Professional Documents

Culture Documents

Yeasd

Uploaded by

asdqwe123dsaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Yeasd

Uploaded by

asdqwe123dsaCopyright:

Available Formats

General

GENERAL

YEMEN

(See Plan)

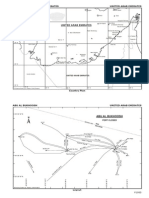

ADEN, including Little Aden: 12 48' N 44 54' E

(See Plan)

GEO-POLITICAL:

OVERVIEW: The port consists of the Outer Harbour, providing anchorage

Capital City: Sanaa.

Nationality: (noun) Yemeni, (adjective) Yemeni.

Population: 21,456,188.

areas, the Oil Harbour in Little Aden to the west and Inner Harbour to the

east. The inner harbour is protected by a short breakwater at Ras Marbut,

where the harbour control tower is located. The Harbour Masters office is

in the control tower.

Port handles oil tankers, containers, general cargo, bulk, passenger

vessels, Ro-Ro, yachts and fishing vessels. Main imports include crude oil,

bulk and bagged foodstuffs, construction materials, lubricants, vehicles,

general cargo, consumer goods and livestock. Main exports include refined

oil products, salt, frozen fish, manufactured foodstuffs, flour, bran and scrap

steel.

LOCATION: On the southern coast of Yemen in the Gulf of Aden,

approximately 95 n.m. east of the Straits of Bab al Mandeb, at the southern

entrance to the Red Sea.

The harbour is situated between the promontories of Aden (Jebel

Shamsan, 553 m.) and Little Aden (Jebel Muzalqam, 374 m.) and is protected

from the NE and SW monsoons by these hills and along the northern

boundary by land, enabling it to operate without restriction all year. The

harbour covers an area approximately 8 n.m. EW and 5 n.m. NS.

CHARTS: BA Charts No. 6, 7, 3660, 3661 and 3662.

Nautical Publications: Red Sea and Gulf of Aden Pilot, NP64.

PORT LIMITS: From Ras Abu Qiyamah in a direction 166 for 1.76 n.m.

to Lat. 12 42.00' N, Long. 44 54.00' E, thence on a bearing of 090 to

Lat. 12 42.00' N, Long. 45 00.00' E, thence on a bearing of 007 for a

distance of 3.15 n.m. to Round Island.

Port regulations are in force in all areas of the port of Aden between these

limits and the shoreline.

COMMUNICATIONS:

International Direct Dial Code: 967.

Number of Internal Airports: 16.

Major Languages Spoken: Arabic.

ECONOMY:

Currency: 1 Yemeni Rial (YER) of 100 Fils.

Main Industries: Crude oil production and petroleum refining, small-scale

production of cotton textiles and leather goods, food processing,

handicrafts, small aluminium products factory, cement and commercial

ship repair.

ENVIRONMENT:

Territorial Sea: 12 n.m.

Other Maritime Claims: Contiguous Zone: 24 n.m.

Continental Shelf: 200 n.m. or to the edge of the continental margin.

Exclusive Economic Zone: 200 n.m.

Coastline Extent: 1,906 km.

Climate: Mostly desert; hot and humid along west coast; temperate in

western mountains affected by seasonal monsoon; extraordinarily hot, dry,

harsh desert in east.

Natural Resources: Petroleum, fish, rock salt, marble, small deposits of

coal, gold, lead, nickel, copper and fertile soil in west.

Natural Hazards: Sandstorms and dust storms in summer.

Terrain: Narrow coastal plain backed by flat-topped hills and rugged

mountains; dissected upland desert plains in centre slope into the desert

interior of the Arabian Peninsula.

Average Temperatures:

Month

High

Low

January

28 C

24 C

June

35 C

29 C

September

36 C

29 C

ISPS COMPLIANCE: The Maritime Affairs Authority has been appointed

to carry out Port State Control and Compliance in respect of SOLAS

regulations. Ships will be inspected for compliance.

Security Level 1 has been declared for the ports of Aden and Mukalla. Any

changes in security level will be posted on the Yemen Ports Authority (YPA)

website Web: www.portofaden.com

PILOTAGE: Pilotage is compulsory on all vessels irrespective of their size,

on entry and departure.

NOTICES: The following notice was handed to a Master on arrival at

Hodeidah.

Re: Formalities, Restriction, Breaches & Penalties at Yemeni Ports:

We are very pleased to welcome you and the vessel under your command

at Hodeidah/Raskateeb/Saleef/Mokha, and request you to note and comply

with the following formalities/restrictions to avoid payment of penalty.

1. Call Pilot only when you are fully ready in all respects. If Pilot is called

to take the vessel out, and the vessel fails to depart after boarding

of the Pilot, the vessel will bear all the consequential expenses of (a)

Pilot waiting time, (b) Launches assistance charges, (c) unmooring

charges, including any other expenses.

2. Fine of YER 500 to 2,000 is imposed, if Yemen flag is not hoisted on

the highest mast.

3. Fine of YER 500 is imposed, for arrival at Port without prior notice,

notifying actual time of arrival of the vessel.

4. Fine of YER 10,000 to 20,000 is imposed for attempting entry to

berthing quay, without prior permission from the Management and

without Pilot on board. Same penalty imposed for attempting departure

without permission and Pilot, from the quays or inner basins.

5. Fine of YER 500 to 1,000 is imposed for draining water onto the quays.

Vessel also to bear responsibility for losses caused therefrom.

6. Fine of YER 1,000 is imposed for throwing garbage, cargo remains,

food remains, oil, etc. into inner harbour or onto quay.

7. Fine equivalent to 100% of the loss in income to the Corporation is

imposed, in the event the vessel submits inaccurate statements on

ships particulars and drafts.

8. Fine of YER 5,000 is imposed, if the vessel leaves anchorage after

registration without clearance from the Corporation.

9. Fine of YER 500 is imposed, if Rat Guards are not provided to avoid

rats escaping to the quays.

10. Fine of YER 2,000 is imposed, if vessel uses her own boats within

Port limits without prior permission.

11. Fine of YER 2 is imposed per hour per metre of LOA of the vessel,

for delay in completion of discharging during the duration set out by

the Corporation.

12. Fine of YER 1,000 is imposed on whoever obstructs Corporations

staff/employees in carrying out their duties or insults them.

13. A shore crane will be compulsorily deployed at 100% surcharge to a

vessel over 100 m. LOA.

14. Corporation reserves the right of removing any vessel from the quays

for any reason in the general public interest.

15. Photography of the Port area is prohibited.

(Notes from Tariff 1/82 published by Ports & Marine Affairs General

Corporation).

Please note that the Port Limits (for Hodeidah) are 14 55' 34" N., 53 37' E.

Pilotage Point for entrance and departure is Buoy No. 2.

We trust that you will find the above information very helpful to promote

cordial relations with all officials and relevant authorities, and at the same

time contribute towards reducing expenses of our mutual Principals.

PLEASE NOTE: All the foregoing information was in effect prior to the

unification of the country and may have been superceded in recent times.

DOCUMENTS:

Arrival Declaration to be filled in by Ships Agent after arrival

Bonded Stores Lists

Cargo Gear Certificate

Crew Effects Declaration

Crew Lists for Ships Agent, Police and Immigration

Dangerous Material Declaration to be handed to Pilot on boarding

1 Derat (Exemption) Certificate

1 Health Form to be shown to Pilot on boarding and handed to Agent

1 ISSC

1 Load Line Certificate

Manifests, Bills of Lading if landing cargo only

1 Notification of Arrival

2 Passenger Lists for Agent, Police and Immigration

1 Pre-Arrival Notification of Security (in advance to Agent)

1 Safety Equipment Certificate

Ships Register to be sighted by Pilot

1 Stores List

1 Tonnage Certificate

1 Vaccination List.

Customs and Immigration: Officers board ships calling at the port when

they enter and leave. For Customs a copy of the Crew/Passenger Lists and

a List of Bonded Goods on board is required on entry. Immigration officers

require a copy of the Crew/Passenger Lists.

ISPS COMPLIANCE: All terminals are compliant. Port security is

provided by personnel under the control of Yemen Ports Authority and the

National Security services. The Yemeni Coastguard is responsible for the

security of all water areas and for gate security at terminals.

MAX. SIZE: Containers: 100,000 d.w.t., LOA 350 m., draft 14.8 m.**

Dry Cargo: 40,000 d.w.t., LOA 229 m., draft 10.4 m.

Tankers: 110,000 d.w.t., LOA 280 m., draft 14.75 m.*

** With favourable tide and special permission from the Harbour Master, ships

entering Aden inner harbour at zero tide are restricted to a maximum draft

of 13.8 m. in the channel. A favourable tide is available during the great

majority of arrival situations as MSL at Aden is 1.39 m.

