Professional Documents

Culture Documents

386 389 PDF

Uploaded by

SinhrooOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

386 389 PDF

Uploaded by

SinhrooCopyright:

Available Formats

Metal Science and Heat Treatment

gol. 38, Nos. 9 - 10, 1996

THERMAL-SHOP EQUIPMENT

UDC 621.783.246:66.096.5

ELECTRIC F U R N A C E S WITH A FLUIDIZED BED

FOR I M P L E M E N T I N G E N V I R O N M E N T A L L Y SAFE

HEAT T R E A T M E N T PROCESSES IN M A C H I N E BUILDING

A. P. Baskakov and E. M. F a i n s h m i d t

Translated fi'om Metallovedenie i Termicheskaya Obrabotka Metallov, No. 9, pp. 19 - 23, September, 1996.

Current designs of electric tank furnaces with a fluidized bed that provide environmentally safe heat treatment

of steels as tested under the conditions of machine-building plants are considered.

Some foreign finns are known to specialize in the production of furnaces with a fluidized bed either separately or

along with other equipment. Russian industry has not yet

started such production.

Several industrial and pilot furnaces (mainly induction

electric furnaces) have been manufactured in shops for nonstandard equipment for machine-building plants that use a

fluidized bed as a heating agent in heat treatment processes.

For example, five modifications of such furnaces have been

produced by the Nizhnii Tagii plant, and ! - 2 furnaces each

have been produced by the Nev'yansk, Chelyabinsk, and

Magnitogorsk plants. In all cases the heating agent used instead of molten metals, salts, caustic alkalis, saltpeters, and

mineral oils used in heat treatment practice in machine-building plants was a fluidized bed of a fine-grained material (predominantly white electrocomndum, which is an indifferent

environmentally safe medium).

In some nonstandard processes (in special technologies

or in the absence of natural gas) producers use molten lead

and KCI, NaCI, BaCI 2 salts as media for oxidation-free heating for hardening of structural and tool steels. Melts of KOH,

NaOH alkalis are used for isothermal cooling of steels; melts

of KNO 3 , NaNO 2 , NaNO 3 saltpeters are used for oxidationfree recrystallization annealing of copper alloys, heating for

hardening of Duralumin, high-temperarure tempering of

high-speed steels, and intermediate-temperature tempering of

spring materials; Vapor mineral oil with t = 150 - 180C (the

flash point exceeds 250C) is used for low-temperarure tempering of structural and tool steels.

All these chemicals contaminate the atmosphere of the

shop and the waste waters, because the shops performing the

mentioned processes (thermal, mechanical, machining) are

often separated from the plant's purification system, which is

overloaded with waste from the chemical, galvanizing, and

other shops. Thus, after washing parts heat treated in the

melts and oils mentioned above, waste waters containing K ,

Na , Ba ++, CI-, NO~, NO], OH- ions, metallic lead, aluminum, and zinc, and mineral oils pass directly into the sewage

system and then into the soil and the water basins. This situation is typical for machine-building plants in the Urals (see

Table 1).

The use of a neutral environmentally safe heating agent

prevents the appearance of the mentioned substances in the

waste and makes the atmosphere of the shops healthier.

The first attempts to use a fluidized bed as a universal

heating agent in heat treatment processes were made in the

1960s. At the present time some experience has been accumulated in the field of heat and mass exchange in fluidized

beds and fluidizing technology [1, 2, etc.]. A characteristic

feature o f a fluidized bed is its high effective thermal conductivity. Intense circulation of particles whose volume heat conduction exceeds that of gases by about three orders of magnirude provides almost equal temperatures (accurate to 5 10C) at all points of the bed even in large furnaces. If necessary, the accuracy can be increased to + 3C. Heating in a

fluidized bed is similar to that in molten salts and metals and

can be used at virtually any process temperature from room to

900C.

