Professional Documents

Culture Documents

Optimal Configuration of Wind/Solar/Diesel/Battery Hybrid Energy System For Electrification of Rural Area

Uploaded by

IOSRjournalOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Optimal Configuration of Wind/Solar/Diesel/Battery Hybrid Energy System For Electrification of Rural Area

Uploaded by

IOSRjournalCopyright:

Available Formats

IOSR Journal of Electrical and Electronics Engineering (IOSR-JEEE)

e-ISSN: 2278-1676,p-ISSN: 2320-3331, Volume 10, Issue 3 Ver. IV (May Jun. 2015), PP 23-31

www.iosrjournals.org

Optimal Configuration of Wind/Solar/Diesel/Battery Hybrid

Energy System for Electrification of Rural Area

Payal Suhane1, Saroj Rangnekar2, Arvind Mittal3

1,2,3,

(Energy Centre, Maulana Azad National Institute of Technology Bhopal, India)

Abstract : With the rapid deployment probability of fossil fuels and fast development of renewable energy

technology, the renewable sources use are being promoted for various applications to reduce the consumption

of fossil fuels. Integration of these sources as Hybrid Energy System (HES) is better option as a small scale

alternative source of electrical energy. Wind/PV HES is more economical and reliable than a single PV or wind

turbine for their complementary nature both in time and geography. And combination of these sources with

diesel generator is better option for un-electrified remote areas as compare to diesel generator alone.

Unpredictable nature of wind and intermittent nature of solar as well as variation in load demand introduces,

complexity in HES, therefore sizing of HES is prerequisite for power supply to areas at minimum cost. In this

paper, Jhiri village of Madhya Pradesh (India) is identified as un-electrified remote area to be considered for

case study. Load profile creation of the above area is done based on the daily consumption of electricity as per

the population and ensuring minimum possible electrification in present scenario. Optimal sizing of selected

HES is done with the help of Homer software. An economical and reliable HES has been proposed for above

area for betterment of human life and overall growth of the village.

Keywords - Renewable Energy Sources, Hybrid Energy System, PV array, Wind Turbine, Battery, Diesel

Generator, Homer software

I.

Introduction

At present, India is a large consumer of fossil fuels. According to present energy consumption rate,

coal reserves should last for about 200 years, oil for approximately 40 years and natural gas for around 60 years

[1]. The majority of the energy requirement around the world now is dependent on fossil fuels for a big portion

of their energy demand. Towering costs of these fuels have converted into remarkable increases in the cost of

energy generation especially for rural areas [2]. For an un-electrified rural area if grid expansion is not

economical viable than diesel generator is one of the alternative energy sources [3], if transportation is possible

and economically feasible. But environmental concern and costly fuel issue has diverted concern towards hybrid

configuration of diesel with other renewable energy sources. Due to natural unpredicable properties of wind and

intermittent nature photovoltaic power, stand-alone wind and/or SPV energy systems normally require energy

storage devices like battery, ultracapacitor and backup sources like diesel generator for increasing the quality

and continuity of power supply [4]. Individual solar and wind can be integrated together in a hybrid system as

they have complement nature and available naturally [5]. It reduces the percentage contribution of auxiliary

source and has a say to clean-green environment policies

The idea is to maximize the powering of consumers by two ways i) renewable energy sources taken as

main source and maintaining the continuity of supply by other backup-source during non availability of main

source ii) all sources are renewable sources [6]. Wind-Diesel and solar-diesel hybrid system are studied for

analyzing the performance of the overall system where diesel generator works as backup power source. Hybrid

system can either be connected to Grid or as standalone system [7]. Stand alone system generally electrifies

those areas far away from the grid and grid connected system used both as an load and source depending on the

scenario, reducing the burden on main grid [8]. At present, Hybrid system consisting solar photovoltaic and

wind systems have been promoted around the globe on a comparatively larger scale. Its development is driven

by the government policy to reduce the greenhouse gas emissions and conserve fossil fuels. Reliability of the

system can further be increased by adding a storage device or back up sources to successfully utilize hybrid

power. HES in this paper include PV array system, WTg system, battery system and DG system for power

generation and optimal sizing of HES is done with the Homer software for economical power generation [9].

II.

Modeling Of Hes

The proposed structure of HES comprises of PV array, variable speed WT, battery and DG as shown in

Fig.1. In this, wind and solar are integrated and complement each other as primary sources to meet the load

requirements, DGs as an auxiliary source and battery backup storage for enhancing the reliability of system

[10]. Modeling of components are explained in detail below.