* With favourable tide, daily maximum permissible drafts are produced by

Aden Refinery Company for ships calling at the oil harbour.

DENSITY: 1023 1025.

RESTRICTIONS: Under-Keel Clearance: Vessels of drafts up to

11.3 m. are required to have a minimum under-keel clearance of 0.6 m.

Vessels with drafts greater than 11.3 m. require a minimum under-keel

clearance of 1.2 m.

Berthing: Throughout 24 hours.

To avoid delay, vessels wishing to berth in the inner harbour or oil harbour

should be equipped with the following items, all to be fully operational and

efficient: radar, VHF with normal marine channels, propulsion machinery,

signalling equipment, engine tachometer, rudder and helm indicators, deck

machinery and sufficient moorings to secure the vessel safely, mooring

station communication systems forward and aft, anchors and windlass. Both

anchors to be on the brake ready for letting go when manoeuvring.

Yachts: Yachts arriving at night wishing to enter the harbour without a Pilot

are required to anchor in the outer harbour in a position given by the Port

Control Tower, unless otherwise advised. Unpiloted yachts can enter during

daylight hours only.

Ballast Draft for Tankers: All tankers when manoeuvring within the port

shall be ballasted properly to a mean ballast draft which shall not be less

than half the summer draft and the trim by the stern not exceeding 6 ft. These

figures are the minimum for normal conditions and may be increased when

conditions necessitate at the discretion of the Pilot.

Also see Anchorages.

APPROACHES: Aden and Little Aden peninsulas are very prominent and

the harbour lies between them. The harbours are reached by an entrance

channel starting from mid-way between the promontories of Elephants Bank

and Little Aden. The outer section of the channel has a depth of 15.0 m.

The channel divides 9 cables north of the channel entrance. From this

point a channel leads NW to the Little Aden Oil Harbour. Channel depth

14.7 m., width 220 m., length 2.3 n.m. from the dividing point.

The channel to the inner harbour, leading NE from the point where the

channel divides, has a least depth of 15.0 m., width 185 m., distance 2.6 n.m.

2

1

1

2

See guidelines on how to compile and submit information to us (page xi).

3335

YEMEN

Aden

to the inner harbour breakwater, marked by pairs of buoys. At the eastern

end of the inner harbour a short channel of depth 11.0 m. leads to the Maalla

Terminal.

Sea Buoys, Fairways and Channels: Approaching Aden from the west,

pass 1 n.m. south of Little Aden Peninsula and then to pilot station at

Lat. 12 44.0' N, Long. 44 57.0' E south of the entrance to the dredged

channel marked by the No. 1 buoys (QR and QG). At night, with Elephants

Back Light (red and white sectored) on a bearing of not greater than 061

(white sector) a ship will clear the Little Aden peninsula on a course to bring

her close to the port entrance.

Approaching from the east, pass 1 n.m. south of the Aden peninsula and

then to the channel entrance. At night, pass 1.5 n.m. south of Ras Marshaq

Light and then steer west to the entrance to the channel.

All approach channels to Aden are marked by pairs of buoys and vessels

should pass mid-way between these buoys. From the No. 1 buoys the outer

section of the dredged channel is 15.0 m. in depth, width 220 m., leading to

No. 3 buoys (S Cardinal, VQ6 +LFl 10 sec.) 9 cables north of the channel

entrance where it divides into channels leading to the oil harbour and to the

inner harbour.

Little Aden Oil Harbour Channel: Immediately after passing No. 2 buoys,

turn to head 300 on the leading marks for the centre of the channel to pass

north of the oil harbour breakwater turning area.

Inner Harbour Channel: Vessels steer 027 to inner harbour channel

No. 2 buoys, then 047 to clear the inner harbour breakwater. The inner

harbour channel is 15.0 m. deep, 220 m. wide and leads on a heading of

068 to the 700 m. diameter turning area off the ACT. Ships proceeding to

the Maalla Terminal should pass from the southern part of the turning area

to the 11.0 m. deep channel lying north of the new bulk grain jetty at the

western end of the Maalla Terminal.

Turning Areas:

a) Off the Aden Container Terminal (ACT), diameter 700 m., depth

15.0 m.

b) at the oil harbour breakwater, diameter 420 m.

c) The turning basin off the oil harbour berths extends 250 m. from the

apron and is dredged to 11.0 m.

Also see Plan.

PILOTAGE: Compulsory for all vessels over 200 g.t. entering or leaving

(with certain exceptions). The pilot station for all vessels bound for the oil

harbour or inner harbour, unless advised otherwise by Aden Port Control, is

at the channel entrance in Lat. 12 44.00' N, Long. 44 57.00' E, shown by

the standard pilot station symbol. A circle radius 5 cables at this position is

marked on the chart to indicate that anchoring within this area is prohibited.

All vessels arriving off the port and wishing to enter must show the standard

international signal to request a Pilot. Pilot boats have red hulls and yellow

superstructures. They exhibit the standard international pilot signal at night.

During all seasons, ships head north before boarding the Pilot. A pilot ladder

should be rigged on the port (lee) side by the ship during the NE monsoon

period (mid-September to May). The ladder should normally be rigged on the

starboard (lee) side during the SW monsoon (June to mid-September) unless

otherwise advised by the Control Tower.

Pilots work throughout 24 hours.

Also see Approaches and Shipmasters Report dated April 2001.

ANCHORAGES: Anchorage areas are available for vessels in the outer

harbour with depths of 6.0 40.0 m. Good holding ground.

Anchorage areas are at present not marked on any navigational charts.

Smaller vessels anchor to the north of the Oil Harbour Approach Channel

and on either side of the Inner Harbour Approach Channel. Vessels with draft

10.0 m. or more anchor to the south of the Oil Harbour Approach Channel

and west or east of the outer approach channel for both harbours.

Anchorage is prohibited within a radius of 5 cables of the outer approach

channel entrance and within 2 cables of any port approach channels.

Vessels are warned that many disused cables exist in the area between

Ras Tarshayn and Jazirat Salil. A fibre-optic cable is laid from SSE of the

port entrance to the shore as shown on BA Chart No. 7.

Yachts: A yacht anchorage is available in the inner harbour between the

Prince of Wales/Abkhari Pier and the dolphin oil berth 6-out north of this but

yachts are warned that pipelines and anchor cables exist on the sea bed in

this area. Yachts should anchor well clear of the coastguard base pontoons

1 cable east of the Abkhari Pier. Large yachts may use the anchorage south

of the western end of the rubble mound or, if taking fuel, bunkering berths

6 in and 6 out.

PRATIQUE: Vessels requiring pratique fly International Code Signals. This

signal to be exhibited until pratique has been granted by the Pilot or Port

Health Officer.

Healthy cargo and passenger ships are given pratique by the Pilot when

entering. Pilgrim ships are given pratique by the port health doctor. A port

doctor will board vessels to carry out an inspection and requires a Health

Declaration and Vaccination List against smallpox.

Also see Pre-Arrival Information.

PRE-ARRIVAL INFORMATION: ETA: At least 48 hours prior to

arrival, except in the case of a vessel with less than 48 hours steaming time

between the last port of call and Aden, when the message should be sent

immediately after leaving the last port.

Standard Messages:

a)

b)

c)

d)

e)

f)

g)

h)

i)

j)

k)

ETA

Masters name

ships nationality

call sign

g.t.

d.w.t.

maximum draft

type of cargo

reason for call

security level on board (if ship is not at Level 1)

declaration of any dangerous cargo on board.

VHF: 24-hour watch on Channel 16, working on Channels 6, 8 and 13. All

port VHF Traffic is recorded.

VTS/RADAR: The Control Tower is fitted with an ARPA radar with traffic

monitoring capability.

3336

TUGS: Towage for vessels berthing in the inner harbour is provided by

tugs owned and operated by Yemen Ports Authority. Towage for vessels

berthing in the Aden oil harbour is provided by tugs owned and operated by

the Aden Refinery Company, with support from YPA tugs if necessary.

Tugs for both harbours normally join just outside breakwater. Ships ropes

always used in Aden Harbour, tugs wires in Little Aden.

Yemen Ports Authority operates four tugs for large vessels. Two are

conventional tugs, 2,800 h.p., 40 tonnes BP. Two ASD tugs, 4,830 h.p.

55 tonnes BP, are normally used for large bulk and container ships and

tankers.

Little Aden Oil Harbour has two Voith-Schneider propelled tugs, 3,200 h.p.

each.