The coefficient of heat transfer ct between a fluidized

bed and the surface of a part immersed in it can exceed

1000 W/(m2. K). Such high values ofct at gas velocities constiruting a tenth of a meter per second are caused first of all

by the heat transferred by the solid particles of the finegrained material used as the fluidization material. Heating in

a fluidized bed is rapid; the heating rates in such a bed lie be-

386

0026-0673/96/0910-0386515.00 0 1997 Plenum PublishingCorporation

Electric Furnaces with a Fluldized Bed

387

tween those o f chloride melts and molten lead, and the medium is environmentally safe.

In principle, a fluidized bed can be heated by electricity

(at least to 700 - 900C) through the walls of a steel heat-resistant converter from resistance heaters placed along the

walls o f the refractory lining o f the shaft or by burning a gas,

for example, in immersed burners [1]. World experience

shows that gas furnaces have not found wide application in

machine building.

In a machine-building plant natural gas is supplied to a

few, usually specialized, shops (forge, heat-treatment, foundry). Choosing the concept o f electric heating o f a fluidized

bed we managed to design a number o f mobile tank electric

furnaces that can operate directly in flow lines o f mechanical

shops, which makes it possible to eliminate transportation of

parts into the heat-treatment department and back. The lower

volume o f intershop transportation makes the process less expensive and shortens the production cycle, making it more

rhythmic.

It has been difficult to develop a process and equipment

with a fluidized bed for low-oxidation recrystallization annealing o f parts maade o f copper and its alloys. In the range

o f annealing temperatures (400 - 550C) copper is intensely

oxidized in air, forming a dense oxide film that is hard to remove. Many parts have to be heated without oxidation, especially if their sizes are finished or in order to provide for a

high quality o f a deposited coating (for example, in tinning).

Previously, saltpeter melts were used for oxidation-free

recrystallization annealing o f copper and its alloys and

for heating parts made o f aluminum alloys for hardening (500

525C).

An alternative for oxidation-free heating in saltpeter was

indirect (through the walls o f a closed muffle) heating o f a

charge o f parts, but it did not provide uniform heating o f the

-

whole o f the charge; parts from different zones had different

levels o f ductility, microstructures, and other properties (at

the walls o f the muffle the parts were superheated, whereas in

the center, underheating caused a deformation texture and the

parts were rejected). In addition, the air left in the muffle oxidized the surface of the parts (to a dark-brown oxide film).

Direct heating o f a charge in a fluidized bed provides the

requisite uniformity o f the distribution o f the temperature,

properties, and microstructure. In order to eliminate the formation o f scale the fluidization was conducted using steam

for the first time in the practice o f a machine-building plant.

Steam played the role o f a fluidizing agent and, simultaneously, o f a medium protecting copper and its alloys from oxidation [3, 4]. Steam from the plant's system was fed into the

furnace at a temperature o f 100 - 110C and a pressure o f up

to 20 MPa. This method o f heating was low-oxidation. A thin

oxide film (colored from yellow to light-brown) was easily

removable by pickling before tinning with a loss o f mass up

to 0.01 g/cm 2 (in heating in a muffle the loss o f mass was up

to 0.03 g/cm2; in the absence o f a protective atmosphere it

was 0.1 - 0.12 g/era 2 for articles made o f M 1 copper sheets

after cold spinning).

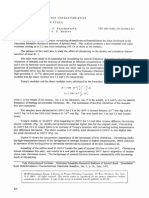

The shaft electric furnace designed in order to implement

the process described has the following characterizes: a power

o f 80 kW, tm~ = 550C, an output o f 250 kg/h, a steam flow

rate o f 86m3/h, a length/width/height proportion o f

1730/1730/2700 mm, a functional space of 600/600/1500 ram, a

mass o f conmdum of 320 kg, and a total weight o f 7.7 tons.