DOI: 10.9790/1676-10342331

www.iosrjournals.org

23 | Page

Optimal Configuration of Wind/Solar/Diesel/Battery Hybrid Energy System

Fig1. Hybrid energy system

2.1Wind System Modeling:

The energy and output current of WT for each time instant is calculated on the basis of local weather

conditions and actual installation height of turbines [9]. Fundamental equation governing the mechanical power

capture of rotor blades of WT, which drives the electrical generator, is given by [11]:

1

P = ACp V 3

(1)

2

where,

: air density (kg/m3)

A : area swept by the rotor blades

V : velocity of air (m/sec)

Cp power coefficient of WT, it is often expressed as function of the rotor tip-speed to wind- speed ratio (TSR)

The power coefficient as a function of the tip-speed ratio and the blade pitch angle is defined below [10]:

Cp( , ) = c1( c2/-c3 - c4 x-c5) e-c6/

(2)

Since this function depends on the wind turbine rotor type, the coefficients c1-c6 and x can be different for

various turbines. The proposed coefficient taken is equal to: c 1=0.5, c2=116, c3=0.4, c4=0, c5 = 5, c6=21 (x is not

used because c4 =0). Additionally the parameter is also defined by

1/ = 1/( +0.08 ) 0.035/(1+ 3)

(3)

Where is the pitch angle[o], which is the angle between the plane of rotation and the blade cross-section chord

The tip speed of blade to wind speed ratio (TSR) is defined as follows:

= r g/ V

(4)

The Cp (, ) characteristic, by taking the above parameters c1-c6 for various blade pitch angles , are presented

in fig 2.

The tip speed of blades can be found through power curve of wind turbine for a corresponding wind

speed. The wind turbine power curve is given in fig 1. At a given wind speed, the maximum energy conversion

efficiency occur at an optimal TSR. Therefore as the wind speed changes, the turbine rotor speed needs to

change accordingly in order to maintain the optimal TSR and thus to extract maximum power from the available

wind resources. So optimal rotor speed can be found by (5)

mopt = opt V / r

(5)

2.2 Solar PV system Modeling:

The power of solar panel calculated on the basis of solar radiation value, derating factor considering

various component losses and solar panel position to collect maximum radiation of Sun [12]. Based on the load

voltage requirement specific number of panel is connected in series.

For a solar PV system the array voltage, including series parallel combination is given as [13]

Va Ia NsRs / Np NsKloge [ NshIL Ia NpIo / NpIo

(6)

And array current

DOI: 10.9790/1676-10342331

www.iosrjournals.org

24 | Page

Optimal Configuration of Wind/Solar/Diesel/Battery Hybrid Energy System

I A N p IL IO {exp q / AkTc VA / Ns

R s / N p } 1

/ R p VA / Ns

R s / Np

(7)

Here IA is the PV array output current, I L is solar cell photocurrent, IO is solar cell reverse saturation

current, VA is PV array output voltage, q is charge of electron, A is P-N junction ideality factor (between 1 to

5), k is Boltzmann constant, T c is absolute operating temperature of cell, Ns is number of cells in series, Np is

number of cells in parallel, Rs is series resistance of cell, Rp is parallel resistance of cell, and K = nkT/q

Regarding modelling of the PV system, there are many models to represent PV generator I-V characteristics. In

PV generator model Iref (reference output current) is chosen according to simplicity and four parameters found in

manufacturers data sheet (short circuit current Isc, current at maximum power point Imp, open circuit voltage

Voc, voltage at maximum power point Vmp ) are employed . A PV generator I-V characteristic is represented by

[32-36].

Iref Isc

1 C1{exp

Vref

/ C2 Voc 1}

(8)

Here C1 and C2 are constants given in terms of Isc, Imp, Voc, Vmp . Vref is reference output voltage.

This equation can be adapted to other levels of irradiance and temperature and thereby V-I curve shifts

accordingly. [33-34, 37]

(9)

T = T -Tref

I Ki

G / Gref

G / Gref

1 ISC

(10)

V K V T R s I

So that

Vnew Vref

(11)

(12)

I new I ref I

(13)

Where Ki and Kv are current and voltage temperature coefficients. Here G denotes solar radiation and T

temperature.