BERTHING:

Berth

DWT

(tons)

LOA

(m.)

Draft

(m.)

Inner Harbour

Buoy Berths

Dolphin Berths

Maalla Terminal

Oil Harbour 1

40,000

40,000

40,000

85,000

229

275

190

260

10.3

10.3

10.7

13.5*

Oil Harbour 2

65,000

180

11.5*

Oil Harbour 3

65,000

235

11.5*

Oil Harbour 4

110,000

280

15.85*

25,000

(tankers)

15,000 (dry

cargo)

175

10.5

Oil Harbour 5 6

Remarks

Tankers, LPG, dry

cargo, Ro-Ro,

containers, fishing,

repairs

General cargo

Bunkering, naval

Container, general, bulk

Loading refined

products

Loading refined

products

Loading refined

products

Crude discharge,

refined products loading

LPG, liquid and dry

cargo

* Depth

Note: Tankers discharging/loading at Berths No. 1 4 (only) are allowed to

bunker alongside.

Berth

Inner Harbour

ACT

Maalla Terminal

Berths No. 1 4

HTQ Berths No. 5 6

Ro-Ro Berth

Lighter and Dhow Quays

Oil Harbour

Dolphin berths

Alongside berths

Berths 5 6

LPG Quay

Dry Cargo Quay

Length

Depth

(m.)

700

(m.)

6.5 11.0

16.0

750

187.5

11.0

11.0

250

6.7

7.6

1.8 2.7

120

220

Remarks

Containers

Multi-purpose

Multi-purpose,

containers

Bulk

Ro-Ro, naval

11.5 15.8 Oil tankers

11.0

LPG, dry cargo, Ro-Ro

11.0

LPG

Little Aden Oil Harbour: This harbour provides four dolphin berths for oil

tankers, alongside berths for LPG and dry cargo vessels and a Ro-Ro berth.

Inner Harbour: The inner harbour has nine alongside berths, nine buoy

berths and three bunkering (dolphin) berths with depths from 6.5 11.0 m.

On the north side of the inner harbour is the Aden Container Terminal

(ACT). The inner harbour also contains a fisheries harbour and a ship repair

yard with one floating dock in operation. At the eastern end of the Maalla

Terminal is the Home Trade Quay (HTQ).

Maalla Terminal: Four alongside multi-purpose berths for cargo ships up to

draft 10.7 m. with favourable tide. A turning area extends 280 m. from the

line of the quay wall and a Ro-Ro berth lies at right angles to Berth No. 1.

Maalla Home Trade Quay (HTQ): Berths No. 5 and 6. The Aden Cement

Enterprises (ACE) receiving and bagging plant, 25,000 tonnes capacity,

operates behind Shed No. 23 on the HTQ, with bulk vessels discharging to

this from Berth No. 4.

East of the HTQ are 800 m. of lighter and dhow quays at depths from

1.8 2.7 m. The Raysut bulk cement plant silos are located at the eastern

end of the HTQ, west of the cargo sheds along the lighter and dhow quays.

Vessels discharging to the Raysut silos use the HTQ berths.

Equipment: Mobile cranes include 150 tonne heavy-lift crane.

Free Port: The area inside the boundary wall of the Maalla Wharf has been

declared the Aden Free Port. Customs inspections are carried out in a

Customs area at the eastern end of the Maalla Wharf. General and other

cargoes are also worked at Maalla.

Dangerous Goods: Class 1 dangerous goods are not handled alongside at

Maalla and must be discharged to barge at a buoy berth for handling at the

Obstruction Pier.

BULK CARGO FACILITIES: At Maalla Terminal bulk wheat is

discharged using three methods.

1. Automatic bagging plant fed by pneumatic suction pumps from the

ships holds automatically fills and stitches bags for direct delivery to

trucks.

2. At Maalla Berth No. 3, a Swiveltel automatic discharging plant delivers

grain to an overhead conveyor and to the 80,000 tonne silos at the

Rowaishan Flour Mills complex behind Berths No. 2 4.

3. Grain is also discharged in bulk using evacuators or grabs directly to

trucks for delivery to the 120,000 tonne Hayel Saeed Anam flour mill

silos complex at the western end of the Maalla Terminal.

Bulk cargoes may also be unloaded by grab at the stream berths into

barges and taken to silos on the North Shore (capacity 18,000 tonnes) where

they are unloaded by an elevator, or by barge to the lighter quays for

unloading using the automatic bagging equipment.

Barges: Barges (flat top barges of 200 tonnes and barges with cargo holds

of 150 tonnes) are available for loading and discharging grain and other cargo

at the inner harbour buoy berths. Barges are also used to carry salt from the

Khormaksar salt pans to ships loading at Maalla or at the buoy berths.

Also see Berthing.

Readers are encouraged to send updates/additions (see p. xi for details)

Aden

YEMEN

CONTAINER FACILITIES: Maalla: Import and export of containers

at Berths No. 1 and 2.

Equipment: 240 tonne Liebherr container gantry cranes each with 20 ft.

and 40 ft. spreaders and operating on rails 21.5 m. apart, outreach 34 m.

from the front of the fenders (12 rows). 150 tonne heavy-lift hook is carried

on a 20 ft. spreader.

Storage: The container yard behind Berths No. 1 and 2 covers a total area

of 7 ha. and has 42620 ft. ground slots with a storage capacity of 852 TEU

(two high). A further 4 ha. of open storage is available behind the cargo sheds

at Berths No. 3 and 4. 342 tonne (1993), 228 tonne (1985) and

212 tonne (1993) Kalmar toplifters handle containers in the yard. Eleven

tractor units and 3920, 40 and 50 ft. trailers move containers from the quay

to the yard. The yard has 110 reefer points. A 170 m. 60 m. CFS shed is

located at to the rear of the yard.

Aden Container Terminal (ACT): Operator: Overseas Port Management

(OPM) Aden.

Facilities: Terminal handles transshipment, import and export of containers.

It has two container berths, each 350 m. in length, depth 16.0 m. alongside

in a dredged pocket.

Location: On the north shore of Aden Harbour.

Equipment: 540 tonne (under-spreader) Reggiane super post-Panamax

shore gantry cranes, each with 48 m. outreach from the front of the fenders

(18 rows); 840 tonne Fels cranes (RTGs) and 5 Reggiane RTGs (2000),

4+1 high, 6+1 wide, and 2 reachstackers handle containers in the yard;

30 tractor units and 65 trailers move containers from the quay to the yard.

Storage: The container yard covers a total area of 35 ha. and has 3,31220 ft.

ground slots in 12 bays, each 46 slots long, with a storage capacity of

13,248 TEU when stacked four high.

Facilities: The yard has 252 reefer container power points. A 9748 m. CFS

and multi-country consolidation shed, with office space, is located to the rear

of the container yard, together with terminal offices, independent power

station (14 MW), desalination plant, workshops, waste treatment plant and

reefer container repair, maintenance and cleaning facilities.

The ACT operates a fleet of service, maintenance and emergency vehicles.

CRUISE FACILITIES: Passenger vessels use the two bunkering

dolphins 6 in and 6 out on the south side of the harbour opposite the tourist

pier. Passenger launches are available to transfer passengers to and from

the ships, but ships may also, with permission, use their own launches.

SPECIALISED CARGO FACILITIES:

Ro-Ro: Maalla Terminal: One alongside Ro-Ro berth, length 150 m., depth

7.62 m., ramp width 20 m., located at right angles to No. 1 cargo berth.

Little Aden Oil Harbour: One Ro-Ro berth located on the NE corner of the

dry cargo Berths No. 5 and 6, depth 11.0 m., ramp width 20 m. Ships moor

stern to this berth. The distance from the face of the berth to the nearest

limiting depth of the 11.0 m. dredged area is 200 m.

TANKER FACILITIES: Little Aden Oil Harbour:

Berths No. 1 4: Berths No. 1 and 2 are T-jetties and Berths No. 3 and 4 are

pier berths.

Berths No. 5 6: For LPG, dry cargoes, heavy lifts and import/export cargoes

(liquid and dry) in containers shipped to or from the refinery. LPG quay length

120 m.

LPG/LNG FACILITIES: See Berthing and Tanker Facilities.

CRANES: 130 tonne floating crane that can be deployed to any berth is

operated by YPA.

Fishing Harbour: 35/10/20 tonne gantry cranes.

Also see Berthing and Container Facilities.

CARGO HANDLING FACILITIES: Cargo Handling: Cargo may be

handled year round and worked round-the-clock in both harbours. Cargo is

not worked at the outer harbour anchorage.