The shaft tank electric furnace (Fig. 1) consists o f a heatresistant muffle 1 (with a square cross section) placed in a

shaft 2 with a heat-insulating refractory lining 3 and registahoe heaters 4. The square cross section provides maximum

charging. A steam-distributing nozzle 5 is mounted on the

bottom o f the muffle and its upper plate is equipped with caps

TABLE 1

No. of

process

Heating agent

Technology

1 Oxidation-free heating for hardening

2 The same

3* The same

Treated material

composition

Carbon and alloyed steels Molten NaCI + KCI

High-speed steels

Molten NaCI + BaCh

Alloy edateels

Molten lead

l,C

Presence of harmful

substances in waste waters

and the atmosphere

780 - 900 Na+, K+, CV, HCI vapor

1260 - 1280 Na, Ba''+, HCI vapor

800 - 850 Pb vapor, Pb in waste

waters

4* Rapid heating for high-temperature

The .same

tempering

5 High-temperaturetempering of cutting High-speedsteels

tools

6 Isothermalcooling(bainite quenching) Carbon and alloyed steels

7 Temperingof spring items

Spring steels

8 Low-temperaturetempering of items and Carbon and alloyed steels

tools

9 Oxidation-freerecrystallization annealing Copper-basealloys

I0

Chemicaloxidation of items and tools Structuraland tool steels

11 Hydrophobizationof parts in powder

Powdersteels

metallurgy

*Special technology.

**Hydrophcbizingsilioon-conminingliquid.

The

same

Molten KNO3 + NaNO3

650 - 680 The same

560

Na+, K+, NO~

Molten KON + NaOH

Molten NaNO-2 + NaNO3 + KNO3

Vaporoil (ttp= 260C)

320-400 Na+,K+,OH230 - 350 Na+, K+, NO~, NO~

160 - 180 Volatilehydrocarbons, oil.

Molten NaNO3 + KNO3

Solution of NaOH, NaNO2, NaNO3

GKZh-94,** gasoline

400-550 Na,K,NO~

130-135 Na+,OH-,NOT,NO~

20

Gasolinevapor, GKZh

tars

388

6. A dense bed of electrocorundum 7 (GOST 3647-71, particle size 120 I.tm) 600 mm high is poured onto the steam-distributing mesh. Steam is fed through nozzle 8 into the steamdistributing nozzle virtually under atmospheric pressure and

is filtered uniformly over a horizontal cross section of the

conveiter through the bed of corundum particles, fluidizing

the latter. The steam also serves as a protective atmosphere

that provides virtually oxidation-free heating of copper parts.

The fluidized bed is heated through the walls of the converter; the latter is heated, in turn, by radiation of the resistance electric heaters.

Due to intense mixing in the functional volume of the

fluidized bed the temperature becomes uniform (the temperature difference is 2 - 3C). The functional volume is situated

60 - 70 mm above the openings in the gas-distributing caps 6.

In the start-up period dried compressed air is fed from the

shop system in order to avoid condensation of steam on the

cold installation and moistening of the corundum, which

hampers normal fluidizing.

The furnace is equipped with a water tank 9 connected

with a tambour 10. The furnace, the tambour, and the tank

have a common cover 11 with a longitudinal groove for pulling a container with parts. Steam passes through the settling

zone (the space above the fluidized bed), is separated from

the eleetroeorundum particles, and is then sucked into a ventillation pump 13 through a longitudinal groove in the cover

11. An excess steam pressure is retained under the cover,

which creates a steam jacket in the tambour and above the

water tank. For this reason, parts moved into the water tank

hardly oxidize. The container with the parts is moved into the

furnace by a telpher, a vertical pull rod moves along the longitudinal groove in the cover, and the charge is immersed in

the fluidized bed when it reaches the end of the groove. The

container is mounted on a stationary support 14.

When the heating is finished, the charge is transported

with the help of the telpher into the water tank for 10 - 20 sec.

The cooling time of the charge is chosen so that the parts

withdrawn from the water have a temperature of 100- 150C,

at which excess moisture evaporates from their surface.

The mass of the charge is 100 - 120 kg, the heating to

the annealing temperature for each stack in the charge lasts

5 - 7 min, and the annealing lasts 40 min (with allowance for

the 30-min hold at 380-450C required by the specifications).

By increasing the heating temperature to 500 - 550C the

annealing time can be reduced to 1 5 - 20 min, but this can

be accompanied by growth of the grains to size No. 5 (at

t < 450C the grains correspond to size No. 7).