Tilt angle which depends on latitude, suns declination angle and insolation, can be obtained with

help of following equation:

(14)

q Vmpref +Impref * Rs Vocref / KTcref *log 1 Impref /Iscref

Radiation and temperature dependence of IL and IO can be obtained with the help of following equations

IL Isc

T1ref

Where

KO

Isc

T2

G / Gref

Isc

T1

And temperature dependence of IO

Isc

IO

qVoc(T 1)

nkT1

e

KO T T1

T2

(15)

T1

(16)

T1

3/ n

T

T1

nk

e

qVq T 1

1 / T 1 / T

1

(17)

2.3 Battery System Modeling:

Battery stores the excess energy generated by HES and supply that energy during low generation

period. If total output power of turbine and PV cell is greater than load power, then battery is in state of charging

and the charged quantity of battery at the moment of (t) is given [12] by

Pb t = Pb t 1 . (1 ) + [PZ t Pl t /inv ] . bc

If total output power of turbine and PV cell is less than load power, then battery is in state of discharging and the

charged

quantity

of

battery

at

the

moment

of

(t)

is

given

by

[8]:

Pb t = Pb t 1 . (1 ) + [Pl t /inv PZ t ] /bf

DOI: 10.9790/1676-10342331

www.iosrjournals.org

25 | Page

Optimal Configuration of Wind/Solar/Diesel/Battery Hybrid Energy System

where,

Pb t battery charged quantity at time (t)

Pb t 1 battery charged quantity at time (t-1)

: self-discharge rate per hour

PZ t total output power of turbine and PV cell in the time interval (t-1, t)

Pl t total load power in the time interval (t-1, t)

inv : inverter efficiency

bc : battery charging efficiency

bf battery discharging efficiency

2.4:Diesel System Modeling

DG power is related to fuel consumption means DG is characterized by its efficiency and its fuel consumption

i.e. hourly and specific fuel consumption. Specific fuel consumption (l/kWh) is defined as the fuel consumption

needed to produce 1 kWh of energy and it is equal to hourly fuel consumption (l/h) to supply a given load

during 1h. Hourly fuel consumption is given by [6] :

q(t)=a.P(t)+b.Pr

where,

a : constant in l/kW for typical DG

b : constant in l/kW for typical DG

P(t) : power generated by DG in kW

Pr : rated/nominal power of DG in kW

III.

Sizing Of Hybrid Energy System

The unit sizing of integrated power system plays an important role in deciding the reliability and

economy of the system. For sizing of HES, prerequisite is load profile analysis, solar irradiance, variations in

wind speed, temperature, and so forth as the metrological data is always changing and also vary from place to

place. Climatic conditions determine the availability and magnitude of wind and solar energy at particular site.

Pre-feasibility studies are based on weather data (wind speed, solar insolation) and load requirements for

specific site [14]. The load side voltage is considered as 3 phase 415V, AC.

3.1 Load profile creation and metrological data collection

For load profile creation of rural area total population of remote area is considered as 1000 person. On

the basis of power requirement of devices and instruments in houses, school, community centre street light,

hospital and their predefined standard rating hourly load is calculated as shown in below fig 2 and monthly load

profile is shown in fig 3.

Fig2: Load daily profile

Fig3: Load monthly profile

Solar radiation and wind speed data is colledted from a data logger installed at MANIT. Bhopal (India)

having latitude as 22031 and longitude as 77035. Monthly solar radiation, wind speed and temperature are

shown in fig 4, fig5, and fig6 respectively.

DOI: 10.9790/1676-10342331

www.iosrjournals.org

26 | Page

Optimal Configuration of Wind/Solar/Diesel/Battery Hybrid Energy System

Fig4: Monthly avg. solar radiation

Fig5: Monthly avg. temperature

Fig6: Monthly avg. wind speed

3.2 Cost curve of HES devices:

For analysis of overall HES, component specification is given below. Individual costing components

are included in software and cost curves for WTg, Solar PV panel, DGs and battery are shown in fig 7,fig 8, fig

9 and fig 10 respectively.