Storage: A large number of cargo storage sheds available at the Maalla

Terminal, including two 17060 m. cargo sheds and the CFS. The Maalla

Terminal provides 6 ha. of open storage area in addition to the container

storage area.

STEVEDORES: ETA advice to Agent at least 48 hours before arrival.

Containers at Maalla are handled by YPA and at the ACT by OPM. Bulk,

general cargo and other stevedoring within the inner harbour is carried out

by the privately owned Joint Stevedoring Company. Tel: +967 (2) 243733.

Fax: +967 (2) 243867.

Working Hours:

Pilotage:

Containers (Maalla):

First shift

Second shift

Containers (ACT):

Other cargoes (Maalla): First shift

Second shift

Third shift

24 hours

0700 1300 (extended to 1800 if

required)

1800 0700

24 hours

0600 1200

1400 1800

1800 0600

Note: Reefer cargoes are generally worked during the hours of darkness

during summer months.

Also see Shipmasters Report dated April 2001.

Opening/Closing Hatches: Normally carried out by stevedores,

derrick-topping by ships crew. Vessels not to move in harbour with beams

off.

BALLAST: Available at the Little Aden Oil Harbour and by barge at the

Maalla Terminal.

POLLUTION: Pollution combatting equipment is available at the Aden

Refinery Company (Little Aden). Standard international regulations to prevent

the pollution of harbour waters are in force. The Maritime Affairs Authority

(MAA) operates a fully equipped Pollution Control vessel stationed in Aden

Inner Harbour.

WASTE DISPOSAL: Facilities available and compulsory. Contact Agent.

SLOPS DISPOSAL: Facilities available. Contact Agent. Oily bilge

water/slops and black/grey water can be collected from ships and disposed

of at shore facilities.

MEDICAL: Notice for medical attention not normally required except for

serious cases requiring doctors attendance on board, or ambulance cases.

Vaccination certificate required for landing. Hospital facilities available.

Also see Chandlery.

FRESH WATER: Ample available by barge. Contact Agent.

FUEL: The Aden Bunkering Department (ABD) operates from two bunkering

dolphins on the south side of the inner harbour (berths 6-in and 6-out) and

can also supply small quantities of bunkers by barge.

Bunkering facilities on the north shore are operated by the Arab Investment,

Manufacturing and Trading Company (AIMT) at Dolphin Berth No. 7. The

company also plans to provide bunkers by barge soon.

Aden Refinery can provide bunkers to tankers that are calling at the oil

harbour to discharge or load.

The former Yemen-Kuwait Company bunker facilities west of Hedjuff on

the south side of the inner harbour supplying Berths 8-in and 8-out are being

refurbished (May 2005).

CHANDLERY: There are no firms specialised in this field in Yemen.

However, the Yemen Ports Authority has a large fleet of tugs and launches.

These craft are available at all times for rendering assistance to sick persons

on board ships in the vicinity of the ports and are also available for crew

changes, mail and spare parts delivery.

SERVICES: Bunkering, towage, launch service, spares, repatriation,

marine/engineering surveys, gyro/radio repairs, life raft repairs and surveys.

Fumigation: Empty ships can be fumigated and a Derat Certificate issued

by the Port Health Authority. Container fumigation is also available.

NEAREST DRY DOCK: The National Dockyard Company operates one

broadside slipway, capacity 1,500 tonnes (currently downrated), four

slipways, 200 300 tonnes capacity; and one floating dock capacity

1,500 tonnes (currently downrated).

Also see Repairs.

REPAIRS: The National Dockyard Company at Hedjuff is equipped with

workshops, large lathes, electrical, casting, refrigeration and other repair

shops and offers in-water repair services.

Tel: +967 (2) 244484, 244502. Fax: +967 (2) 241681.

SURVEYORS: There are surveyors available to conduct

marine/engineering surveys, gyro/radio surveys/repairs and life raft

surveys/repairs.

Surveys are arranged through the Agent. Engineering surveys are arranged

through the National Dockyard Company. All surveyors working at the port

are licensed by the authority.

Also see Repairs.

POLICE/AMBULANCE/FIRE: Ambulance at Crater Tel: +967 (2)

53232. Harbour Police Tel: +967 (2) 22851. Port Health Tel: +967 (2)

22626/7. Fire Tel: +967 (2) 22222.

EMERGENCY RESPONSE CENTRE: The Yemen Army and Air

Force make their helicopters available for rescue at sea whenever possible.

Also see Chandlery.

FIRE PRECAUTIONS: As per the Refinery regulations (International

Standard). Tug wires to be rigged and check list to be furnished. Harbour

tugs are fitted with fire monitors. The Maalla Terminal is equipped with a fire

main. Fire engines are stationed about 0.5 km. from the Maalla Terminal, at

the airport and at the Aden Oil Refinery Harbour. The ACT operates a fire

engine and water bowser.

GANGWAY/DECK WATCHMEN: It is recommended watchmen are

employed; they can be supplied by ships Agent. Safety net to be rigged.

REGULATIONS: A copy of port notices and regulations is provided to

the Master by the Pilot and Agent when entering the port. No movement of

dangerous petroleum at night. Vessels must vacate oil berths on completion

of bunkering. Main engines must not be immobilised in an oil berth. Sufficient

crew must remain aboard vessel at all times to move her.

Ships carrying dangerous cargoes calling at Yemen Ports must inform the

Port Authority concerned not less than 48 hours prior to arrival. IMO

Class 1 dangerous cargo to discharge at Outer Harbour Anchorage, if IMO

Class 1 in transit vessel will manoeuvre during day time only.

Immobilisation of main engines should not be executed at any berth before

obtaining written permission from Port Authority, through Agent. Same

procedure applies for overside hull painting. Application to be through Agent

in duplicate. Main engine immobilisation in oil berths and Home Trade Quay

not allowed.

TIME: GMT plus 3 hours. No alteration of clocks.

LOCAL HOLIDAYS: Most holidays are religious which have movable

dates. National holidays are 14 October and 30 November. Cargo work

usually carried out during all holidays. Friday is a public weekend holiday.

WEATHER/TIDES: Tidal Range: Approximately 1.0 m. (neaps) and

1.7 m. (springs). Maximum recorded tidal flow spring tide 0.43 m./sec.

(1.0 knot).

Winds: Prevailing winds NEly from October to May, SWly from June to

September.

DELAYS: See Shipmasters Report dated April 2001.

CONSULS: China, Egypt, Germany, Libya, Russia, Saudi Arabia, Somalia

and UK.

TELEPHONES: No connection to ships but link calls can be made on

VHF through Yemen Communications using Channel 16 to call and working

on Channel 26. Some Agents have private VHF Channels.

NEAREST AIRPORT: Aden International Airport, 6 km.

BANKS: National Bank of Yemen, The Arab Bank, Indo Suez, Yemen

International, Yemen Commercial Bank.

CUSTOMS ALLOWANCES: Tobacco/wine, spirit allowance. No

restriction at the moment. Bonded stores not allowed to be supplied more

than 1 hour before ship sails.

SHORE LEAVE: Regulations: In accordance with Art. 8 of the

Immigration Rule No. 28 of the year 1969, all crew members coming ashore

will be excused from obtaining visa provided they surrender their passports

to the Immigration Officer-in-Charge. These passports will be given back to

the holders before they return to their particular vessels. Any crew member

unable to comply with these instructions will not be permitted to visit the town.

Ships crew are not allowed to stay ashore after 0000 hrs.

Taxi and air-conditioned bus services to Sanaa, Taiz, Hodeidah, and other

towns are available from stations in Sheikh Othman, 8 km. from Maalla and

3 km. from the ACT.

REPATRIATION: Crew changes can be arranged through Agent. Transit

visas for crew members joining or leaving vessels are arranged with the

Immigration authorities.

Also see Chandlery.

See guidelines on how to compile and submit information to us (page xi).

3337

YEMEN

Aden

IDENTIFICATION CARDS: Shore pass to be carried at all times when

Fuel: The gas oil bunker barge came alongside the vessel on the port side

ashore.

soon after vessel was made fast. Bunkering was commenced immediately

on arrival, even before ship was cleared by the port authorities. Minimum

amount of gas oil to be supplied was 35 tons. Bunkering went smoothly.

SEAMANS CLUBS: A representative of the Missions to Seamen visits

ships berthed at Aden inner harbour and Little Aden oil harbour. Publications

of the Missions to Seamen are distributed to ships. Library and video

exchange facilities are available at the Community Centre in Tawahi (Steamer

Point). Occasional social events are arranged at the Centre. Contact

Tel/Fax: +967 (2) 201204.