We used the same fluidizing technique in another technological process, namely, rapid steam oxidation of sintered

steels (instead of hydrophobization impregnation in GKZh94 and convective steam oxidation) [5]. In this case the second (technological) function of steam consists in oxidizing

iron and the impurities and filling the branched pore (capillary) system with this oxide phase. This increases substantially the corr_,~sionresistance of the sintered steels. For exam-

A . P . B a s k a k o v a n d E. M . F a i n s h m i d t

7:~1

Fig. 1. Shaft tank elecUic furnace with a fluidized bed for oxidation-free r~

crystallization annealing of parts made of copper and it3 alloys.

pie, corrosion spots appear on parts made of steel SP 50D2

after sintering (without closing the pores) in 1 - 2 h, after hydrophobization they appear in 12 h, after convective steam

oxidation they appear in 12 h, and after rapid steam oxidation

in a fluidized bed they appear in 48 h (in cyclic tests in a 3%

solution of NaCl at 18 - 25C).

The tank furnace for rapid steam oxidation differs from

the one described above by the absence of a water tank (the

charge of oxidized parts is cooled in still air) and preliminary

heating of steam to 3 0 0 - 350C [6]. Furnaces of both types

operate stably and reliably in several plants.

A universal tempering tank furnace with a bed fluidized

by compressed air from the plant's system, which is dried in

an oil and moisture separator, has been designed for all kinds

of tempering (low-, intermediate-, and high-temperature).

The air flow rate is 65 m3/h, and the rate of fluidizing is

0.2 m/sec. The functional space (a converter made of steel

KhI8NIOT) is 600 mm in diameter and 1900 mm high, and

the dense electrocorundum bed is 650 mm high. The furnace

operates in the 150- 650C temperature range, i.e., can be

used for isothermal cooling or can serve as a cooling (hardening) tank for martensitic hardening of alloy steels (with

switched-off heaters). The design of the furnace is described

in detail in [3, 4].

In our opinion, the problem of low-temperature heating

ofa fluidized bed (up to 700C) has been solved successfully,

which is confirmed by the reliable operation of the existi~lg

Electric Furnaces with a Fluldized Bed

389

Air

high-temperature tank furnace with induction heating (a cast

thick-wailed heat-resistant converter with a gas-distributing

mesh and a poured corundum bed placed in an inductor and

heated by current of industrial frequency) presented in Fig. 2

has shown good prospects for the method [3, 4].

We also believe that the experience of rapid nitriding in a

furnace with a vibrofluidized bed [7] is quite promising and

environmentally safe.

CONCLUSIONS

The developed industrial electric furnaces with a

fluidized bed (of three modifications) and semi-industrial furnaces (of two modifications) have been tested successfully

under industrial conditions and provide environmentally safe

heat treatment processes.

REFERENCES

Fig. 2. Shall tank electric furnace with induction heating of the fluidized

bed: / ) inductor;,2 ) monolithic lining (heat-resistantconcrete);3 ) converter;,

4 ) air-di~atbuting nozzle; 5 ) caps; 6 ) fluidized bed.

industrial furnaces designed as described above and providing environmentally safe heat treatment processes.

Laboratory and engineering developments exist for hightemperature (up to 900C or more) heating of the fluidized

bed. Some experimental designs have been tested (oxidationfree heating for hardening). We do not consider these designs

in the present paper, because the creation of production prototypes (if needed) will be accompanied by inevitable changes.

However, it should be noted that the experimental model of a

1. A. E Baskakov, Heating and Cooling Metals in a Fluidized Bed

[in Russian], Metallurgiya, Moscow (1974).

2. A.P. Baskakov, B. V. Berg, and A. F. Ryzhkov, Processes o f Heat

and Mass Transfer in a Fluidized Bed [in Russian], Metallurgiya,

Moscow (1978).

3. E. M. Fainshmidt, A. S. Zavarov, and Yu. B. Pirogov, Heat Treatment o f Machine Parts in a Fluidized Bed [in Russian], TsNIINTI, Moscow (1984).

4. A. S. Zavarov. A. P. Baskakov, S. V. Graehev, and E. M. Faiushmidt, "Use of a fluidized bed for heat and chemical heat treatment," Metalloved. Term. Obrab. Met., No. 10, 35 - 40 (1984).

