously from end to end of the line and

are grounded at both ends, so that, the fault

current can flow through them.

Moreover, due to the transposition of screens, the

voltage induced in the screen during a fault is

lower compared with Single End configuration.

The induced voltage on screens is highest in the

transposition intermediate joints, and should not

exceed 150V under nominal conditions of service

and the maximum current for the conductor, taking

into account the longest stretch. Induced voltages

in a steady state and short circuits are calculated

for each project.

In the transposition screen points must be installed

a junction box provided with a screen surge

arrester.

Obtaining parameters before

measurement

Usually, the first step is to receive data from the

study of our online database (BDI), which is

composed on one side with the data provided by

the manufacturer and on the other with a

calculation tool, and both sets of data are

compared.

For our part we try to measure the impedance of all

underground cables that make it possible for their

construction work. There are occasions when it is

not possible to have a cable access point.

After both parameters have been obtained, both

are compared, contrasted and evaluated and the

differences examined.

In most cases the calculated parameters are very

close to the real ones.

Fig. 8 Theoretical parameters

The impedance calculating is mainly based on two

factors:

a. Characteristics of the conductor

(diameter of the screens, materials

and type of insulation).

b. Physical geometry of the conductors

and the ground wire.

Measurements experience

As mentioned before, our experience in cable

impedance measuring means we consider this test

to be very important, a useful tool to contrast

theoretical settings with those obtained after

measure.

Observe below some line-measured data, in which

we can observe that the differences are slightly

bigger in some cases and might lead to an over or

under reach in case of faults.

Fig. 7 Cross Bonding

Fig. 9 Comparative

OMICRON 2013 International Protection Testing Symposium

Presentation 02.4

The table shows some results reported, and we

can check, for instance, in the circuit connecting

the substations Azca-Norte a difference of 29.5%

in positive sequence resistance and 70% in zero

sequence resistance.

Another striking case is the circuit connecting the

substations Puente Princesa and Cerro de la

Plata, which are measured after a gap of "98%" in

the zero sequence resistance.

In previous cases we referred to XLPE insulation

cables, but we also have examples of paperinsulated cables, such as circuit Prosperidad

Hortaleza 220kV (O.F. technology). In this case,

the calculation of their characteristics may seem

easy because the layout and grounding of the

sheaths is done in a more conventional way

(Single End with surge arresters at the far

isolated), but we still had a calculation deviation of

51% in positive sequence resistance and 52.8% in

case of zero sequence resistance.

Due to the discrepancies found, errors have been

detected (connection of screens, execution a Link

Box). In the same way we have found damage and

problems in the line and its earthing system after

faults and shortcircuits in the surrounding grid.

The errors mentioned above have been one of the

causes of the discrepancies, but on the other hand

due to uncontrollable factors such as ground

conditions, the current season, or the influence of

other factors external to the line such as pipes,

parallel lines, railway infrastructure, and more

items that cannot be evaluated because significant

changes can occur in a city in a very short period

of time that directly influence these parameters and

these can only be examined if a field test is

performed.

Conclusion

After having carried out the impedance

measurement of 220kV cables and a number of

132kV and 45kV cables, a conclusion can be

reached.

Due to soil characteristics in a city like Madrid, the

impedance of the lines needs to be measured

because large differences can be found, especially

in the parameter R0, which being dependent on

return paths, is strongly influenced by the structural

conditions that affect this type of circuit, whether

medium voltage lines flowing through the same

gallery, water or gas pipelines, railways, steel

structures of buildings, the current season or

characteristics of the soil. Furthermore, impedance

line measurement helps us to check that the

connection of the screens has been successful,

according to current hypotheses.

In the end, many factors make it very difficult to

estimate a theoretical calculation compared with

the true scenario.

Fig. 10 Cable gallery

Literature

[1]

Alstom

Grid:

Network

Protection

Automation Guide. May 2011

&

[2]

S. Kaiser 2004,Different Representation of

the earth Impedance Matching in distance

Protection Relays. OMICRON User Meeting

2004.

[3]

Roeper, Richard, Short-Circuit Currents in

Three-Phase

Networks.

Siemens

Aktiengesellschaft, 1972

[4]

William D. Stevenson & John J. Grainger,

"Power system Analysis", McGraw-Hill, Jan 1,

1994.

About the Author

Jose Maria Madrid (9 October 1973) is a Systems

Engineer from the University of Catalonia. He has

performing coordination work commissioning of

electrical installations since 2001 for different

Spanish utilities having developed his main activity

for Union Fenosa, both in generation and in

distribution and transportation.