3.2.1PV panel specification:

Rated Power

Open circuit voltage

Short circuit current

Optimum voltage

Optimum current

250 W

37.3 V

8.30 A

30.8 V

8.71 A

3.2.2 WTg specification:

Rated power

Cut-in speed

Cut-out speed

Rated power speed

5 kW

2.7 m/s

25 m/s

10 m/s

3.2.3 DGs specification:

Rated capacity

Rated voltage

10 KVA

415 V

3.2.4 Battery specification:

Rated capacity

Rated voltage

Minimum state of charge

200 Ah

12 V

15 %

DOI: 10.9790/1676-10342331

www.iosrjournals.org

27 | Page

Optimal Configuration of Wind/Solar/Diesel/Battery Hybrid Energy System

Fig7: PV panel cost curve

Fig9: Diesel generator cost curve

Fig8: WTg cost curve

Fig10: Battery cost curve

3.3Optimal sizing of HES:

Sizing depends on various constrained requisite like renewable energy sources minimum capacity,

diesel generator minimum capacity, battery capacity to supply the energy to load on unavailability of primary

sources of system, Loss of Power supply Probability(LPSP) etc [15]. All the selected constrained is considered

for optimal sizing with Homer Jhiri village for a specified LPSP the optimal sizing of the HES. The minimum

capacities of components are decided based on following equations [16] [17]

3.3.1PV array installation minimum sizing is decided by average load required and

Npvmin>avgLoad/ pv

(15)

pv: overall efficiency for PV array

maximum size is decided by maximum load requirement

Npvmax< (MaxLoad/ pv)

(16)

3.3.2.Wind turbine minimum sizing is decided by average load required and maximum sizing is decided

by maximum load required

avgLoad<Nwt< (MaxLoad / wt) (17)

wt: overall efficiency for wind turbine

3.3.3. Battery minimum sizing is decided to provide at least back power to load for number of days

Nwt> * avgLoad

(18)

: number of days

IV.

Results And Discussion

Sizing of HES is done for two cases with and without battery storage backup and Homer results for

both of the cases is discussed below.

4.1Case 1-With battery storage as backup:

Minimum backup storage has been considered as supplying power to load for four hours on nonavailability of primary sources. Monthly average production of electricity is shown in fig 11 and optimal sizing

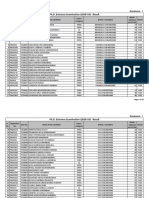

Homer window in fig 12 and results for this case is complied in Table1.

DOI: 10.9790/1676-10342331

www.iosrjournals.org

28 | Page

Optimal Configuration of Wind/Solar/Diesel/Battery Hybrid Energy System

Fig11: Monthly avg. electricity production

Fig12: Optimal sizing results from homer (with battery storage as backup)

Table 1: Detailed sizing and cost of each component (with battery storage as backup)

S.No.

Total sizing capacity

Total Investment Cost

Total Operational Cost

Total Replacement Cost

Total fuel cost

Energy production in

kWh/Year

Wind

turbine

170 kW

170 Lakh

90.72 lakh

0

0

Solar PV panel

DG set

Battery

50 kW

62 lakh

26.62 lakh

0

0

40 kW

16.62 lakh

102.12 lakh

0

93.5 lakh

52 kAh, 12 V

48.43 lakh

43.1 lakh

201 lakh

0

Converter (Inverter/

Rectifier)

100 kW/100 kW

7 lakh

4000/- Rs

4.75 lakh

0

639,880

17,396

44,677

86,657

5.2 Case2-Without battery storage:

In this case optimal sizing is done without specifying any minimum storage requirement. Monthly

average production of electricity is shown in fig 13 and optimal sizing Homer window in fig 14 Sizing value of

all sources and other components corresponding to minimum cost function are given in Table2.

DOI: 10.9790/1676-10342331

www.iosrjournals.org

29 | Page

Optimal Configuration of Wind/Solar/Diesel/Battery Hybrid Energy System

Fig13: Monthly avg. electricity production

Fig14: Optimal sizing results from homer (without battery storage)

Table 2 : Detailed sizing and cost of each component (without battery storage )

S.No.

Wind turbine

Solar PV panel

DG set

Battery

Total sizing capacity

Total Investment Cost

(in Rs)

Total Operational Cost

(in Rs)

Total Replacement Cost

(in Rs)

Total fuel cost (in Rs)

Energy production

(kWh/year)

110 kW

137.1 lakh

140kW

174.5 lakh

30kW

12.46 lakh

0

0

Converter (Inverter/

Rectifier)

100kW/100kW

7.79 lakh

90.31 lakh

77.68 lakh

31.15 lakh

4674 Rs

15.11 lakh

5.28 lakh

0

414,038

0

48,710

230.37lakh

102,420

0

0

0

0

For analysis of both cases, sizing value of component is compiled in Table 3 for each scenario. On

considering battery storage as backup for supplying average load power for specified hours, per unit cost of

energy is increasing but increment in cost is compensated by Loss of Power Supply Probability (LPSP), which

is around 1 % case 1 much less than as case 2 (10 %).