A Seafarers Centre is planned, to have telephone, email/internet and

recreational facilities.

DEVELOPMENTS: A new coastguard base being constructed 1 cable

east of the Abkhari Pier on the south side of the inner harbour was due to

be completed during 2005.

Bunkering facilities west of Hedjuff on the south side of the inner harbour

at Berths 8-in and 8-out are being refurbished.

Phases II and III of the Aden Container Terminal will extend the berths from

the present 700 m. to 1,650 m. Material for Phase II construction has been

stockpiled to the west of Phase I.

A new finger jetty with alongside depths of 14.0 m. (north side) and 11.0 m.

(south side) is under construction (May 2005) to serve a bulk grain facility

on the west side of the Maalla Terminal. Dredging to depths of up to 14.0 m.

in this area was completed in September 2004. Additional bulk import and

rock export facilities are planned.

YPA has prepared a project to widen the port access channel to the inner

harbour to 250 m. and deepen it, and the inner harbour turning area to 17.0 m.

Under the Aden City Master Plan, new berths north and west of the Aden

Container Terminal are planned for bulk rock export, bulk and other imports,

with storage space and other facilities.

SHIPMASTERS REPORT: October 1994.

Vessel called at Aden for bunkers and fresh water.

Documents:

Agent:

3 Crew Lists.

Customs:

1 Crew List

2 Customs Declarations

1 Crew Declaration.

Immigration:

2 Crew Lists.

Police:

2 Crew Lists.

Arrival Declaration filled in by Agent after arrival. Departure Declaration

was also signed for Agent to fill in later for Departure Clearance. No Ships

Certificates were requested by the Agent or the Port Authorities. Immigration

officers check passports. Shore leave allowed with Passports/Seamans

Book. Agent and Port Authorities very co-operative and arrival formalities

were quick and smoothly carried out.

Agent returned on board prior to vessels departure to give Port Clearance

papers and instructions to call Aden Port Control by VHF Channel 16 for Pilot

when vessel is ready to sail.

Pilotage/VHF: When 25 miles from Aden and approaching from the west,

Aden Port Control was contacted on VHF Channel 16.

Following information was requested:

Ships name:

Draft

Flag:

Last port

G.r.t.:

Next port

Type of vessel:

Agent in Aden.

We were then instructed to call again when vessel was 4 miles off the

Fairway Buoy. We reported again when vessel was 4 miles off the Fairway

Buoy, and were then informed by Port Control that no arrangements made

by our Agent for Pilot to bring the vessel into port. We were then instructed

to anchor vessel 2.5 miles SW of the Fairway Buoy and to report again when

vessel was anchored.

After reporting anchoring time and position back to Port Control, we were

then instructed to call our Agent on VHF Channel 16. Agent was then

contacted on Channel 16 with working Channel 11. We were then informed

by our Agent that as no confirmation from the bank of funds from the Owners

received by them yet, vessel will not be allowed into the port and we were

to keep VHF watch on Channel 16 for their call again when confirmation was

received. Two other vessels were also outside the anchorage who had arrived

2 days before us and were similarly waiting for confirmation of funds from

their Owners to the Agents.

Next morning, our Agent called again on VHF to advise that funds had

been received by them and vessel could now proceed into port for bunkers

and fresh water. Thereafter Aden Port Control called up for vessel to heave

up anchor and proceed to the Fairway Buoy, where the Pilot will board. Pilot

boards near the Fairway Buoy with lee side pilot ladder.

For departure, call Aden Port Control for Pilot. Vessel has to inform them

that Port Clearance papers are on board and no barges alongside the vessel.

Pilot checks the Port Clearance papers after boarding. We were instructed

to exhibit the pilot lights (red white red) vertically on the masts. As our

vessel did not have the lights required, we informed Port Control about it and

they were kind enough to disregard the lights. Pilot and mooring gang arrived

together 45 minutes later by boat. Pilot disembarks after clearing harbour

entrance breakwater and at No. 4 Buoys. We were informed by the Pilot that

some of the buoys are unlit, but can be picked-up clearly on the radar.

No. 2 and No. 3 starboard green lights were not lit. Similarly No. 1 port red

light was not lit. The Fairway Buoy could not be seen to be lit also.

Mooring: Vessel berthed starboard side alongside dolphin berth with

bunkering facilities, but which were not used during bunkering. One tug and

two mooring boats meet the vessel near the berth, but the tug was not used.

Port anchor was let go while coming alongside with 1.5 shackles out. Three

mooring ropes were used forward and aft, 2 ropes as springs, 2 ropes as

stern lines to the dolphin berth, and remaining 2 ropes also as stern lines to

buoys forward and aft of the dolphin berth. Pilot disembarks to the mooring

boat after vessel is all fast alongside.

During departure, one tug is made fast at the stern with ships line. All lines

were cast off and the port anchor heaved up with the tug aft pulling the stern

of the vessel, away from the berth. When the port anchor was aweigh, engines

were used with astern movements to swing the vessel round to starboard to

face the entrance harbour breakwater. Tug was then cast off from the stern.

3338

Fresh Water: The fresh water barge also came alongside and made fast

forward of the bunker barge. After completion of bunkering and the bunker

barge had cast off, the fresh water barge moved aft to take its place and

commenced to supply fresh water to the vessel. Capacity of the fresh water

barge was approximately 200 tons. Supply was made using normal canvas

hose, and there were three supply outlets to supply to different tanks on

board our vessel simultaneously. We were informed by the Agent that there

are three fresh water barges in Aden port, but only one is available to supply

fresh water to the vessels in port, as the other two barges were undergoing

repairs at the time. Cost of fresh water is US$ 4.00/ton.

SHIPMASTERS REPORT: April 2001.

Vessel: General cargo vessel, 18,100 d.w.t.

Cargo: Bagged rice and steel pipes.

Documents: Once the vessel was secured alongside, the ships Agent

boarded with one Customs Officer, an Immigration Officer and a Health

Officer. Inward clearance took approximately 20 minutes.

The following documents were required:

Health Officer:

1 Derat (Exemption) Certificate

1 Crew List

1 Vaccination List (Yellow Fever).

Also see Health.

Immigration Officer:

1 Crew List

All Passports.

All Passports were checked by the Immigration Officer.

The ships Bonded Store was not sealed by the Customs Officer. Our vessel

is an alcohol-free ship.

Arrival: On our arrival off the port, due to port congestion, we were advised

to either anchor 1.5 n.m. to the SW or SE of the Fairway Buoy, which is also

the inner pilot boarding area. Due to the western anchorage being crowded,

we decided to anchor in the eastern anchorage.

Anchorages: The anchorage area is congested and the holding ground

good. Despite the frequent fresh winds, our loaded vessel did not drag her

anchor.

Also see Arrival.

Approaches: All the buoys in the approach channel were in their charted

positions with navigational lights working.

Also seeVHF.

Pilotage: After spending 8 days in the anchorage, Port Control advised us

to heave up anchor and proceed to the inner pilot boarding area. On

approaching the pilot boarding area, our vessel was advised to stand-by for

one hour. We therefore decided to anchor 0.25 n.m. off the inner pilot station,

which was just as well as we ended up waiting for 3 hours. Finally, the pilot

boat called up when nearly alongside our vessel, and once the Pilot had

boarded, we weighted the anchor and proceeded inwards to the inner

harbour.

Both the inward and outward Pilots were very professional and courteous.

Health: The Pilot granted the vessel free pratique on boarding at the

anchorage.

Tugs: See Berthing.

Berthing: Once inside the harbour, our vessel was secured to several

mooring buoys, and letting-go the port anchor to check the bow, berthed

starboard side alongside. Two tugs using ships lines were used during the

berthing operation.

Cargo Handling Facilities: We commenced discharging the bagged rice

the following morning with ships gear.

Stevedores: The stevedores were surprisingly efficient (quick) and the

discharge was continuous. They are unskilled labour and had little regard for

their own safety. Twice on the same day, stevedores approached the Duty

Officer with minor hand injuries. Although the injuries occurred in the barges

while discharging bagged rice and steel pipes, the stevedores tried to blame

our vessel.

The ships Agent advised us that any injury whether incurred on our vessel

or the barges, our vessel would be held liable. We therefore took photographic

evidence of the discharge operation and of the lack of protective equipment

being worn by the stevedores. In the end, the stevedores did not push the

issue any further.

Shore Leave: Permitted. Ships crew going ashore have to take their

Seamans Books and deposit them at the main gate, collecting a receipt that

acted as a shore pass.

Medical: Satisfactory facilities are available. No advance notice required for

sending crew members for general or specialised medical attention.