OMICRON 2013 International Protection Testing Symposium

You might also like

- RD P WW P00 1022 - Rev.3 - P&ID Waste Water Treatment SystemDocument2 pagesRD P WW P00 1022 - Rev.3 - P&ID Waste Water Treatment SystemInsan AzizNo ratings yet

- RD-I-CI-G00-1020-02 - Rev.1 - Layout of Instrument Plot Plan Wiring & Grounding For Well PAD RD-MDocument3 pagesRD-I-CI-G00-1020-02 - Rev.1 - Layout of Instrument Plot Plan Wiring & Grounding For Well PAD RD-MInsan Aziz100% (1)

- RD-P-WA-P07-2002 - Rev.4 - Piping & Instrumentation Diagram HP & LP Steam Scrubbing (UNIT2)Document1 pageRD-P-WA-P07-2002 - Rev.4 - Piping & Instrumentation Diagram HP & LP Steam Scrubbing (UNIT2)Insan Aziz100% (2)

- RD-I-CI-G00-1018-02 - Rev.1 - Layout of Instrument Plot Plan Wiring & Grounding For Well PAD RD-BDocument3 pagesRD-I-CI-G00-1018-02 - Rev.1 - Layout of Instrument Plot Plan Wiring & Grounding For Well PAD RD-BInsan Aziz100% (1)

- RD-I-CI-G00-1024-02 - Rev.1 - Layout of Instrument Plot Plan, Wiring & Grounding For Well Pad RD-CDocument2 pagesRD-I-CI-G00-1024-02 - Rev.1 - Layout of Instrument Plot Plan, Wiring & Grounding For Well Pad RD-CInsan Aziz100% (1)

- RD-I-CI-G00-1018-02 - Rev.1 - Layout of Instrument Plot Plan Wiring & Grounding For Well PAD RD-BDocument3 pagesRD-I-CI-G00-1018-02 - Rev.1 - Layout of Instrument Plot Plan Wiring & Grounding For Well PAD RD-BInsan Aziz100% (1)

- RD-I-CI-G00-1024-02 - Rev.1 - Layout of Instrument Plot Plan, Wiring & Grounding For Well Pad RD-CDocument2 pagesRD-I-CI-G00-1024-02 - Rev.1 - Layout of Instrument Plot Plan, Wiring & Grounding For Well Pad RD-CInsan Aziz100% (1)

- RD-I-CI-G00-1024-02 - Rev.1 - Layout of Instrument Plot Plan, Wiring & Grounding For Well Pad RD-CDocument2 pagesRD-I-CI-G00-1024-02 - Rev.1 - Layout of Instrument Plot Plan, Wiring & Grounding For Well Pad RD-CInsan Aziz100% (1)

- RD-I-CI-G00-1024-02 - Rev.1 - Layout of Instrument Plot Plan, Wiring & Grounding For Well Pad RD-CDocument2 pagesRD-I-CI-G00-1024-02 - Rev.1 - Layout of Instrument Plot Plan, Wiring & Grounding For Well Pad RD-CInsan Aziz100% (1)

- RD-I-CI-G00-1017-01 - Rev.1 - Layout of Instrument J Main Cable Way and Cable Way For SeparatorDocument2 pagesRD-I-CI-G00-1017-01 - Rev.1 - Layout of Instrument J Main Cable Way and Cable Way For SeparatorInsan AzizNo ratings yet

- RD-I-CI-G00-1024-02 - Rev.1 - Layout of Instrument Plot Plan, Wiring & Grounding For Well Pad RD-CDocument2 pagesRD-I-CI-G00-1024-02 - Rev.1 - Layout of Instrument Plot Plan, Wiring & Grounding For Well Pad RD-CInsan Aziz100% (1)

- RD-I-CI-G00-1020-02 - Rev.1 - Layout of Instrument Plot Plan Wiring & Grounding For Well PAD RD-MDocument3 pagesRD-I-CI-G00-1020-02 - Rev.1 - Layout of Instrument Plot Plan Wiring & Grounding For Well PAD RD-MInsan Aziz100% (1)

- RD-PRD01-EnG-CSPC-2076 - Rev.0 - Piping Material Class For Lube Oil, Control Oil, Gland Steam SystemDocument3 pagesRD-PRD01-EnG-CSPC-2076 - Rev.0 - Piping Material Class For Lube Oil, Control Oil, Gland Steam SystemInsan AzizNo ratings yet

- RD-I-CI-G00-1015-17 - Rev.0 - Typical Drawing For Instrument Installation Cable Installation Detail (1 of 3)Document1 pageRD-I-CI-G00-1015-17 - Rev.0 - Typical Drawing For Instrument Installation Cable Installation Detail (1 of 3)Insan AzizNo ratings yet