DOI: 10.9790/1676-10342331

www.iosrjournals.org

30 | Page

Optimal Configuration of Wind/Solar/Diesel/Battery Hybrid Energy System

Table 2: Detailed sizing and cost of each component (without battery storage)

V.

Conclusion

This paper discusses the optimal sizing of HES. Optimal sizing is done by taking into account the

investment cost, operational cost and replacement cost of devices and fuel cost of DG set. The constraint for

objective function is to electrify the selected area with reliable power at minimal cost. The obtained per unit

energy cost of proposed system is much less as compare to diesel generator. The optimal sizing of system

strongly depends solar and wind resource,(which can only be estimated on the basis of statistical data, or

measured on site) and at the considered year of sizing, these has been taken into account. If large variation in the

resource data occur than reliability of system can be reduced and results obtained may vary, therefore the

application of above method may be limited to the pre-feasibility stage. However secondary source as DG set

and battery backup storage are able to maintain the reliability of system if any acceptable variation occurs in

resources data and load demand. Also inclusion of forecasting of these data, based on previous 5-10 years

metrological data, can provide more appropriate figure as compared to considered one year data figure.

References

[1].

[2].

[3].

[4].

[5].

[6].

[7].

[8].

[9].

[10].

[11].

[12].

[13].

[14].

[15].

[16].

[17].

(2014, Mar.) [Online]. www.indianpowersector.com

T. Urmee, D. Harries, and A. Schlapfer, "Issues related to rural electrification using renewable energy in developing countries of

Asia and Pacific ," Renewable Energy , vol. 34, no. 2, pp. 354-357, 2009.

S. R. Bull, "Renewable energy today and tomorrow," Proceedings of the IEEE, vol. 89, no. 8, pp. 1216-1226, Aug. 2001.

A. Chauhan and R. P. Saini, "A review on Integrated Renewable Energy System based power generation for stand-alone

applications: Configurations, storage options, sizing methodologies and control ," Renewable and Sustainable Energy Reviews , vol.

38, no. 0, pp. 99-120, 2014.

J. E. M. S. Paiva and A. S. Carvalho, "An integrated hybrid power system based on renewable energy sources," in Industrial

Electronics, 2009. IECON '09. 35th Annual Conference of IEEE, Nov. 2009, pp. 4548-4554.

D. Yamegueu, Y. Azoumah, X. Py, and N. Zongo, "Experimental study of electricity generation by Solar PV/diesel hybrid systems

without battery storage for off-grid areas ," Renewable Energy , vol. 36, no. 6, pp. 1780-1787, 2011.

Y. Zhou, J. A. Ferreira, and P. Bauer, "Grid-connected and islanded operation of a hybrid power system," in Power Engineering

Society Conference and Exposition in Africa, 2007. PowerAfrica '07. IEEE, Jul. 2007, pp. 1-6.

A. B. Kanase-Patil, R. P. Saini, and M. P. Sharma, "Integrated renewable energy systems for off grid rural electrification of remote

area ," Renewable Energy , vol. 35, no. 6, pp. 1342-1349, 2010.

B. S. Borowy and Z. M. Salameh, "Methodology for optimally sizing the combination of a battery bank and PV array in a wind/PV

hybrid system," Energy Conversion, IEEE Transactions on, vol. 11, no. 2, pp. 367-375, Jun. 1996.

E. I. Vrettos and S. A. Papathanassiou, "Operating Policy and Optimal Sizing of a High Penetration RES-BESS System for Small

Isolated Grids," Energy Conversion, IEEE Transactions on, vol. 26, no. 3, pp. 744-756, Sep. 2011.

P. Bajpai, S. Kumar, and N. K. Kishore, "Sizing optimization and analysis of a stand-alone WTG system using hybrid energy

storage technologies," in Energy and Sustainable Development: Issues and Strategies (ESD), 2010 Proceedings of the International

Conference on, Jun. 2010, pp. 1-6.

C. E. C. Nogueira, et al., "Sizing and simulation of a photovoltaic-wind energy system using batteries, applied for a small rural

property located in the south of Brazil ," Renewable and Sustainable Energy Reviews , vol. 29, no. 0, pp. 151-157, 2014.

C. S. Solanki, Solar Photovoltaics-Fundamentals, Technologies and Applications, second edition, 2nd ed. India: PHI, 2011.