Fresh Water: Available, but we did not load any.

Fuel: Available, but we did not load any.

Garbage Disposal: Available. Garbage is collected once a day. Contact

ships Agent.

Delay: There is a continuous backlog of cargo vessels waiting to berth at

the port.

AUTHORITY: Yemen Ports Authority, Port of Aden, PO Box 1316,

Tawahi, Aden, Yemen. Tel: +967 (2) 202666, 203521. FAX: +967 (2)

205805, 203521. Telex: 6278 MAWANY YE. Email: ypa@y.net.ye

Web: www.portofaden.com Contact: Captain Abdulla Ibrahim Abkar,

Director General (Tel: +967 (2) 243096, 202953 (after hours). Fax: +967 (2)

243211). Captain Hussein Ahmed As-Saaidi, Harbour Master

(Tel: +967 (2) 202850. Fax: +967 (2) 206241).

Readers are encouraged to send updates/additions (see p. xi for details)

Ash Shihr Terminal

YEMEN

ASH SHIHR TERMINAL: 14 41' N 49 31' E

(See Plan)

LOCATION: The Ash Shihr Petroleum Export Terminal, operated by

Canadian Nexen Petroleum Yemen, is located on the southern coastline of

the Republic of Yemen, approximately 230 n.m. east of Aden.

The terminal has an exclusion area radius 3 km. from SPMs No. 1 and 2.

Only terminal and military craft other than offloading vessels are allowed to

enter this area.

CHARTS: BA Chart No. 3784 (Ras al Kalb to Ras Marbat).

DOCUMENTS: Upon arrival at the terminal, the following documents will

be required by the Republic of Yemen Government authorities. The Pilot will

collect these documents on behalf of the appropriate authorities:

2 Bonded Stores Lists

2 Cargo Manifests

2 Crew Effects Declarations

3 Crew Lists

1 Last Port Clearance (original)

1 Maritime Declaration of Health

2 Vaccination Lists.

Documentation required by the terminal operator:

Current CLC Certificate (copy)

Document of Compliance (copy)

International Ship Security Certificate (ISSC) (copy)

P&I Club Pollution Insurance Certificate (copy)

Safety Management Certificate (copy)

Signed Agreement for Agent to sign documents (EDP)

Signed Conditions of Use letter (by Master)

Signed Forecastle Watchkeeper

Signed Information to Masters Communications Procedure

Signed Information to Masters Early Departure Procedure

Signed Non-Intrinsically Safe Equipment

Signed Notice of Readiness Notification

Signed Safety Requirements

Signed Ship/Shore Safety Check List

Signed Ships Stores List

Signed Tanker Deficiency Report.

Shipping Documents: The terminal operator prepares all cargo related

documentation, including Bills of Lading, Quality & Quantity Report, Cargo

Manifest, Certificate of Origin, Tanker Time and Loading Report, Ships Ullage

Report and Receipt for Documents and Samples. The terminal utilises an

Early Departure Procedure (EDP). See Cargo Operations.

Bills of Lading are based on shore metered quantities and will be dated

according to the time of completion of loading. No amendment to any Bill of

Lading is permitted.

Letters of Protest: Any Letters of Protest must be signed by the Master

and dated and endorsed with the ships stamp. The Mooring Master has the

authority to receive all letters, without prejudice.

MAX. SIZE: Minimum 80,000 d.w. tonnes, maximum 400,000 d.w. tonnes

(loading restricted to 265,000 tonnes of cargo), depth 45.0 m.

RESTRICTIONS: The terminal only accepts vessels with segregated

ballast water tanks (SBT).

The terminal operates throughout 24 hours but tankers are only berthed

during daylight hours (sunrise to sunset) with all berthing operations being

completed prior to sunset. During the monsoon season, berth is carried out

during the early morning daylight hours due to strong midday SW thermal

winds, unless decided otherwise by the terminal operator.

Age Restriction: The terminal will not accept a vessel for loading if the

calendar year in which the vessel was built precedes the calendar year in

which the vessel is nominated to the terminal by twenty years or more.

Also see Berthing.

PILOTAGE: Compulsory, Mooring Master and his assistant provided by

the terminal operator will board an arriving vessel approximately 2 n.m.

seawards of the SPM. Vessels shall not proceed inwards without a Mooring

Master on board.

A combination of accommodation ladder/pilot ladder should be rigged on

the leeward side, 1.0 m. above sea level and conform to SOLAS and IMO

requirements.

Mooring Master: A Mooring Master will remain on board the vessel to

coordinate the loading operation throughout the vessels stay. The Master of

the vessel must provide the Mooring Master, his assistant, the cargo inspector

and possibly an Oil Ministry representative with full messing and

accommodation, equivalent to that enjoyed by the vessels officers.

Terminal Terms of Acceptance: The Mooring Master will give the Master

of the vessel a Terminal Rules and Regulations booklet and duplicate copies

of documents entitled Ash Shihr Petroleum Export Terminal Conditions of

Use, Ship/Shore Safety Check List and Safety Requirements. These

documents specify the conditions of use and safety requirements which must

be satisfied. The Master must personally sign the Conditions of Use document

before the terminal operator will accept the vessel and allow her to berth.

ANCHORAGES: Masters are advised that the terminal operator cannot

advise suitable anchorage areas due to poor holding ground, seabed mainly

dolomite limestone.

Masters must not attempt to anchor within the terminal area.

All attempts to anchor must be well clear of the terminal and its facilities.

The terminal operator will have no liability whatsoever for any claims,

charges, damages or losses of any nature or kind incurred by or in any way

relating to anchoring of vessels.

Vessels shall have their anchors made secure prior to their final approach

to the terminal.

Approach to Terminal: Approach to the terminal is direct from the open

sea.

Vessels Waiting to Berth: All vessels waiting to berth at Ash Shihr Export

Terminal must keep a safe distance offshore to the south and east of the

terminal.

PRE-ARRIVAL INFORMATION: Masters are advised that the terminal

only accepts vessels with segregated ballast (SBT). Vessels shall maintain

trim and draft so as to be able to depart the terminal in an emergency if

required.

Masters are advised that the terminal utilises a compulsory Early

Departure Procedure which will be fully explained on arrival.

The terminal operator must be provided with answers to the following

questionnaire, 3 days prior to the vessels arrival at the terminal:

AAA ETA

BBB Cargo requirements and cargo on board in barrels at 60 F.

CCC Maximum loading rate through 216 in. connections and the

minimum loading rate.

DDD Quantity and type of ballast on board to be discharged at this terminal.

EEE Number and size of cargo manifolds. Do they comply with OCIMF

Recommendations for Oil Tanker Manifolds and Associated

Equipment, 4th Edition 1991.

FFF Availability of two reducers to adapt port side manifold to suit 26 in.

150 ANSI loading hoses.

GGG Whether inert gas system is operative and percentage oxygen level

in cargo tanks, prior to arrival at terminal.

HHH Is vessel equipped with one or two bow chain stoppers capable of

accepting a 76 mm. chain.

JJJ Does forecastle mooring arrangement comply with OCIMF

Recommendations for Equipment Employed in the Mooring of Ships

at Single Point Moorings, 3rd Edition 1993.

KKK SWL of cranes or derricks

LLL Last port and destination

MMM Name of pollution insurers

NNN Summer deadweight tonnage

OOO Arrival displacement, sailing displacement

PPP Arrival draft, sailing draft

QQQ Nationality of officers and crew, including total persons on board.

RRR Masters name

SSS Flag state and registry

TTT Equipment defects

UUU Confirmation that suitable accommodation (officer) is available on

board for three persons

VVV Confirmation that the vessel has valid International Ship Security

Certificate (ISSC)

WWW ISPS security level

XXX Other.

Attention is drawn to the serious view of pollution taken by the terminal

operator. Fines may be imposed by government authorities to which will be

added the cost of any clean-up operations. You are responsible to ensure

that crew members cause no pollution during the vessels stay at the terminal.

Principal pollution causes include leaking sea and overboard discharge

valves and cargo or bunker overflows. Prior to arrival, sea discharge valves

must be flushed and deck scuppers must be plugged.

VHF: Arriving vessels call the terminal call sign Ash Shihr Terminal on

listening Channel 16, then switch to working Channel 9. All vessels shall have

a working VHF radio in their cargo control room.

Information to Masters Communications Procedure:

1. The primary means of communications between the tanker and the

terminal control room during loading is VHF Channel 9.

2. The call sign of the terminal control room is Operations Control.

3. The secondary means of communications is by private UHF radio

(Channel 1), which is in use by terminal personnel.