- 33 File 20210813-135348 PRODUCT CATALOGUE 2021 PDFDocument20 pages33 File 20210813-135348 PRODUCT CATALOGUE 2021 PDFInsan AzizNo ratings yet

- RD-PRD01-EnG-CTEN-2003 - Rev.6 - Setting Value List For STG & AuxiliariesDocument24 pagesRD-PRD01-EnG-CTEN-2003 - Rev.6 - Setting Value List For STG & AuxiliariesInsan AzizNo ratings yet

- RD-I-CI-G00-1017-02 - Rev.1 - Layout of Instrument J Main Cable Way and Cable Way For SeparatorDocument2 pagesRD-I-CI-G00-1017-02 - Rev.1 - Layout of Instrument J Main Cable Way and Cable Way For SeparatorInsan AzizNo ratings yet

- RD I PC p00 2002 - Rev.3 - Dcs I o ListDocument87 pagesRD I PC p00 2002 - Rev.3 - Dcs I o ListInsan AzizNo ratings yet

- RD M PO P00 1030 - Rev.0 - Welding Map Overhead CranesDocument7 pagesRD M PO P00 1030 - Rev.0 - Welding Map Overhead CranesInsan AzizNo ratings yet

- RD P WW P00 1022 - Rev.3 - P&ID Waste Water Treatment SystemDocument2 pagesRD P WW P00 1022 - Rev.3 - P&ID Waste Water Treatment SystemInsan AzizNo ratings yet

- RD-PRD01-EnG-CDAT-1602 - Rev.1 Special Motorized Control Valve (MOV) For SGSDocument17 pagesRD-PRD01-EnG-CDAT-1602 - Rev.1 Special Motorized Control Valve (MOV) For SGSInsan AzizNo ratings yet

- RD L Po g00 1005 0009 - Rev.0 - Isometric Drawing For DW (Line No. Rd00 Ghd10 Drain Wastafel Dn50 120a)Document1 pageRD L Po g00 1005 0009 - Rev.0 - Isometric Drawing For DW (Line No. Rd00 Ghd10 Drain Wastafel Dn50 120a)Insan AzizNo ratings yet

- RD-L-PO-G00-1003-004 - Rev.0 - Piping Alignment Sheet Relocation SWS Sheet 4 of 6Document1 pageRD-L-PO-G00-1003-004 - Rev.0 - Piping Alignment Sheet Relocation SWS Sheet 4 of 6Insan AzizNo ratings yet

- RD L PO G00 1005 0004 - Rev.0 - Isometric Drawing For DW (Line No. RD00 GHD10 BR005 DN50 120A)Document1 pageRD L PO G00 1005 0004 - Rev.0 - Isometric Drawing For DW (Line No. RD00 GHD10 BR005 DN50 120A)Insan AzizNo ratings yet

- RD-L-PO-G00-1003-005 - Rev.0 - PA Sheet Relocation SWS Line at PWR Station SHT 5Document1 pageRD-L-PO-G00-1003-005 - Rev.0 - PA Sheet Relocation SWS Line at PWR Station SHT 5Insan AzizNo ratings yet

- RD L Po g00 1005 0001 - Rev.0 - Isometric Drawing For DW (Line No. Rd00 Ggdb10 Li Cl501 Dn50 120a) Rd00 Gdb10 Li Cl501 Dn50 120a - sht1 001Document1 pageRD L Po g00 1005 0001 - Rev.0 - Isometric Drawing For DW (Line No. Rd00 Ggdb10 Li Cl501 Dn50 120a) Rd00 Gdb10 Li Cl501 Dn50 120a - sht1 001Insan AzizNo ratings yet

- RD L Po g00 1005 0003 - Rev.0 - Isometric Drawing For DW (Line No. Rd00 Ghd10 Ven Dn50 120a)Document1 pageRD L Po g00 1005 0003 - Rev.0 - Isometric Drawing For DW (Line No. Rd00 Ghd10 Ven Dn50 120a)Insan AzizNo ratings yet

- RD-L-PO-G00-1003 - Rev.0 - DWG Index Relocation SWS Line PWR Station AreaDocument2 pagesRD-L-PO-G00-1003 - Rev.0 - DWG Index Relocation SWS Line PWR Station AreaInsan AzizNo ratings yet

- RD-L-PO-G00-1003-003 - Rev.0 - Piping Alignment Sheet Relocation SWS Sheet 3 of 6Document1 pageRD-L-PO-G00-1003-003 - Rev.0 - Piping Alignment Sheet Relocation SWS Sheet 3 of 6Insan AzizNo ratings yet