H. X. Yang, L. Lu, and J. Burnett, "Weather data and probability analysis of hybrid photovoltaicwind power generation systems

in Hong Kong ," Renewable Energy , vol. 28, no. 11, pp. 1813-1824, 2003.

M. Bashir and J. Sadeh, "Size optimization of new hybrid stand-alone renewable energy system considering a reliability index," in

Environment and Electrical Engineering (EEEIC), 2012 11th International Conference on, May 2012, pp. 989-994.

L. Xu, X. Ruan, C. Mao, B. Zhang, and Y. Luo, "An Improved Optimal Sizing Method for Wind-Solar-Battery Hybrid Power

System," Sustainable Energy, IEEE Transactions on, vol. 4, no. 3, pp. 774-785, Jul. 2013.

D. Abbes, A. Martinez, and G. Champenois, "Eco-design optimisation of an autonomous hybrid wind photovoltaic system with

battery storage," Renewable Power Generation, IET, vol. 6, no. 5, pp. 358-371, Sep. 2012.

DOI: 10.9790/1676-10342331

www.iosrjournals.org

31 | Page

You might also like

- A Review of Rural Local Government System in Zimbabwe From 1980 To 2014Document15 pagesA Review of Rural Local Government System in Zimbabwe From 1980 To 2014International Organization of Scientific Research (IOSR)No ratings yet

- Assessment of The Implementation of Federal Character in Nigeria.Document5 pagesAssessment of The Implementation of Federal Character in Nigeria.International Organization of Scientific Research (IOSR)No ratings yet

- Attitude and Perceptions of University Students in Zimbabwe Towards HomosexualityDocument5 pagesAttitude and Perceptions of University Students in Zimbabwe Towards HomosexualityInternational Organization of Scientific Research (IOSR)No ratings yet

- Socio-Ethical Impact of Turkish Dramas On Educated Females of Gujranwala-PakistanDocument7 pagesSocio-Ethical Impact of Turkish Dramas On Educated Females of Gujranwala-PakistanInternational Organization of Scientific Research (IOSR)No ratings yet

- "I Am Not Gay Says A Gay Christian." A Qualitative Study On Beliefs and Prejudices of Christians Towards Homosexuality in ZimbabweDocument5 pages"I Am Not Gay Says A Gay Christian." A Qualitative Study On Beliefs and Prejudices of Christians Towards Homosexuality in ZimbabweInternational Organization of Scientific Research (IOSR)No ratings yet

- The Role of Extrovert and Introvert Personality in Second Language AcquisitionDocument6 pagesThe Role of Extrovert and Introvert Personality in Second Language AcquisitionInternational Organization of Scientific Research (IOSR)No ratings yet

- The Impact of Technologies On Society: A ReviewDocument5 pagesThe Impact of Technologies On Society: A ReviewInternational Organization of Scientific Research (IOSR)100% (1)

- Investigation of Unbelief and Faith in The Islam According To The Statement, Mr. Ahmed MoftizadehDocument4 pagesInvestigation of Unbelief and Faith in The Islam According To The Statement, Mr. Ahmed MoftizadehInternational Organization of Scientific Research (IOSR)No ratings yet

- Comparative Visual Analysis of Symbolic and Illegible Indus Valley Script With Other LanguagesDocument7 pagesComparative Visual Analysis of Symbolic and Illegible Indus Valley Script With Other LanguagesInternational Organization of Scientific Research (IOSR)No ratings yet

- A Proposed Framework On Working With Parents of Children With Special Needs in SingaporeDocument7 pagesA Proposed Framework On Working With Parents of Children With Special Needs in SingaporeInternational Organization of Scientific Research (IOSR)No ratings yet

- Relationship Between Social Support and Self-Esteem of Adolescent GirlsDocument5 pagesRelationship Between Social Support and Self-Esteem of Adolescent GirlsInternational Organization of Scientific Research (IOSR)No ratings yet

- Classical Malay's Anthropomorphemic Metaphors in Essay of Hikajat AbdullahDocument9 pagesClassical Malay's Anthropomorphemic Metaphors in Essay of Hikajat AbdullahInternational Organization of Scientific Research (IOSR)No ratings yet

- Importance of Mass Media in Communicating Health Messages: An AnalysisDocument6 pagesImportance of Mass Media in Communicating Health Messages: An AnalysisInternational Organization of Scientific Research (IOSR)No ratings yet