5. USSR Inventor's Certificate 1321523, "A method for steam oxiclarion of sintered articles of iron powders," Byull. Otkryt. Izobret., No. 25 (1987).

6. E. M. Fainshmidt, T. A. Pumpyanskaya, and A. A. Shalamov,

Fabrication o f Powder Parts [in Russian], TsNIINTI (1986).

7. Patent 2007497 RF, "An installation for nitriding articles in a vibrofluidized bed," Byull. Otkryt. Izobret., No. 3 (1994).

You might also like

- Thermal Process Information BookDocument15 pagesThermal Process Information Book45 Aadhya RoyNo ratings yet

- Ateco Tank Geodesic Dome Drawings For Information PDFDocument47 pagesAteco Tank Geodesic Dome Drawings For Information PDFJavierfox98100% (1)

- Blast Furnace IronmakingDocument83 pagesBlast Furnace IronmakingKumar Varun100% (1)

- Annealing (Metallurgy)Document5 pagesAnnealing (Metallurgy)Vijay Vikram SinghNo ratings yet

- Cryogenic Heatexchanger Unit LNG PlantDocument6 pagesCryogenic Heatexchanger Unit LNG Plantrissa100% (1)

- Alcoa Nautic Al Plate PDFDocument8 pagesAlcoa Nautic Al Plate PDFAryNo ratings yet

- Report Heat Treatment Eng Lab 3Document7 pagesReport Heat Treatment Eng Lab 3khalifawhan43% (7)

- 'TWI CSWIP Macro Practical Inspection (Compatibility Mode)Document36 pages'TWI CSWIP Macro Practical Inspection (Compatibility Mode)Vinoth KannanNo ratings yet

- Electrolysis of Silver SulphateDocument5 pagesElectrolysis of Silver SulphateJackson_de_Roz_6005100% (1)

- Thermal Energy Management of Blast Furnace PlantDocument4 pagesThermal Energy Management of Blast Furnace Plantakshuk100% (1)

- Heat Loss of Liquid MetalDocument7 pagesHeat Loss of Liquid Metalmarcotulio123No ratings yet

- ISO 630-6-2014 - Technical Delivery Conditions For Seismic-Improved Structural Steels For BuildingDocument22 pagesISO 630-6-2014 - Technical Delivery Conditions For Seismic-Improved Structural Steels For BuildingMohanrajMJNo ratings yet

- 16.1.1 Furnaces For Roasting and Calcining: 16.1.1.1 Rotary KilnsDocument66 pages16.1.1 Furnaces For Roasting and Calcining: 16.1.1.1 Rotary Kilnshisem100% (1)

- Calcination and Reduction of Laterite Nickel OresDocument10 pagesCalcination and Reduction of Laterite Nickel OresrikocahyopNo ratings yet

- Advanced Heating Techniques For Glass MeltingDocument44 pagesAdvanced Heating Techniques For Glass Meltingmetalman_m67% (3)

- Crucible FurnacesDocument10 pagesCrucible FurnacesZara SaeedNo ratings yet

- Au Extraction ProcessDocument3 pagesAu Extraction ProcessBhupesh MulikNo ratings yet

- CSWIP (Welding Inspector Exam) Perparatory Question (Set 1 To 7)Document19 pagesCSWIP (Welding Inspector Exam) Perparatory Question (Set 1 To 7)Box EmptyNo ratings yet

- Metallurgical Industrial Furnaces 5Document21 pagesMetallurgical Industrial Furnaces 5Mining ReviewNo ratings yet

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesFrom EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesRating: 3.5 out of 5 stars3.5/5 (3)

- Blast FurnaceDocument32 pagesBlast FurnaceShailesh SharmaNo ratings yet

- Literature ReviewDocument19 pagesLiterature ReviewManjari Jha0% (1)

- Ferro Nickel FurnaceDocument11 pagesFerro Nickel FurnaceJoseph Lorsen T. ChavezNo ratings yet

- Contro Corrosion FactorsDocument10 pagesContro Corrosion Factorsramadoss_alwar7307No ratings yet