4. An emergency stop of loading by the tanker will be activated by the

words Operations Control, Emergency Stop and repeated until

acknowledged by the terminal control room.

5. Regular communication checks between tanker and terminal control

room must be made during loading. It is procedure that tanker and

terminal duty personnel will exchange cargo figures frequently, usually

at hourly intervals, and this practice will also serve as a

communications check.

6. The Mooring Master has a marine VHF radio with him at all times.

He can be contacted by the tanker duty officer on Channel 9, if

required.

TUGS: A tug is available at the terminal. The operator will require that the

tug be in attendance throughout operations. A ships line must be provided

at the stern of the vessel for use in an emergency. The tug is secured using

a tugs wire.

BERTHING: Ships Security: Vessels will be met by military vessels on

their approach to the terminal, escorting vessels to the SPM. On completion

of loading, military craft will again escort the offtake vessel from the terminal.

Whilst at the terminal, if any watchkeeper sees anything unusual, report it

to the officer of the watch who should in turn advise the Mooring Master/Pilot

immediately.

Berthing on Arrival: Government officials may board the vessel with the

Mooring Master and his assistant. The Agent seldom boards the vessel.

SPM No. 1: Located in position Lat. 14 40' 35" N, Long. 49 31' 16" E.

Navigation light white flashing U 15 seconds, visible 3 n.m.

The buoy is rated to handle tankers 80,000 300,000 d.w. tonnes, but can

load to displacement 374,000 tonnes. Tankers up to 400,000 d.w. tonnes

have been accepted for loading but been restricted to max. 265,000 tonnes

of cargo. Max. draft 22.2 m.

SPM No. 2: located in position Lat. 14 41' 24" N, Long. 49 32' 26" E.

Navigation light white flashing U 15 seconds, visible 3 n.m.

The buoy is rated to handle tankers 80,000 320,000 d.w. tonnes, max.

draft 24.0 m.

Navigation Buoys: Permanent navigation lights are exhibited on the two

navigation buoys marking the 27.4 m. contour, Fl. Y. 5 sec. with radar

reflectors.

Positions of the buoys:

East Buoy:

Lat. 14 41' 15" N, Long. 49 31' 10" E

Mid Buoy:

Lat. 14 41' 47" N, Long. 49 31' 52" E

West Buoy:

Lat. 14 40' 55" N, Long. 49 30' 31" E

Service Tug Mooring Buoys:

Mooring Buoy A:

Mooring Buoy B:

Mooring Buoy C:

Lat. 14 41' 08" N, Long. 49 29' 30" E

Lat. 14 40' 50" N, Long. 49 29' 30" E

Lat. 14 42' 01" N, Long. 49 32' 15" E

SPM Buoy: The 12 m. diameter Single Point Mooring buoy is moored in

approximately 45 m. water depth. A small boat harbour is provided for the

use of terminal support craft only.

See guidelines on how to compile and submit information to us (page xi).

3339

YEMEN

Ash Shihr Terminal

Draft Upon Arrival: Vessels must arrive at the terminal with sufficient

ballast/cargo on board, to ensure safe manoeuvring of the vessel and be

trimmed no more than 4.0 m. by the stern and with propellers submerged.

Vessels will not be berthed with excessive trim or insufficient ballast.

Partly Loaded Tankers: Vessels that are partly loaded to the extent it

effects the manoeuvrability of the vessel in the vicinity of the SPMs will not

be accepted for loading. Partly loaded tankers will only be accepted for

loading if the cargo on board on arrival is in accordance the following:

VLCC ULCC: Max. cargo on board 1,000,000 bbls. (net) or less

Suez Max.: Max. cargo on board 500,000 bbls. (net) or less

Afr Max.: Max. cargo on board 300,000 bbls. (net) or less.

Mooring Master Authority: The Mooring Master can instruct any vessel

to leave a berth.

Vessels Officers and Crew: A ships officer with an adequate command

of English and sufficient qualified crew must always be available at all times

for operational requirements and emergencies.

MOORING: Mooring Systems: The mooring system is comprised of two

endless grommet 17 in. circumference mooring ropes each with a single

U3 grade 76 mm. chafing chain.

Provision of Mooring Equipment: Vessels must be equipped with

mooring equipment in accordance with the OCIMF Recommendations for

Equipment Employed in the Mooring of Ships at Single Point Moorings.

Panama Lead Size: Panama leads and chain stoppers must accept

76 mm. diameter chains.

Messenger Lines: The vessel must supply at the bow two floating

messenger lines of 25 mm. minimum diameter and minimum 50 m. long.

Deployment of Emergency Towing Wires: All vessels must deploy

emergency towing wires forward and aft on the starboard side.

HOSES: Each 20 in. loading hose string tapers to a 16 in. diameter tanker

over-rail hose, to which is secured a shut-off valve, camlock coupling, hang-off

chain and pick-up rope.

Manifold Connections: 216 in. 150 ANSI rated loading manifolds must

be prepared on the port side. The manifold must comply fully with the OCIMF

Recommendations for Oil Tanker Manifolds and Associated Equipment,

4th Edition 1991.

Crane/Derrick: Vessels hose lifting equipment shall be Safe Working Load

(SWL) certified and rigged to handle at least 12 tonnes.

Handling of the Equipment: Equipment supplied by the terminal will be

taken on board from a line handling boat, using the vessels lifting equipment.

The vessels crew must be available to receive equipment and connect the

loading hoses. A tag line must be provided on the cargo hook.

CARGO OPERATIONS: Notice of Readiness: Tender Notice of

Readiness on arrival by contacting Ash Shihr Terminal, if the vessel is ready

in all respects to load.

Acceptance of the Notice of Readiness: Notice of Readiness will be

accepted by the terminal operator during daylight hours and subject to the

following conditions:

1. The terminal is open and vessel has arrived.

2. The Estimated Time of Arrival (ETA) has been advised to the terminal,

72, 48, 24 and 12 hours prior to arrival, and Masters have advised the

terminal of any change of ETA in excess of 3 hours.

3. Vessel complies with the Terminal Rules and Regulations.

4. The vessel must arrive within the designated loading range.

5. If the vessel arrives outside the designated loading range, the following

applies:

a) A vessel that tenders NOR within its loading range or before the

first day of its loading range shall have priority over a vessel that

tenders NOR after the last day of its loading range.

b) A vessel that tenders NOR within its loading range shall have priority

over a vessel that tenders NOR before the first day of its loading

range.

c) In the event two or more vessels tender NOR within their respective

loading ranges, priority shall be given to the vessel with the earlier

loading range.

d) In the event two or more vessels tender NOR before the first day

of their respective loading ranges, priority shall be given to the vessel

with the earlier loading range.

e) In the event two or more vessels tender NOR after the last day of

their respective loading ranges, priority shall be given to the vessel

with the earlier loading range.

f) In the event a vessel tenders NOR after the last day of their loading

range, the terminal operator shall, subject to a) e), use reasonable

efforts to berth the vessel at the first available opportunity, provided

that doing so will not delay another vessel expected to arrive before

or during that other vessels loading rang.

Vessels Alongside the Loading Vessel: Only vessels authorised by the

terminal operator are allowed alongside, while deballasting and loading

operations are in progress.

Standards of Operations: Loading operations are conducted in

accordance with the following standards and recommendations:

a) Oil Companies International Marine Forum (OCIMF), International

Chamber of Shipping (ICS), International Safety Guide for Oil Tankers

and Terminals (ISGOTT)

b) special emphasis on the OCIMF Recommendations for Tanker

Manifolds and Associated Equipment, and the OCIMF

Recommendations for Equipment Employed in the Mooring of Ships

at Single Point Moorings

c) MARPOL (73/78) as amended

d) Ash Shihr Petroleum Export Terminal Rules and Regulations (latest

revision).

Safe Loading: Safe operations and continuing compliance with the

Terminal Rules and Regulations on board the vessel throughout the vessels

stay at the terminal, is the Masters responsibility.

Forecastle Watchkeeper: While the vessel is moored at the facility, it is

a requirement that the position of the vessel in relation to the SPM buoy is

continuously monitored by vessel personnel.

Please ensure that a competent watchkeeper is continuously posted on

the forecastle throughout the entire period that your vessel is moored.

The watchkeeper must receive clear instructions that he shall inform the

officer-on-watch by radio when the vessel moves into a position closer than

3340

usual to the SPM buoy. Further to this, they will also report the vessels

position in relation to the SPM to the cargo control room (CCR) every

15 minutes and Mooring Master/Pilot every 30 minutes on VHF Channel 9.