- Topic: Using Wiki To Improve Students' Academic Writing in English Collaboratively: A Case Study On Undergraduate Students in BangladeshDocument7 pagesTopic: Using Wiki To Improve Students' Academic Writing in English Collaboratively: A Case Study On Undergraduate Students in BangladeshInternational Organization of Scientific Research (IOSR)No ratings yet

- Human Rights and Dalits: Different Strands in The DiscourseDocument5 pagesHuman Rights and Dalits: Different Strands in The DiscourseInternational Organization of Scientific Research (IOSR)No ratings yet

- Edward Albee and His Mother Characters: An Analysis of Selected PlaysDocument5 pagesEdward Albee and His Mother Characters: An Analysis of Selected PlaysInternational Organization of Scientific Research (IOSR)No ratings yet

- An Evaluation of Lowell's Poem "The Quaker Graveyard in Nantucket" As A Pastoral ElegyDocument14 pagesAn Evaluation of Lowell's Poem "The Quaker Graveyard in Nantucket" As A Pastoral ElegyInternational Organization of Scientific Research (IOSR)No ratings yet

- Beowulf: A Folktale and History of Anglo-Saxon Life and CivilizationDocument3 pagesBeowulf: A Folktale and History of Anglo-Saxon Life and CivilizationInternational Organization of Scientific Research (IOSR)No ratings yet

- The Lute Against Doping in SportDocument5 pagesThe Lute Against Doping in SportInternational Organization of Scientific Research (IOSR)No ratings yet

- Women Empowerment Through Open and Distance Learning in ZimbabweDocument8 pagesWomen Empowerment Through Open and Distance Learning in ZimbabweInternational Organization of Scientific Research (IOSR)No ratings yet

- Transforming People's Livelihoods Through Land Reform in A1 Resettlement Areas in Goromonzi District in ZimbabweDocument9 pagesTransforming People's Livelihoods Through Land Reform in A1 Resettlement Areas in Goromonzi District in ZimbabweInternational Organization of Scientific Research (IOSR)No ratings yet

- Role of Madarsa Education in Empowerment of Muslims in IndiaDocument6 pagesRole of Madarsa Education in Empowerment of Muslims in IndiaInternational Organization of Scientific Research (IOSR)No ratings yet

- An Exploration On The Relationship Among Learners' Autonomy, Language Learning Strategies and Big-Five Personality TraitsDocument6 pagesAn Exploration On The Relationship Among Learners' Autonomy, Language Learning Strategies and Big-Five Personality TraitsInternational Organization of Scientific Research (IOSR)No ratings yet

- Substance Use and Abuse Among Offenders Under Probation Supervision in Limuru Probation Station, KenyaDocument11 pagesSubstance Use and Abuse Among Offenders Under Probation Supervision in Limuru Probation Station, KenyaInternational Organization of Scientific Research (IOSR)No ratings yet

- Designing of Indo-Western Garments Influenced From Different Indian Classical Dance CostumesDocument5 pagesDesigning of Indo-Western Garments Influenced From Different Indian Classical Dance CostumesIOSRjournalNo ratings yet

- Motivational Factors Influencing Littering in Harare's Central Business District (CBD), ZimbabweDocument8 pagesMotivational Factors Influencing Littering in Harare's Central Business District (CBD), ZimbabweInternational Organization of Scientific Research (IOSR)No ratings yet

- Design Management, A Business Tools' Package of Corporate Organizations: Bangladesh ContextDocument6 pagesDesign Management, A Business Tools' Package of Corporate Organizations: Bangladesh ContextInternational Organization of Scientific Research (IOSR)No ratings yet

- Micro Finance and Women - A Case Study of Villages Around Alibaug, District-Raigad, Maharashtra, IndiaDocument3 pagesMicro Finance and Women - A Case Study of Villages Around Alibaug, District-Raigad, Maharashtra, IndiaInternational Organization of Scientific Research (IOSR)No ratings yet

- A Study On The Television Programmes Popularity Among Chennai Urban WomenDocument7 pagesA Study On The Television Programmes Popularity Among Chennai Urban WomenInternational Organization of Scientific Research (IOSR)No ratings yet

- Kinesics, Haptics and Proxemics: Aspects of Non - Verbal CommunicationDocument6 pagesKinesics, Haptics and Proxemics: Aspects of Non - Verbal CommunicationInternational Organization of Scientific Research (IOSR)No ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- دفيوشن PDFDocument3 pagesدفيوشن PDFحمامة السلامNo ratings yet