- Energy Recovery - TspaceDocument26 pagesEnergy Recovery - TspaceAlfonso Blanco100% (1)

- Refractory Materials PDFDocument18 pagesRefractory Materials PDFadi nugroho100% (2)

- Drmpfile 1Document10 pagesDrmpfile 1ramadoss_alwar7307No ratings yet

- Combustion EnggDocument51 pagesCombustion EnggRiki MandolNo ratings yet

- Oschatz Non-Ferrous Metallurgy enDocument12 pagesOschatz Non-Ferrous Metallurgy enSelene Acosta MauricciNo ratings yet

- Learning Center. SailDocument5 pagesLearning Center. SailpdiconpNo ratings yet

- Analysis of Temperature Loss of Hot Metal During Hot Rolling Process at Steel PlantDocument7 pagesAnalysis of Temperature Loss of Hot Metal During Hot Rolling Process at Steel PlantIJMERNo ratings yet

- Acer PaperDocument17 pagesAcer PaperAbdul SabirNo ratings yet

- Ali Mohamed Awadallah Training ReportDocument9 pagesAli Mohamed Awadallah Training Reportahmedameer20189No ratings yet

- 2nd Part of CalculationDocument26 pages2nd Part of CalculationLohith NatarajNo ratings yet

- Heat Treatment Equipments Part 1Document45 pagesHeat Treatment Equipments Part 1ajaiforceNo ratings yet

- FurnacesDocument5 pagesFurnaceshasan_waqar2004No ratings yet

- Indirect HeatingDocument4 pagesIndirect HeatingYogesh BadheNo ratings yet

- Working of Blast FurnaceDocument3 pagesWorking of Blast Furnacehk168No ratings yet

- Table C-2. Energy Efficiency Technologies and Measures Applied To EAF Steel Production in The U.S. (Worrell 1999, 2009 AISI, 2011)Document12 pagesTable C-2. Energy Efficiency Technologies and Measures Applied To EAF Steel Production in The U.S. (Worrell 1999, 2009 AISI, 2011)janfarsa9623No ratings yet

- High Temperature Corrosion Problems in Waste Heat BoilersDocument2 pagesHigh Temperature Corrosion Problems in Waste Heat BoilersEdenrafaNo ratings yet

- pp24-31 MS07Document8 pagespp24-31 MS07halder_kalyan9216No ratings yet

- Proceso Bof en InglesDocument25 pagesProceso Bof en InglesMossstazzzaNo ratings yet

- Wood Stove TroubleShooting GuideDocument19 pagesWood Stove TroubleShooting Guideew6082No ratings yet

- Protective Properties of A Nitrogen Atmosphere With An Admixture of Natural GasDocument4 pagesProtective Properties of A Nitrogen Atmosphere With An Admixture of Natural GasSinhrooNo ratings yet

- Twin Hearth FurnaceDocument3 pagesTwin Hearth Furnaceshreyasi_mahantyNo ratings yet

- Material Selection Distillation Column Initial FindingsDocument7 pagesMaterial Selection Distillation Column Initial FindingsAhmet Samet ÖzdilekNo ratings yet

- High Temperature Heat ExchangersDocument13 pagesHigh Temperature Heat ExchangersuvsarathiNo ratings yet

- Hydrogen, Ammonia, Methanol Plant Material Selection: Educational Institute For Equipment and Process DesignDocument11 pagesHydrogen, Ammonia, Methanol Plant Material Selection: Educational Institute For Equipment and Process Designyusif samNo ratings yet

- Kovar PDFDocument2 pagesKovar PDFkhers_zalNo ratings yet

- FinincialDocument10 pagesFinincialtesfaye mitikuNo ratings yet

- Advanced Minerals Engineering Ia Course NotesDocument78 pagesAdvanced Minerals Engineering Ia Course NotesPrince KamutikanjoreNo ratings yet

- Furnaces ReportDocument10 pagesFurnaces ReportMay FadlNo ratings yet

- Crucible FurnacesDocument10 pagesCrucible FurnacesZara Saeed0% (1)