Suspension and Stopping of Loading See Combination Carriers

(OBO): The Master may suspend loading at any time. A minimum of

30 minutes notice is required prior to change of loading rate or suspension

or completion. Emergency stops excepted.

The Mooring Master and the vessels Master must liaise as to the amount

of cargo that will be received on board the vessel after the shore pumps have

stopped. The terminal operator will not be responsible for any overloading

that may occur. There is no capability to pump excess cargo back to the

terminal storage tanks.

Ship and shore quantities will be verified at regular intervals throughout

the loading, usually hourly.

Closure of Vessels Valves: The vessels loading system valves must

never be closed against the terminals loading pumps. After completion of

loading, the terminal operator will notify the vessel through the Mooring

Master when it is safe to close the manifold valves.

Loading Rates: Initial loading is by gravity at approximately 6,000 bbls./hr.

Once it is confirmed that cargo is being received on board and the vessel is

ready to receive an increased rate, the rate will be increased to max.

50,000 bbls./hr. or as requested by the offtake vessel.

The minimum loading rate is 15,000 bbls./hr.

The maximum loading rate is 60,000 bbls./hr.

Hydrostatic Balance Loading (HBL): Hydrostatic balanced loading is

not permitted at the terminal.

Inert Gas System (IGS): Vessels loading at the terminal shall have a fully

functioning IGS as per SOLAS requirements. All tanks must be maintained

in positive pressure with oxygen content 8% or less by volume. This will be

verified by a terminal representative.

Water Plugs and Flushes: Vessels may be required to provide a water

plug or receive a water flush. The ships Master will be advised in advance

of this requirement.

Special Requirements for Vessels at the Terminal: The vessels fire

main must be pressurised at all times with two hoses with foam delivery

nozzles connected to foam hydrants available for emergency use. Records

must be at hand to show that the foam system is in good working order and

functions correctly.

Two portable dry powder extinguishers must be available close alongside

the loading manifolds.

Combination Carriers (OBO): Particular care should be taken when

loading or discharging liquid cargo from combination carriers and when

handling ballast on such ships to ensure that the total free surface effect of

cargo and ballast is kept within safe limits, otherwise a sudden, and possibly

violent, change of list could occur.

In compliance with government requirements, all combination carriers are

supplied with stability data and loading and unloading instructions.

Prior arriving at the terminal, a plan must be prepared for the anticipated

loading sequence, bearing in mind the free surface effect and distribution of

cargo, fuel and ballast at all stages of the operation. This plan must be

discussed with the Mooring Master prior to the commencement of loading or

deballasting.

If a loss of stability becomes evident during loading, all cargo and

deballasting operations must cease and a plan prepared for restoring positive

stability. This plan must be discussed with the Mooring Master prior to

implementation.

The terminal will only accept combination carriers if the vessels three

immediate preceding cargoes have been crude/fuel oil.

Double Hull Operations: Single hull tankers usually have such a high

metacentric height in all conditions of loading and ballasting that they can

be considered as being inherently stable.

The main problem likely to be encountered with a double hull tanker is the

effect on the transverse metacentric height of liquid free surface in the cargo

and double bottom tanks.

The most critical stages of any operation will be whilst emptying the double

bottom ballast tanks during loading of cargo.

It is imperative that the tanker and terminal personnel involved in cargo

and ballast operations are aware of this potential problem, and that all cargo

and ballast operations are conducted strictly in accordance with the ships

loading manual.

Where they are fitted, interlock devices to prevent too many cargo and

ballast tanks from being operated simultaneously, thereby causing an

excessive free surface effect, should always be maintained in full operational

order, and should never be over-ridden.

Ships which operate with limited metacentric height should be equipped

with a loading computer which calculates metacentric height.

Early Departure Procedure:

1. Masters should be aware that the Early Departure Procedure is

compulsory at the terminal as all companies lifting cargo have been

informed. In any case, on arrival Masters are requested to sign a letter

which is an agreement in principle to the procedure.

2. On completion of loading, cargo hoses will be disconnected and the

vessel unmoored from the SPM.

3. Concurrent with (2) above, vessels tank ullages, water dips, etc., will

be taken. Usually this practice is completed prior to unmooring

operations.

4. The vessel will be manoeuvred to a safe position which is to seaward

of the SPM and then stopped to await shore cargo figures.

5. Shore cargo figures will be passed to the vessel from the terminal by

VHF radio.These figures represent the Bill of Lading figures.

The ships cargo figures will be passed to the terminal by radio by

the Mooring Master. If there is no dispute over the difference between

ship and shore cargo figures, then the vessel is free to sail. In case

of a dispute, the respective cargo figures will be recalculated and

compared once before the vessel is released.

If the Master chooses to issue a Letter of Protest, this will be

received by the Mooring Master.

6. No cargo documents will be placed on board the vessel, either in

completed or blank form.

Readers are encouraged to send updates/additions (see p. xi for details)

Ash Shihr Terminal

7. All cargo documents which require Masters signature will be signed

by the vessels Agent after the documents have been prepared by

the terminal, which will be after the vessels departure. Authorisation

to sign cargo documents is a matter between the Master and the

vessels Agent.

8. Copies of the signed Bill of Lading and Q & Q Certificate will be sent

by fax to the vessel. If the vessel does not have a fax, the Master

can nominate a fax number to which they can be sent.

9. Masters copies of cargo documents are forwarded to the discharge

port by courier.

10. An outward clearance certificate for the vessel is issued by the

vessels Agent and presented by the Pilot prior to sailing.

BALLAST: Discharge of Ballast: The discharge of dirty or

contaminated ballast is strictly forbidden. The operator will have no liability

whatsoever for any deadfreight incurred due to retention of ballast or any

other residues. No ballast reception facilities exist at the terminal.

Clean Ballast: Clean Segregated Ballast (SBT) may be discharged to the

sea at any time. The Mooring Master will check that vessels with cargo tanks

dedicated to Ballast (CBT) comply fully with MARPOL regulations and that

complete segregation exists between the ballast and cargo systems before

approving deballasting.

Prior to commencing discharge, cargo tanks should be depressurised

enough so as to allow up to three ullage ports to be opened. Venting shall

only be to vessels riser system and open venting shall not be allowed.

Simultaneous Deballasting and Loading: All vessels shall be capable

of loading/deballasting simultaneously at all times. The draft and trim must

be maintained in a condition whereby emergency evacuation of the berth can

be achieved. The terminal operator accepts no responsibility for the mixing

of crude oil and water on board the vessel.

POLLUTION: Documentary Requirements: The vessels owner or

bareboat charterer shall be enrolled as a member of the International Tanker

Owners Pollution Federation Ltd (ITOPF) and at all times Certificate of

Insurance or an equivalent certificate of financial responsibility.

Each vessel which is to load at the terminal must have P&I insurance in

force and effect that provides the standard $1,000,000,000 pollution

coverage. Documentary evidence must be presented to the terminal operator

at the terminal before being accepted to load.

WASTE DISPOSAL: Disposal of waste, sewage waters or garbage in

the sea is forbidden. No facilities exist to receive waste material, garbage or

sewage waters at the terminal.

MEDICAL: Medical and dental services are not available at the terminal,

except in an emergency.

FRESH WATER: Not available.

FUEL: Not available.

CHANDLERY: Provisions: The embarkation and/or disembarkation

foodstuffs, provisions, fuels and different types of commodities using the

terminal facilities is strictly forbidden.

Any of the aforementioned services will be supplied by the Agent with his

own resources and through his own means, either before or after loading

operations.

The vessel cannot take on stores or provisions at the terminal.

REPAIRS: No facilities available.

Immobilisation of Vessel: The vessels main engines and essential

machinery must be ready at all times in order to allow immediate vacation

of the berth.

CONSULS: The nearest consuls are in Sanaa.

NEAREST AIRPORT: Riyan Mukalla Domestic Airport, 10 km.

SHORE LEAVE: Only in cases of approved emergency, or for

humanitarian reasons, or for special circumstances as approved by the

terminal operator and on whatever terms and conditions the terminal operator

may impose, can the vessels personnel embark or disembark at the terminal.

In these cases, the terminal operator can provide transportation for the said

embarkation or disembarkation.

Also see Repatriation.

REPATRIATION: Crew changes cannot be carried out at the terminal.

No member of the ships crew or passengers is permitted to land, except in

an emergency.

GENERAL: Lifeboats: Except for an emergency abandonment of the

vessel, no vessel shall lower its lifeboats to the sea.

Ships Agents: Ships Agents must be registered with the appropriate

government authority.

Mail and Correspondence: Official communications and crew mail will be

handled by the ships Agent.

SHIPMASTERS REPORT: December 1993 (Updated 1998).