- What Is Perpendicular ForceDocument1 pageWhat Is Perpendicular ForceseinsheillNo ratings yet

- Voltage Drop CalculationDocument6 pagesVoltage Drop CalculationAtef MohamedenNo ratings yet

- BEE Final Power Protection and SwitchgearDocument3 pagesBEE Final Power Protection and SwitchgearKumaranNo ratings yet

- Physics 4E03 MT2 2002Document2 pagesPhysics 4E03 MT2 2002api-3740082No ratings yet

- Plant Maintenance Work Service-Practice: Deetaf College of EngineeringDocument11 pagesPlant Maintenance Work Service-Practice: Deetaf College of EngineeringTHEOPHILUS ATO FLETCHERNo ratings yet

- Question 1Document8 pagesQuestion 1abdul wahabNo ratings yet

- Course Code: ES 110Document38 pagesCourse Code: ES 110scolastica nyegaNo ratings yet

- Physics Ia IdeaDocument2 pagesPhysics Ia Ideaoğuz hamurculuNo ratings yet

- Moment of A Force Lesson PlanDocument23 pagesMoment of A Force Lesson PlanPaschal CatherineNo ratings yet

- 160 Instruments and Measurements Mcqs With AnswersDocument19 pages160 Instruments and Measurements Mcqs With AnswersRakeshKrNo ratings yet

- Electric Circuits: ElectricityDocument9 pagesElectric Circuits: ElectricityFernanda VillacísNo ratings yet

- Fuzzy A Thermnoelectric Cooler: Temperature Control ofDocument6 pagesFuzzy A Thermnoelectric Cooler: Temperature Control ofAnupriya GhoshNo ratings yet

- EE 111 Final Project: Permanent Magnet DC MotorDocument3 pagesEE 111 Final Project: Permanent Magnet DC MotorDarrel PasaloNo ratings yet

- CU PET 323 - Reservoir Engineering I - Full #118Document118 pagesCU PET 323 - Reservoir Engineering I - Full #118ademola adelakunNo ratings yet

- IEEE Industry Applications Control Strategy v7Document12 pagesIEEE Industry Applications Control Strategy v7raghbendrat3884No ratings yet

- Class 10: Class 10 Electricity Important QuestionsDocument45 pagesClass 10: Class 10 Electricity Important QuestionsSoma Paine SardarNo ratings yet

- Assure AU Physics SyllabusDocument3 pagesAssure AU Physics SyllabussNo ratings yet

- Datasheet PDFDocument5 pagesDatasheet PDFMomento EléctricoNo ratings yet

- Basic Design Concepts of Industrial Plants System and EquipmentDocument30 pagesBasic Design Concepts of Industrial Plants System and EquipmentEam EvieNo ratings yet

- Basic Electronic Circuits Explained - Beginner's Guide To Electronics - Homemade Circuit ProjectsDocument85 pagesBasic Electronic Circuits Explained - Beginner's Guide To Electronics - Homemade Circuit ProjectsJuan fernando RoldanNo ratings yet

- Fireworks Projectile Explodes High and AwayDocument3 pagesFireworks Projectile Explodes High and AwayRocel Marie SullestaNo ratings yet

- Product Data Sheet: iC60N - Miniature Circuit Breaker - 1P - 32A - C CurveDocument3 pagesProduct Data Sheet: iC60N - Miniature Circuit Breaker - 1P - 32A - C CurveLaviniu S. NacuNo ratings yet

- TI Webinar 9 - Designing Wide-VIN Low-EMI Power Converters PDFDocument28 pagesTI Webinar 9 - Designing Wide-VIN Low-EMI Power Converters PDFhuytung1501No ratings yet

- Cell ChargerDocument13 pagesCell Chargerpawan dhingraNo ratings yet

- Lab Final Exam Answer PDFDocument4 pagesLab Final Exam Answer PDFhelen tsegayNo ratings yet

- Result - Final (Annexure - I) - 923680Document25 pagesResult - Final (Annexure - I) - 923680patelsandip1989No ratings yet

- CapacitorDocument38 pagesCapacitorPiyush Vidyarthi100% (3)

- VATIMETRO UPM-DT50SP - Manual PDFDocument12 pagesVATIMETRO UPM-DT50SP - Manual PDFFernando CharryNo ratings yet

- Basic Inverter (VFD) : Oleh: Bagus OlifiantoDocument10 pagesBasic Inverter (VFD) : Oleh: Bagus OlifiantoAlwi HasibuanNo ratings yet