- FurnaceDocument3 pagesFurnaceAshish ThakurNo ratings yet

- OF Manufacturing Sciences 104: Melting Practices and FurnacesDocument14 pagesOF Manufacturing Sciences 104: Melting Practices and FurnacesnikhilzzNo ratings yet

- Iron Metallurgy by Nwaogbe JohnDocument26 pagesIron Metallurgy by Nwaogbe JohnDavid UdohNo ratings yet

- Decarburization Kinetics During Annealingil.44.618Document5 pagesDecarburization Kinetics During Annealingil.44.618Suvro ChakrabortyNo ratings yet

- Blast Furnace ProcessDocument4 pagesBlast Furnace ProcessmohommedaamirNo ratings yet

- Sinterizare Zirconiu Si Carbura 2Document10 pagesSinterizare Zirconiu Si Carbura 2Iulia IuliaaNo ratings yet

- Cupola FurnaceDocument9 pagesCupola FurnaceAakanksha RamtekeNo ratings yet

- Continuous and Cyclic Oxidation of T91 Ferritic Steel Under SteamDocument20 pagesContinuous and Cyclic Oxidation of T91 Ferritic Steel Under Steamrampw14581No ratings yet

- 1-s2.0-S0040603116301952-Dick C Engbrecht Gypsum Anhydrite 2016Document29 pages1-s2.0-S0040603116301952-Dick C Engbrecht Gypsum Anhydrite 2016Sulthon Sholahuddin SofyanNo ratings yet

- Cokeless CupolaDocument12 pagesCokeless CupolaGovind RaoNo ratings yet

- 158 170 PDFDocument13 pages158 170 PDFNoman AliNo ratings yet

- Scientific American Supplement, No. 360, November 25, 1882From EverandScientific American Supplement, No. 360, November 25, 1882No ratings yet

- Innovation in Electric Arc Furnaces: Scientific Basis for SelectionFrom EverandInnovation in Electric Arc Furnaces: Scientific Basis for SelectionNo ratings yet

- Heating IN AN Electrically Conducting Layer Carbon-Containing Particles OFDocument4 pagesHeating IN AN Electrically Conducting Layer Carbon-Containing Particles OFSinhrooNo ratings yet

- Effect of Various Kinds of Thermomechanical Treatment On The Structure and Properties of Steels Studied Using Acoustomicroscopic MethodsDocument5 pagesEffect of Various Kinds of Thermomechanical Treatment On The Structure and Properties of Steels Studied Using Acoustomicroscopic MethodsSinhrooNo ratings yet

- Foreign TechnologyDocument1 pageForeign TechnologySinhrooNo ratings yet

- Phase Composition of Scale of Hot-Rolled Automobile Sheet Steel 08yuDocument2 pagesPhase Composition of Scale of Hot-Rolled Automobile Sheet Steel 08yuSinhrooNo ratings yet

- Hydrostatic Extrusion at 100°C and Its Effect On The Grain Size and Mechanical Properties of Magnesium AlloysDocument5 pagesHydrostatic Extrusion at 100°C and Its Effect On The Grain Size and Mechanical Properties of Magnesium AlloysSinhrooNo ratings yet

- Hardness OF: CementiteDocument2 pagesHardness OF: CementiteSinhrooNo ratings yet

- 1006 1009Document4 pages1006 1009SinhrooNo ratings yet

- Technology of Heat Treatment: Volume-Surface Hardening of by A High-Speed Water Stream Railroad Transport PartsDocument5 pagesTechnology of Heat Treatment: Volume-Surface Hardening of by A High-Speed Water Stream Railroad Transport PartsSinhrooNo ratings yet

- 390 394 PDFDocument5 pages390 394 PDFSinhrooNo ratings yet

- 382 385 PDFDocument4 pages382 385 PDFSinhrooNo ratings yet

- Hardening From The Liquid StateDocument5 pagesHardening From The Liquid StateSinhrooNo ratings yet

- 374 376 PDFDocument3 pages374 376 PDFSinhrooNo ratings yet

- Protective Properties of A Nitrogen Atmosphere With An Admixture of Natural GasDocument4 pagesProtective Properties of A Nitrogen Atmosphere With An Admixture of Natural GasSinhrooNo ratings yet