- RD-L-PO-G00-1003-001 - Rev.0 - PA Sheet Relocation SWS Line at PWR Station SHT 1Document2 pagesRD-L-PO-G00-1003-001 - Rev.0 - PA Sheet Relocation SWS Line at PWR Station SHT 1Insan AzizNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5782)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- 5000VG7S Series: Instruction ManualDocument97 pages5000VG7S Series: Instruction ManualsunhuynhNo ratings yet

- High Voltage X-Ray GeneratorDocument52 pagesHigh Voltage X-Ray GeneratorMunish Dogra100% (3)

- 6 MohdetalDocument11 pages6 MohdetalHoàng Chu ĐứcNo ratings yet

- Sheet 1 Rev 01Document1 pageSheet 1 Rev 01pwmvsiNo ratings yet

- WP Schneider Electric Renewable Energies CatalogDocument72 pagesWP Schneider Electric Renewable Energies CatalognaveedfndNo ratings yet

- A Protection and Grounding Strategy For Integrating Inverter-Based Distributed Energy Resources in An Isolated MicrogridDocument9 pagesA Protection and Grounding Strategy For Integrating Inverter-Based Distributed Energy Resources in An Isolated MicrogridMichael DavisNo ratings yet

- Power System Simulation Lab I Report: Hawassa UniversityDocument27 pagesPower System Simulation Lab I Report: Hawassa UniversityTahir KedirNo ratings yet

- SSG Course Outline DJM 5103Document7 pagesSSG Course Outline DJM 5103api-293198287100% (1)

- Revo Series - II: Product SnapshotDocument2 pagesRevo Series - II: Product SnapshotStefan CorneaNo ratings yet

- How To Design Multi-kW DC - DC Converters For Electric Vehicles (EVs) - The Phase Shifted Full BridgeDocument2 pagesHow To Design Multi-kW DC - DC Converters For Electric Vehicles (EVs) - The Phase Shifted Full BridgeThien DinhNo ratings yet

- Utility Bill August 2023Document4 pagesUtility Bill August 2023bartsusy.67100% (1)

- Lab 9 The Effects of Diodes and Rectifiers in CircuitsDocument10 pagesLab 9 The Effects of Diodes and Rectifiers in Circuitsapi-709999921No ratings yet

- United Security CVD-2025 User ManualDocument2 pagesUnited Security CVD-2025 User ManualJMAC SupplyNo ratings yet

- 34 Samss 622Document12 pages34 Samss 622naruto256No ratings yet

- High-Speed DC Circuit Breakers For Fixed Installations (En / Iec) Type URDocument16 pagesHigh-Speed DC Circuit Breakers For Fixed Installations (En / Iec) Type URMouth GoonieNo ratings yet

- OPzS Solar PowerDocument2 pagesOPzS Solar PowerSINES FranceNo ratings yet

- Dexxo Optimo RTSDocument2 pagesDexxo Optimo RTSNumele VantuluiNo ratings yet

- HT 66 KV Sf6 Circuit BreakerDocument9 pagesHT 66 KV Sf6 Circuit BreakerJoint Power ElectricalNo ratings yet

- Assistant and Sub Assistant Job Question With AnswerDocument10 pagesAssistant and Sub Assistant Job Question With AnswerEj ParañalNo ratings yet

- Modeling and Simulation of a Hybrid Solar Wind Floating Power PlantDocument19 pagesModeling and Simulation of a Hybrid Solar Wind Floating Power PlantVikas PatelNo ratings yet

- Horn FOTON - TunlandDocument10 pagesHorn FOTON - Tunlandgire_3pich2005No ratings yet

- KEB R6 S Rev 2D ManualDocument42 pagesKEB R6 S Rev 2D ManualTeoNo ratings yet

- Industrial Visit: Report OnDocument7 pagesIndustrial Visit: Report OnSenthil KumarNo ratings yet

- Subject: Range of Application: Performance Class G1Document2 pagesSubject: Range of Application: Performance Class G1anujpkr5118100% (1)

- EE 155 Quiz #2 Complex Power 3-Phase AC CircuitsDocument1 pageEE 155 Quiz #2 Complex Power 3-Phase AC CircuitsMahpuja JulangNo ratings yet

- Repairing Electric MotorsDocument7 pagesRepairing Electric Motorsbhdamr100% (4)

- Abstracts TotalDocument232 pagesAbstracts TotalhaleemforyouNo ratings yet

- IEC 60364-4-42 Ed 3Document12 pagesIEC 60364-4-42 Ed 3Сергей ОблакевичNo ratings yet

- Donald Smith Devices Too Good To Be TrueDocument16 pagesDonald Smith Devices Too Good To Be TrueSilviu CorcanNo ratings yet

- Directional Induction Overcurrent RelayDocument3 pagesDirectional Induction Overcurrent RelayK.GuruCharan ReddyNo ratings yet