- Effect of Alloying, Heat Treatment, and Deformation On The Structure and Properties of Damping Z N - A I AlloysDocument4 pagesEffect of Alloying, Heat Treatment, and Deformation On The Structure and Properties of Damping Z N - A I AlloysSinhrooNo ratings yet

- E 1 - 6 3 8 8 - L o - / Y) - 7 - Zi : Corporation, StreetDocument1 pageE 1 - 6 3 8 8 - L o - / Y) - 7 - Zi : Corporation, StreetSinhrooNo ratings yet

- 9 (I,, TillDocument4 pages9 (I,, TillSinhrooNo ratings yet

- 118 Elements Name List With SymbolDocument5 pages118 Elements Name List With SymbolSathya BharathiNo ratings yet

- Asme Ix QuizDocument5 pagesAsme Ix Quizamalhaj2013No ratings yet

- HB DCBDocument7 pagesHB DCBIBRAHIM MAKHLOUKANo ratings yet

- Introduction To Manufacturing Systems Design and Analysis: Spring 2019 Isye 415Document41 pagesIntroduction To Manufacturing Systems Design and Analysis: Spring 2019 Isye 415VaikunthtendulkarNo ratings yet

- 3 Iron Carbon DiaDocument21 pages3 Iron Carbon DiaChhavi SharmaNo ratings yet

- BS 2HR 650-2011Document12 pagesBS 2HR 650-2011Stanislav PerevezentsevNo ratings yet

- 6061 Vs 6063Document9 pages6061 Vs 6063SrRonNo ratings yet

- Heavier Elements (Metallurgy)Document34 pagesHeavier Elements (Metallurgy)Natish JaglanNo ratings yet

- - กลศาสตร์ของวัสดุนาโน Mechanics of Nanomaterials อาจารย์ประจ าวิชา:ผศ.ดร.วรรณวิลัย วิทยากร:อ.ดร.อภิลักษณ์ เอียดเอื้อDocument60 pages- กลศาสตร์ของวัสดุนาโน Mechanics of Nanomaterials อาจารย์ประจ าวิชา:ผศ.ดร.วรรณวิลัย วิทยากร:อ.ดร.อภิลักษณ์ เอียดเอื้อTan NakaphanNo ratings yet

- Astm A447Document4 pagesAstm A447Đoàn Thoại Đông TriềuNo ratings yet

- BS 7191 Weldabel Structural Steel For OffshoreDocument48 pagesBS 7191 Weldabel Structural Steel For Offshoreyasser awadallhNo ratings yet

- Vendor Document Cover SheetDocument11 pagesVendor Document Cover SheetSagar SawantNo ratings yet

- SSAB Domex v2 2019 DatasheetDocument12 pagesSSAB Domex v2 2019 DatasheetpeterNo ratings yet

- Activity Series Lab (Akey)Document4 pagesActivity Series Lab (Akey)Elah Palaganas100% (1)

- Purchase Summary Aine Infra Till Nov 2022Document1 pagePurchase Summary Aine Infra Till Nov 2022Rishabh Naresh JainNo ratings yet

- Development and Testing of Al5083 Alloy Reinforced by SiC ParticlesDocument8 pagesDevelopment and Testing of Al5083 Alloy Reinforced by SiC Particlesijsret100% (1)

- Steel RebarDocument10 pagesSteel RebarStructureClassNo ratings yet

- Nimblewill Nomad's Wood Burning Stove With Optional FrontDocument7 pagesNimblewill Nomad's Wood Burning Stove With Optional FrontAlan DemarcosNo ratings yet

- Hardware 1-20Document56 pagesHardware 1-20July TadeNo ratings yet

- BS en 10154-2002Document20 pagesBS en 10154-2002Bravo RdNo ratings yet

- Submerged Arc WeldingDocument13 pagesSubmerged Arc WeldingManish MNo ratings yet

- Datasheet 316 316L Imperial Hpsa Outokumpu en Americas PDFDocument3 pagesDatasheet 316 316L Imperial Hpsa Outokumpu en Americas PDFgauravme1983No ratings yet